PRIMARY PRODUCTION OF MILK

Essential food for a growing world

Milk is a complex food that contains vital nutrients for the bodies of young mammals. Milk is the only food for a mammal during the first period of its life and the substances in milk provide energy and antibodies that help protect against infection. For humans, milk and dairy products make a significant contribution to meeting our bodies’ needs for calcium, magnesium, selenium, riboflavin, vitamin B12 and pantothenic acid (vitamin B5) and therefore play a key role in our development.

The origins of milk production

Today’s dairy animals are the product of thousands of years of breeding untamed animals that lived at different altitudes and latitudes, at times exposed to severe and extreme weather conditions. The techniques used in the production of milk from cows, goats, sheep and buffaloes began around six thousand years ago. The same species of animals are kept for milking today. These herbivorous animals were the natural choice to satisfy humans’ need for food and clothing as they are less dangerous and easier to handle than carnivorous animals. The animals used for milk production are ruminants that eat quickly, in great quantities, and later digest their food.

Today, the most widespread milking animal in the world is the cow. The cow can be found on all continents around the world. Other animals commonly used in both subsistence and industrial dairy farming are goats, sheep and buffaloes. The milk of these animals is of great importance to rural communities as a source of high-quality protein and other constituents. Sheep and goats are of exceptional importance in areas such as the Mediterranean and in large areas of Africa and Asia. The number of sheep and goats in the world is in the billions and they are the most numerous of all milk- and meat-producing animals. The contribution of sheep and goats to milk and meat production in the poorest areas is also considerable. Both animals are a cheap source of food and are mainly kept in conditions where climatic, topographical, economic, technical or sociological factors limit the development of more sophisticated protein production systems.

The nutritional qualities of milk

Among the essential minerals and vitamins in milk are iron and vitamin D. They are, however, not present in sufficient amounts, or in optimum proportions, to fulfil the requirements for complete nutrition. During the first period of its life, the young animal therefore makes up for the shortage of certain nutrients in milk by exploiting the reserves it receives from its mother at birth, which are normally sufficient until its diet includes other foods. To make the nutrients easily consumable and digestible, they are available in a liquid state, partly as a solution, and partly as dispersion or suspension. There is a wide variation in the balance of components in milk from various mammals, although the components themselves are basically the same.

Quantities of the various main constituents of raw milk from cows can vary considerably, between cows of different breeds and between individual cows of the same breed. Water is the principal constituent, and is the carrier of all other components. Cows’ milk consists of around 87% water and 13% dry substances suspended or dissolved in the water. Besides "total solids", the term solids non-fat is used in discussing milk composition.

Cows

Considerable changes have taken place in the genetic makeup of the Bos Taurus species since the cow was taken on as a service animal some six thousand years ago. The most significant of these is that the modern lactating dairy cow has a much higher milk production than its calf needs. Genetic development has resulted in vastly increased lactation production. Today’s cows produce roughly six times as much as primitive cows. Even around thirty years ago, a cow would typically only produce somewhere in the region of 4,000 kilograms of milk per calf, whereas today’s cows yield an average of between 7,000 and 12,000 kilograms of milk. Some cows can produce up to 14,000 litres of milk or more per calf. Increased knowledge about the importance of herd management, animal well-being and optimised feeding has contributed to this genetic development.

As is the case with all mammals, cows produce milk for their offspring. Therefore, the production of milk is closely linked to the reproductive cycle. Before a female cow can start to produce milk, she must first have birthed a calf. Females reach sexual maturity at the age of seven or eight months and are then called heifers. Heifers are usually mated when they are 15 – 18 months old by either "natural service" using a bull or via artificial insemination. The gestation period typically lasts 265 – 300 days and heifers tend to give birth to their first calves at the age of 2 – 2.5 years old. They are typically bred again four to eight weeks after calving.

