Mixers

Early dairy processing relied heavily on manual labour and rudimentary tools, with mixing often performed by hand or with simple implements such as wooden paddles or churns. However, as demand for dairy products grew and industrialisation swept across the food industry, the need for more efficient and precise mixing methods became apparent.

Mixing plays a crucial role in the dairy industry, where it ensures uniformity and consistency in products like milk, yoghurt, cheese, and ice cream. Whether it is blending ingredients, dispersing additives, or homogenizing milk fat, precise mixing is essential to achieve the desired taste, texture, and quality. Modern dairy mixing processes utilise advanced equipment like agitators and mixers to maintain product integrity while meeting stringent hygiene and safety standards. Effective mixing not only enhances product quality but also optimises production efficiency, ensuring consistent results that meet consumer expectations.

In this chapter, the various technologies and principles will be explained.

What is mixing?

Mixing is a fundamental unit operation in dairy processing. The overall purpose of mixing is to combine two or more ingredients, achieving a homogenous product. The production of many dairy products includes one or several mixing steps. Mixing can be done in many ways depending on what components are to be mixed. Fundamentally these components can be in 3 states: liquids, solids and gas, which gives the following mixing combinations:

For dairy applications, it is most common to mix a liquid with a liquid or solid with a liquid. There can be specific cases where a solid is mixed with another solid or a liquid with gas. However, these cases will not be covered in this chapter.

Liquid + liquid mixing

For liquid + liquid mixing, sometimes referred to as blending, the goal is to do one of two things:

Dissolve one liquid in another: When the two liquids are miscible and mutually soluble, they can be added together and mixed to create a homogenous liquid.

Disperse one liquid in another: When the two liquids are immiscible, i.e. do not naturally mix, the purpose of mixing is to create a dispersion or an emulsion. In both cases, the intention is to obtain a product that is stable and homogenous enough for its intended purpose.

Solutions

Miscible liquid blending is considered to be the easiest mixing task of all. Often the different liquid streams can be simply merged in a pipeline and mixed by the flow turbulence. However, depending on differences in viscosity and/or density, a static mixer or sometimes even a dynamic in-line mixer, can be employed. In many cases, miscible liquids are also blended in tanks using an agitator.

Dispersions and emulsions

Emulsions are mixtures containing two liquid phases, one of which is dispersed into the other as droplets. There are two types of emulsions in the food industry – oil-in-water emulsions and water-in-oil emulsions. In oil-in-water emulsions, the oil phase is the dispersed phase, and the water phase is the continuous phase. Milk is a natural oil-in-water emulsion where the fat globules are distributed in the continuous water phase (serum). In water-in-oil emulsions, which include types of margarine, butter and spreads, water is the dispersed phase and oil/ fat is the continuous phase. Without a stable emulsion, oil separates into an undesirable layer on top of the water phase.

Droplet size is important to the stability of an emulsion. The drop size of emulsions is typically < 10 μm and achieving this requires significant energy. High-shear mixing can be sufficient in some applications, or to make a semi-stable emulsion that can go to future processing. But often homogenizers are needed to create small enough droplets. The smaller the droplet size, the more stable an emulsion will be. Homogenizers are covered in chapter 7.3.

Solid + liquid mixing

Solid + liquid mixing is perhaps the most common type of mixing in the dairy industry. Today, a wide range of ingredients used in the industry are available in powder form, including different types of milk powders, sugar, starches, fibres, vitamins, proteins, emulsifiers, stabilisers, and flavours. The various powder ingredients may have vastly different characteristics, depending on what raw ingredients they are made from and how they are modified to fit different recipes and processing needs. Some powders are prone to foaming, while others may require mixing at specific temperatures to be dissolved or to deliver their “functional properties” to the product. This functionality may be the right mouthfeel, the right consistency for keeping particles in a solution, or the possibility for the product to be frozen and thawed. Powders may also have been modified to make them easier to dissolve.

As the powders are mixed with the liquid, they either

- Disperse, dissolve, and eventually form a uniform solution

- Disperse, but do not dissolve. Instead, the solid particles, together with the liquid, form a suspension

Whether or not a powder will dissolve in the liquid depends on the type and properties of the powder and liquid, as well as the amount of powder added, and the mixing temperature, intensity, and duration.

Suspensions

Some particles will, due to their nature, never dissolve in a liquid, or at least not at the specific mixing conditions (temperature, time, applied shear, powder concentration). For instance, cocoa particles, often used in chocolate milk, will not dissolve in milk. The purpose of mixing is then to ensure that the cocoa particles are homogenously distributed in the liquid and that no lumps remain that might cause product safety issues during subsequent heat treatment.

