RECOMBINED MILK PRODUCTS

Milk is a perishable commodity and therefore scarce in many countries with little or no dairy production of their own. In such countries, raw milk is replaced either partly or fully by milk powder as a raw material.

Recombination is an alternative method of supplying products that closely resemble dairy products based on fresh milk in regions where raw milk is not available. Manufacturing of recombined milk and milk products has been well established in many countries around the world, and a variety of processes and equipment have been developed for this purpose.

The principles of the processes are much the same as those for fresh milk, which was the initial application, but this was followed by the production of recombined evaporated milk and sweetened condensed milk. Today recombination also includes yoghurt, whipping creams, high-protein beverages, butter and cheese.

The processes have been developed over the years from simple batch operations to sophisticated systems with high capacities.

The main processes in the basic reconstitution and recombining operations are:

- Raw material handling

- Weighing and mixing

- Homogenization and heat treatment

Definitions

The following definitions are given as a guide to clarifying certain expressions used in the industry.

Reconstituted milk is the liquid milk obtained by adding water to skim milk powder (SMP), whole milk powder (WMP) or a mix of the two to standardize fat content.

Recombined milk is liquid milk obtained by adding water to SMP and adding milk fat separately in such a quantity that the desired fat content is achieved.

Reconstituted milk products are products resulting from the addition of water to the dried or condensed form of product in the amounts necessary to re-establish the specified water/solids ratio.

Filled milks and milk products are “semi-dairy” products in which the milk fat is replaced by vegetable oils. These include liquid milk, evaporated milk, condensed milk or cheese. Alternative terms could be called “imitation” or “substitute” milk products.

Fortified milk is made from fresh milk, reconstituted milk or recombined milk with the addition of one or more ingredients like vitamins and minerals. The most common additives are vitamins A, D and the mineral calcium.

Anhydrous milk fat (AMF) is a pure dairy fat product obtained from fresh milk, cream or butter with almost all water and non-fat solids removed. AMF typically contains 99.8% milk fat.

Anhydrous butter oil is an all-fat product made from butter of unspecified age. Otherwise, the composition is the same as anhydrous milk fat.

Butter oil is a product made from cream or butter of unspecified age.

Vegetable oils used in recombined products are refined, bleached and deodorised oils, preferably coconut, palm and soybean oils.

Raw material

Milk powder

Non-fat solids for recombined milk are usually supplied in the form of skim milk powder (SMP). This is made by skimming the fat from the whole milk in centrifugal separators and then removing the water from the skim milk by evaporation and drying. The powder can be stored for months, or even years, without being spoiled, and dissolves easily in water to form reconstituted skim milk.

The most common method of classifying skim milk powder is to refer to the heat treatment which the skim milk has been exposed to prior to evaporation and spray drying.

During the heat treatment of milk, the whey proteins are denatured to different degrees, depending on the heat load applied. The degree of denaturation can be classified according to the whey protein nitrogen index (WPNI), which is discussed in Chapter 19. Such classification is used for skimmed milk powder only.

The different recombined milk products usually require skim milk powder of various types of heat classification (see Table 20.1).

Milk powder is typically supplied in 25 kg plastic-lined laminated bags.

In smaller plants, the powder is often emptied manually, directly from the bags into the system. In larger plants, even more sophisticated is the use of silo tanks to which the powder from the emptied bags is transferred pneumatically.

There are also rational methods for transporting milk powder to recombining plants in bulk bins containing 200 – 1,000 kg. The size of the containers is limited by the handling facilities in the locality receiving the powder.

Dissolving of milk powder

The dissolving properties of milk powders are very important for the recombined product quality and are affected by the following factors:

- Wettability

- Ability to sink

- Dispersibility

- Solubility

Analytical methods for these properties are given in:

- Standards for Grades of Dry Milk, Including Methods of Analysis, American Dairy Products Institute, Inc., USA

- ISO/IDF standard methods

Wettability and ability to sink

The wettability of powder refers to how easily a liquid spreads across the surface or penetrates the powder particle. If a powder is highly wettable, the liquid will spread fast, cover the particle and penetrate well, leading to efficient mixing or dispersion.

Low wettability means that the liquid tends to form droplets on the powder particle surface leading to poor mixing or clumping.

The degree of wettability is very much a function of the particle volume and shape, and especially of the capillarity. Other important factors are surface energy and chemistry.