Secretion and the lactation period

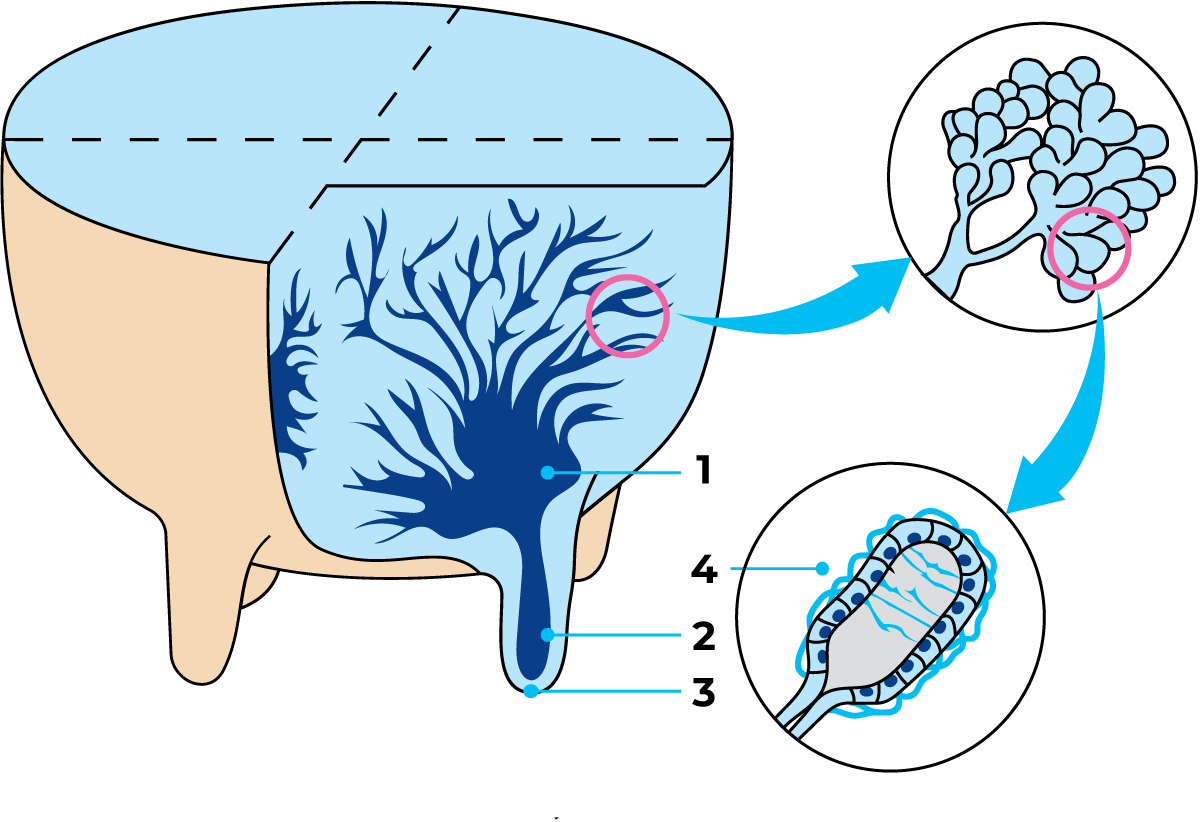

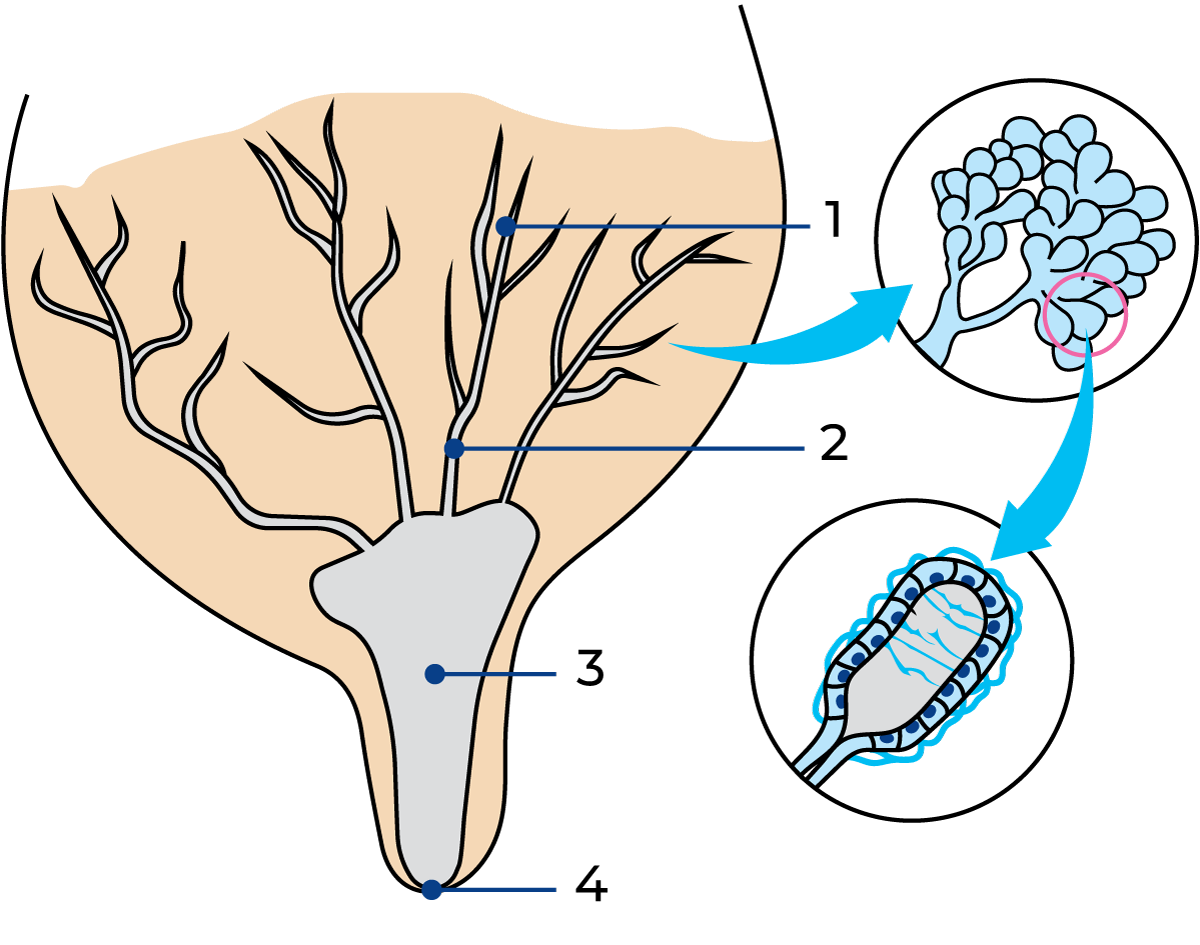

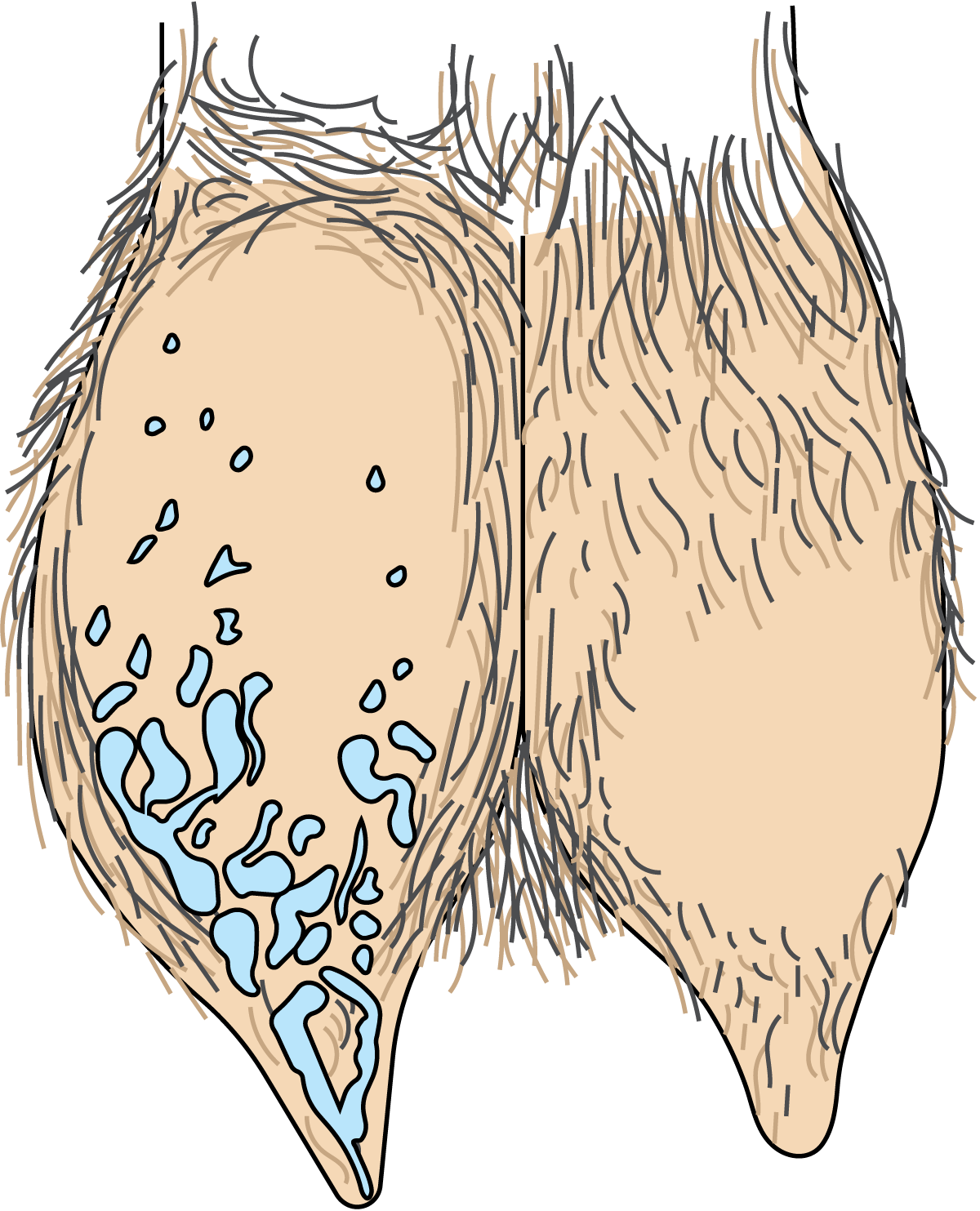

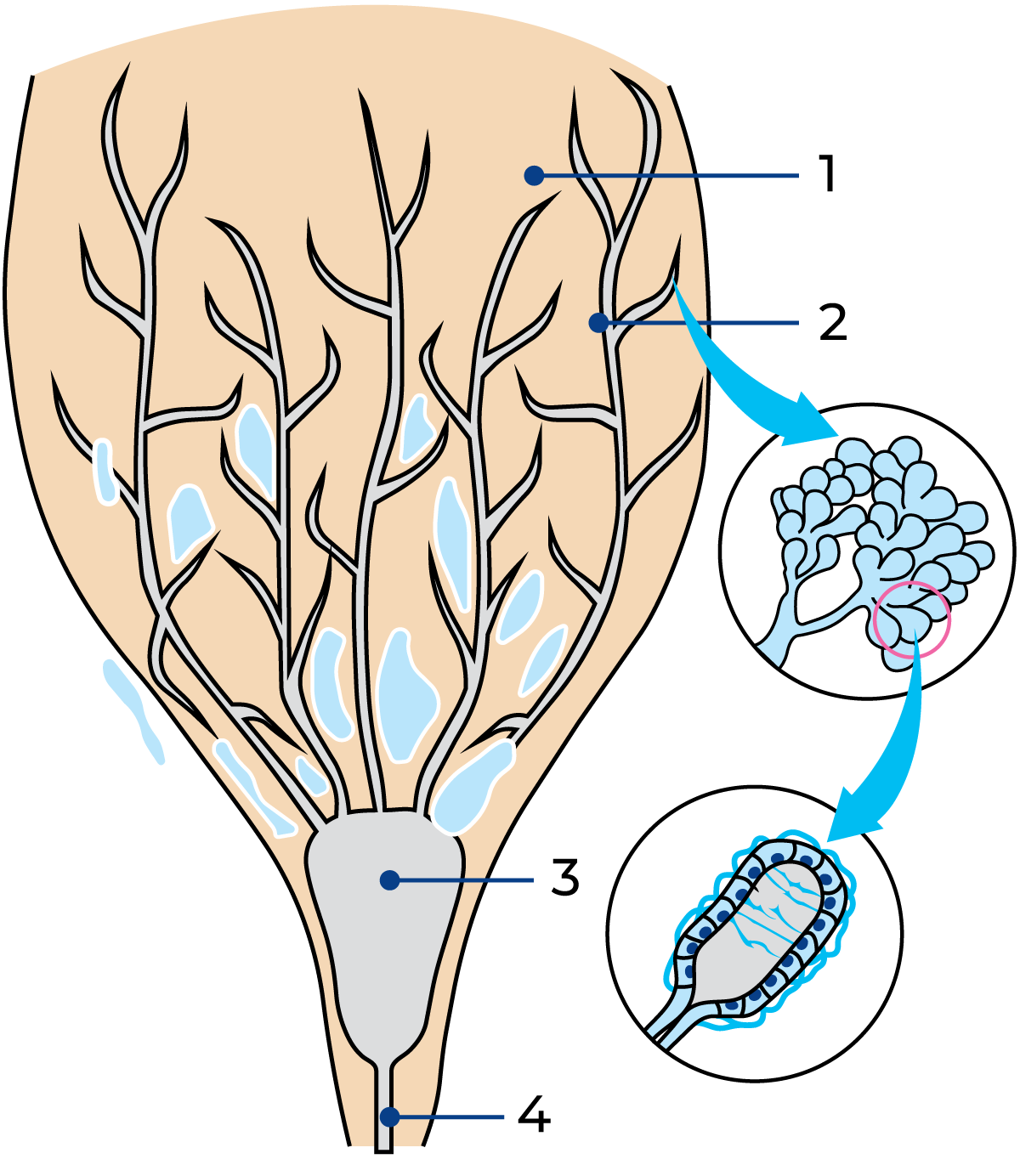

Milk is secreted in the cow’s udder – a hemispherical organ divided into right and left halves by a crease. Each half is divided into quarters by a shallower transverse ligament. Each quarter has one teat with its own separate mammary gland. It is therefore theoretically possible to get milk of four different qualities from the same cow. A sectional view of the udder is shown in Figure 1.1.

The cow’s udder is composed of glandular tissue containing milk-producing cells. The external layer of this tissue is muscular, thus giving cohesion to the body of the udder and protecting it against injury. The glandular tissue contains around two billion tiny bladders called alveoli. The milk-producing cells are located on the inner walls of the alveoli, which occur in groups of 8 – 120. Capillaries leading from the alveoli converge into progressively larger milk ducts which lead to a cavity above the teat. This cavity, known as the cistern of the udder, can hold up to 20% of the total milk in the udder.

The cistern of the udder has an extension reaching down into the teat called the teat cistern. At the end of the teat, there is a channel 1 – 1.5 centimetres in length. Between milking, the teat channel is closed by a sphincter muscle which prevents milk from leaking out and bacteria from entering the udder. The whole udder is laced with blood and lymph vessels. These bring nutrient-rich blood from the heart to the udder, where it is distributed by capillaries surrounding the alveoli. In this way, the milk-producing cells are furnished with the necessary nutrients for the secretion of milk. Spent blood is carried away by the capillaries to veins and returned to the heart. Large quantities of blood flow through the udder. A cow that produces 60 litres of milk per day will need some 30,000 litres of blood circulating through its mammary gland.

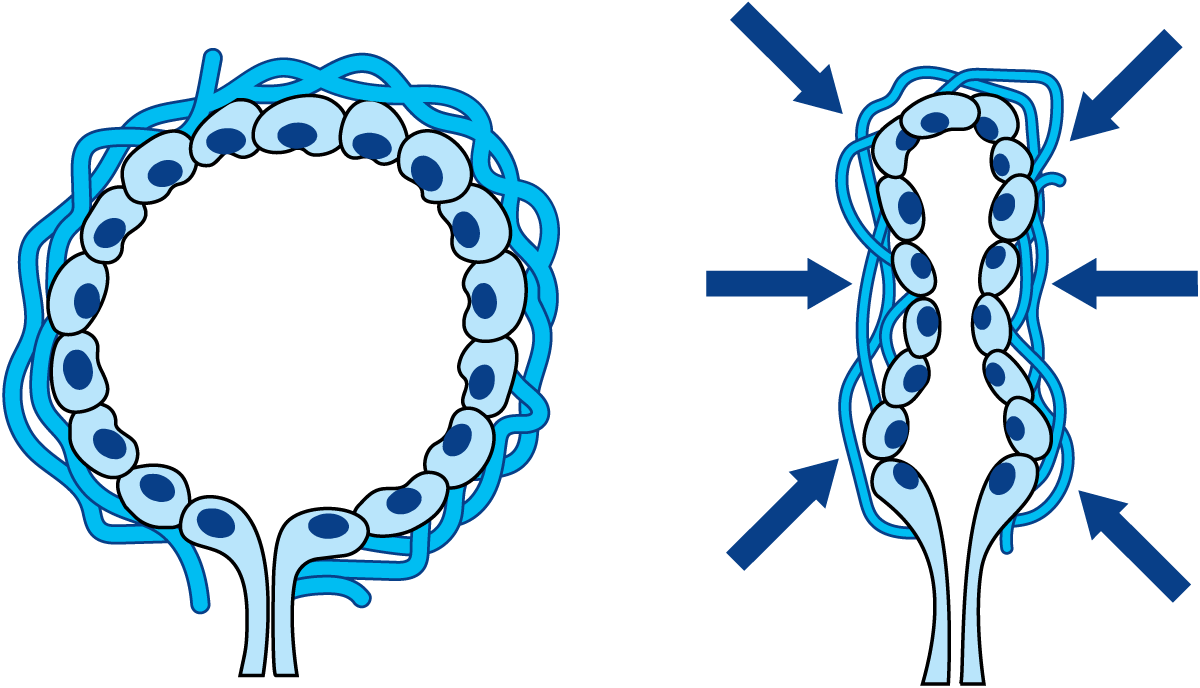

As the alveoli secrete milk their internal pressure rises. If the cow is not milked, secretion of milk stops when the pressure reaches a certain limit. An increase of pressure forces a small quantity of milk out into the larger ducts and down into the cistern. Most of the milk in the udder, however, is contained in the alveoli and the fine capillaries in the alveolar area. These capillaries are so fine that milk cannot flow through them of its own accord. It must be pressed out of the alveoli and through the capillaries into the larger ducts. Muscle-like cells surrounding each alveolus perform this duty during milking (see Figure 1.2).