Solutions

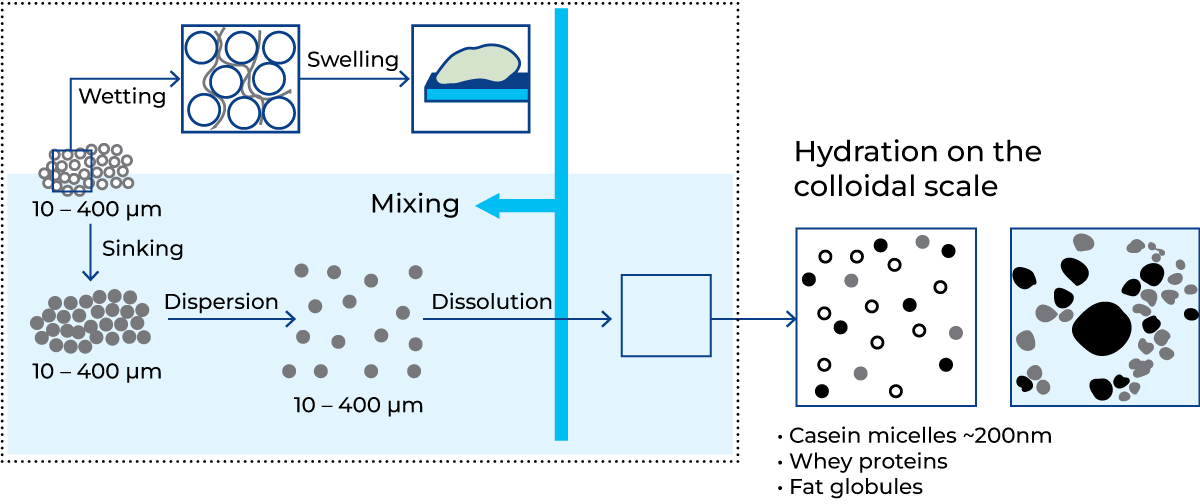

The complex dissolution process, and the influence of mixing, can be illustrated using milk powder as an example. The dissolution of milk powder in water can be divided into four phases, as shown in Figure 7.5.2. It starts with a wetting step where the liquid penetrates the powder particles and between the particles. This replaces the air with liquid, making the particles denser, which causes them to sink into the liquid. If the wetting of the powder is insufficient, the powder particles may instead swell and form lumps.

After the sinking phase, the powder is dispersed into individual particles. For the single particles, given the right conditions, there can be a final dissolution into individual colloidal components. For milk powder, these individual components include casein micelles, whey protein, lactose, fat, and minerals. After dissolution, the changes occur on the colloidal scale and are difficult to monitor. Therefore, it is still unclear what exactly happens after the powder particles have dissolved into their individual colloidal particles. It is believed that after dissolution, the milk proteins hydrate and regain their functional properties, which is crucial for further processing. This last step is therefore often referred to as “hydration”.

While mixing enhances the wetting, dispersion, and dissolution of the powders, it does not (or only marginally) affect the hydration occurring on the colloidal scale. Certain types of powder can be easily dissolved using only agitation, but for others, high-shear mixing is required. High-shear mixing will also make the process of solid + liquid mixing faster.

