RAW MILK QUALITY

The importance of raw milk quality

Since raw milk is either the only or primary ingredient in dairy products, its quality has a major impact on the quality of the final product. Poor quality raw milk can lead to deviations in the taste and smell of dairy products, their shelf life, and their functionality. Furthermore, raw milk quality affects the efficiency and cost-effectiveness of a dairy plant’s processing machinery, particularly the heating units. Poor quality milk can clog heat exchangers, causing processing interruptions, shorter production times and requiring extra cleaning time – with all the costs associated with these issues. Overall, processing efficiency can be greatly reduced, along with the quality of the finished product.

For the above reasons, it is important to take preventative actions during the production and transport of milk to ensure good raw milk quality. It is also crucial to monitor the quality by measuring it at key points in the supply chain.

This chapter focuses on milk originating from cows. However, the information provided is also relevant for milk originating from sheep, goats and buffalo.

Where can milk quality go wrong?

Milk is a highly complex biological system containing fats, sugars, proteins, minerals, vitamins and other elements. Its composition and microbiological quality determine the milk’s suitability for processing and human consumption. Exactly what kinds of microorganisms are present and what the temperature conditions are will determine the final microbiological quality of the milk. There are also many factors impacting composition. These, along with how the milk is handled on the farm, during transport and at the processing plant, impact the milk’s chemical and physical qualities.

Dairy farm operations

Contamination of milk with microorganisms during milk production on the farm will have the greatest influence on the milk quality and the quality of the finished products. The health of the individual cows, barn maintenance, good hygiene during milking and proper cleaning of milking equipment and milk storage vessels are of the utmost importance in terms of minimising contamination with microorganisms. The cow's udder contains normal microbiota present in a healthy cow. When the milk passes out through the teat channel, contamination by other microorganisms takes place. Furthermore, raw milk quality will also be impacted by the cow’s feed, water, age, breed and genetics.

To minimise the risk of bacterial growth, it is important to cool down the milk as soon as possible, preferably to 4 °C or below. If the milk is not cooled quickly and stored at refrigerator temperatures, the microorganisms in the milk will start growing rapidly.

Many steps can be taken on the farm to improve raw milk quality. Guidelines for good farming practices exist to assist dairy farmers in improving the livelihood of their cattle or other livestock and, thereby, the quality of their products. Some of the most important steps include:

- Cleaning and maintenance of milking equipment, utensils and milk tanks

- Avoid contamination from the surrounding environment or from the milker to the milk

- Ensure good cow health by correct milking practices, cleaning, and separation of cows suffering from mastitis

- Immediate cooling and gentle handling of raw milk

For more information on good hygiene practices and farm maintenance, please refer to the DeLaval Dairy Farming Handbook.

Transportation

Around the world, there are many different ways of transporting milk. How it is transported and stored impacts quality. In general, storing and transporting milk in bulk will reduce the risk of contamination. Using clean milk containers and keeping the milk properly refrigerated at low temperatures (2 – 4 °C) will limit its deterioration. Trucks for the transportation of milk are usually insulated but not refrigerated. According to EU legislation, the milk should not increase above 10 °C during transport, and it is common practice to cool the milk again upon arrival at the processing plant.

