BUTTER

Butter is a well-known dairy product derived exclusively from milk. It’s primarily a water-in-oil emulsion, containing over 80% milk fat. Butter serves as a versatile ingredient. People use it as a spread, a cooking fat, or in baking recipes.

Definitions

Referring to Codex Standard CXS 279, butter is a fatty product derived exclusively from milk and/or products obtained from milk, principally in the form of an emulsion of the water-in-oil type.

The composition of butter is expressed as:

- Minimum milkfat content 80% m/m

- Maximum water content 16% m/m

- Maximum milk solids-not-fat content 2% m/m

Butter

Butter is usually divided into two main categories:

- Sweet cream butter

- Cultured or sour cream butter made from bacteriologically soured cream

*Butter can also be classified according to salt content: unsalted, salted and extra salted.

Until well into the 19th century, butter was still made from cream that had been allowed to sour naturally. The cream was then skimmed from the top of the milk and poured into a wooden tub. Butter was made by hand in churns.

The natural souring process is very sensitive, and infection by foreign microorganisms often spoiled the result.

As knowledge of cooling increased, it became possible to skim the cream before it had gone sour and make butter from the sweet cream. Butter-making methods gradually improved, and so did the product quality and economic yield. It was eventually found that sweet cream could be soured by the addition of naturally soured milk or acid buttermilk. It then became possible to make ripened cream butter under more controlled conditions.

The invention of the separator (1878) meant that cream could be skimmed from milk quickly and efficiently. It was also the start of large-scale buttermaking. Contributions to the quality of the product and butter-making economics were also made by the introduction of pasteurization in the 1880s, the use of pure bacteria cultures in the 1890s and the introduction of the butter-making machine at the turn of the century.

Today’s commercial buttermaking is a product of knowledge and experience gained over the years concerning such matters as hygiene, bacterial acidification and temperature treatment, as well as the rapid technical development that has resulted in the advanced machines now used.

Sweet and cultured (sour) cream butter

Butter naturally contains the Vitamins A and D. The colour of butter varies with the content of carotenoids, which make up from 11 to 50% of the total vitamin A activity of milk. As the carotenoid content of milk normally fluctuates between winter and summer, butter produced in the winter period has a brighter colour. In this context, it might also be worth mentioning that butter made of cream from buffalo milk is white, as buffalo milk does not contain carotenoids. Butter should also be dense and taste fresh. The water content should be dispersed in fine droplets so that the butter looks dry. The consistency should be smooth so that the butter is easy to spread and melts readily in the mouth.

Sour cream butter should smell of diacetyl, while sweet butter should taste of cream. A faint cooked flavour is acceptable in the case of sweet butter.

Butter made from sour cream has certain advantages over the sweet cream variety. The aroma is richer, the butter yield is higher, and there is less risk of reinfection after temperature treatment, as the bacteria culture suppresses undesirable microorganisms.

However, sour cream butter has its drawbacks. Buttermilk from sour cream butter has a far lower pH than buttermilk from sweet cream butter, which sometimes makes it harder to dispose of than sweet buttermilk. Another disadvantage of cultured cream butter is that it is more sensitive to oxidation defects, which give it a metallic taste. This tendency is accentuated if the slightest trace of copper or other heavy metals is present, and this reduces the chemical-keeping properties of the butter considerably.

Buttermaking

Butter was originally made on the farm for household use. In those days, a manually operated butter churn, Figure 14.1, was used. Following churning and discharge of buttermilk, the butter grains were collected in a shallow trough and manually worked until acceptable dryness and structure were achieved.

