Tanks

Tanks

Tanks in a dairy factory are used for a number of purposes. Typical sizes range from 250,000 litres for the silo tanks in the reception department down to approximately 100 litres for the smallest tanks.

Tanks can generally be divided into two main categories according to function:

- Storage tanks

- Process tanks

Storage tanks

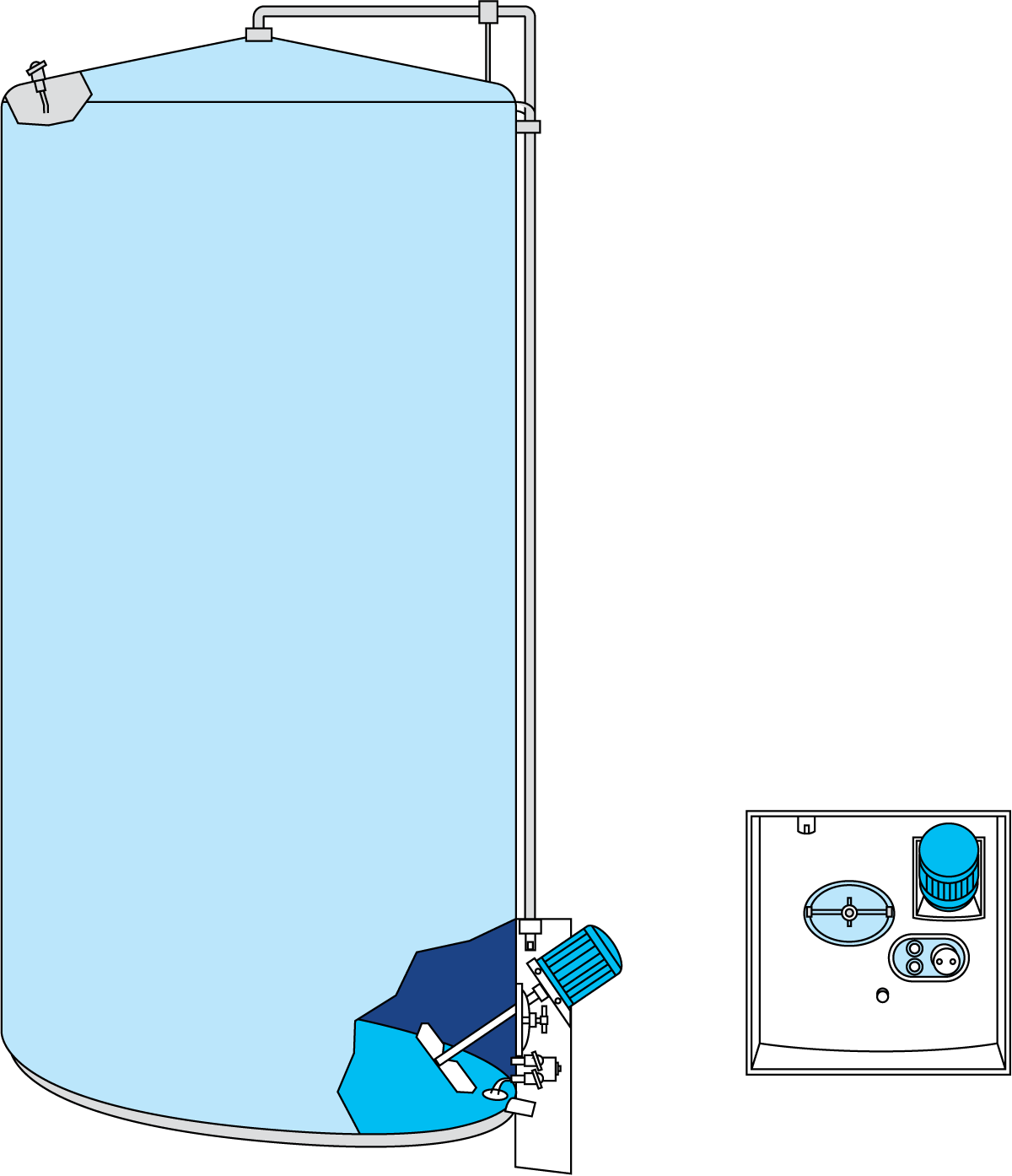

Silo tanks

Silo tanks for milk reception belong to the storage category and have been described in Chapter 6, Collection and reception of milk. They normally vary in size from 30,000 to about 250,000 litres and the wetted surfaces are made of stainless steel. They are often placed outdoors to save on building costs.

In these cases, the tanks are insulated with a minimum of 70 mm of mineral wool insulation. The outer shell can be stainless steel, but for economic reasons, it is usually made of mild steel and coated with anti-corrosion paint.

To make complete drainage easy, the bottom of the tank slopes downwards with an inclination of about 6% towards the outlet. This is a statutory requirement in some countries. Alternatively, the tanks can be manufactured with a dished bottom featuring a centre outlet. The benefit of using this design is that it doesn’t require tight tolerances for the foundation to support the plane slope bottom. However, depending on design, this can result in larger alcoves and higher tanks as the tanks are supported by legs or a skirt.

Silo tanks can be fitted with various types of agitators. A side mounted agitator is generally used, along with monitoring and control equipment.

The number and size of the silo tanks are determined by such factors as the milk intake per day, the number of days per working week, the number of hours per working day (one to five shifts), the number of different products to be manufactured, and the quantities involved.