Handling and processing at the plant

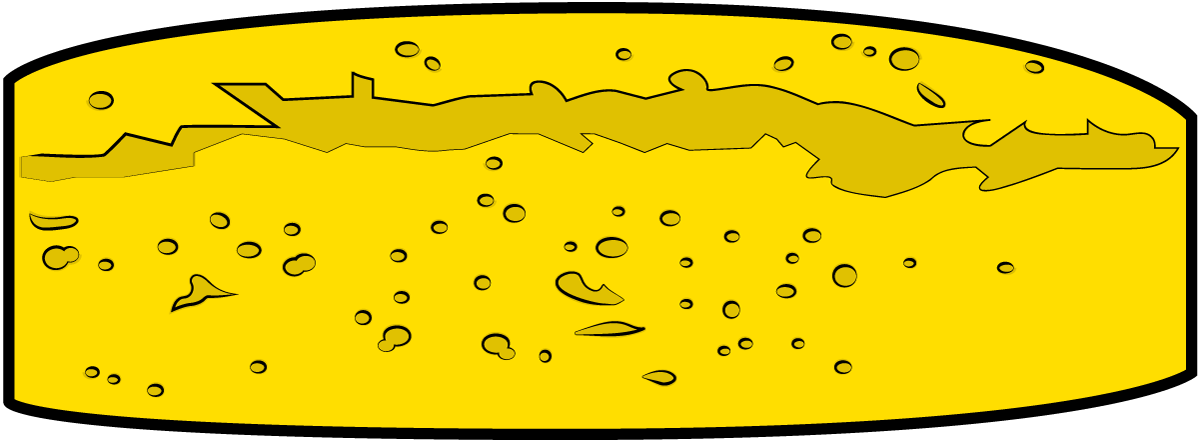

In general terms, raw milk should be heat-treated as quickly as possible to maintain good quality of the final products. However, variation in the quantity of supplied milk and storage availability between dairies means that, in some cases, more storage time is needed before processing. When milk arrives at the dairy, it should be chilled down to 2 – 4 °C as quickly as possible to prevent the growth of microorganisms. Some microorganisms can grow even at refrigerated temperatures, forming heat-resistant enzymes that may challenge the quality and shelf life of the filled product, especially for UHT products with a long shelf life, an example of which can be seen in Figure 5.2. Hence, storage and transportation time are still limited even in the right conditions. To limit air incorporation, care should be taken to avoid splashing, and to prevent light oxidation, milk should never be exposed to sunlight during storage or transport. One option for extending the storage time before processing is to thermise the milk upon arrival. Thermisation is a heating process which eliminates most of the microorganisms that can grow at low temperatures and thus enables cold storage of milk for another 1 – 2 days without major deterioration of the quality. It involves heating the milk to 63 – 65 °C for 15 seconds, which kills most of the vegetative microorganisms but not all pathogens. As the process does not kill all pathogens, legislation prohibits the use of thermised milk for direct consumption.

Preferably, milk should have been stored for at least one hour before being processed, as natural degassing occurs during this period. Agitation interferes with the natural degassing process and should, therefore, be kept to a minimum. Short periods of agitation are acceptable, but agitation is not needed until about 5 – 10 minutes before the silo is to be emptied to ensure a homogenous quality throughout the milk, as creaming will have taken place during transport or in the silo.

It is recommended to thoroughly test the incoming milk for a range of quality parameters before processing. The most common tests are described in this chapter. Some milk may, for example, not be appropriate for UHT but may be appropriate for other uses.

Microbiological quality

One of the primary reasons for poor milk quality is the impact of microbiological activity in the milk. To understand the changes that can occur in milk that negatively impact its processability and how to prevent them, we must first understand which microorganisms play an important role. A general introduction and overview of microbiology and the microbiology of milk is given in Chapter 4. This section summarises some key sources and characteristics of the most relevant microorganisms that affect processability.

Lactic acid bacteria

Lactic acid bacteria are present on the skin of the cow, its bedding material and feed. They do not grow at low temperatures, so fast cooling of the milk at the farm will prevent them from growing in the raw milk. Lactic acid bacteria do not survive pasteurization. Lactic acid bacteria will ferment lactose to lactic acid, causing acidification of the milk and a decrease in pH value. In some cases, this is purposefully done to produce fermented milk products, but when not deliberately added, lactic acid bacteria can have detrimental effects on the processability of the milk. Just a small drop in pH (0.1 – 0.2 pH units) can cause problems with fouling in heat exchangers and shortened production time. A larger drop in pH will make the milk unsuitable for UHT processing due to the high temperatures and pH, causing the milk to coagulate during processing or later in the package.

Gram-negative psychrotropic bacteria

Gram-negative psychrotrophic bacteria are generally present in dirty water and form biofilms on the surface of milking equipment that is not cleaned properly. While they grow optimally in warmer conditions, they can also grow at refrigerator temperatures. Because of this, they contribute heavily to the total plate count of refrigerated raw milk, especially when it has been stored for a while and the bacteria have had some time to grow. These bacteria don’t ferment lactose and, therefore, don’t lower the milk pH, but they produce heat-stable enzymes that have a detrimental effect on the milk during storage. The bacteria do not survive pasteurization, but the remaining enzymes can cause off-flavours, fat separation, sedimentation and gelation in UHT milk (see fig 5.2). The higher the number of Gram-negative psychrotrophic bacteria in the raw milk – and the longer they have been present in the milk – the shorter the shelf life of the product will be, which is especiallyproblematic for long-shelf-life dairy products.

