Deaerators

Air and gases in milk

Milk always contains greater or lesser amounts of air and gases. The volume of air in milk in the udder is determined by the air content of the cow’s bloodstream. The oxygen (O2) content is low, being chemically bound to the hæmoglobin in the blood, while the carbon dioxide (CO2) content is high because the blood carries large volumes of CO2 from the cells to the lungs. The total volume of air in milk in the udder can be from around 4.5 – 6%, of which O2 constitutes about 0.1%, N2 (nitrogen) about 1% and CO2 3.5 – 4.9%.

Milk is exposed to air in several ways during milking. Atmospheric oxygen dissolves in the milk, while CO2 is released from it. Part of the air does not dissolve in the milk but remains in a finely dispersed form, often adhering to the fat.

After milking and collection in a churn or cooling tank, the milk may contain 5.5 – 7.0% air by volume, with 6% as an average figure (see Table 7.7.1).

The equilibrium that prevails between those three states of aggregation is determined by temperature and atmospheric pressure. When the temperature rises, during pasteurization, for instance, dissolved air goes from solution to dispersion. It is the dispersed air that causes problems in milk treatment.

Air in milk occurs in three states:

- Dispersed

- Dissolved

- Chemically bound

Further air admixture

More air is introduced into the milk during handling at the farm, transportation to the dairy, and during reception at the dairy. It is not unusual for incoming milk to contain 10% air by volume or even more. Finely and coarsely dispersed air predominates at this stage. The basic problems caused by dispersed air are:

- Inaccuracy in volumetric measurement of milk

- Incrustation of heating surfaces in pasteurizers (fouling)

- Reduced skimming efficiency in separators

- Loss of precision in automatic in-line standardization

- Concentration of air in cream, causing

- inaccurate in-line fat standardization

- incrustation of cream heaters

- "pre-churning" resulting in

- loss of yield in butter production

- adhesion of free fat to the tops of packages

- Reduction of the stability of cultured milk products (expulsion of whey). Various methods of deaeration are therefore used to avoid jeopardising production and the quality of the products.