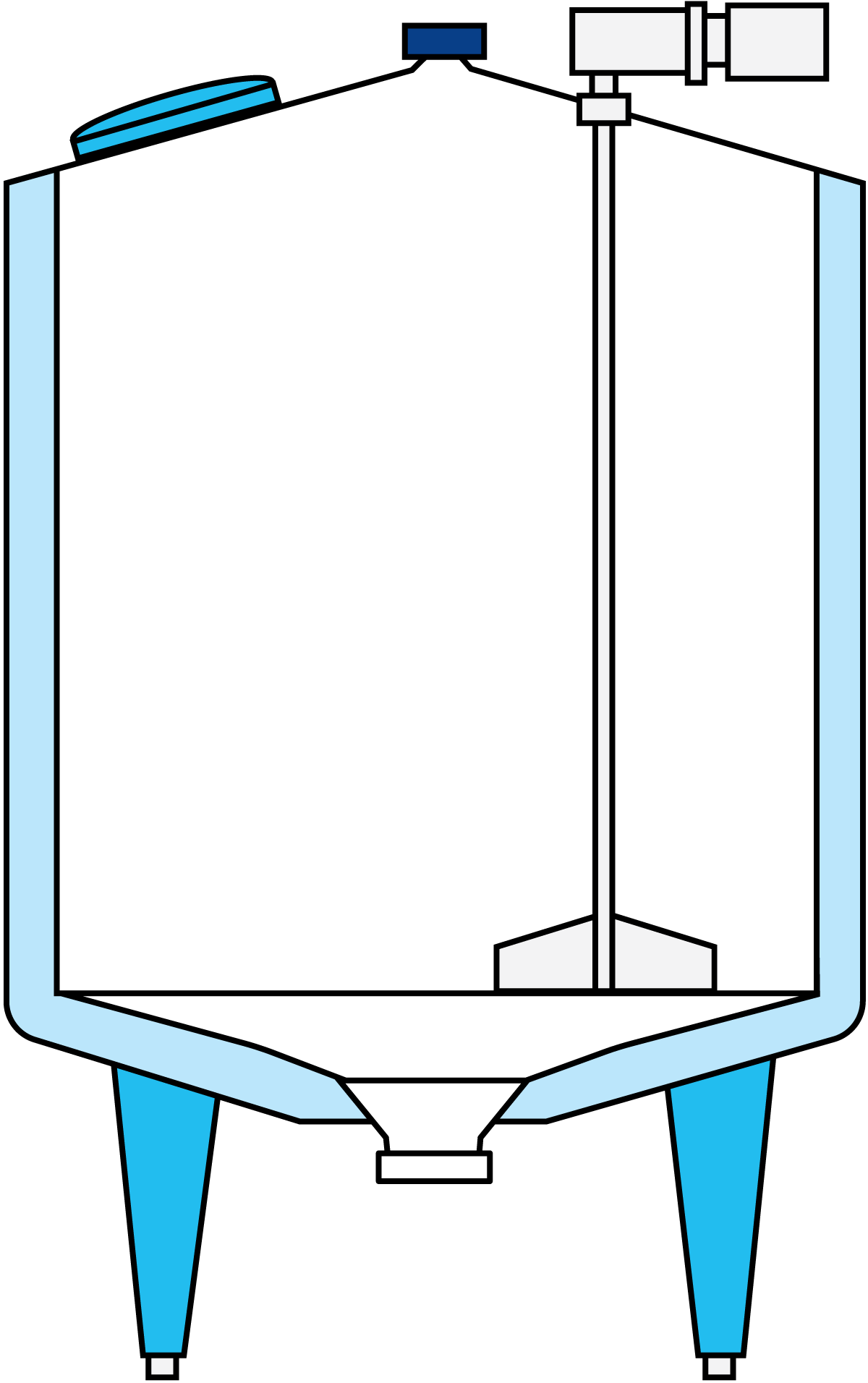

Intermediate storage tanks

These tanks are used to store a product for a short time before it continues along the line. They are used for buffer storage to level out variations in flow. After heat treatment and cooling, the milk is pumped to a buffer tank, and from there to filling. If filling is interrupted, the processed milk is buffered in the tank until operation can be resumed. Similarly, milk from this tank can be used during a temporary processing stoppage.

In storage tanks (Figure 7.10.3) with a capacity of 1,000 to 80,000 litres, the inner shell is made of stainless steel. Depending on the location of the storage tank in the process, the tank is insulated, fitted with dimpled jackets, channels or atmospheric jackets, or both cooling applications and insulation to maintain a constant product temperature. In this case, the outer shell is also of stainless steel, and there is a layer of mineral wool between the shells.

The storage tank has an agitator and can be fitted with various components and systems for cleaning and for control of level and temperature. This equipment is basically the same as previously described for silo tanks.

A good general assumption is that the process requires a buffer capacity corresponding to a maximum of 1.5 hours of normal operation, i.e. 1.5 x 20,000 = 30,000 litres.