Spore-forming bacteria

As described in Chapter 4, Microbiology, as a survival mechanism some bacteria form spores when in harsh environments. Spores are very heat-resistant and can be found in many different places, leading to contamination, including on milking equipment, on the cow, its feed and the surrounding environment. Spores will germinate when in suitable conditions for bacterial growth, for example, after heat treatment, even after being inactive for long periods – sometimes years! Once active, the bacteria can adversely impact the milk or milk product, often resulting in a much shorter shelf life. Spores are also a major problem in cheese manufacturing as specific types can lead to blowing in cheese (as shown in figure 5.3).

Spores come from the environment, and the most effective way to manage spore load in milk is at the farm with GMP (good manufacturing practices). Like with bacteria, spore load can be reduced using ESL technologies such as bactofugation, microfiltration and applying high heat treatment. Storing milk at recommended cold conditions greatly reduces the risk of spore germination.

Thermoduric bacteria

Thermoduric bacteria are part of the skin flora of the cow and can be found in bedding material and feed. They are a significant group as they can survive pasteurization temperatures and, therefore, contribute greatly to the total count after processing. Some of these bacteria may degrade milk components, decreasing quality. They can be an issue for powder production as the quality of powder is often determined by their total count. They can also form biofilms in processing equipment if cleaning is not effective. The most effective way to reduce the thermoduric bacteria load is to reduce them at the farm level with GMP, maintenance, and cleaning. ESL technologies such as bactofugation, microfiltration and high heat treatment can be used to reduce their quantity, although the reduction by bactofugation and microfiltration is low due to the small size of some thermoduric bacteria. High heat treatment inactivates vegetative thermoduric bacteria.

The thermoduric bacteria load is not measured directly, though some countries measure the total plate count after pasteurization or on the last day of the shelf life of pasteurized milk, which is equal to the thermoduric bacteria load.

Pathogenic bacteria

Pathogenic bacteria are described in more detail in Chapter 4. These bacteria can cause illness in humans. All pathogenic bacteria are killed at pasteurization temperatures, but toxins that are formed before heat treatment can be heat-resistant, even to UHT temperatures. Pathogenic spores might survive heat treatment and can grow if the product is kept at ambient temperature. With the exception of Listeria monocytogenes, pathogens cannot grow at low temperatures. Cold storage and clean milking conditions and storage tanks are important factors in limiting the growth of pathogens prior to heat treatment.

Mastitis bacteria

Mastitis bacteria cause udder infections in cows. Mastitis will cause an increase of somatic cells, white blood cells, in the milk. The somatic cells ally themselves with heat-resistant enzymes in the milk called plasmin, which can degrade proteins in a similar way to bacterial enzymes. This can cause bitterness, gelation and sedimentation of UHT milk. Milk from cows with mastitis also has an altered composition of proteins and salts. More whey proteins and higher salt concentration make the milk more prone to fouling. Some of the bacteria that cause mastitis can also be human pathogens and form heat-resistant toxins, for example, Staphylococcus aureus. Somatic cell count is a common analysis done on milk upon reception at the dairy processor. The maximum amount of somatic cells allowed is 400,000 cells/ml in the EU and 750,000 cells/ml in the US.

Yeast and mould

Yeasts and moulds can be present in raw milk. They grow slowly at low temperatures, and relevant species are inactivated by pasteurization at 72 °C for 15 seconds. The presence of mould toxins in milk is a feed-related problem. Aflatoxin B1 is a liver-toxic and carcinogenic mould toxin that can be present in high amounts in feed. The cow metabolises the aflatoxin B1 into aflatoxin M1 and secretes it into the milk. Aflatoxin M1 is also liver-toxic and carcinogenic, and many countries have legal limits for its presence in milk. Aflatoxin M1 is not inactivated by UHT processing conditions.

Yeast and moulds, and their spores, are also present in the air and the environment. While the cells present in the raw milk are deactivated by heat, recontamination is an issue for pasteurized and chilled dairy products. Good hygiene and handling on the processing site reduce the risk of contamination of the product after heat processing. Yeasts and moulds can grow at chilled temperatures and will impact the sensory quality of the product, resulting in a reduced shelf life.

Yeast and mould spores are not all deactivated by pasteurization. However, this is normally not the limiting factor for pasteurized milk spoilage, as spoilage bacteria grow faster than the time needed for the yeast and mould spores to germinate.