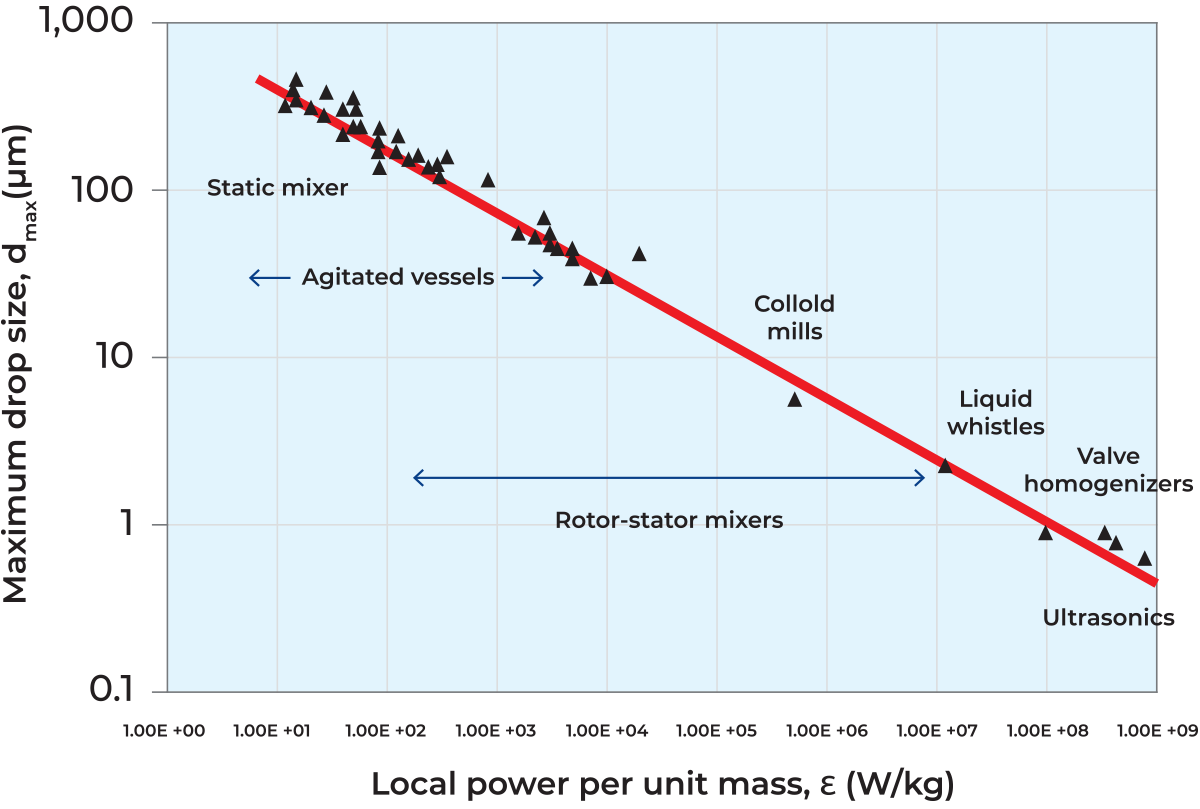

Mixing intensity

Different types of mixing equipment can provide different levels of mixing intensity and thereby achieve different mixing results. With a high-shear mixing device, it is possible to create very intense turbulence, resulting in very small turbulent eddies that interact with and impose shear forces on droplets and particles. The size of the smallest turbulent eddies correlates with the maximum size of undissolved powder particles and the maximum size of fat droplets. It is therefore possible to estimate the size of the smallest eddies in a mixer and thereby estimate the maximum size of fat droplets and undissolved powder particles. The smallest turbulent eddy size, often referred to as the Kolmogorov microscale η (unit: m), can be calculated by the following formula:

Where ν (unit: m2/s) is the kinematic viscosity of the fluid and ε (unit: m2⋅s−2 or J/kg) is the average dissipation rate of turbulent kinetic energy. The average turbulent kinetic energy dissipation rate can be calculated by the following formula:

Where P (unit: kg⋅m2⋅s-3 or W) is the power input, V is the liquid volume and ρ is the density. So, by simply knowing the kinematic viscosity, the power input from the mixer unit and the liquid mass it is distributed in, it is possible to estimate the maximum size of undissolved powder or fat droplet. For a high-shear mixer, this is normally in the range of 1 – 10 μm. An overview of the effect with different mixing equipment is shown in the plot below.

Mixer types and line setups

There are many different mixing duties in dairy production, ranging from adding sugar and milk powder to milk to incorporating fruit preparation into yoghurt or preparing stabiliser slurries. The choice of what mixer to use as well as how to set up the mixing line will depend on the type of ingredients to be mixed, product quantity, investment cost and flexibility in terms of mixing intensity, and the required product range.

There are many ways to set up a mixing line. A product can be produced batch-wise using a single mixer, or continuously using an in-line mixer or a mixer combined with recirculation tanks. The type of mixing technology used impacts the mixing intensity. Gentle mixing may be needed for fragile ingredients such as fruit pieces, while high-shear mixing might be necessary for hard-to-mix ingredients such as some dairy protein powders.

Batch

Batch mixing is perhaps the most traditional mixing setup and is still often used in the dairy industry. In batch mixing, predetermined quantities of ingredients are added to a dedicated tank where they are mixed for a specific time. When the process is complete, the tank is emptied and the product is sent for further processing and/or filling. The batch process can be very simple: adding ingredients into the batch mixer, mixing it and then sending it downstream. Alternatively, the batch unit can be a complete process solution on its own, where the tank also acts as a heat treatment, cooling and storage unit before the product is filled into the final package.

In dairy manufacturing, batch mixing is generally used for smaller batch sizes, typically ranging from 250 to 10,000 kg. Since there is just one tank and a limited amount of piping, there is a low amount of product loss when producing in batch mode. It is also possible to produce larger batch sizes, however with an increasing batch size, the overall CapEx and TCO increase due to bigger mixing unit scales with the tank size.

The main advantages of batch mixing are:

- Simple and precise control over product composition

- Fully traceable batches due to handling one recipe at a time

- Possibility to handle high-viscous products

- Flexibility in producing many different recipes due to efficient production of small batch sizes

Some downsides to batch mixing are:

- Batch size is limited to the size of the mixer.