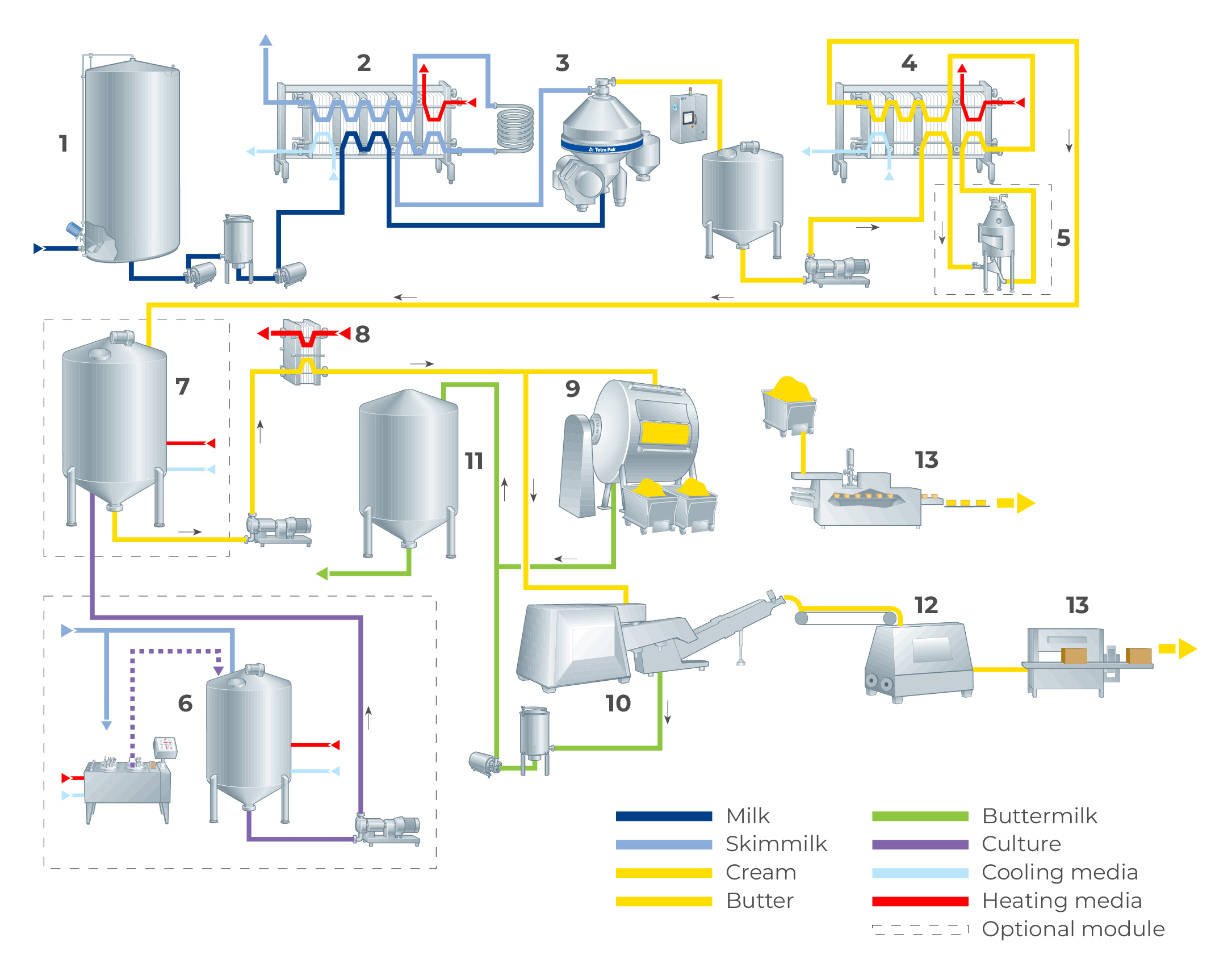

Large-scale butter manufacturing processes generally involve quite a number of stages. Figure 14.2 schematically shows both batch production in a churn and continuous production in a butter-making machine. Churns are still used but are rapidly being replaced by continuous butter-making machines.

The cream can be supplied by a liquid milk dairy (surplus cream) or separated from whole milk at the creamery. In the former case, the cream should have been pasteurized by the supplier. Storage and delivery to the creamery should be undertaken in such a way that reinfection, aeration or foaming do not take place. After reception procedures, weighing-in and analysis, the cream is stored in tanks.

If the cream is produced at the creamery, the whole milk is pre-heated to separation temperature in the pasteurizer before being separated. The warm cream is routed into an intermediate storage tank before being pumped to the cream pasteurization plant. For gentle treatment of the cream, please see the description of the Scania method in Chapter 9.

From the intermediate storage tank(s) the cream continues to pasteurization at a temperature of 85 °C for 15 seconds or higher. The high temperature is needed to destroy enzymes and microorganisms that would impair the keeping quality of the butter.

The destruction of unwanted microorganisms is also beneficial in the case of sour cream butter, as this creates perfect growth conditions for the bacteria culture. The heat treatment releases strongly antioxygenic sulfhydryl compounds, which further reduce the risk of oxidation.

Vacuum deaeration can also be included in the line if the cream has an undesirable flavour or aroma, e.g. onion taste. Any flavouring will be bound in the fat and transmitted to the butter unless removed. Vacuum treatment before pasteurization involves pre-heating the cream to the required temperature and then subjecting it to flash cooling to free any entrapped gas and volatile substances. After this, the cream is returned to the pasteurizer for further treatment – heating, holding and cooling – before proceeding to the ripening tank.

In the ripening tank, the cream is subjected to a temperature programme which will give the fat the required crystalline structure, when it solidifies during cooling. The programme is selected to match factors such as the composition of the butterfat, expressed, for example, in terms of iodine value, which is a measure of the unsaturated fat content. The treatment can also be modified to produce butter with good consistency despite a low iodine value, e.g. when the unsaturated proportion of the fat is low.

Ripening usually takes 12 – 15 hours. Where possible, the acid-producing bacteria culture is added before the temperature treatment. The quantity of culture added depends on the treatment programme selected with reference to the iodine value (Table 14.1).