Warm water generally speeds up wetting, stirring and shaking break up clumps, distributing the liquid over the surface and in this way reducing the wetting time. Finer particles have larger surfaces and may wet faster.

There are different methods for measuring the wettability of powder in practice. The most common one is the sinking time method, when a specific amount of milk powder is gently placed on the surface of water at a controlled temperature (often around 25 °C) and the time it takes for the powder to sink below the water surface is measured. Shorter sink times indicate better wettability. This method measures both wettability and ability to sink. Wettability is the first step when the water spreads over the surface and sinkability is the time it takes the wetted particles to move below the water surface. The ability to sink is a function of specific volume and particle size.

Agglomerated powders have improved capillarity, resulting in increased wettability. Increased particle size (130 – 150 μm) also results in improved wettability and ability to sink. Large particles present lower specific surface areas weaker capillary forces and reduced agglomeration. Good wettability is 10 – 30 seconds.

Dispersibility

Good dispersibility is obtained when powders added to the water are distributed as single particles, leaving no lumps. High dispersibility means that milk powder mixes evenly and quickly in water, creating a smooth and consistent product. This is essential for convenient consumer products like instant milk powders, infant baby formulas and the production of reconstituted and recombined dairy beverages.

The structure of the powder particles, as well as the configuration of the protein molecules, are important. A powder with a high content of denatured proteins is very difficult to disperse. Denaturation of proteins may build aggregates and create lumps, making them harder to disperse evenly. The change of protein structure alters their interaction with water (wettability) which further impairs dispersibility as wetting is the first step in proper dispersion. A dispersibility of at least 90% is considered acceptable for milk powders for recombination. This means that when a powder is mixed with water, at least 90% of the weight of the powder should be either dissolved or dispersed evenly without forming lumps or leaving residues. Powder with a dispersibility of 95% and over is an excellent or premium product.

Solubility

The solubility index describes how well the powders dissolve and measures the amount of non-dissolving particles. How good the solubility is depends (as with dispersity, described above) on the technology used to produce the powder, especially the heat load applied.

The solubility of milk powder is measured by dissolving a known amount of milk powder in water, separating undissolved particles (via filtration or centrifugation) and calculating the proportion of powder which was not dissolved. A good solubility index when measured after centrifugation should be as low as 0.25 ml undissolved sediment in 50 ml recombined milk.

Fats and oils

The most common source of milk fat for recombination is anhydrous milk fat (AMF), which does not require chilled storage. It is typically packed in 19.5 kg cans or boxes, or 196 kg drums. To maintain the quality of the AMF, air should be excluded by packing the product under inert gas (nitrogen). At such conditions, AMF will keep for several months even at elevated ambient temperatures.

Milk fat packed in cans can be melted by immersion in hot water at 80 °C for 2 – 3 hours. Drums of AMF, however, require longer melting times. The normal method is to store the drums in a hot room at 45 – 50 °C for 24 – 28 hours before use, or to use a steam chest or tunnel which can melt the contents of the drums in about 2 hours. Another option is to use heated blankets. Once melted, the AMF should be transferred to a jacketed holding tank with facilities for maintaining temperature.

Unsalted sweet butter can also be used in the manufacture of recombined milk products, but it must be kept under refrigerated storage.

Similar handling systems for AMF can also be employed when non-liquid vegetable oils are used in the production of recombined “filled” milk products.

Water

Water is also an important raw material in all types of reconstituted and recombined milk products. It must be of good drinking quality, free from harmful microorganisms and of acceptably low hardness, expressed as calcium carbonate (CaCO3), preferably below 100 mg/l, corresponding to about 5.5 °dH. As only “distilled” water is removed in the production of milk powder, the water used for reconstitution or recombination must also be pure. An excessive mineral content will jeopardise the salt balance and heat stability of the reconstituted or recombined product, which in turn will cause problems during pasteurization, not to mention sterilisation or UHT treatment.

Too much copper or iron in the water may cause off-flavours, due to oxidation of fat. The maximum levels recommended are therefore:

- Cu (copper), mg/l 0.05

- Fe (iron), mg/l 0.1

- Ca (calcium) mg/l 40.0 (correspondent to 100 mg CaCO3)

- Mg (magnesium) mg/l 25.0

- Water hardness dH° 5.5

- Total solids (mg/l) 500

- pH range 7.0 – 8.0

Additives

Dry additives, such as mixtures of stabilisers and emulsifiers, can be handled in the same way as the milk powder, i.e. they are dumped from the bags either directly into the mixing vessel or mixing system. As stabilisers can cause lumps, it can be favourable to dry mix them with an equal amount of milk powder before adding them to the liquid.