Non-microbial quality aspects

Aside from microbial contamination, other factors play a role in raw milk quality.

Chemical changes in milk

There are chemical changes that can take place during the storage of milk. The presence of dissolved oxygen or sunlight can result in the oxidation of milk fat or protein, resulting in off-flavours in dairy products. High storage temperatures and poor handling resulting in damage to the fat globules can lead to lipolysis of fat. This also leads to off-flavours, resulting in a rancid taste and smell.

Contaminants

Contaminants such as antibiotics, detergents, pesticides, or dirt can end up in raw milk. In many regions, there are limitations set by legislation to mitigate the risk of contaminant quantities that are unsafe for human consumption.

Antibiotics and other treatments may be given to cows that are sick. However, since antibiotics can pass from the cow to the milk, the milk from treated cows must be kept separate until the milk is free from antibiotic traces. Antibiotic residues can impact the production of fermented dairy products by inhibiting the bacteria present in the starter culture. Furthermore, antibiotic residues pose human health concerns, such as allergic reactions and an increased risk of antibiotic resistance if consumed regularly.

Detergents or disinfectant residues present in equipment due to insufficient rinsing before use can contaminate raw milk. This can occur on the farm or at the processing plant. Contamination can lead to a deviation in milk pH, which impacts the processability and stability of dairy products. Of course, in significant quantities, these contaminants will also impact the safety and sensory attributes of milk, and therefore, good manufacturing practices should be adopted to prevent this from happening.

Pesticides are widely used in farming and, if improperly monitored, can be present in the cows’ feed, water or grazing areas. When ingested, pesticides can accumulate in the cow and transfer into the milk. Pesticide content that exceeds acceptable limitations can pose a human health risk.

Dirt in milk refers to the sand, soil, fibres, hair, etc. which may be in the milk coming from the farm resulting from poor hygiene during collection and distribution and it is a source of microorganisms. It can be removed by filters at the reception of raw milk and with the use of a centrifugal separation device. Dirt in milk is easily removed and therefore is not a common stop criterion for processing the milk. However, dirt is a food safety hazard due to the risk of inadequate pasteurization effect and must be removed before processing.

Alduteration

Adulteration is the practice of incorporating water or other ingredients to increase the quantity of raw milk or milk components or increase the shelf life. It is normally done to raise profit margins. Adulteration can significantly impact raw milk quality and pose safety risks, and therefore should be carefully monitored.

Diluting milk with water is sometimes done to increase profits by increasing the volume of milk sold. This can be monitored by checking the freezing point of milk. Adding water to milk changes its composition and also poses a risk of contamination by microorganisms present in the water.

Other ingredients may be added to milk to alter its composition. For example, if a farmer is compensated based on the quantity of protein in the milk, adding non-milk forms of nitrogen can increase the measured protein content. This is a severe safety risk as the composition of the milk is unknown.

Preservatives could also be added to milk to prolong its shelf life and decrease microbial activity. Again, this can pose a food safety risk and impact the processability of raw milk.

Milk composition

Milk and dairy products are normally standardized to achieve a consistent composition. The composition of dairy products is often defined by legislation. However, the composition of raw milk delivered to the processor can vary, and this needs to be accounted for during processing. There are many factors that impact the composition of milk. Some have already been discussed, such as microbial activity (or the activity of enzymes they produce), chemical changes in milk, or adulteration. One of the main factors is the cow itself. Cow health, the composition of its feed, its water intake, and the stage in the lactation cycle can significantly impact the composition of the milk it produces.

Air

Air incorporation in milk is due to the poor design of milk loading facilities at the farm, raw milk reception processes, and factors during transportation. It could, for example, be due to an overly high flow rate, the type of pump, tank inlets or other equipment design faults. Dispersed air content can be managed by allowing time for deaeration in the tank before processing, ensuring the line is designed to minimise air incorporation. It can also be managed by incorporating a deaerator in the line. Dispersed air in milk can result in several processing issues:

- Inaccuracy in the volumetric measurement

- Increased fouling on heated surfaces

- Reduced skimming efficiency in separators

- Less precise in-line standardization

- Issues specifically in cream processing as air will accumulate in the cream

- Reduced stability of cultured milk products (expulsion of whey)

Raw milk quality tests

Due to a limitation in time when it comes to processing milk and the high costs of extensive testing, not all quality attributes of milk are tested upon arrival at the dairy processor. Table 5.1 outlines the most common tests carried out on milk upon arrival at the dairy processor and which quality issues they are linked to.