From the ripening tank, the cream is pumped to the continuous buttermaker or the churn; sometimes a passage through a plate heat exchanger is desirable to bring it to the required temperature. In the churning process, the cream is agitated violently to break down the fat globules, causing the fat to coalesce into butter grains. The fat content of the remaining liquid, i.e. buttermilk, decreases.

The cream is split into two fractions: butter grains and buttermilk. In traditional churning, the machine is stopped when the grains have reached a certain size, and then the buttermilk is drained off. Buttermilk drainage is continuous in continuous butter-making machines.

After drainage, the butter is worked to a continuous fat phase containing a finely dispersed water phase. It used to be common practice to wash the butter with water after churning, to remove any residual buttermilk and milk solids, but this is rarely done today. If the butter is to be salted, salt is spread over the surface in batch production, or added in slurry form during the working stage in continuous buttermaking.

After salting, the butter must be worked further to ensure uniform distribution of the salt. The working of the butter also affects the characteristics by which the product is judged – aroma, taste, keeping quality, appearance and colour. The finished butter is discharged into the packaging unit and then to cold storage.

The raw material

The cream must be of good bacteriological quality, without taste or aroma defects. The iodine value is the deciding factor in the selection of manufacturing parameters. Unless corrected, fat with a high iodine value (high unsaturated fat content) will produce greasy butter. Butter of acceptable consistency can be obtained from both hard fat (iodine value down to 28) and soft fat (iodine value up to 42), by varying the ripening treatment to suit the iodine value.

Cream containing antibiotics or disinfectants is unsuitable for the manufacture of acidified butter. If harmful microorganisms have been given the chance to develop, the cream cannot be used, even if those organisms can be rendered inactive by heat treatment. Therefore, strict hygiene is essential in all stages of the production process.

A problem in countries with a refrigerated distribution chain for raw milk is that cold storage causes changes in the composition of microorganisms. Where lactic acid bacteria once dominated, there are now bacteria strains that have a high resistance to cold – psychrotrophic bacteria. These are normally destroyed during pasteurization and therefore do not affect the quality of the butter. Some psychrotrophic bacteria strains, however, produce lipolytic enzymes which can break down fat. These enzymes can withstand temperatures above 100 °C. Consequently, it is vital that the development of psychrotrophic bacteria is prevented. One solution is to chill the raw material to 2 – 4 °C immediately on arrival at the dairy and store it at that temperature until it is pasteurized or, even better, to thermise the milk at 63 – 65 °C for 15 seconds and cool it to 2 – 4 °C. Pasteurization should take place as soon as possible, and not later than 24 hours after arrival. Cream containing antibiotics or disinfectants is unsuitable for cultured butter manufacture.

Pasteurization

Cream is pasteurized at a high temperature, usually 85 °C for 15 seconds or higher. The heat treatment should be sufficient to result in a negative peroxidase test.

This vigorous treatment kills not only pathogenic bacteria but also other bacteria and enzymes that could affect keeping quality. The heat treatment should not be so intense that there will be defects, such as a cooked flavour. Heat treatment should be strong enough to result in a negative peroxidase test, but not so intense as to cause defects such as cooked flavour

Vacuum deaeration

If necessary, any undesirable flavouring substances of a volatile nature can be removed by vacuum treatment. The cream is first heated to 59 °C and then pumped into a vacuum chamber where the pressure corresponds to a boiling temperature of 55 °C. The reduced pressure causes volatile flavouring and aromatic matter to escape in the form of gas when the cream is flash-cooled. After this treatment, the cream is returned to the heat exchanger for pasteurization and cooling and then continues to the ripening tank.

Onion off-flavour is a very common defect during the summer when various onion plants grow in the fields. Sorting the cream is sometimes necessary to avoid strong flavours. Vacuum deaeration is recommended when the cream has a very strong flavour or aroma defect, e.g. onion taste. Vacuum treatment may have an unfavourable effect on the yield and the butter consistency.

Bacterial souring

The souring of the cream and the temperature treatment that gives the fat the necessary crystalline structure for optimum butter consistency take place simultaneously in the ripening tanks. These are usually triple-shell insulated stainless-steel tanks with heating and cooling media circulating between the shells. They are fitted with reversible scraper agitators for efficient stirring, even when the cream has coagulated. Both heating and cooling are very gradual, and this smooth temperature characteristic is advantageous from a consistency point of view.

The cream needs temperature treatment if the butter is to have the required consistency. The treatment programme depends on the iodine value of the cream. The acidification temperature will also be determined by this programme, as ripening takes place at the same time. It is possible to modify the consistency-related temperature programme so that it is adapted to the starter culture.

Temperature treatment

Before churning, the cream is subjected to a programme of temperature treatment, which will control the crystallisation of the fat, so that the butter will have the desired consistency. The consistency of the butter is one of its most important quality characteristics, both directly and indirectly, as it affects the other characteristics – mainly taste and aroma. Consistency is a complicated concept involving properties such as hardness, viscosity, plasticity and spreadability.