Secretion of milk in a cow’s udder begins shortly before calving so that the calf can begin to feed almost immediately after birth. The cow then continues to give milk for around 10 months (approximately 305 days). This period is known as lactation. During the lactation period, milk production gradually decreases and after 305 days it can drop to 25 – 50% of its peak volume. At this stage, milking is discontinued, and the cow has a non-lactating period of up to 60 days prior to calving again. With the birth of the calf, a new lactation cycle begins.

The udder also contains a lymphatic system. It carries waste products away from the udder. The lymph nodes serve as a filter that destroys foreign substances. They also provide a source of lymphocytes to fight infections. Sometimes, around parturition, cows giving birth for the first time suffer from oedema, partly caused by the presence of milk in the udder which compresses the lymph nodes.

Colostrum

Calves are born lacking immune protection as their immune system develops slowly. In response, the first milk a cow produces after calving is called colostrum, which differs greatly from normal milk in both composition and nutritional properties. Calves depend on receiving maternal antibodies and an essential supply of immunoglobulins via colostrum. Antibodies are globular proteins produced by the body’s immune response system to fight diseases. Each individual varies in its ability to produce antibodies and thus fight disease. Animals receiving inadequate colostrum are extremely vulnerable to intestinal infection and subsequent scours.

A calf needs around 1,000 litres of milk for normal growth, which is the approximate quantity the primitive cow produced for each calf. To illustrate an individual cow’s milk production, milk yield is typically plotted against time to get a lactation curve. Yield will rise during the first months after calving, followed by a long period of continuous decline. The shape of the lactation curve will differ from individual to individual and from breed to breed. The lactation curve is influenced by feeding and management, which also significantly impact the total amount of milk produced. Lactation is ideally 305 days, but in practice it is usually more, followed by a two-month dry period prior to the next calving.