Recombination of milk products

Mixing temperature and hydration time

The solubility of milk powder is temperature dependent. Higher temperature increases the solubility due to the higher kinetic energy of the water molecules. Because of this, warm water (40 – 60 °C) dissolves milk powder more readily than cold water. Warm water breaks down and disperses particles more quickly, reducing lumping and facilitating the dissolution of particles. At higher temperatures, other components such as milk fat are melted, improving the dispersing of fat. Another advantage of warm mixing is the reduced solubility of air, causing less air to be incorporated into the recombined product. Cold mixing (< 10 °C) can lead to incomplete dissolution and sedimentation and is therefore not recommended. In general, more powder particles remain undissolved at a mixing temperature of 10 – 20 °C compared to warm mixing, even if the mix is kept for 24 hours. There is also a limitation of the high-temperature range. Exceeding a mixing temperature of 65 °C will lead to the denaturation of whey proteins which may reduce powder solubility. It is therefore not recommended.

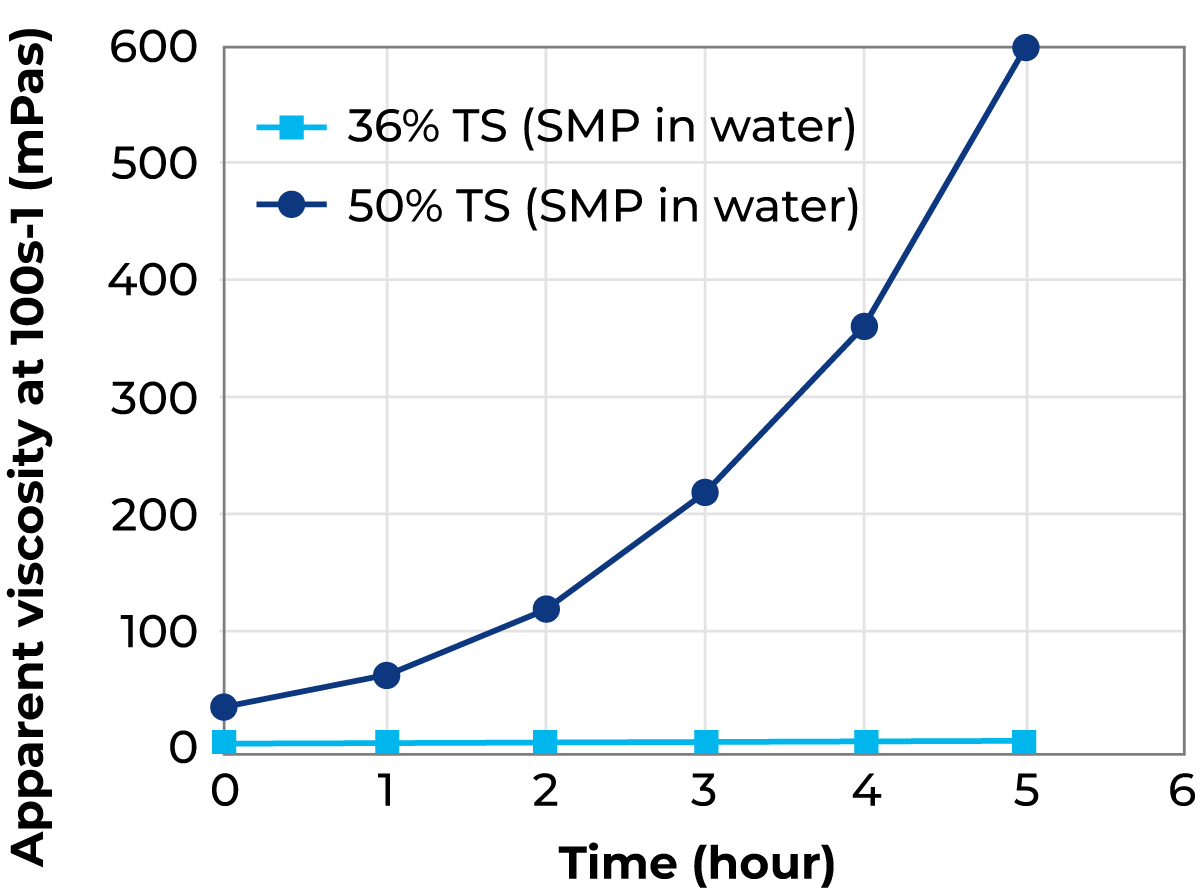

The number of undissolved particles in powder slurry is also dependent on powder concentration. In a highly concentrated slurry (high concentration of milk powder to available water ratio) the likelihood of undissolved particles or particle aggregation and clumping increases. Higher concentrations require more careful management, often involving higher temperatures and extended stirring to minimise undissolved particles. The highest possible safe concentration of skimmed milk powder in water at 48 °C without fast aggregation of particles is 35 – 40% (preferably ≤ 36%). Higher concentrations may lead to protein aggregation and increased viscosity, resulting in gel formation of the slurry. In case there is fat included, it is possible to increase the concentration to 44% where 12.5% comes from the fat.

Low-heat powder, as described earlier, is easier to dissolve than high-heat powder. After all the milk powder is added to the water, the proteins and minerals need time to equilibrate. At 40 – 50 °C, this hydration step takes about 20 minutes. Insufficient hydration time may lead to a “chalky” defect or sediment in the final product.

The recombined milk should not be kept at this high mixing temperature for more than three hours due to the risk of bacterial growth.

Fat addition and emulsification

Incorporation of fat into recombined products has always been a relatively difficult operation. The fat must be properly dispersed and emulsified, which places certain requirements on the processing equipment and parameters.

Traditionally, the melted fat is measured into the line during continuous operation, followed by thorough mixing in a static or mechanically operated mixer before entering a homogenizer.