The fatty acids in milk fat were described in Chapter 2, The chemistry of milk. The relative amounts of fatty acids with high melting points determine whether the fat will be hard or soft. Soft fat has a high content of low-melting fatty acids, and at room temperature this fat has a large continuous phase of liquid fat, i.e. the ratio of liquid to solid fat is high. On the other hand, in hard fat, the ratio of liquid to solid fat is low.

In buttermaking, if the cream is always subjected to the same temperature treatment, it will be the chemical composition of the milk fat that determines the consistency of the butter. Soft milk fat will result in soft and greasy butter, whereas butter from hard milk fat will be hard and stiff. The consistency of the butter can be optimised if the temperature treatment is modified to suit the iodine value of the fat. The temperature treatment regulates the amount of solid fat to a certain extent – this is the major factor that determines the consistency of the butter.

Butterfat crystallisation

The fat in the fat globules is in liquid form after pasteurization. When the cream is cooled to below 40 °C, the fat starts to crystallise. If the cooling is gradual, the different fats will crystallise at different temperatures, depending on their melting points. This is advantageous, as this type of cooling results in a minimum of solid fat – a soft butter could then be made from cream containing hard milk fat with low iodine values. The course of crystallisation in 40% cream is discussed in Chapter 9 under the heading Production of cream. Crystal formation is very slow during gradual cooling, and the crystallisation process takes several days. This can be dangerous from a bacteriological point of view, as the fat is kept at temperatures sensitive to bacterial attack. It is also impractical for economic reasons.

A method of speeding up the crystallisation process is the quick cooling of the cream to a low temperature, where the formation of crystals is very rapid. The drawback of this method is that triglycerides with low melting points are “trapped” in the same crystals and mixed crystals are formed. A great proportion of the fat would be crystallised if no measures were taken. The ratio of liquid to solid fat would be low and the butter made from this cream would be hard.

This can be avoided if the cream is heated carefully to a higher temperature to melt the low-melting triglycerides out of the crystals. The melted fat is then recrystallised at a slightly lower temperature, resulting in a higher proportion of “pure” crystals and a lower proportion of mixed crystals. A higher liquid-to-solids ratio and a softer fat will consequently be obtained.

Of course the amount of mixed crystals, and thereby the ratio of liquid to solid fat, can be determined to a certain degree by selecting the heating temperature at which the fat crystals are melted after cooling and crystallisation and also the recrystallisation temperature. The temperatures are selected according to the hardness (iodine value) of the fat.

Several methods are now available for measuring the ratio of liquid to solid fat in a sample. The NMR pulse spectrometer test is a very fast and accurate method. This technique is based on the fact that protons (hydrogen nuclei) in fat have different magnetic properties according to whether the fat is in a liquid or solid state.

Table 14.1 gives examples of programmes for different iodine values. The first temperature is the value to which the cream is cooled after pasteurization, the second is the heating/souring value, and the third is the ripening value.

Treatment of hard fat

For optimum consistency when the iodine value is low, i.e. the butterfat is hard, the amount of mixed crystals must be minimised and the amount of “pure” fat maximised to increase the ratio of liquid to solid fat in the cream. The liquid-fat phase in the fat globules will then be maximised and much of it can be pressed out during churning and working, resulting in butter with a relatively large continuous phase of liquid fat and with a minimised solid phase.

The treatment necessary to achieve this result comprises:

- Rapid cooling to about 8 °C and storage for about two hours at that temperature

- Gentle heating to 20 – 21 °C and storage at that temperature for at least two hours. Water at a maximum of 27 °C is used for heating.

- Cooling to about 16 °C and then to churning temperature

Cooling to about 8 °C starts the formation of mixed crystals that bind fat from the liquid continuous phase.

When cream is heated gently to 20 – 21 °C, the bulk of the mixed crystals melt, leaving only pure crystals of fat with a high melting point. During the storage period at 20 – 21 °C, the melted fat crystals begin to recrystallise, now forming pure crystals.

After one or two hours the higher-melting fat has started to recrystallise. When the temperature is reduced to about 16 °C, the melted fat continues to crystallise and form pure crystals. During the holding period at 16 °C, all fat with a melting point of 16 °C or higher will crystallise. The treatment has caused the high-melting fat to form pure crystals and thereby reduced the amount of mixed crystals. This increases the ratio of liquid to solid fat, and the butter made from the cream will consequently be softer.

Treatment of medium-hard fat

With an increase in the iodine value, the gentle heating is stopped at a lower temperature. A greater amount of mixed crystals will form, absorbing more liquid fat than is the case in the hard-fat programme. For iodine values up to 39, the heating temperature can be as low as 15 °C. The souring time is extended at lower temperatures.