- Intermittent output flow means that downstream equipment must also run in batch mode.

- CapEx and TCO go up when production size increases compared to other solutions.

By using several batch units, it is possible to produce batches in a staggered manner to ensure that there is a continuous supply of product to the downstream equipment. Some products commonly produced using batch mixing include cheese curds, ice cream mix, or mixing of stabiliser slurries, due to their high viscosities and smaller batch sizes.

Mixing tank with an agitator

Batch mixing using a tank with an agitator is the most common mixing setup in the dairy industry. In dairy production, tank mixing with an agitator is mostly used for gentle stirring of products and to prevent separation during intermediate storing. However, tank agitators can also be employed in applications where the ingredients are easily mixed, and high shear is not required. Agitators, paddle mixers, ribbon blenders and impellers are utilised to ensure uniform mixing while preserving the desired product characteristics.

For efficient agitation, the agitator choice is very important, and different designs are used based on the flow need and the direction of the flow.

Some of the benefits of tank mixing with agitation are:

- Less equipment is needed as the mixing is done in the tank rather than in a separate mixer.

- Less energy is required in comparison to high-shear mixing.

- Low shear mixing – good if the product is sensitive to mechanical treatment (cold cream or yoghurt).

Some of the drawbacks are:

- Cannot handle solid-liquid applications where large amounts of solids are added

- Cannot handle solids that require high shear to be dispersed

- Cannot create stable small-droplet emulsions

In addition to being the main mixer, agitated tanks are often used in combination with other mixers or as stand-alone units.

High-shear mixers

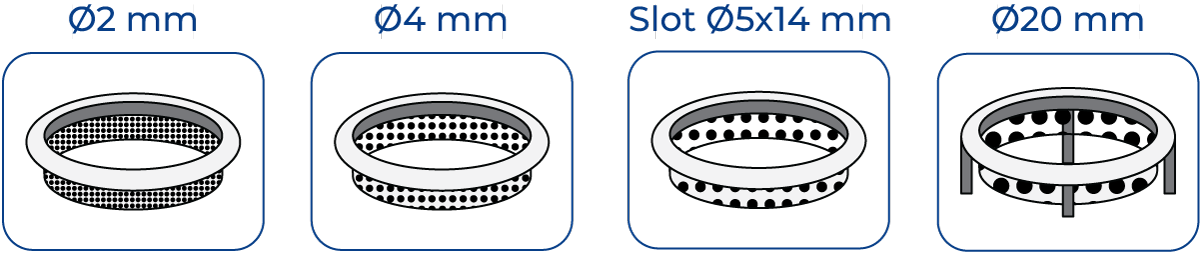

High-shear mixing involves subjecting substances to intense mechanical forces, breaking down particles and promoting dispersion. High-shear mixing is often driven by a rotor-stator geometry (see Figure 7.5.6), where part of the mixing head is rotating (rotor) and part of the mixing head is stationary (stator). The liquid is pushed by the rotor through

the hole geometry of the stator, causing high-shear forces on the product. The amount of shear produced by the mixing head can be controlled by the rotor speed and stator design. Different stator designs are shown in Figure 7.5.7.

In the dairy industry, high-shear mixing is used to emulsify, reduce particle size, and create homogenous dispersions in a variety of products. The high mechanical force increases product stability or helps in achieving the desired product characteristics (e.g. texture and mouthfeel). High-shear mixing is often used in the production of products with hard-to-mix ingredients like protein powders and stabilisers. High-shear mixers, such as rotor-stator systems, are employed to generate the necessary shear forces. By ensuring consistent particle distribution and enhancing product properties, high-shear mixing is especially useful for mixing out protein, stabilisers and other hard-to-disperse ingredients.

It is very important to design the stator-and-rotor part in the right way to balance outflow and shear amount. Below are examples of different stator designs.

Some of the benefits of high-shear mixing with a rotor-stator are:

- High shear makes it possible to disperse hard-to-mix powders and emulsify liquids.

- High control and flexibility in the amount of shear applied to a product by changing the rotor speed and stator type

Some of the drawbacks are:

- Expensive equipment

- Requires much more energy than a normal mixing tank with an agitator

- Could damage sensitive ingredients

Vacuum mixers

In dairy applications, where most recipes include a lot of protein, air incorporation and foam can often be a problem, as this can negatively influence downstream processing and jeopardise product quality. Air can come from several sources during the mixing process together with the powder introduction. Air facilitating the powder transport, air trapped inside powder particles and the wrong mixing setup create a large vortex that draws air into the mixing unit, providing very fine dispersed air bubbles.