Taste and smell

The taste and smell of milk give a quick indication of whether the milk is of good overall quality. Any deviations from normal will result in immediate rejection of the delivery, as this indicates severe quality deviations. A change in taste or smell could be due to microbial activity or chemical changes like lipolysis, or the oxidation of fat or protein.

Cleaning check

During a cleaning check, the insides of the farm tanks are inspected for the presence of milk residues. If present, then this means that the tanks were likely not cleaned properly, and there is a higher risk that the milk is contaminated.

Methylene blue/Resazurin test

The total amount of microorganisms present in raw milk can be evaluated through direct or indirect methods. Direct methods involve incubating a sample of raw milk and measuring the amount of bacteria present in the milk. The indirect processes are more commonly applied due to speed and low cost; they are, however, not as precise as the direct methods. Two of the indirect methods most often used to evaluate the total amount of microorganisms present in raw milk are methylene blue reduction and Resazurin reduction. Both are based on the colour compound being reduced by the biological activity of the microorganisms, resulting in a colour change.

Somatic cell count

In general, a high somatic cell count indicates that the animal is unwell and usually suffering from mastitis (see section on mastitis bacteria). This leads to poor quality milk, which can have a high bacterial count, changed composition (low fat content, low casein content, high whey protein content, high salt content), and high plasmin activity, causing casein degradation. Therefore, the presence of somatic cells does not directly impact the milk quality but indicates that the milk may have poor quality attributes. This often leads to decreased processability, shorter running times, and poor final product quality.

Somatic cells can be reduced through centrifugal separation, providing approximately 1 log reduction. Other undesired components caused by udder inflammation, like enzymes, are not removed by centrifugal separation, and hence, this method does not solve all issues linked to high somatic cell load.

Not all markets have limits for somatic cell count. However, examples of limits for certain markets include 400,000 cells/ml (EU), 750,000 cells/ml (US), and 1,000,000 cells/ml (Brazil). EU legislation also states that milk for human consumption should come from healthy cows.

Bacteria count

Bacteria count is generally measured by total plate count, which measures the aerobic, mesophilic bacterial load in the milk, expressed as the amount of colony-forming units (CFU) per ml. As previously discussed in this chapter, bacteria can enter the milk at any point it comes into contact with the cow, environment or contaminated equipment, and good manufacturing practices (GMP) help to limit this. It is important to note that the total plate count will increase over time due to the multiplication of bacteria and activation of spores in the milk. Bactofugation and microfiltration can be applied to reduce the spore count and some thermoduric vegetative bacteria. A high total plate count can cause degradation of the milk, resulting in an irreversible decrease in product quality and issues with processability.

For some applications and troubleshooting, it is more useful to perform selective differential testing to understand which microorganisms are present. When troubleshooting, understanding which microorganisms are responsible for the issue will indicate where in the production chain the issue has occurred. When it comes to applications, the heat-resistant spore count is relevant for UHT products, as all other spores and bacteria are deactivated during processing. For cheese production, the amount of anaerobic spores is of interest. For ESL products, the psychotropic spore count is the relevant group. Which microbiological tests are done is decided by the quality program set up by the producer and can differ from dairy to dairy.

In many markets, there are regulations to limit the total plate count in raw milk. According to EU and PMO requirements, the limits for total plate count are <100,000 CFU/ml at delivery to dairy and <300,000 CFU/ml at the time of processing. However, this limit can vary greatly depending on local legislation.

Milk with a high total plate count (>1,000,000 CFU/ml) or very high total plate count (>5,000,000 CFU/ml) can also be processed, but the shelf life and product quality will be compromised. This is the case in most parts of India, where pasteurized milk commonly has a shelf life of only a few days. In that case, the shelf life is mainly impacted by the thermoduric bacterial load.

The temperature-time program for pasteurization will secure a high log reduction (minimum 5 log) on pathogenic bacteria. This means that statistically, if the load of microorganisms is very high, the risk that pathogens will survive pasteurization and cause illness increases. If gram-negative bacteria are present after pasteurization, then there is a risk of pathogenic bacteria.