Treatment of very soft fat

The “summer method” of treatment is used when the iodine value is higher than 39 – 40. After pasteurization, the cream is cooled to 20 °C and soured for about five hours at that temperature. It is cooled when the acidity is about 22 °SH. The cream is cooled to about 8 °C if the iodine value is around 39 – 40, and to 6 °C if it is 41 or higher. It is generally believed that souring temperatures below 20 °C will result in soft butter. The same applies to higher cooling temperatures after souring.

Churning

Batch production

The cream is churned after temperature treatment and after souring, where applicable. Butter is traditionally made in cylindrical, conical, cubical or tetrahedral churns with adjustable speed. Axial strips and dashers are fitted inside the churn. The shape, setting and size of the dashers in relation to the speed of the churn are factors that have an important effect on the end product. Modern churns have a speed range that permits the selection of the most suitable working speed for any set of butter parameters.

The size of churns has increased greatly in recent years. Churns of 8,000 to 14,000 litres capacity or more are used in large central creameries. Before transfer to the churn, the cream is stirred, and the temperature adjusted. The churn is usually filled to 40 – 50% to allow space for foaming.

Butter formation

The fat globules in cream contain both crystallised fat and liquid fat (butter oil). The fat crystals have become structured, to some extent, so that they form a shell (albeit a weak one) closest to the membrane of the fat globule.

A foam of large protein bubbles forms when the cream is agitated. Being surface-active, the membranes of the fat globules are drawn towards the air/ water interface and the fat globules are concentrated in the foam.

When agitation continues, the bubbles become smaller as the protein gives off water, making the foam more compact and thereby applying pressure on the fat globules. This causes a certain proportion of the liquid fat to be pressed out of the fat globules and causes some of the membranes to disintegrate.

The liquid fat, which also contains fat crystals, spreads out in a thin layer on the surface of the bubbles and on the fat globules. As the bubbles become increasingly dense, more liquid fat is pressed out and the foam is soon so unstable that it collapses. The fat globules coagulate into grains of butter. At first, these are invisible to the naked eye, but they grow progressively larger as work continues.