Air elimination at collection

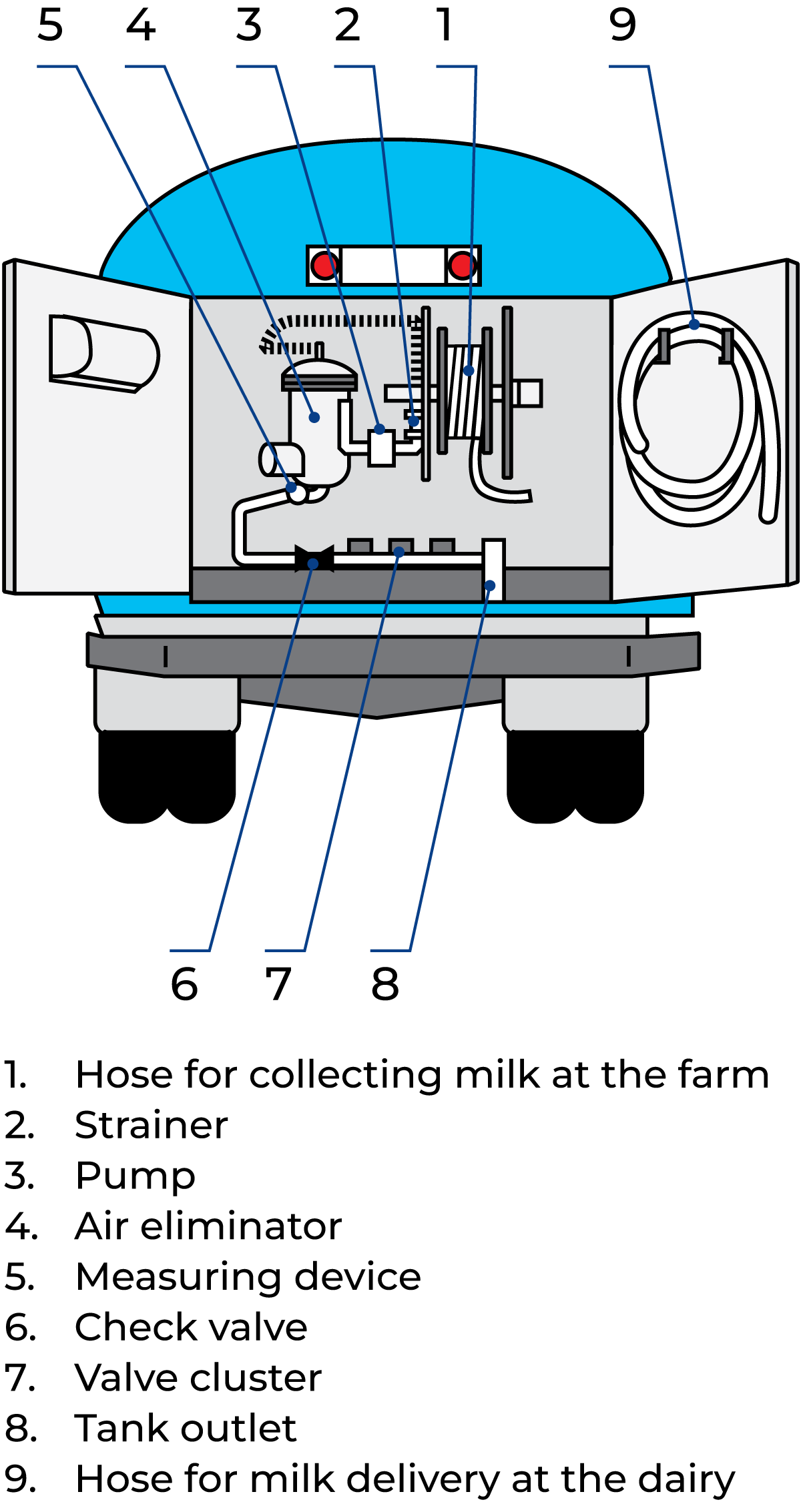

When milk is collected in road tankers, from churns or bulk cooling tanks, the milk from each farm is normally measured by a volumeter. To optimise measuring accuracy, the milk should be passed through an air eliminator just before being measured. Most tankers are therefore provided with an air eliminator through which the farmer’s milk must pass before being measured and pumped aboard the tanker.

One system (Wedholms, S) is shown in Figure 7.7.2. The pump equipment is placed in a cabinet at the rear end of the tanker. The equipment strains, pumps, eliminates air and measures the volume of the milk, before it enters the collecting tanks of the tanker.

The suction hose (1) is connected to the farmer’s churns and/or bulk cooling tanks. The milk is sucked through a strainer (2) and pumped to the air eliminator (4). The positive displacement pump (3) is self-priming.

While the level of milk rises in the air eliminator, the float inside also rises; at a certain level, the float closes the valve at the top of the vessel. The pressure inside the vessel increases and the check valve (6) is released. The milk flows via the measuring unit (5) to the valve cluster (7) and the tanks in the tanker. The tanker is emptied through the outlet (8) by the hose (9).