In modern systems using high-shear mixing devices, fat can be dosed directly into the mixing unit and well emulsified by the high-shear mixing device. The fat must be added at a temperature above its melting point. To ensure this, AMF and the liquid phase temperature must be above 40 °C, typically 55 – 60 °C for the fat and 45 – 50 °C for the liquid base.

The dispersion of fat by using high-shear mixers is sufficient to create a stable emulsion, which allows for eliminating homogenization at this stage of the time-limited pre-process. Later, the recombined products will finally be homogenized during pasteurization and/or UHT processing.

In small-scale batch production, fat is sometimes added to the milk in a mixing tank. To ensure that the composition of the product is uniform when it is pumped to downstream processing, the milk must be thoroughly agitated, often with a high-speed agitator. Even when a homogenizer is integrated into the system, the fat in the feed must be uniformly distributed. Proper fat distribution is very important for homogenization efficiency because it influences the stability of the recombined product during its shelf life.

An emulsifier is sometimes added to facilitate and improve the emulsification of milk fat. It can be added either into the water phase or the fat phase.

Recombined products can be of different kinds and compositions, from white milk and flavoured milk to high-protein beverages and creams.

Cream with a fat content of up to 40% can be recombined from skim milk powder or buttermilk powder and anhydrous milk. The stability is improved by the addition of emulsifiers and stabilisers.

Mixing temperature and microbiological considerations

The disadvantage of recombining at warm temperatures is the risk of microbiological growth when the milk is kept at an elevated temperature for a long time. From a microbiological growth point of view, it is optimal to keep as low a temperature as possible. However, since an elevated temperature is positive for so many other reasons, it is inevitable to mix at a less favourable temperature regarding microbiological aspects. The question is what the most optimal mixing temperature is to get as low risk as possible for microbiological growth and ensure that no pathogens can multiply but still achieve a stable high-quality emulsion.

Simply put, the microorganisms to focus on that can grow in this area and that can cause food safety risks are mainly Staphylococcus aureus, Geobacillus stearothermophilus and Bacillus licheniformis. Of these, S. aureus is the only pathogenic bacteria, since it is a toxin producer. The toxin is heat-stable and will not be eliminated by heat treatment, meaning if the toxin is produced, it will still be in the final packaged product. S. aureus does not grow at temperatures above 48 °C, which means to eliminate the risk of S. aureus growth, recombination should take place above 48 °C.

Geobacillus stearothermophilus (GST) is a spore former and is very heat-stable but not a pathogen. It is, however, a potential process survivor. GST has its optimum growing temperature at 55 °C, but at 50 °C its growth is already slower.

Bacillus licheniformis is heat resistant but not to the same extent as GST.