Churning recovery

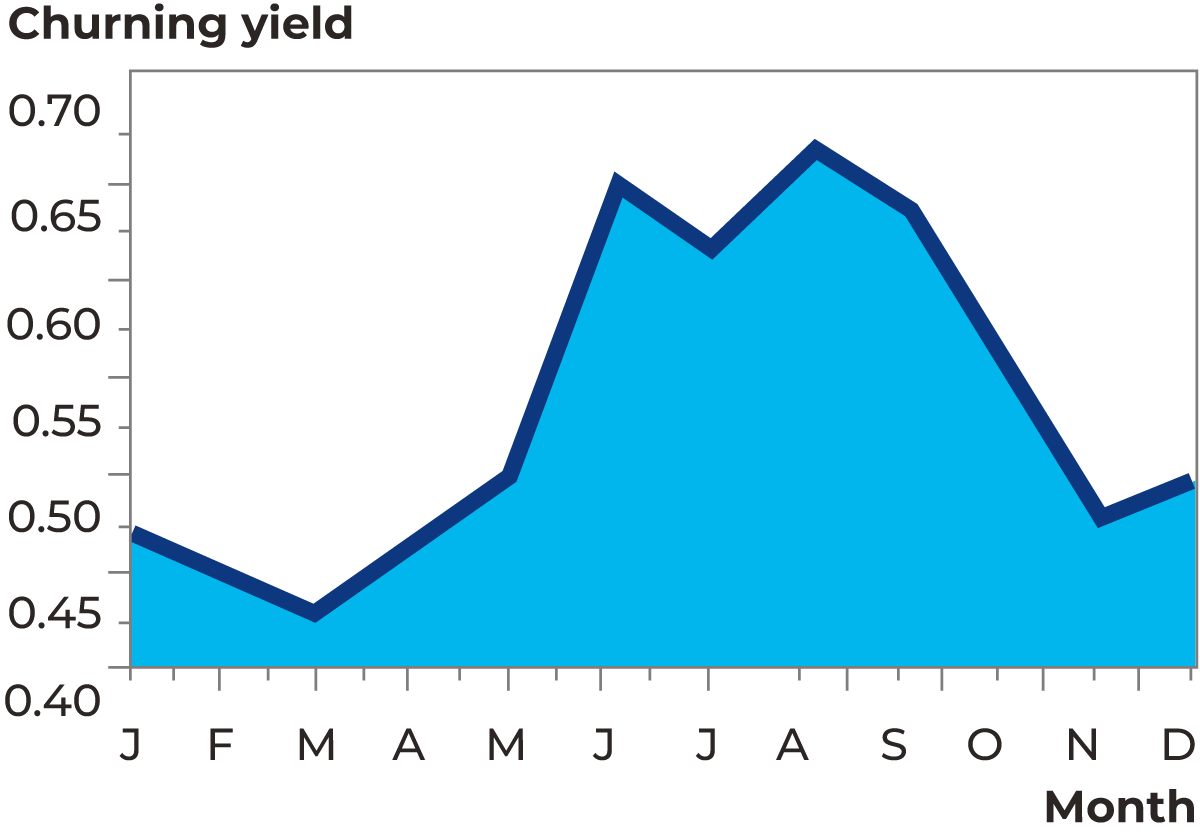

Churning recovery (yield) is a measure of how much of the fat in the cream has been converted to butter. It is expressed in terms of the fat remaining in the buttermilk as a percentage of the total fat in the cream. For example, a churning recovery of 0.50 means that 0.5% of the cream fat has remained in the buttermilk and that 99.5% has been turned into butter. Churning yield is considered acceptable if the value is less than 0.70.

The curve in Figure 14.4 shows how churning recovery can vary over the year. The fat content of buttermilk is highest during the summer.

Working

Working takes place when the buttermilk has been drained off. The butter grains are pressed and squeezed to remove the moisture between them. The fat globules are subjected to high pressure, and liquid fat and fat crystals are forced out. In the resulting mass of fat (eventually the continuous phase), the moisture becomes finely dispersed by the working process, which is continued until the required moisture content is obtained. The finished butter should be dry, i.e. the water phase must be very finely dispersed. No water droplets should be visible to the naked eye.

The moisture content should be checked regularly during working, and adjusted so that it complies with the requirements for the finished butter.

Vacuum working

Working at reduced air pressure is a method that is frequently used. The result is a butter that contains less air, and it is therefore somewhat harder than normal. In vacuum-worked butter, the air amounts to about 1% by volume as compared with 5 – 7% for normal butter.

Continuous production

Methods of continuous buttermaking were introduced at the end of the 19th century, but their application was very restricted. Work was resumed in the 1940s and resulted in three different processes, all based on the traditional methods: churning, centrifugation and concentration or emulsifying. One of the processes, based on conventional churning, was the Fritz method. This now predominates in Western Europe. In machines based on this method, butter is made in more or less the same way as by traditional methods. The butter is basically the same, except that it is somewhat matte and denser as a result of uniform and fine water dispersion.

The manufacturing process

The cream is prepared in the same way as for conventional churning before being continuously fed from the ripening tanks to the buttermaker.