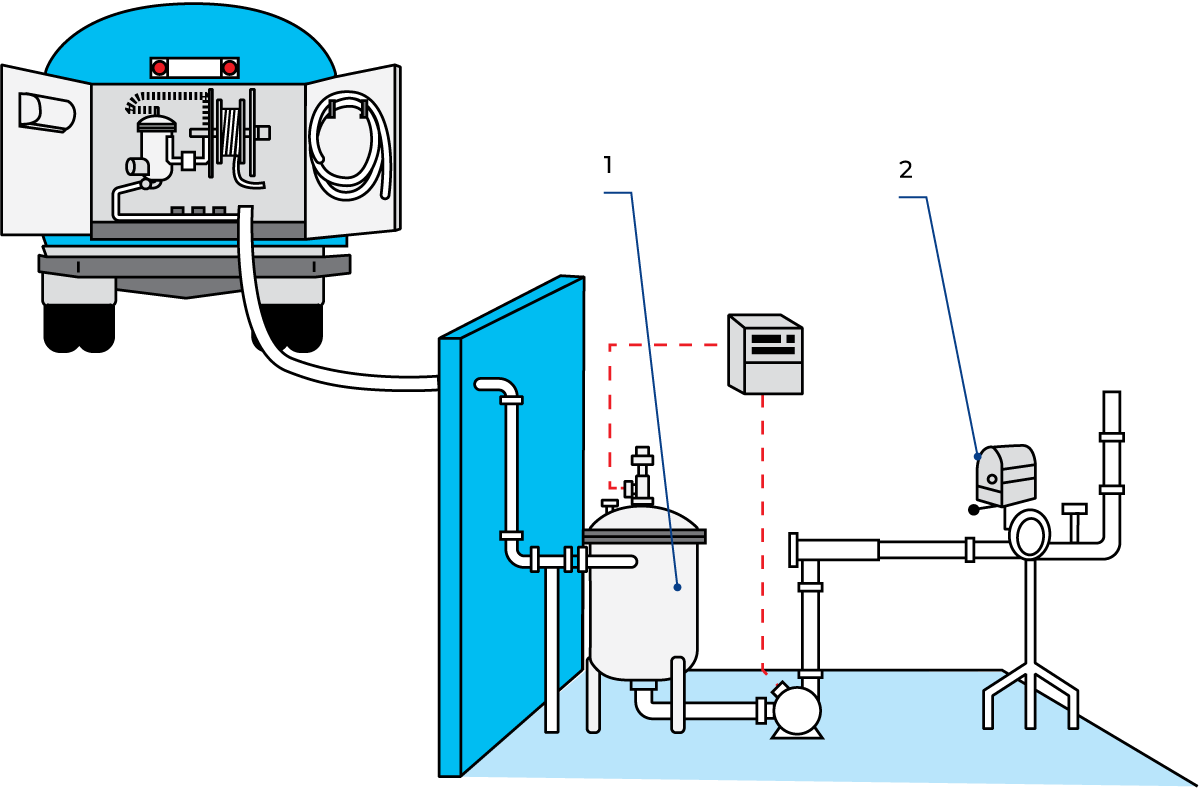

Milk reception

On arrival at the dairy, the milk will again contain dispersed air as a result of the jolting of the road tankers en route. Normally, the milk is measured as it is pumped to the reception tanks. Here again, the milk should first pass an air eliminator of the same type to ensure accurate measurement (Figure 7.7.3).

The inlet of the cylindrical vessel must be located at a lower level than the outlet pipe of the milk tank(s) on the vehicle, as the milk should not be pumped into the vessel but transferred to it by gravity. The system can be manually or automatically operated.

In both cases, the efficiency of air elimination depends very much on how finely dispersed the air is. The smallest air bubbles cannot be removed.