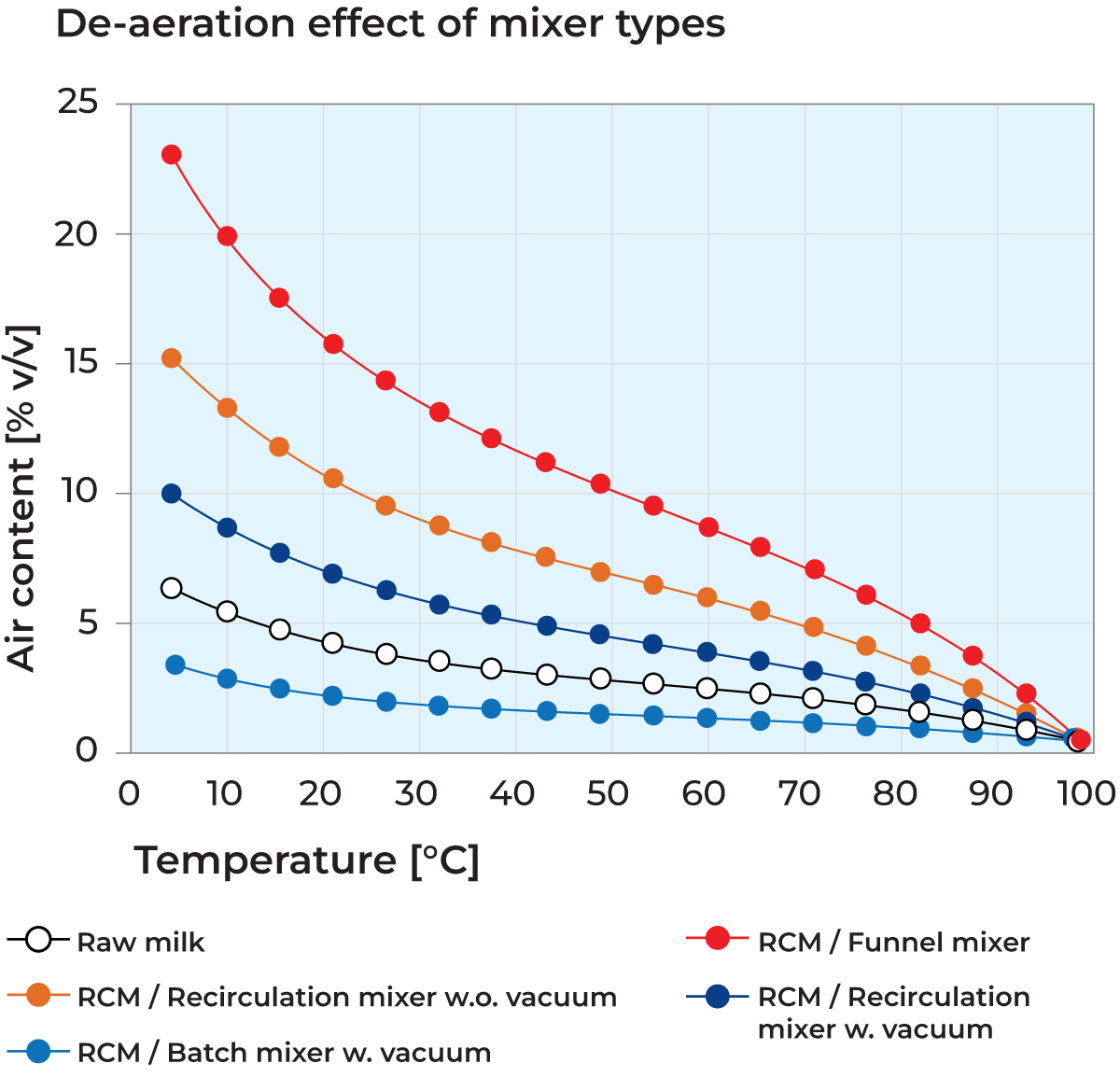

To remove air from the product it can be useful to mix under low pressure, also known as vacuum mixing. A high vacuum is pulled in the mixer tank as this increases the air bubble size, facilitating the bubble breakage, and removal from the product. It is even possible to lower the pressure to below boiling point, facilitating a very fast de-aeration of the product. Figure 7.5.8 shows the de-aeration effect by various mixer types and how the air content of the final product (recombined milk) can be on the same level (or even a lower level) as fresh raw milk in the receiving tank.