Based on the properties of the microorganism, to reduce the risk of possible microbiological spoilage for the recombined products that should be UHT treated, the recombined mix should be stored at a temperature between 48 and 55 °C for up to 3 hours. The time is of course determined by the microbiological quality of the raw materials involved.

Design of recombination lines

Mixing

There are, in principle, 3 different ways of mixing recombined products:

A. Traditional batch process

B. Single-stream continuous process

C. Multi-stream continuous process

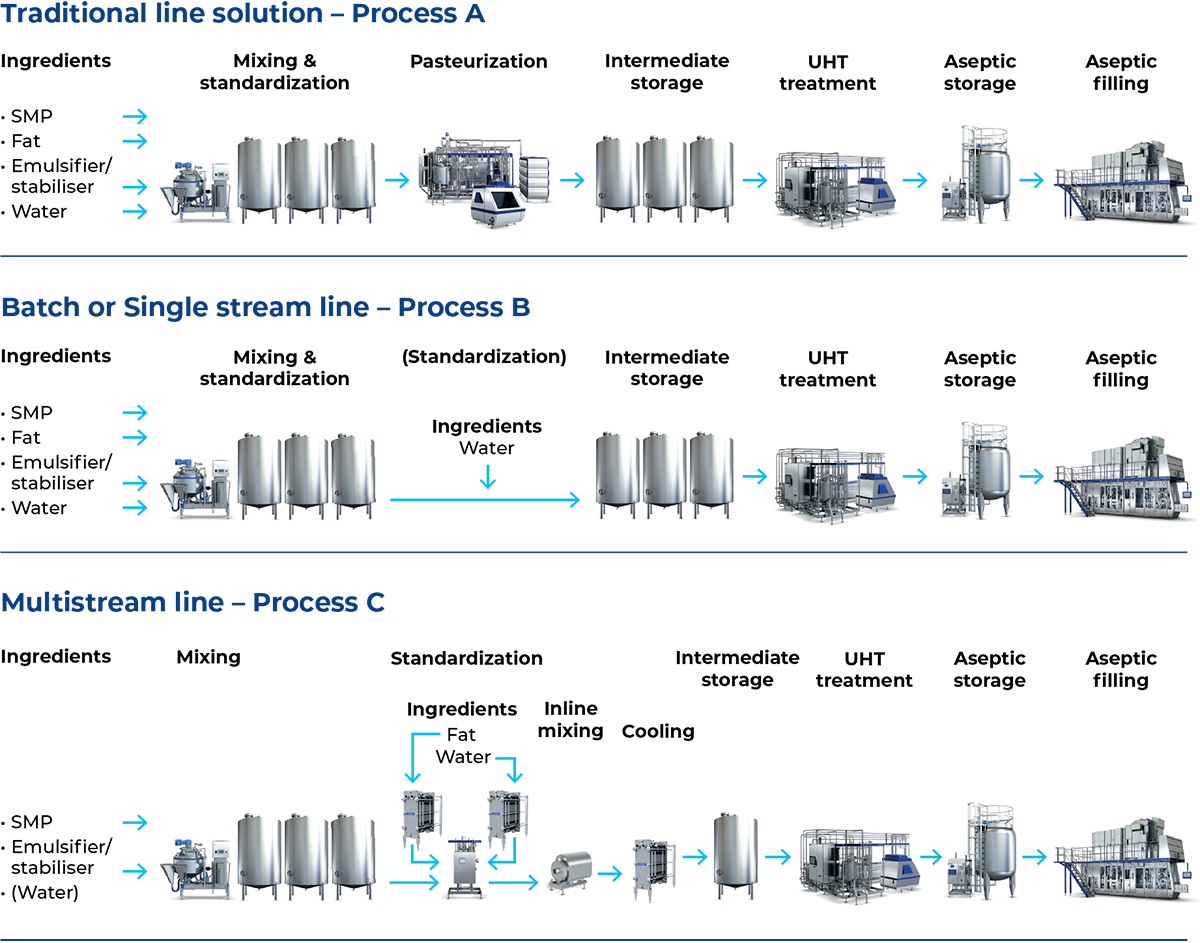

Examples of recombination lines for production of recombined UHT products are shown in the Figure 20.2.

Traditional batch process – Process A

In traditional batch processing, the production volume of a single batch is limited to the volume of one mixing tank. During the mixing, all the ingredients are added to reach the required composition, after which the product can continue to heat treatment. For processing of UHT products in the traditional line, the mix is first pasteurized and thereafter UHT treated. The processing flow chart can be seen in Figure 20.2 – Process A.