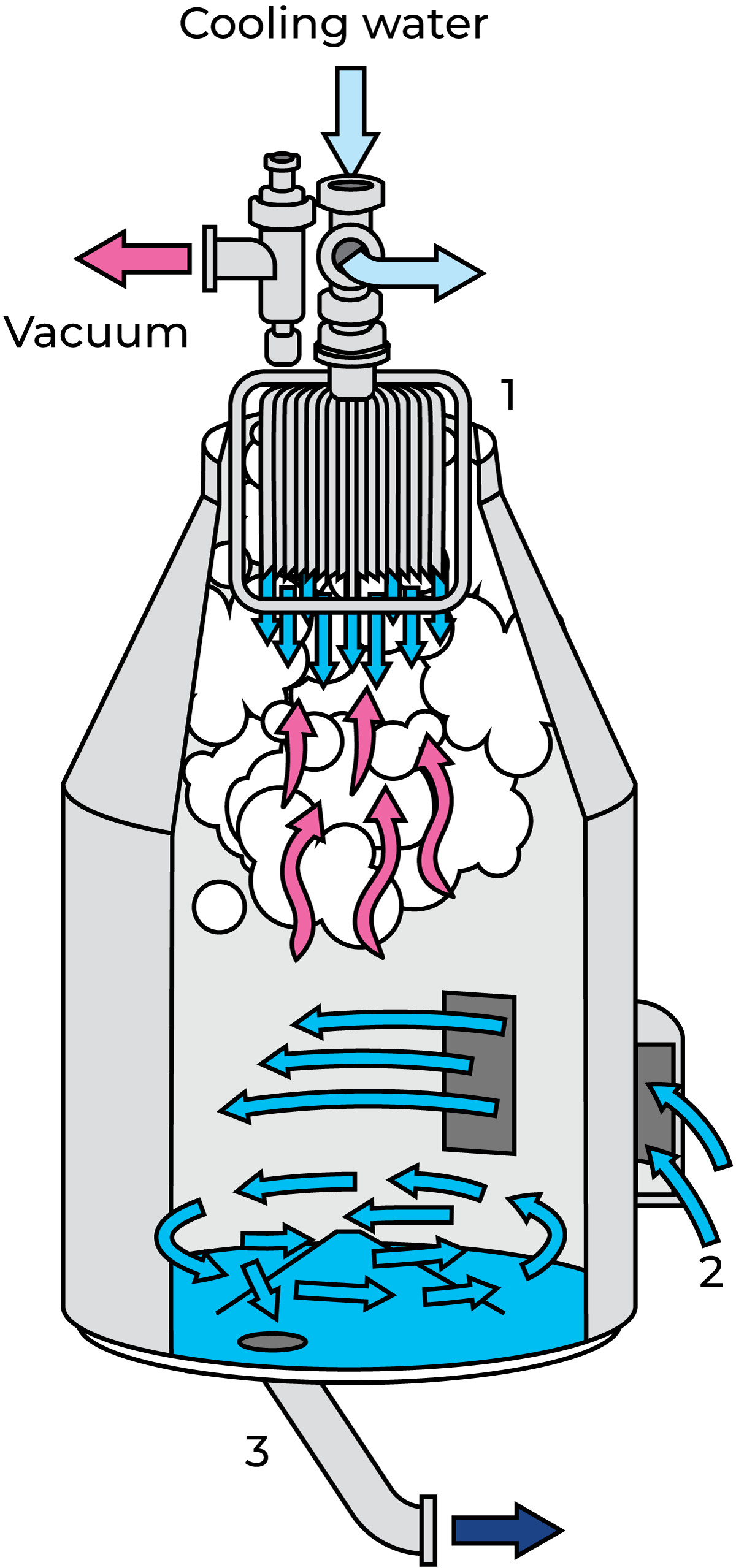

Vacuum treatment

Vacuum deaeration has been used successfully to expel dissolved air and finely dispersed air bubbles from milk. Pre-heated milk is fed to an expansion vessel (Figure 7.7.4) in which the vacuum is adjusted to a level equivalent to a boiling point about 4 to 5 °C below the pre-heating temperature. If the milk enters the vessel at 64 °C, the temperature will immediately drop (64 – 4) to 60 °C. The drop in pressure expels the dissolved air, which boils off, together with a certain amount of the milk.

The vapour passes a built-in condenser in the vessel, condenses, and runs back into the milk, while the boiled-off air, together with non-condensable gases (certain off-flavours) is removed from the vessel by the vacuum pump.

For the production of yoghurt, the vacuum vessel is not provided with a condenser, as milk intended for yoghurt is often also slightly (15 – 20%) concentrated. Condensation of vapour is arranged separately.