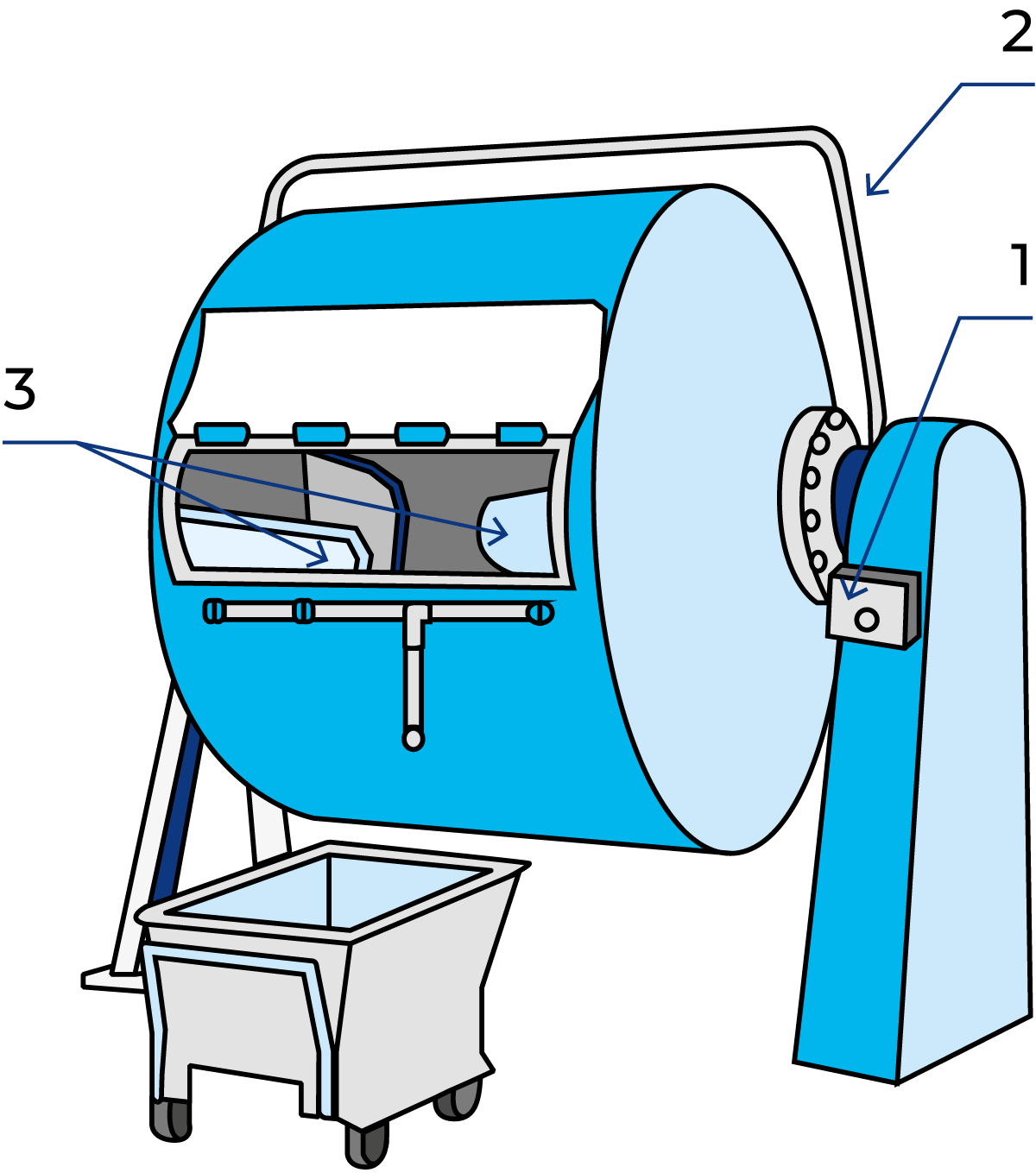

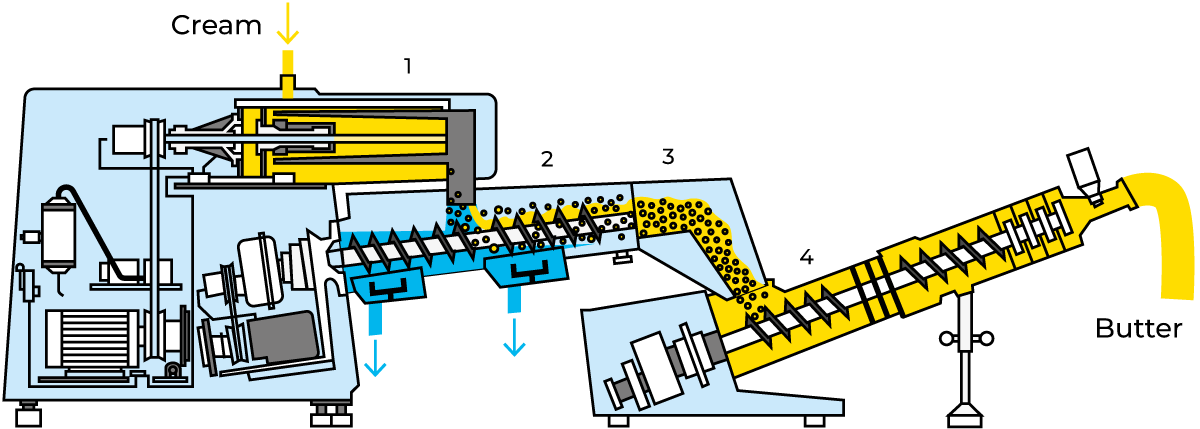

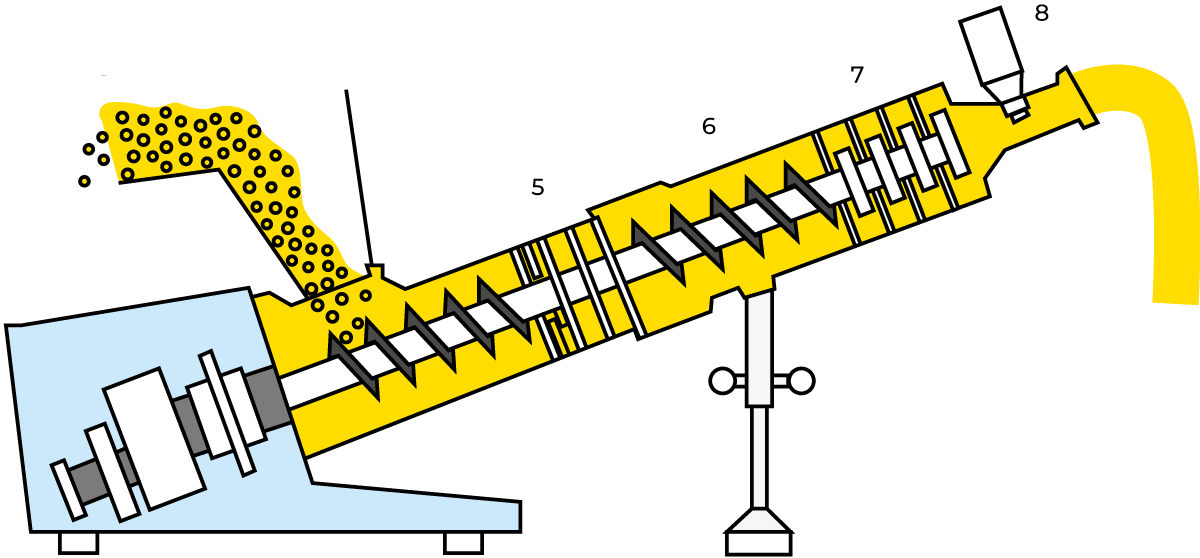

A sectional view of a buttermaker is shown in Figures 14.5 and 14.6. The cream is first fed into a double-cooled churning cylinder (1) fitted with beaters that are driven by a variable-speed motor.