Milking

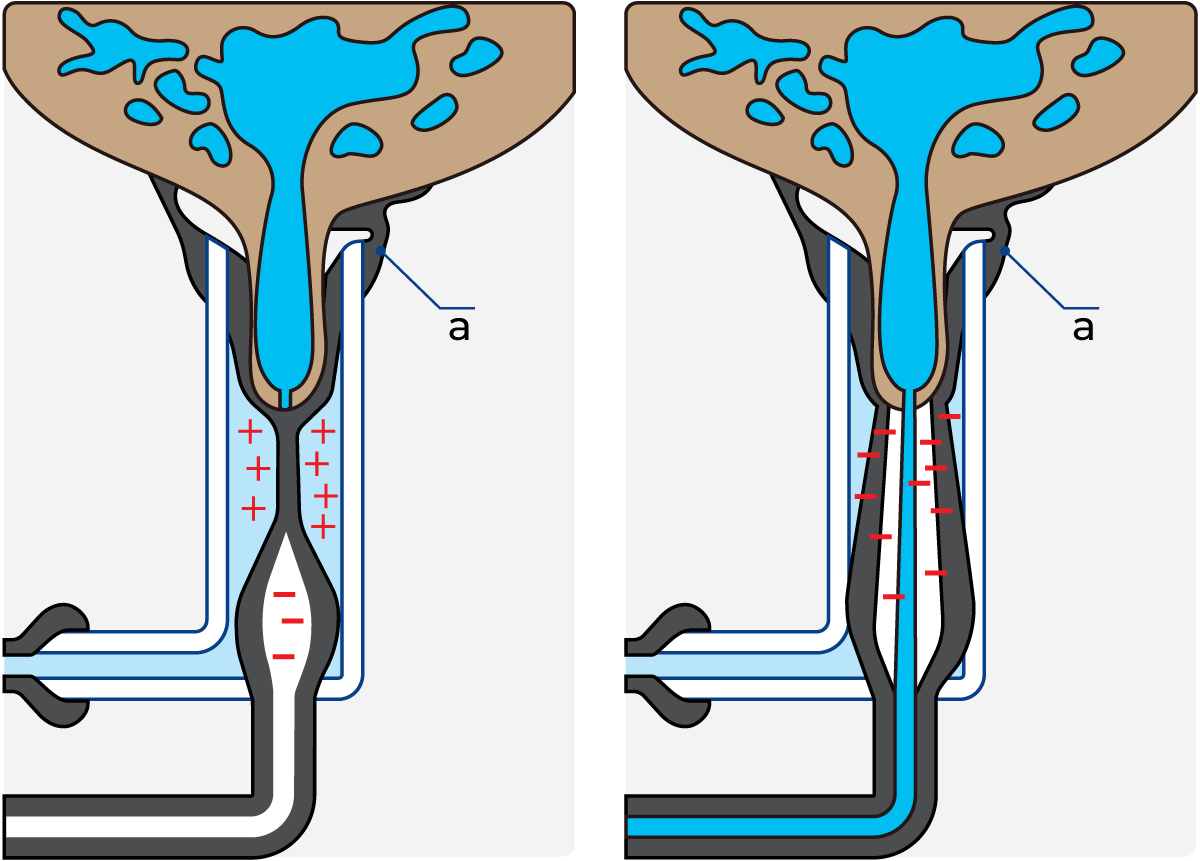

During milking, the oxytocin hormone must be released into the cow’s bloodstream for the udder to empty. This hormone is secreted and stored in the pituitary gland. When the cow is prepared for milking by tactile stimuli, a signal is sent to the gland, which then releases its store of oxytocin into the bloodstream. In the primitive cow, the stimulus was provided by the calf’s attempts to suck on the teat. The oxytocin was released when the cow felt the calf sucking. A modern dairy cow normally has no calf present during milking, so stimulation of the milk “let-down” is done either by manual stimulation by the operator/milker during teat cleaning and preparation, or by the mechanical stimulation of the milking machine. The oxytocin hormone begins to take effect about a minute after preparation has begun and causes the muscle-like cells to compress the alveoli. This generates pressure in the udder and can be felt with the hand; it is known as the let-down reflex. The pressure forces the milk down into the teat cistern, from which it is sucked into the teat cup of a milking machine or pressed out by the fingers during hand milking. If the milking procedure is prolonged in an attempt to “strip” the cow, unnecessary strain is placed on the udder and the cow becomes irritated and may be difficult to milk.

Milk fat consists mainly of triglycerides, which are synthesised from glycerols and fatty acids. Long-chained fatty acids are absorbed from the blood. Short-chained fatty acids are synthesised in the mammary gland from the components acetate and beta-hydroxybutyrate, which have their origins in the blood. Milk protein is synthesised from amino acids also originating from the blood and consists mainly of caseins and to a smaller extent whey proteins. Lactose is synthesised from glucose and galactose within the milk-secreting cell. Vitamins, minerals, salts and antibodies are transported from the blood across the cell cytoplasm into the alveolar lumen.

Milking frequency

Due to labour patterns and working hours, milking twice a day has long been the norm in industrial nations. In countries where labour is inexpensive, more frequent milking is often practised. During the last few decades, focus has increasingly been put on milking more frequently, in particular in high-yielding herds. There are many benefits associated with more frequent milking.

Changing from milking twice a day to three times a day markedly increases milk production. Published data shows that one additional milking can produce 5 – 25% more milk per cow per day. In addition, lactation becomes more persistent and prolonged. It is hypothesised that one reason for the increase in milk production with more frequent milking could be the higher exposure of the mammary gland to the hormones that stimulate milk secretion. Additionally, milk is believed to contain an inhibitor that downregulates milk secretion, though this inhibitor has not yet been isolated, nor has its mechanism of action been fully explained. Cows with a small udder cistern are more sensitive to the frequency of milking. Smaller cisterns are more susceptible to frequent milk removal.

Frequent milking has both short- and long-term effects. In the short term, milk production increases due to enhanced activity in the milk-secreting cells. In the long term, production increases due to the increased number of milk-secreting cells. The latter indicates that it is possible to influence the number of milk-secreting cells during an established lactation, which is of importance to the milk-producing capacity of the animal.

Among the most important benefits of more frequent milking is improved animal welfare. It has been observed that high-yielding animals will typically not lie down for a few hours before milking. Moreover, many high-yielders are producing up to 60 kilograms of milk per day and are milked twice with 8 to 16-hour milking intervals. These cows yield nearly 40 kilograms of milk during morning milking alone. Cows with such high amounts of milk in the mammary gland are exposed to high udder pressure, which undoubtedly causes discomfort. It has been observed that high-yielding cows prefer to be milked more frequently than two or three times a day when they are given the choice.

Milking techniques

Traditional milking by hand

Milking continues to be done by hand as it has been for thousands of years on farms all around the world. Cows on smallholder farms tend to be milked by the same people every day and become accustomed to their milker. The first squirts of milk from the teats are normally discarded as careful visual inspection of the first milk enables the milker to look for visible signs of the status of udder health.

Two opposing quarters of the udder are milked at a time: one hand presses the milk out of the teat cistern, after which the pressure is relaxed to allow more milk to run down from the udder cistern. At the same time, milk is pressed out of the other teat. In this way, the two teats are milked alternately. When two quarters have been emptied, the milker can proceed to milk the other two.