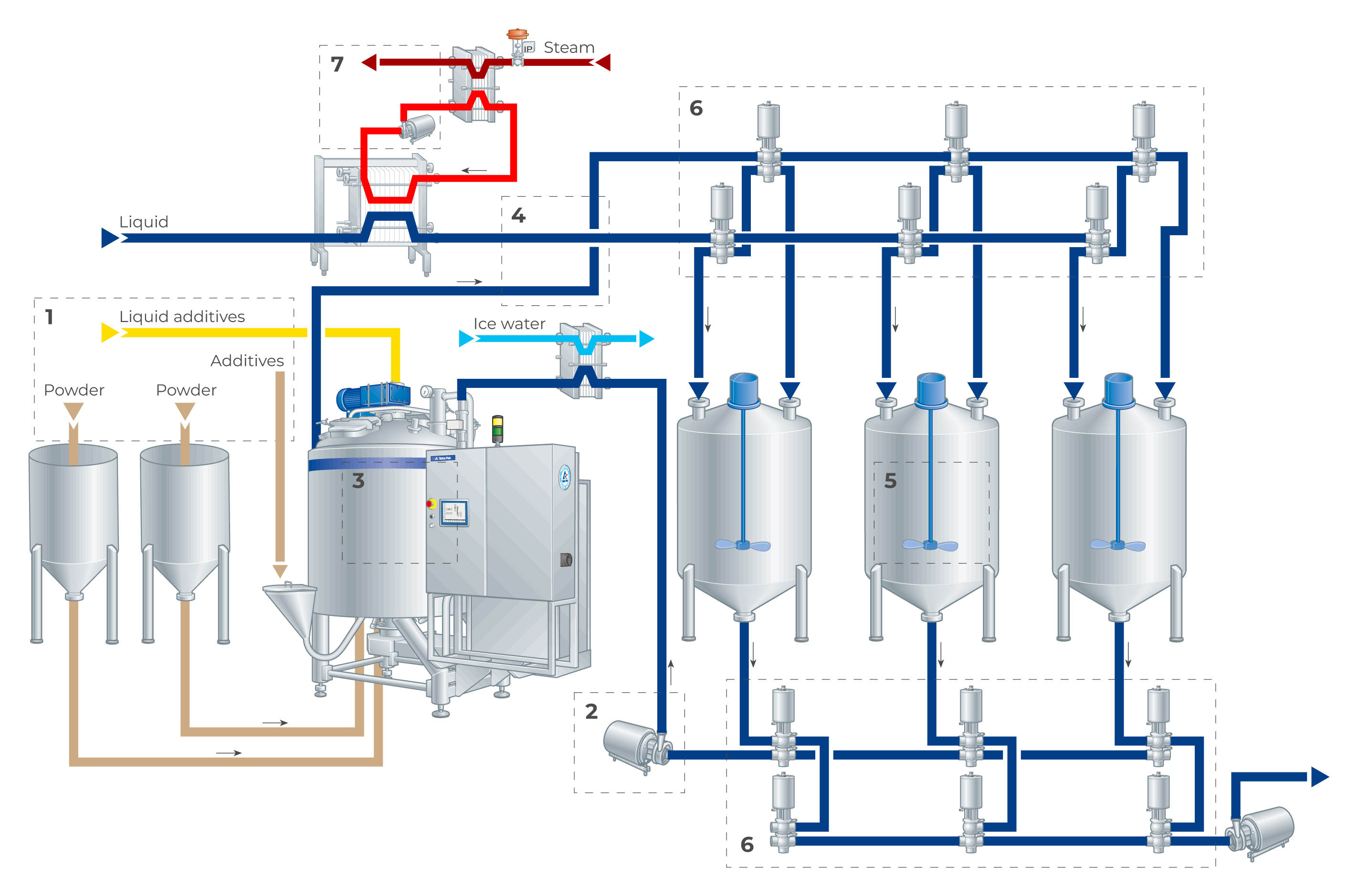

Recirculation mixing

Unlike traditional batch mixing, where ingredients are combined in a single vessel, recirculation mixing involves circulating the mixture from the mixer vessel to an external recirculation tank and back again. Ingredients are dosed by pumps, added into the mixer through the manhole or taken in by vacuum if the mixer is a vacuum mixer. The product passes through the mixer at least once or, more commonly, several times during the process. When the mixing is finalised, the product is stored in the recirculation tank, making it possible to start mixing a second batch using the mixer together with a different recirculation tank. The mixing process is therefore still a batch process, but since there are several tanks, it is possible to get a continuous flow of product from the mixing station. This optimises production planning and minimises the downtime of equipment.

In dairy production, recirculation mixing is common and utilised for tasks such as the emulsification of milk fat in ice cream bases, recombination of milk and yoghurt milk preparation. It has the advantage over batch mixing in that a smaller mixing unit can be utilised to mix a larger volume of product.