Rapid conversion takes place in the cylinder and, when finished, the butter grains and buttermilk pass on to a separation section (2), also called the first working section, where the butter is separated from the buttermilk. The first washing of the butter grains takes place en route with recirculated chilled buttermilk. The separation section is equipped with a screw that initiates the working of the butter while conveying it to the next stage.

As it leaves the separation section, the butter passes through a conical channel and a perforated plate, the squeeze-drying section (3), where any remaining buttermilk is removed. The butter grains then proceed to the second working section (4). Each working section has its own motor so it can operate at different speeds for optimum results. Normally, the first screw rotates at twice the speed of the screw in the second section.

Following the last working stage, salt may be added by a high-pressure injector in the injection chamber (5).

The next section, the vacuum working section (6), is connected to a vacuum pump. In this section, it is possible to reduce the air content of the butter to the same level as for conventionally churned butter.

The final working stage (7) is made up of four small sections, each of which is separated from the adjacent one by a perforated plate. Perforations of different sizes and working impellers of different shapes are used to optimise the treatment of the butter. In the first of these small sections, there is also an injector for the final adjustment of the moisture content. Once regulated, the moisture content of the butter deviates less than ~ 0.1%, provided the characteristics of the cream remain the same.

Transmitters (8) for moisture content, salt content, density and temperature can be fitted in the outlet from the machine. The signals from the instruments can be used for automatic control of these parameters.

The finished butter is discharged from the end nozzle as a continuous ribbon into the butter silo, for further transport to the packing machines.

Continuous buttermaking machines are available for production capacities of 200 – 5,000 kg/h butter from sour cream and 200 – 10,000 kg/h butter from sweet cream.

Packaging

There are basically three ways of transporting butter from the machine to packaging:

- The product is discharged into a silo with a screw conveyor at the bottom. The conveyor feeds the product to the packaging machine.

- The product is pumped directly to the packaging machine.

- Transfer using trolleys filled with product. The trolleys are often fitted with screw conveyors.

A combination of these methods is also possible.

Butter can be packed in bulk packs of more than 5 kg and packets from 10 g to 5 kg. Various types of machines are used, depending on the type of packaging. The machines are usually fully automatic, and both portioning and packaging machines can often be reset for different sizes, for example, 250 g and 500 g or 10 g and 15 g.

The wrapping material must be greaseproof and impervious to light, flavouring and aromatic substances. It should also be impermeable to moisture, otherwise, the surface of the butter will dry out and the outer layers become more yellow than the rest of the butter.

Butter is usually wrapped in aluminium foil. Parchment paper, once the most common wrapping material, is still used but has now been largely replaced by aluminium foil, which is much less permeable.

After wrapping, the pat or bar packets continue to a cartoning machine for packing in cardboard boxes, which are subsequently loaded on pallets and transported to the cold store.

Figure 14.2 shows the transport of butter from churning equipment to packaging machines.

Cold storage

For the sake of consistency and appearance, butter should be placed in cold storage after packing and kept at +5 °C.

Alternative buttermaking methods

There have been many attempts to develop new methods for manufacturing butter with no undesirable properties. One of these methods, the NIZO method (Dutch), uses sweet cream as a raw material. One of the NIZO method’s advantages is that it is easier to utilise sweet buttermilk. In this process, sweet butter grains are mixed after churning with a highly aromatic starter and a concentrated starter permeate, which is basically a solution of lactic acid.The highly aromatic starter is prepared using skim milk, which has an increased DM content, e.g. raised by evaporation or the addition of SMP. To prepare the starter permeate, a partially de-lactosed whey is soured by Lactobacillus helveticus. After fermentation, the liquid is ultrafiltered and the permeate is further concentrated by evaporation to achieve a lactic acid concentration of approximately 16%.

The highly aromatic starter is then mixed with the starter permeate, and the mixture is aerated to stimulate the formation of diacetyl. For the final process of buttermaking, two types of culture are used to prepare two starter types. Starter 1 (highly aromatic) is mixed with the permeate and aerated.

Starter 2 is incubated in the traditional way. Both starters interact with the butter grains during the buttermaking process.

In this way, it is possible to obtain aromatic butter, which is also very stable regarding auto-oxidation.

Several similar methods will likely be adopted in the future if current tests fulfil their promises. However, there are still some obstacles. These methods cannot be used in countries where the addition of foreign substances (lactic acid) to dairy products is prohibited.