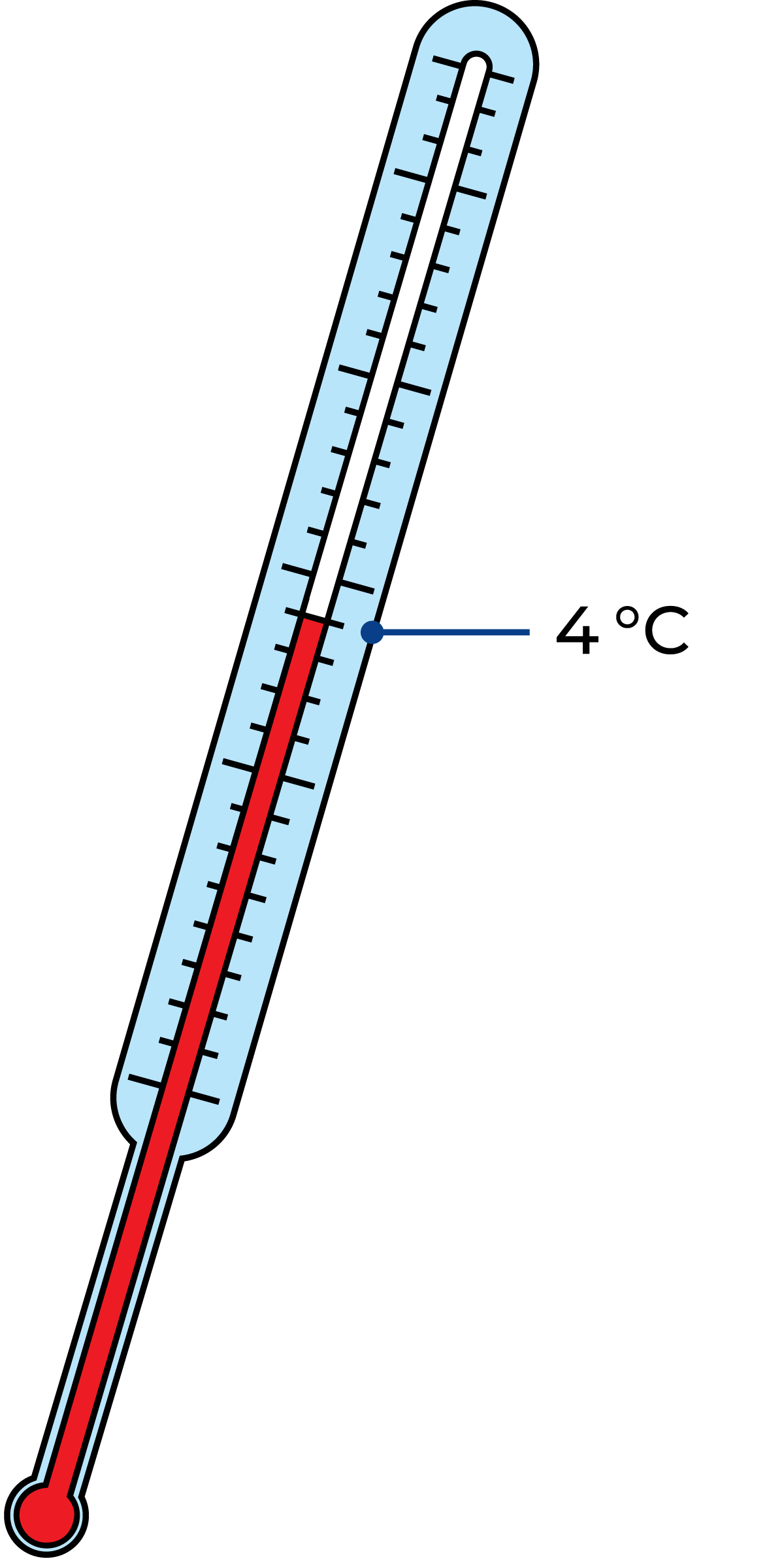

Milk is collected in pails and poured through a strainer to remove coarse impurities into a churn holding 30 – 50 litres. The churns are then chilled to 4° C and stored before being transported to the dairy. Immersion or spray chillers are commonly used for cooling.