Deaeration in the milk treatment line

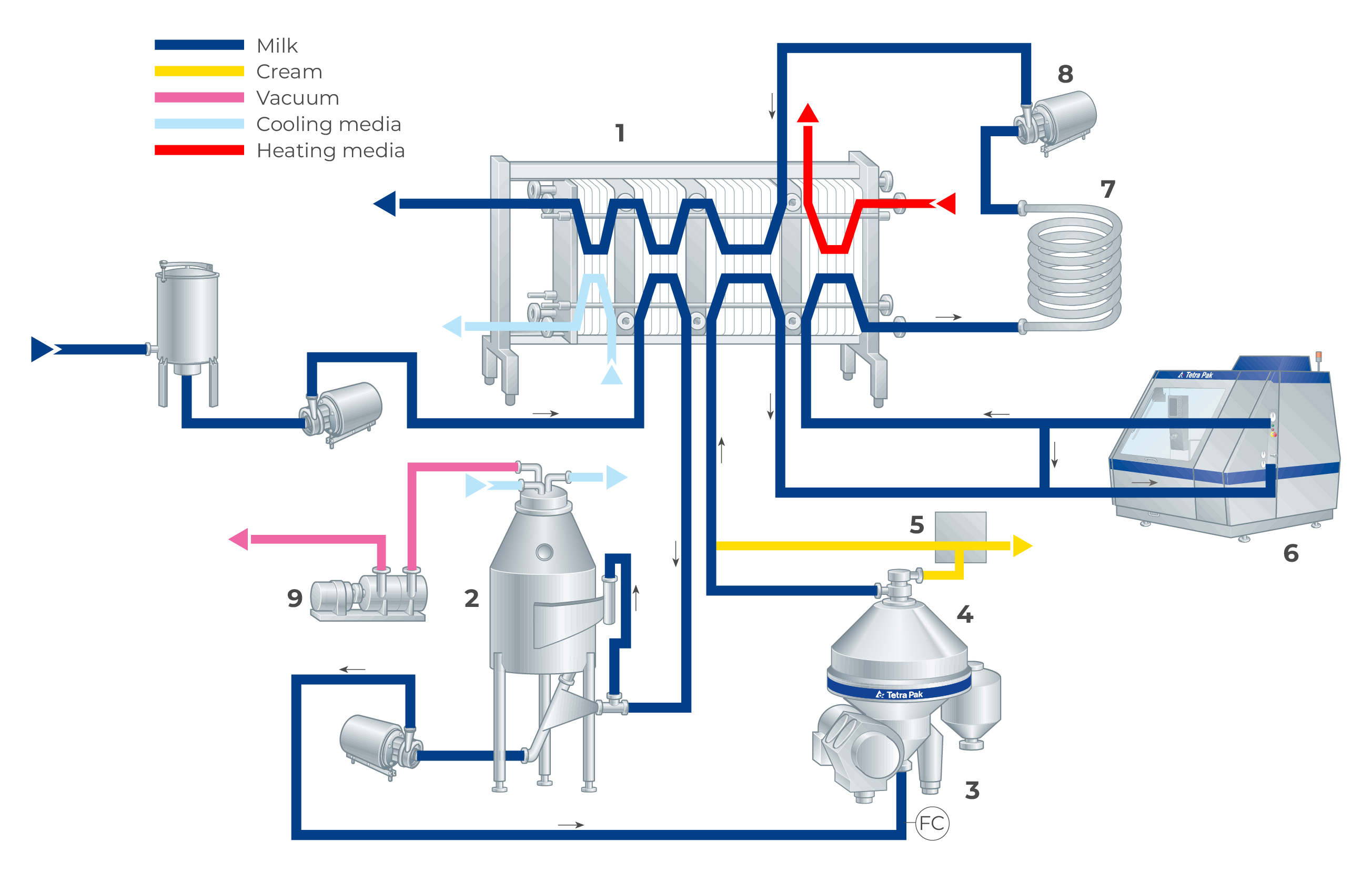

Figure 7.7.6 shows a milk pasteurization line that includes a deaerator. Whole milk is supplied to the pasteurizer and heated to 64 °C. It then proceeds to the expansion vessel for vacuum treatment. To optimise the efficiency, the milk enters the vacuum chamber tangentially through a wide inlet, which results in the exposure of a thin film on the wall. Expansion of the vapour flashed off from the milk at the inlet accelerates the flow of milk down the wall.

On the way down towards the outlet, which is also located tangentially, the velocity decreases. The feed and discharge capacities are thus identical. The deaerated milk, now at a temperature of 60 °C, is separated, standardized and homogenized before returning to the pasteurizer for final heat treatment.

With a separator integrated into the processing line, a flow controller must be placed before the separator to control the flow through the deaerator. In this case, the homogenizer must be provided with an open bypass. In a process line without a separator, the homogenizer (without an open bypass) will control the flow through the deaerator.