It is important to control the inlet flow into the mixer as well as at the mixing level. Securing enough pumping power out of the mixer is equally important as the local concentrations in the mixer can be much higher than what is seen in the final mix.

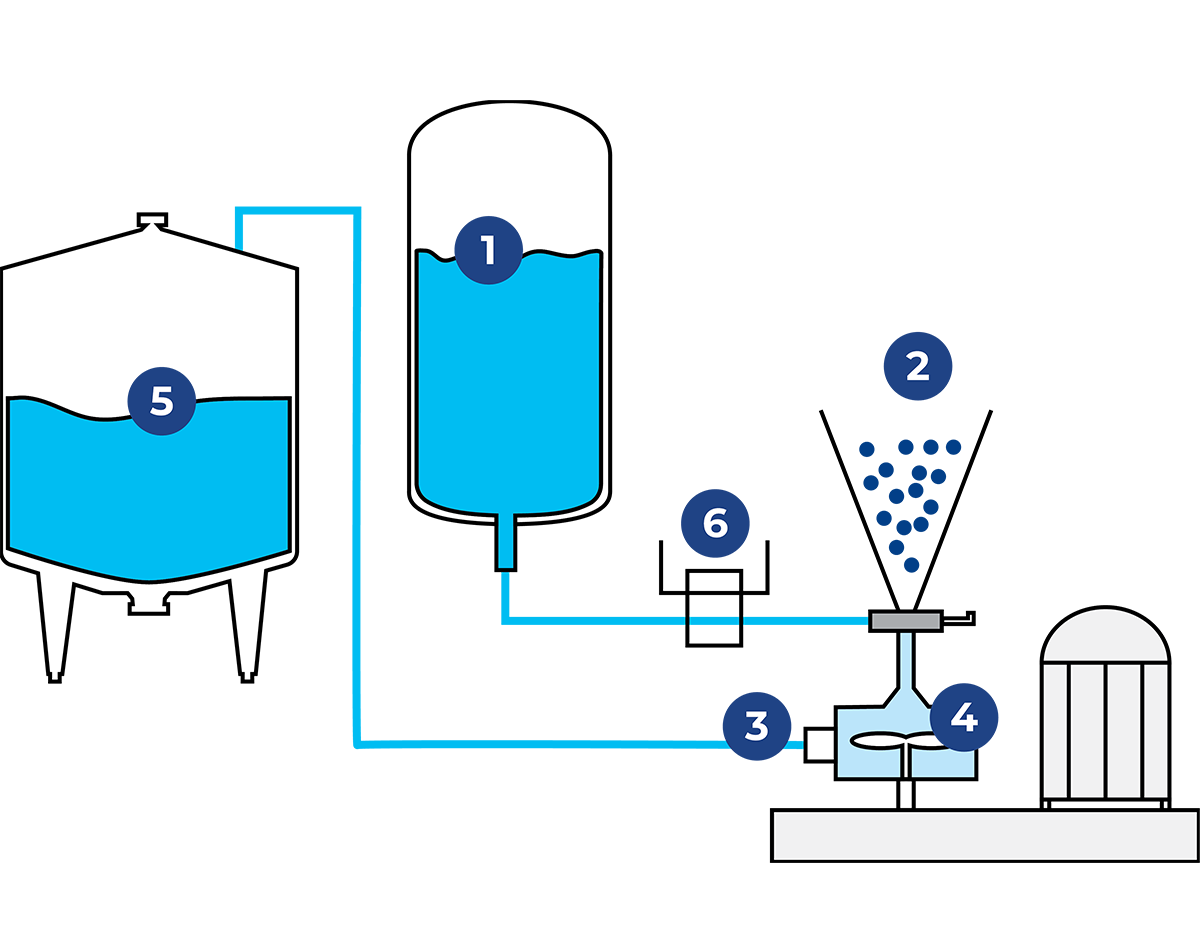

Figure 7.5.9 shows a line setup for recirculation mixing. The bulk of the liquid is added to the designated recirculation tank (5) and is circulated over the rotor-stator mixer (2, 3, 4). Powdered and or liquid ingredients are added (1) directly into the rotor-stator mixer (3). When in the mixer, the ingredients are dispersed by the mixing head and are circulated over the recirculation tank.

Some of the benefits of recirculation mixing are:

- Flexibility to have multiple recipes running on the same equipment

- Optimal usage of equipment saves on total cost of operation

- Possibility of having a continuous flow of product to downstream equipment

Some of the drawbacks are:

- More expensive investment when compared to a single batch mixer

- More complex control and production planning

It is possible to use a rotor-stator system, similar to that used in a batch setup for recirculation mixing as well. The high shear generated by the rotor-stator means the system can disperse difficult powders and can even be used for emulsifying liquids.