Protein and fat content

It is common practice to evaluate the composition of the raw milk upon arrival at the dairy. In some cases, the compensation for the farmer is based on the protein content of the delivered milk. Milk composition can vary seasonally, per region and per cow, but can also be a sign of adverse raw milk quality (for example, a cow with mastitis produces milk with a different composition).

Generally, an instrument based on mid-infrared FTIR technology is used for a quick compositional analysis. This is a spectroscopy instrument that is calibrated specifically to milk to be able to give an overview of its composition. It can also detect other abnormalities, for example, those due to adulteration or microbial activity.

Freezing point

Evaluating the freezing point of milk helps detect milk that deviates from the normal composition or if it has been diluted by water. The addition of water to milk not only reduces its quality but also leads to spoilage or contamination that can present a health hazard. A deviation in the freezing point can also be caused by the cow getting too little water to drink, increasing the total solids content of the milk.

Raw milk has an average freezing point of –0.54 °C. When milk is mixed with water, its freezing point moves closer to 0 °C. When the total solids in the milk increase, the freezing point drops. The milk freezing point is measured using a digital cryoscope.

pH value

Measuring the pH value of milk is a preliminary quality control step to identify microbiological spoilage as well as chemical contamination. Milk normally has a pH of about 6.7 (6.6 – 6.8) at 20 °C. Small decreases in pH (0.1 – 0.25 units) have a large impact on the running time of the heat exchanger and may lead to precipitation of milk proteins (e.g. in a deaerator or separator). UHT processing is not recommended when the milk has a pH of less than 6.45. A low pH indicates poor hygiene at the farm or during distribution, high storage temperature, or long storage time of the raw milk, which leads to increased microbial activity. A pH of above 6.8 could indicate a risk of mastitis, which can be checked with the somatic cell count.

Milk acidity

Evaluating the acidity of milk samples submitted to a normal solution of NaOH is done to identify the result of an intense microbiological metabolism in the sample, leading to acid formation. Since the buffering capacity of milk is high, a lot of acid is needed to change the pH and measuring the milk acidity will give the actual acid content.

Potential acidity can be expressed in several units: Soxhlet-Henkel degrees (°SH), Dornic degrees (°D), Thorner degrees (°Th) and lactic acid percentage (% l.a.) are the most common.

A Soxhlet-Henkel degree is obtained by titrating 100 ml of milk with a sodium hydroxide solution (N/4) with every millilitre corresponding to 1 °SH. The newly formed milk must be between 6.4 – 7.2 °SH.

A Dornic degree is obtained by titrating 100 ml of milk with a sodium hydroxide solution (N/9) with every millilitre corresponding to 1 °D. The normal value of the potential acidity of milk is between 15 – 22 °D.

A Thorner degree is obtained by titrating 100 ml of milk with a sodium hydroxide solution (0.1N) with every millilitre corresponding to 1 °Th.

It is possible to convert the three units to each other, as they are directly correlated using the ratio 1 : 2.5 : 2.25 (°SH : °D : °Th).

Lactic acid percentage is obtained by dividing the Dornic degree by 100.

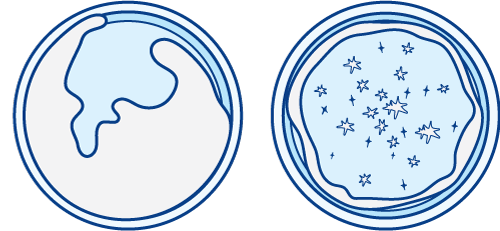

Alcohol stability

The alcohol stability test is used to assess the stability of milk proteins. Neutralised ethyl alcohol solution is added to milk in increasing concentrations until the proteins in the milk form flakes or clots, as shown in Figure 5.4.

Raw milk of good quality will be able to handle a higher alcohol concentration before precipitation. This test indicates how stable proteins will be during processing. The International Dairy Federation suggests 72% alcohol as a minimum concentration, but higher alcohol stability indicates that the milk will cause less fouling and the running time of the equipment will be longer.

Inhibitors

Some dairies use the Delvo test to test for microbial growth inhibitors, which could be detrimental to fermented dairy products such as yoghurt and cheese. The Delvo test is an inhibitor test using a fast-growing test bacterium. If the bacteria grows, there will be a decrease in pH, resulting in a colour change, indicating that the milk is free from inhibitors. If there are growth inhibitors present in the milk, these will prevent the bacteria from growing, and there will be no pH drop and no colour change. This test will catch antibiotics but also other growth inhibitors, e.g. some immune system components from sick cows or adulterants such as chlorine added to prevent microbial growth or acid or base added to correct the pH.