Conventional milking systems

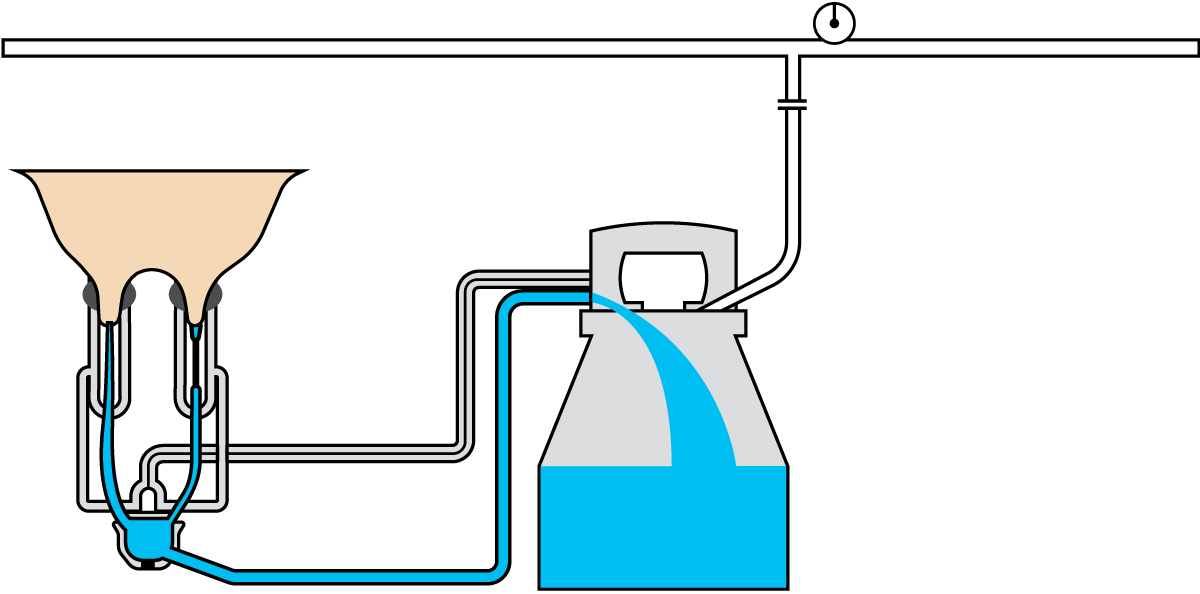

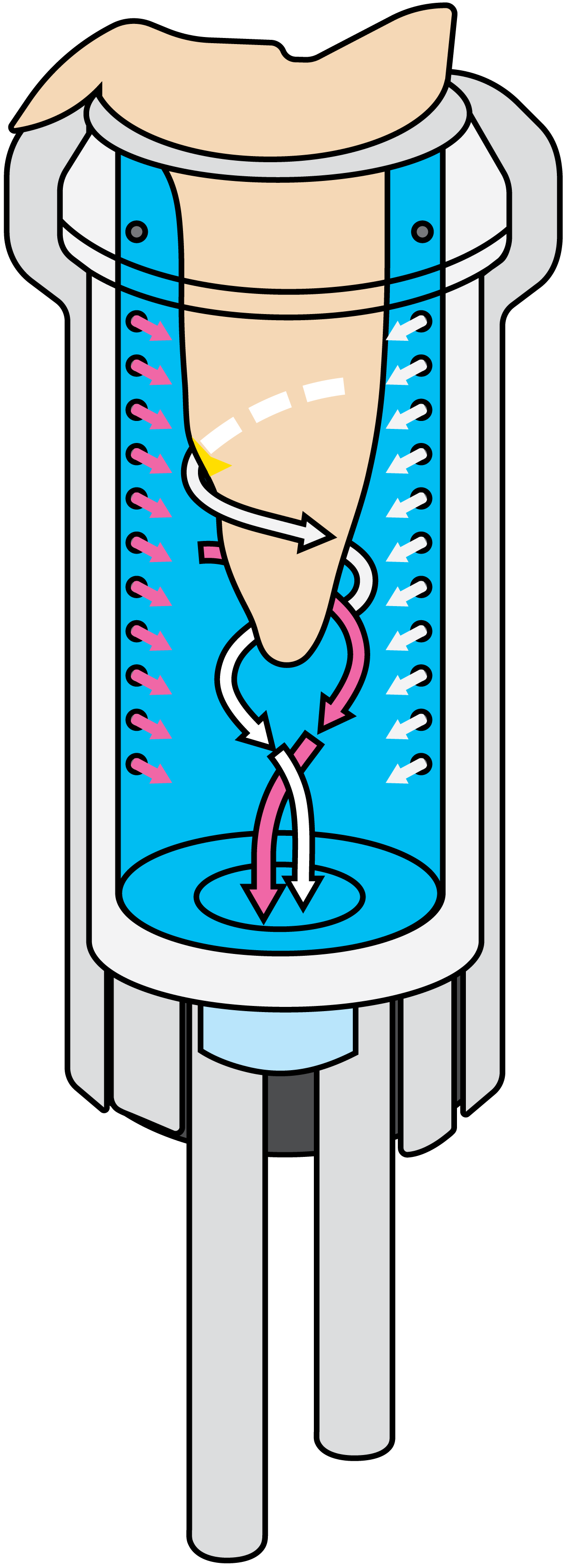

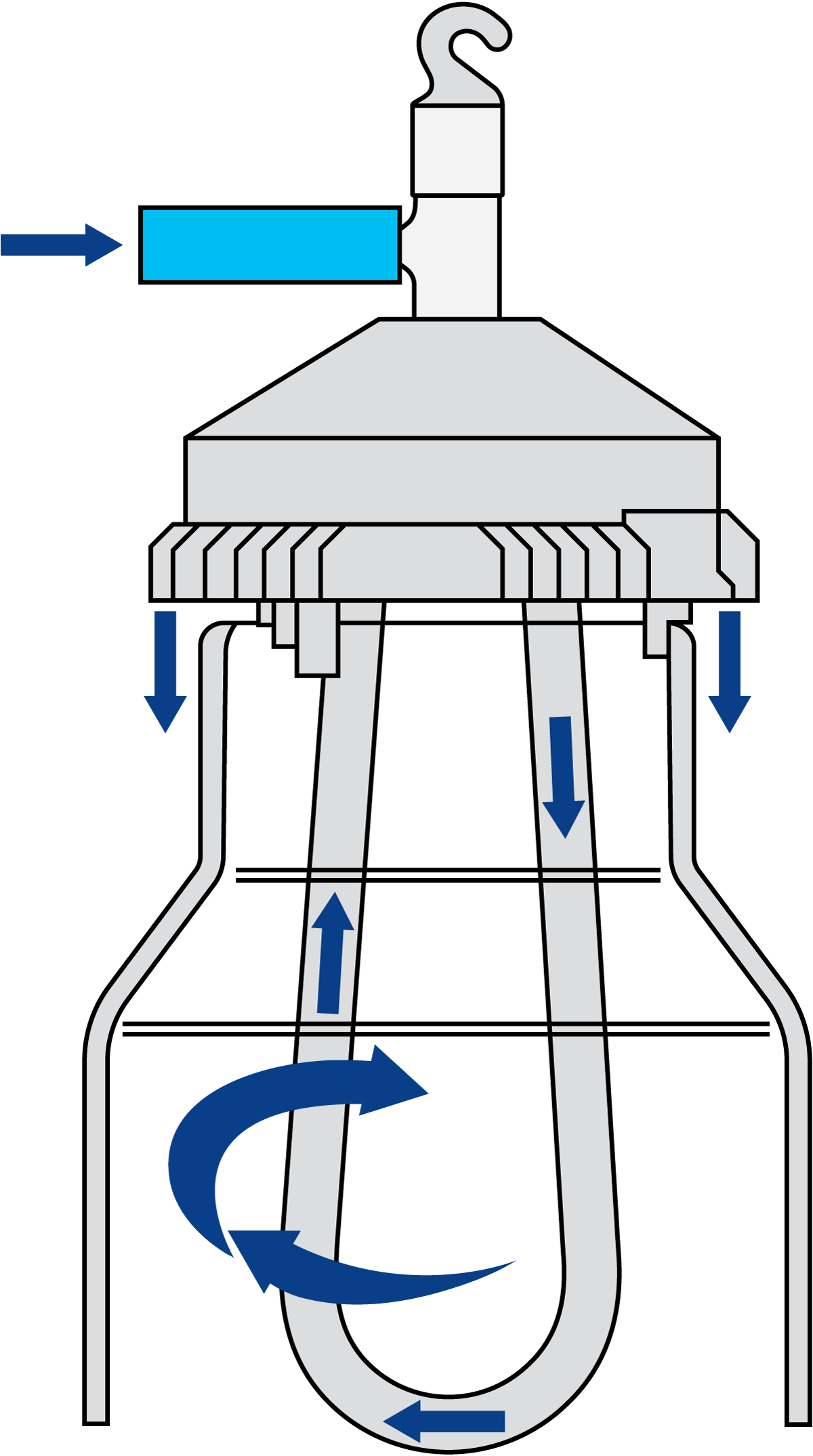

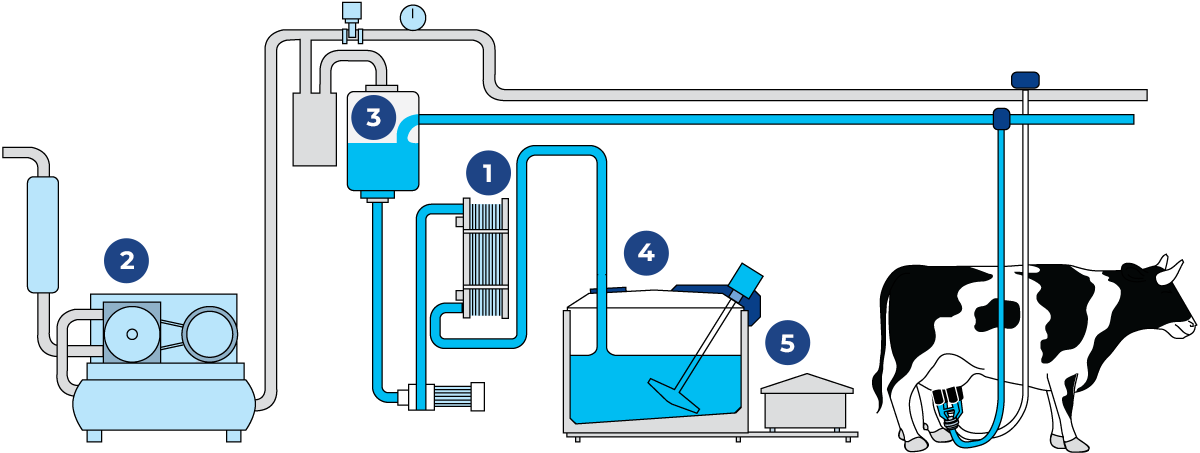

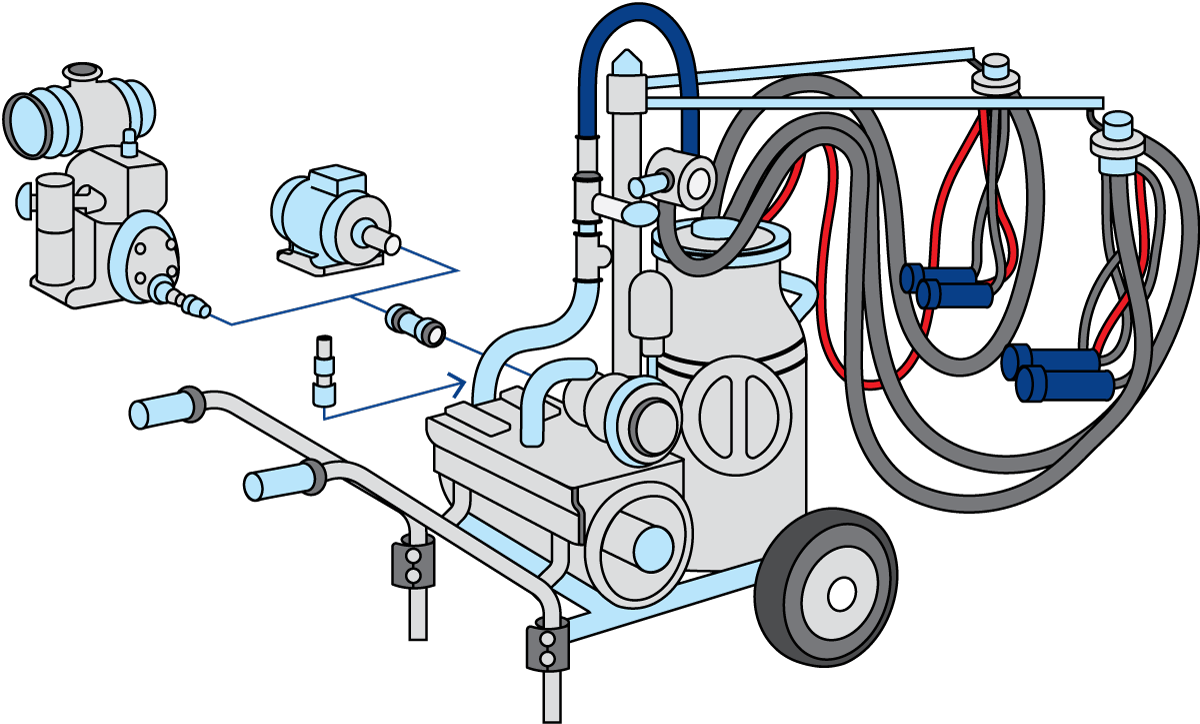

The basic principle of the milking machine is shown in Figure 1.3. The milking machine extracts the milk from the teat by vacuum. A vacuum pump, a vacuum vessel, a vessel for collecting milk, teat cups and a pulsator are all essential parts of the milking machine.

The teat cup unit consists of a cup containing an inner tube of rubber called the teat cup liner. The inside of the liner, in contact with the teat, is subjected to a constant vacuum of 32 – 42 kPa during milking (for cows).