The batch water volume is measured into one of the mixing tanks. On the way, it is heated in a heat exchanger to 48 – 53 °C. At this temperature, milk powders have better solubility.

After all the milk powder has been added, it is recommended to leave the product in the tank without any, or with very gentle, agitation for at least 20 minutes for deaeration and hydration.

Milk fat, which is solid at room temperature, needs to be heated and melted before it can be added to the dissolved milk powders and emulsified into small fat droplets if enough energy is applied, e.g. from a high-shear mixer. If emulsifiers are used, they also need to be present during this fat-addition step and – together with the milk proteins – create the fat globule membranes. The emulsifier, if separate, can be added to the fat phase or, if in the form of a mixture with a stabiliser, it is typically added to the recombined water phase at the temperature of 48 – 53 °C prior to the addition of fat. Adding melted milk fat into cold liquid is not recommended, nor is adding solid fat directly into the mixer. If the mixing is performed cold, there is a risk of insufficient emulsification and quick separation of the fat on top.

To minimise any microbiological issues, the product can stay at the recombination temperature for a maximum of three hours. In case the product needs to stay for a longer time, it must be cooled down to about 5 °C.

Now the mix is prepared for the next processing step – pasteurization. In the case of products for ambient distribution, pasteurization is followed by UHT treatment.

Single-stream continuous process – Process B

In this technology, the mixing only uses a part of the total water amount, leading to a concentration of all solids (a maximum of 36% in the case of fat-free solids or 44% if 12.5% fat is included). The final product composition is reached through inline dilution with the rest of the necessary water en route to a storage buffer tank or heat treatment. In this way, the number of storage tanks is reduced. The line for UHT milk production is also simplified by removal of the pasteurization step.

Multi-stream continuous process – Process C

This is the most advanced technology, where all product components are recombined in the form of concentrates or separate streams, which are used for inline standardization of the final product composition en route to UHT heat treatment. The skimmed milk slurry is prepared in the same way as in Process B, sometimes also containing emulsifier(s) and stabiliser(s). Fat is melted and heated to 60 – 70 °C and the water stream is heated to about the same temperature. All streams are mixed using a standardization unit and pass through an inline high-shear mixing device on the way to heat treatment.

The continuous systems (B and C) are more modern technologies that are utilised by producers of a limited number of products on each production line, but in large quantities and during long production runs. Modified processing lines may lead to reduced running time or stability of the final product.

Heat treatment

The design of the plant is influenced not only by its capacity but also by the method of heat treatment of the recombined milk. Two main alternative methods are used:

Pasteurization at a temperature of at least 72 °C for 15 seconds, followed immediately by cooling to below 4 °C.

UHT treatment is normally carried out in indirect heating systems at temperatures of 138 – 140 °C with 4 seconds holding time. Placement of homogenization is dependent mainly on the product’s fat and protein contents. In most cases, it is in the upstream position, while for products with a fat content above 10%, it is often in the downstream position.

Storage

Recombined milk normally flows from the production line to the packing machine. A storage tank is needed to compensate for temporary stoppages in the production or packing lines. In the case of UHT-treated products, the storage tank must be an aseptic version to avoid reinfection. On some occasions, the product is filled directly without using an aseptic storage tank. Since most aseptic filling machines require overpressure, in these cases, the capacity of the UHT unit must be higher than the capacity of the filler and the flow which cannot be packed is recirculated and reprocessed. This may negatively influence the quality of the product.

Packaging

The milk should be packaged as soon as possible after production. UHT-treated milk must flow in a closed aseptic system to the aseptic filling machine. Pasteurized milk can be packed in paperboard-based packages, plastic or glass bottles.

If bottles are used, they should have barriers which prevent the flavour of the dairy product from being spoiled by exposure to light.

The aseptic packages must always be airtight to protect the milk from oxidation. In the case of carton-based packages, they should also be strong enough for stacking in crates or boxes.

Distribution

Since UHT-treated and sterilised milk can be stored at ambient temperatures, the whole distribution chain is simpler than for pasteurized milk, which needs to be refrigerated all the time. For example, UHT milk can be transported on an ordinary lorry for long distances and sold in a shop with no refrigeration. Pasteurized milk, on the other hand, requires a refrigeration chain of insulated distribution vans, chilled storage in shops and (preferably) home refrigerators.