Raw milk requirements differ according to application

The tests described above give a general evaluation of the quality of incoming raw milk. However, there are slight differences in what is seen as acceptable milk quality depending on the application, be it pasteurized milk, ESL milk, UHT milk, yoghurt, cheese, or powder.

When it comes to using milk for UHT treatment, there is generally a greater demand for high-quality raw milk than for pasteurized or ESL milk. The high temperatures used to treat UHT milk increase the level of fouling in comparison with lower temperatures, and the running time is more sensitive to deviations in raw milk quality and composition. Furthermore, the long storage time requires a high homogenisation efficiency and milk that is virtually free from spores or bacterial enzymes. The presence of undissolved air not only increases fouling but also reduces homogenisation efficiency, which could impact the creaming rate in UHT milk. It is therefore extra important that the raw milk has had sufficient storage time to deaerate and is handled gently.

Even though high temperature kills all vegetative micro-organisms, the impact of microbial activity before heat treatment can have detrimental effects. For example, enzymes formed by bacteria survive heat treatment and can later break down milk compontents, greatly reducing the shelf life of UHT milk. Methods to measure enzyme activity are generally not sensitive enough, and therefore, it is advisable to reject milk that has a high plate count. The aim of UHT temperatures is, of course, to target spores so that they cannot germinate during a long storage time. However, if raw milk contains a high amount of spores, a higher heat load is required to sufficiently reduce the spore content. Since the acceptable heat load is limited by the acceptance of organoleptic properties, it is better to start with milk that has a lower spore content.

Fermented dairy products like yoghurt and cheese have other sensitivities. Two major issues are bacteriophages and antibiotics. As discussed in Chapter 4, Microbiology, bacteriophages are viruses that inhibit the growth of specific microorganisms, which can impact the fermentation process. The level of bacteriophages increases with increased total plate count. They are normally inactivated by the heat treatment of yoghurt milk (95 °C for 5 min), but in the case that there is a high bacteriophage content, not all of them may be inactivated. They can also be reintroduced into the milk by cross-contamination if cleaning or disinfection is not properly carried out. Likewise, antibiotics also inhibit micro-organism growth. Antibiotics are used to treat sick cows, and when used excessively, they can end up in the milk. They can slow down or even completely hinder the fermentation process.

Bacteriophages and antibiotics present in raw milk do not have a significant effect on the processability of pasteurized, ESL, or UHT milk. However, depending on local legislation, there may still be limitations on the antibiotics content allowed. Other quality issues detrimental to pasteurized, ESL, or UHT milk are sometimes not a big issue for fermented products. For example, minor off-flavours are easily masked by the acidity developed or other ingredients added to yoghurt. Furthermore, a pH deviation before fermentation is not a major quality concern as it is limited in comparison to the pH drop caused by the fermentation process, and the low final pH also prevents any spores from germinating in the final product.

Powder is sensitive to the thermoduric count in raw milk. Thermoduric bacteria survive pasteurization temperatures, and after drying, their total count will multiply by 10 per gram of powder. For example, if the thermoduric count is 1,000 or 5,000 CFU/ml in raw milk, it doesn’t make a big difference in quality. However, it will make a big difference in powder quality where the bacteria will be concentrated to 10,000 CFU/g or 50,000 CFU/g.

Quality control and assurance

Raw milk quality is important for food safety and the processability of milk. There are many microbiological and non-microbiological reasons for poor milk quality. All actors in the dairy industry have an interest in ensuring milk of high quality is produced, and there are many standards and practices in place to monitor this. National and international regulatory standards, such as those set by the Codex Alimentarius and local regulatory bodies, provide guidelines for raw milk quality. Implementing HACCP (hazard analysis critical control points) and other quality assurance systems helps dairy farmers and processors maintain high standards from farm to processing plant. Furthermore, best practices on farms and good manufacturing practices decrease the risk of poor milk quality, for example, regular health checks for dairy animals, maintaining clean milking and processing environments and ensuring proper storage and transportation conditions.

In summary, understanding and ensuring raw milk quality is not only vital for consumer health but also for optimising dairy processing and maintaining high standards in the quality of dairy products.