The pressure in the pulsation chamber (between the liner and teat cup) is regularly alternated by the pulsator between approximately 40 kPa during the suction phase and atmospheric pressure during the massage phase. The result is that milk is sucked from the teat cistern during the suction phase. During the massage phase, the teat cup liner is pressed together allowing a period of teat massage. This is followed by another suction phase, and so on as shown in Figure 1.4.

Relief of the teat during the massage phase is necessary to avoid the accumulation of blood and fluid in the teat. Such congestion in the teat can be painful to the cow, and milk let down and milking performance can be affected. Repeated congestion at successive milking sessions can even influence udder health. The pulsator alternates between suction and massage phases about 50 – 60 times per minute.

The four teat cups, attached to a collector called the milk claw, are held on the cow’s teats by suction and the friction between the teat and the teat cup liner. Vacuum is alternately applied (alternate pulsation) to the left and right teats or, in some instances, to the front teats and rear teats. The applying of vacuum to all four teats at the same time (simultaneous pulsation) is less common. The milk is drawn from the teats directly to the milk pail or via a vacuum transport pipe to a receiver unit.

An automatic shut-off valve operates to prevent dirt from being drawn into the system if a teat cup should fall off during milking. After the cow has been milked, the milk pail is taken to a milk room where it is emptied into a churn or a special milk tank for cooling. To eliminate the heavy and time-consuming work of carrying filled pails to the milk room, a pipeline system may be installed for direct transport of the milk to the milk room (Figure 1.5). It allows milk to be conveyed in a closed system straight from the cow to a collecting tank in the milk room. This is a considerable advantage in terms of ensuring proper hygiene.

Dominant conventional milking systems

The milking parlour is a designated stall for cows that allows a group of cows to be milked simultaneously. It provides the milker with good ergonomics, as they work in a pit at a lower level compared to the cows. By changing groups, the entire cow herd is milked. The parlour can be located within the cow housing or in a separate building. On larger farms, rotary milking parlours are an alternative to the static milking parlours described above. A rotary is a slowly rotating platform on which the milking system is installed. The cows step onto the rotating platform, are milked while the rotary is in motion, and exit after a full rotation when milking is completed. On a rotary, the milkers also work from a lower level, providing good ergonomics.

Regardless of whether the milking system is of bucket, pipeline, parlour, rotary, or automatic type, it is important that it is designed to prevent air admission during milking. Excessive air leakage can affect the quality of the milk and cause elevated levels of free fatty acids. The machine milking plant also includes cleaning-in-place facilities.

Automatic milking systems

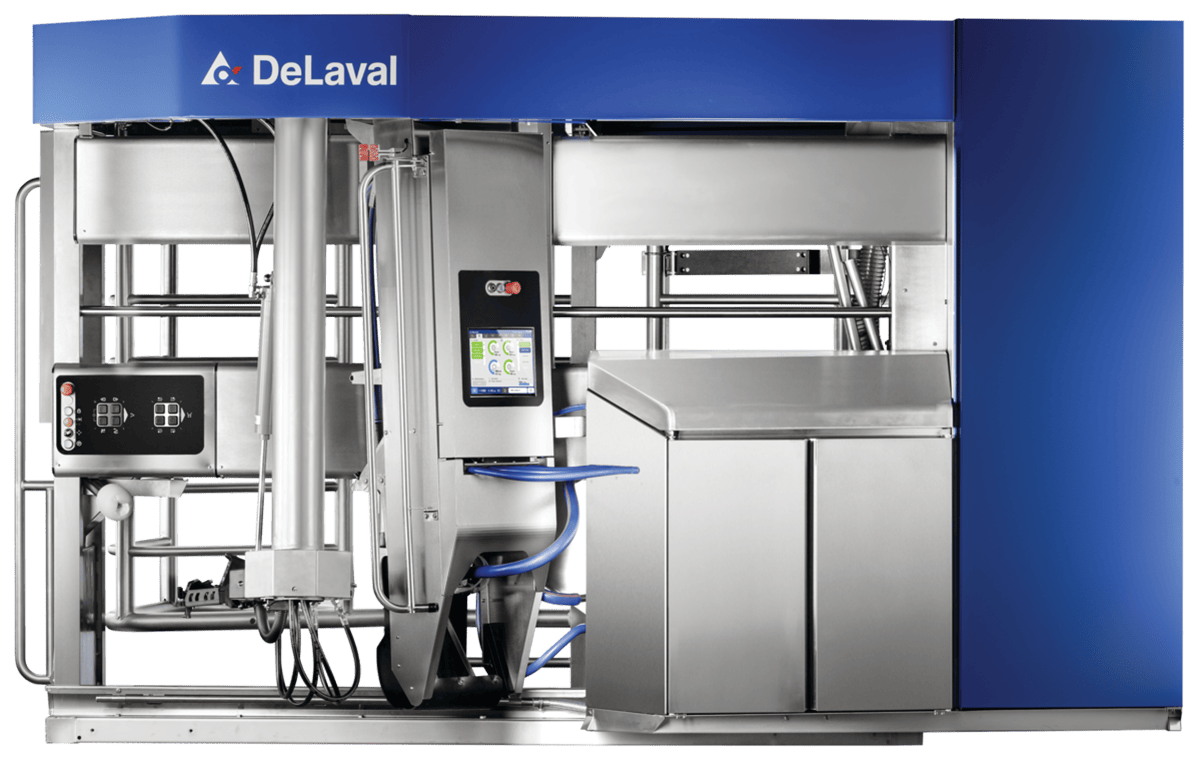

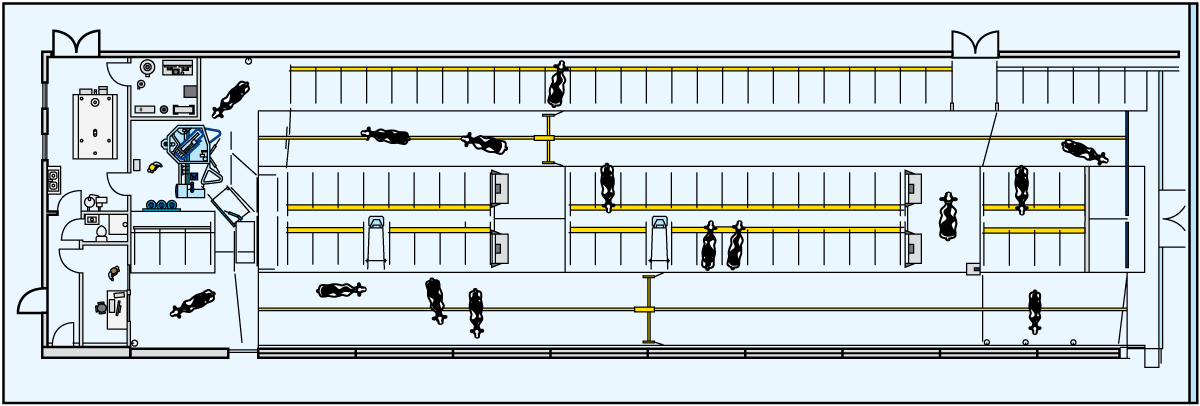

Milking is one of the most labour-intensive and time-consuming jobs in dairy farming. In addition, milking has to take place at least twice a day all year around. Automated milking systems (Figure 1.6) are one solution to this problem as they offer dairy farmers reduced labour requirements, higher milk quality, improved animal health and increased yield. In contrast to conventional milking, in which people bring the cows to be milked, automatic milking places emphasis on the cow’s inclination to be milked in a self-service manner several times a day. Figure 1.8 shows a typical dairy farm layout including an automatic milking system.

When the cow wants to be milked, she walks to the milking station. A transponder on the cow identifies it, and if the cow was milked recently, she is directed back to the resting or feeding area. The cow enters the automatic milking station, and an individual amount of concentrate is served. In an automatic milking system (or “voluntary milking system”) teats are detected by lasers and a vision camera. For example, the teats can be cleaned separately by means of a teat-cup-like device (Figure 1.7) using tepid water applied intermittently at a certain pressure and turbulence to ensure efficient cleaning. Drying of the teats is carried out by compressed air in the same teat-cup.