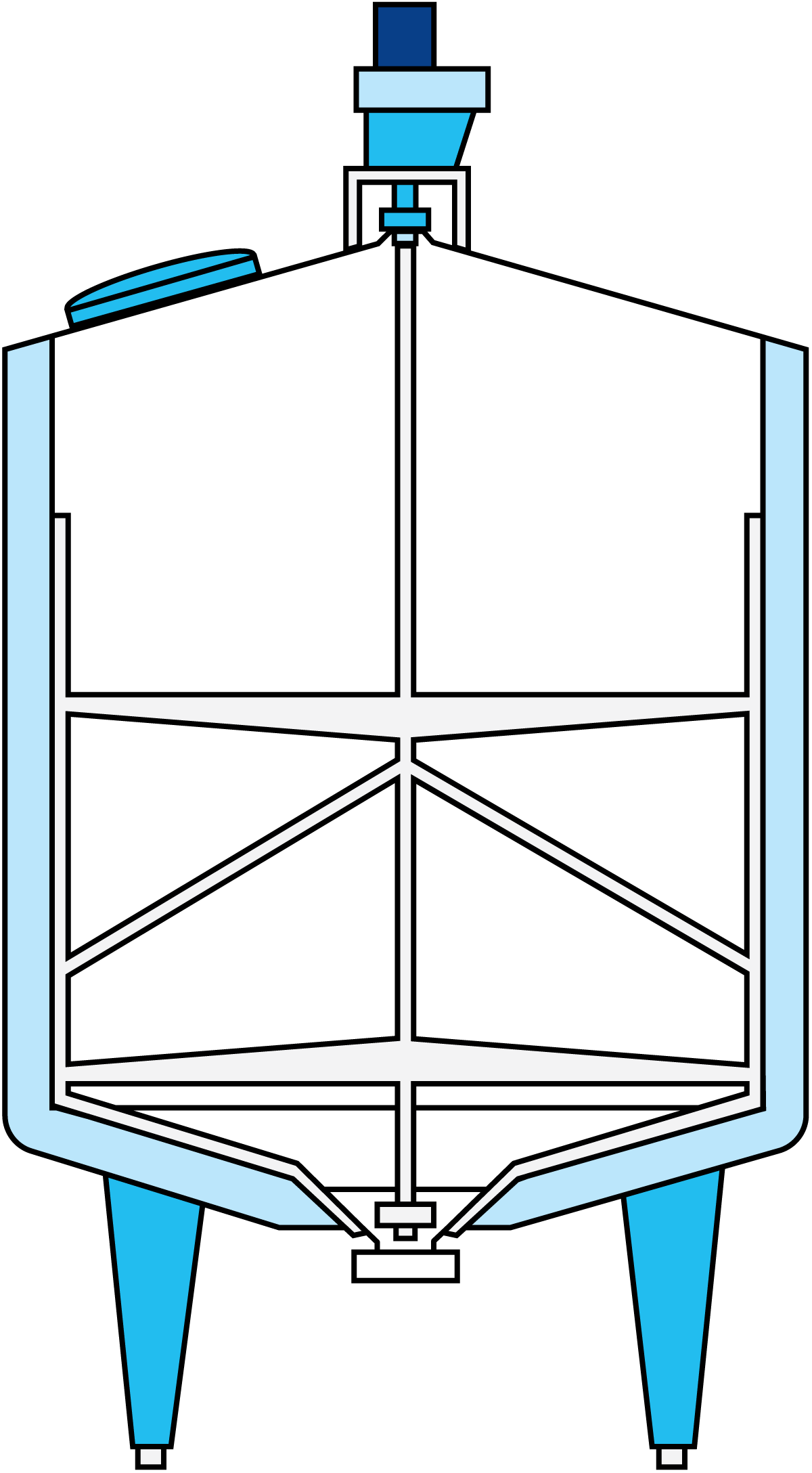

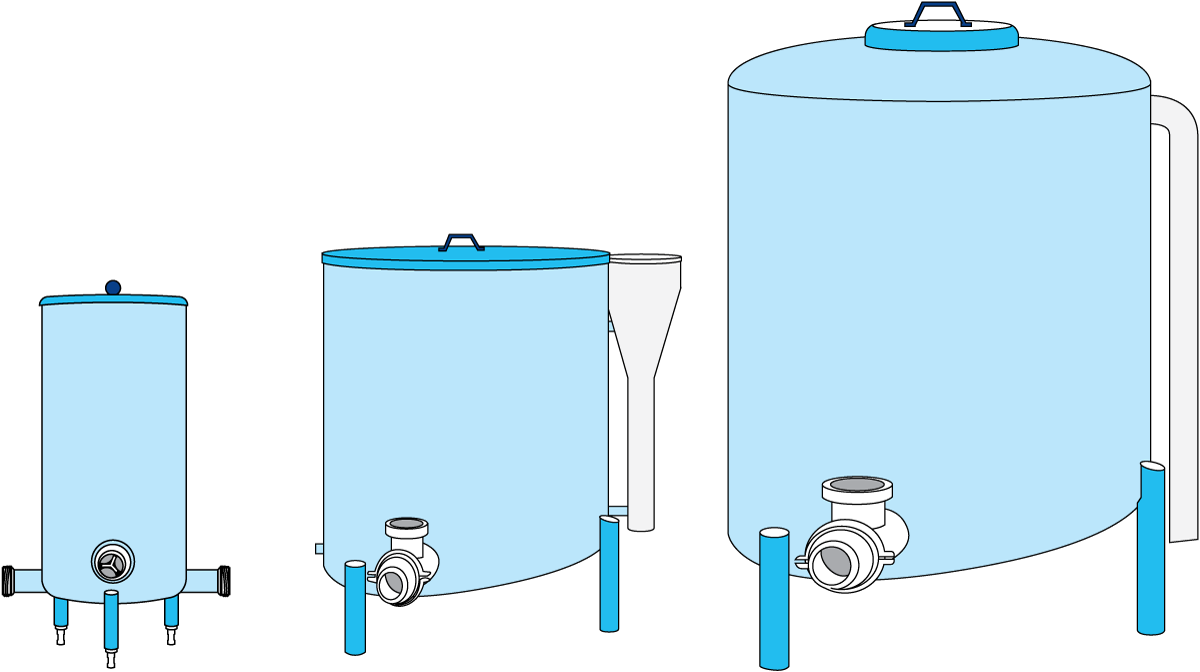

Mixing tanks

As the name implies, these tanks (Figure 7.10.4) are used for mixing different products and for the admixture of ingredients to the product. The tanks may be of the insulated type or have a single stainless steel shell. Equipment for temperature control may also be fitted. Insulated tanks, with mineral wool between the inner and outer shells, have a jacket outside the inner shell through which a heating/ cooling medium is pumped. The jacket can have welded-on channels or dimples.

Agitators for mixing tanks are designed to suit the specific application.

Process tanks

In these tanks (see Figure 7.10.5) the product is treated for the purpose of changing its properties. They are widely used in dairies, e.g. ripening tanks for buttercream and cultured products such as yoghurt, crystallisation tanks for whipping cream, and tanks for preparing starter cultures.

There are many different types of process tanks. The application determines the design. Common features include some form of agitator and temperature control. They have stainless steel shells, with or without insulation. Monitoring and control equipment may also be fitted.