In-line mixing

In-line mixing is where the mixing device is delivered without a mixing tank or vessel. Instead, the mixer is placed directly into the processing pipeline, streamlining production and minimising downtime. The solution is mostly used for blending two liquid streams or mixing a small amount of powder.

In-line mixers utilise various mechanisms, including static mixers and rotor-stator devices. In-line mixing equipment is normally cheaper than batch and recirculation setups in terms of initial investment, but might limit overall production time as there are limitations as to how fast ingredients can be introduced. A variant of in-line mixing is continuous mixing, where the liquid is continuously fed to a mixing unit/ vessel, where liquid or powdered ingredients are added in real-time as it flows through. Continuous mixing enables uninterrupted production flow. Unlike recirculation mixing, no additional recirculation tanks are needed. In the dairy industry, continuous mixing can be employed for tasks such as the emulsification of milk fat in ice cream production, blending of ingredients for flavoured milk or yoghurt, and dispersion of additives in dairy-based sauces or dressings.

Continuous mixing devices include static mixers or rotor-stator devices to achieve blending and homogenization of ingredients. Even though continuous mixing offers less downtime than batch or recirculation mixing, more effort is required to get the right setup around the mixer which increases production complexity as well as initial investment cost. This makes it most suitable for high-volume production of products with a limited number of easily mixed ingredients.

A typical line is setup with one or two inlets to the mixer and then one outlet. For a continuous line, the inlet flows need to be controlled using, e.g. flowmeters to ensure the correct ratio in the mixing line.

Some of the benefits of in-line/continuous mixing:

- Low downtime

- Low investment and building footprint

Some of the drawbacks are:

- Continuous solutions can be hard to trim in and require high throughput.

- Limitations on production capacity when using hard-to-mix ingredients

- Works best with liquid + liquid mixing

Static mixer

Static in-line mixers utilise stationary elements within a pipeline to disrupt and distribute the flow. This facilitates mixing without imparting high-shear forces. Static mixers are available in various configurations, such as helical elements or baffles, some intended for smooth liquids and others for particulate liquids.

Some of the benefits of a static mixer:

- Minimal investment cost

- Minimal maintenance cost

- Applies a mechanical shear, making it suitable for blending shear-sensitive products like yoghurt.

Some of the drawbacks are:

- As the setup is based on a physically fixed configuration of mixer elements, it is not very flexible when handling products with varying properties in the same line.

- Integrating the elements in the pipeline will cause additional pressure drop, particularly if the product in the line is viscous.

- The low shear also means that it cannot be used for handling ingredients that are difficult to mix.

Dynamic mixer

Dynamic in-line mixers are essentially small, agitated tanks integrated into the pipeline. The agitator can be designed in many ways depending on the application and the mixer can be used for smooth as well as particulate liquids.

Some of the benefits of a dynamic mixer:

- By varying rotation speed, the mixing efficiency can also be varied which gives flexibility when several different products are being produced on the same line.

- The mixing is still very gentle, meaning it is suitable for products sensitive to mechanical shear, but unlike static mixing, dynamic mixers generate very little additional pressure drop.

Some of the drawbacks are:

- Dynamic mixers have a higher investment cost than static mixers and require more maintenance due to the movable parts.

In-line rotor-stator mixers can also be considered dynamic in-line mixers.

Key process parameters

Most chemical-physical processes are enhanced by the 3 T’s, namely Turbulence, Temperature, and Time. This includes emulsification, powder dissolving, concentration limits and more. In the previous sections, we have already discussed how turbulence (mixing intensity) plays a crucial role by enhancing the contact between different phases, such as liquids, solids, and air, which accelerates the mixing process and ensures uniformity in texture and consistency. Higher turbulence increases the shear forces within the mixture, promoting better dispersion of ingredients and preventing phase separation. In the following paragraphs, we will also briefly describe the influence of temperature and time.

Temperature

One of the most basic decisions to make concerns hot mixing or cold mixing, and how they fit into the overall processes and equipment lines. From a mixing standpoint, hot mixing is favoured because of its many advantages in terms of mixing efficiency and quality. In some cases, hot mixing can improve the dissolving of powders, deaeration, and the emulsification of oil in the mixture. However, if the product quality is not strongly impacted by the mixing temperature, cold mixing could be an option to reduce operational costs.

Time

Time governs the extent to which turbulence and temperature influence the final product. Longer mixing times allow for more thorough integration of ingredients and improved homogeneity. Increased mixing time will also reduce fat droplet size in emulsions and reduce the size or presence of lumps in solid + liquid mixing applications. However, excessive mixing time may also lead to undesirable effects like over-shearing, which can alter texture and flavour.