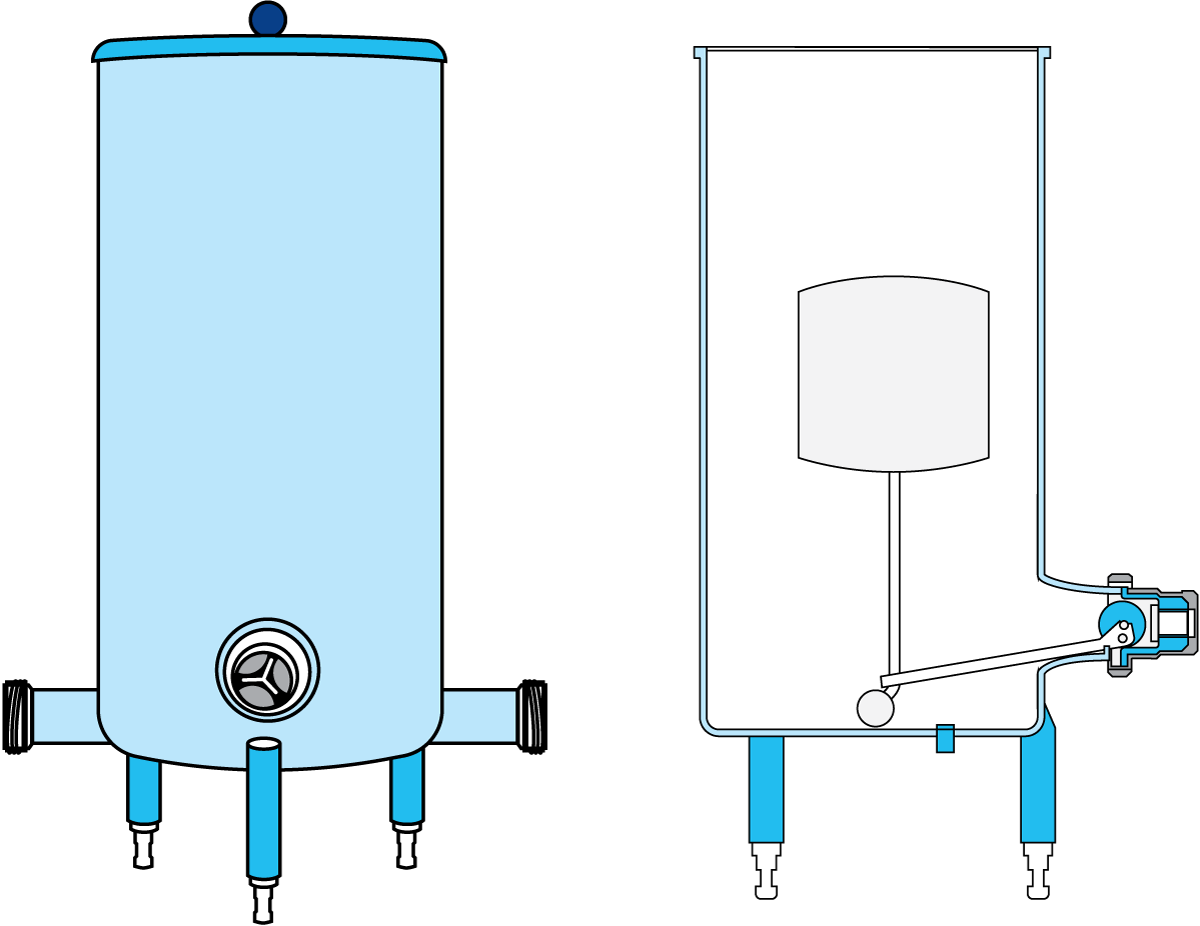

Balance tank

There are a number of problems associated with the transport of the product through the line:

- The product handled must be free from air or other gases if a centrifugal pump is to function properly.

- To avoid cavitation, the pressure at all points in the pump inlet must be higher than the vapour pressure of the liquid.

- A valve must be actuated to redirect the untreated liquid, should the temperature of a heat-treated product drop below the required value.

- The pressure on the suction side of the pump must be kept constant to ensure a uniform flow in the line.

These problems, as well as some others dealt with here, are often resolved by fitting a balance tank in the line on the suction side of the pump. The balance tank keeps the product at a constant level above the pump inlet. In other words, the head on the suction side is kept constant.

The tank in Figure 7.10.7 contains a float connected by a lever to an eccentrically pivoted roller that operates the inlet valve on the tank. As the float moves downwards or upwards with the liquid level, the valve is opened and closed respectively.

If the pump draws more from the tank than flows in at the inlet, the level drops and the float with it. The valve opens and lets in more liquid. In this way, the liquid in the tank is kept at a constant level. Today the same functionality is usually achieved with level sensors that control a regulating valve.

The inlet is located at the bottom of the tank so that the liquid enters below the surface. Consequently, there is no splashing and, above all, no aeration. Any air already present in the product on entry will rise in the tank. Some deaeration takes place. This has a favourable effect on the operation of the pump, and the product is treated more gently.

The balance tank is often included in a recirculating system where liquid is returned for recycling, e.g. as a result of insufficient heat treatment. In this case, a temperature indicator actuates a flow diversion valve, which directs the product back to the balance tank. This causes a quick increase in the liquid level and an equally quick movement of the float mechanism to close the inlet valve. The product then circulates until the fault has been repaired or the plant is shut down for adjustment. A similar procedure is employed for circulating cleaning solution when the line is cleaned.