Pre-milking is carried out by the cleaning teat cup, which applies a vacuum at the end of the cleaning cycle. The cleaning teat cups are finally flushed with water. Sensors detect whether or not pre-milking has been carried out and fore-milking is applied for a few seconds to ensure that sufficient milk is evacuated, and the let-down reflex is activated. Teat cups are automatically attached sequentially and milk from the four teats is collected separately until the milk meter records the amount from each quarter. Spraying each teat with disinfectant is the final stage of automatic milking.

Milk quality and animal health

Cows are normally productive for around three lactations. A prerequisite for producing milk in an economical way is to have a relatively high yield of high quality for as long as the farmers plan to keep the animal while avoiding any causes for involuntary culling. This means high production from healthy animals that are not suffering from any kind of disease. Mastitis is the most common and costly disease in dairy herds. In many cases, the farmer is only aware of the clinical cases.

It has been reported that clinical mastitis rates are generally 20 – 100 cases/100 cows per year. subclinical infections affect 5–35% of quarters and are caused by major pathogenic bacteria. Clinical mastitis is rather easy to detect for the farmer. Symptoms include clotting and discolouration of the milk, and the gland becomes hard, red or swollen. In severe cases, the cow has a fever and loss of appetite. Subclinical mastitis can be harder to detect, since both the milk and udder can appear rather normal, while the somatic cells in the milk increase. Mastitis is an inflammation in the mammary gland which can be caused by bacterial infections or trauma, and on rare occasions viruses. When bacteria are growing, they release metabolites and toxins that stimulate defence mechanisms in the cow. The inflammation response leads to a migration of white blood cells from the peripheral circulation into the udder. The cell count of the milk increases from 100,000 cells per millilitre or less per udder quarter up to several million. The increased cell count is accompanied by an activation of several milk enzymes.

The science of cow comfort

The production of high-quality milk is closely linked to animal well-being and comfort has been identified as one of the leading influences on both quality and yield. Observation and experience show that cows housed in a comfortable environment produce more milk and generally live healthier, longer lives. They should have plenty of quality feed and water, fresh air, a soft and clean resting surface, plus sound footing. They should be encouraged to behave as naturally as possible and stand or lie down easily. Mastitis, sore feet, rubbed necks, and rubbed or swollen hocks can indicate cow comfort problems .

An important concept in all animal husbandry systems is the concept of animal welfare and the five freedoms. The five freedoms relate to the ideal states of the animal and include:

- Freedom from hunger and thirst

- Freedom from discomfort

- Freedom from pain, injury and disease

- Freedom to express normal behaviour

- Freedom from fear and distress

Good animal welfare implies that an animal is of good health both physiologically and psychologically and that it is not exposed to unnecessary suffering (FAWC, 2009). The concept of cow comfort in dairy farming includes animal welfare and productivity. And accordingly, dairy farmers should work towards creating an environment for the cow in which we minimise the risk of the cow experiencing hunger, thirst, discomfort and pain. Creating an environment for dairy cows in which they feel comfortable is of great importance, from both an economic and animal-welfare perspective. Apart from the dimensions, the comfort of stalls that house the cows depends on the type and quality of the bedding material. Bedding material should provide thermal comfort and softness yet be durable and have sufficient friction to allow rising and lying down without slipping. Bedding material should also help to keep cows clean and healthy while minimising daily labour requirements.

More and more research is being carried out on comfortable environments for dairy cows. However past observation and experience have shown that cows housed in a comfortable environment produce more milk and generally live healthier, longer lives

The term “cow longevity” is often used in the dairy farming industry to describe how long a cow stays in the herd. It is convenient to break the total lifespan of the animal into the time before and after their first calving. The average age of calving for Holstein is 24.3 months in the US. The trend shows that the time until the first calving has improved in the last 15 years across the USA and farmers are focusing more on this key performance figure. In addition, this improvement is also more profitable for the farmers. The age at first calving slightly overestimates the expected lifespan of a newborn dairy calf because it excludes the approximately 15% of heifers that are culled before their first calving.

Culling is the departure of animals from the herd because of sale, slaughter, salvage, or death (Fetrow et al., 2006). Productive life is the time from first calving to culling. It is calculated as the reciprocal of (cow) cull rate. For Holstein herds in a number of US states, culling rates averaged 38% (DRMS-Dairy Metrics accessed 6-14-2022). This number varies across the globe. This is the equivalent of a productive life of 2.63 years, or 31.6 months. The average dairy cow’s longevity is therefore approximately 57.1 months or 4.8 years in the U.S., according to USDA data. Productive life has decreased from 35 months for cows born in 1960 by about 40% for cows born in 2000 (USDA-AIPL, 2013). In 1930, the average annual cull rate was approximately 25% (Cannon and Hansen, 1939). The natural life span for cattle is reported to be up to 20 years when they die of old age. A shorter lifespan is primarily the result of an economic decision-making process by dairy farmers. Dairy producers cull cows because they are no longer profitable, or they are replaced by more profitable cows.

The importance of liner and tube design

On a milking machine, the liner is the only part of the milking equipment that is in direct contact with the animal. The quality and characteristics of each liner greatly influence milking performance and overall animal health. Additionally, performance and hygiene are put at risk if liners are used past their recommended milking life. The first criterion is related to hardware. The liners should fit the farm equipment in use in relation to claw, shell and cluster cleaner or jetter cup type. Other considerations include the herd’s average teat size and udder confirmation.

Milk cooling

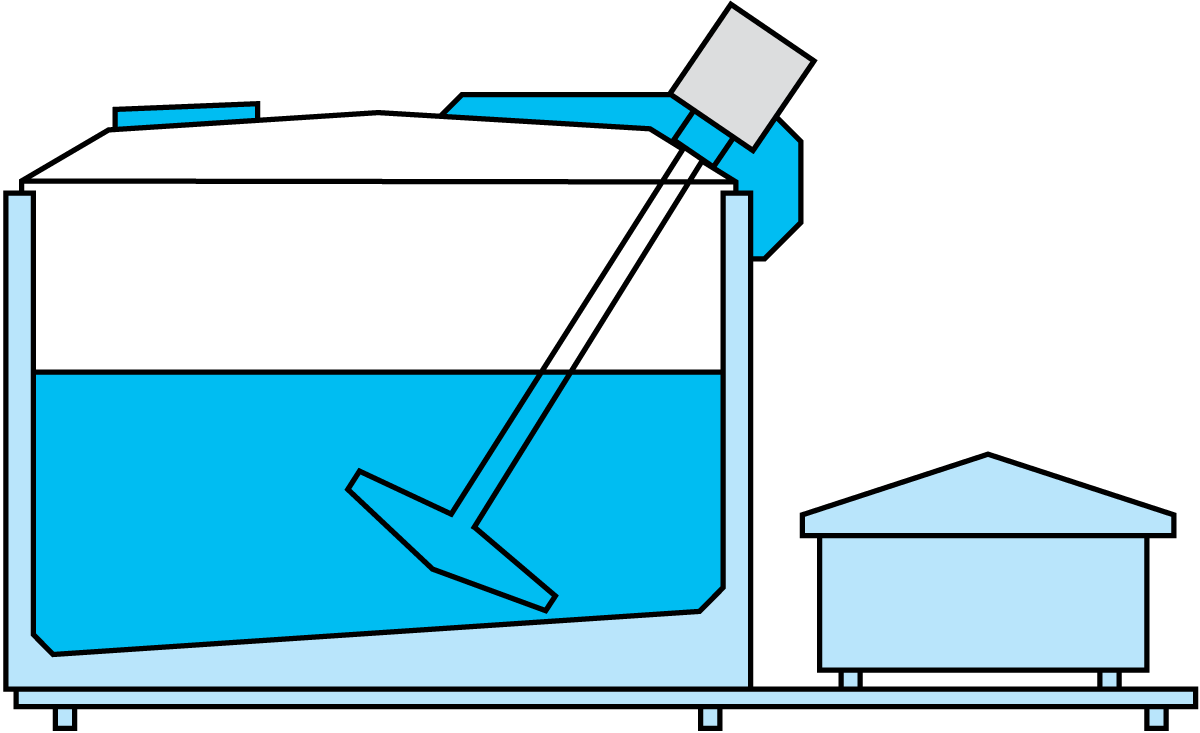

Milk leaves the udder at a temperature of around 37 °C. Fresh milk from a healthy cow's udder contains only normal microbial flora, and it must be protected from being contaminated after it has left the udder. Microorganisms capable of spoiling the milk are everywhere – on the udder, on the milkers’ hands, on airborne dust particles and water droplets, on straw and chaff, on the cow’s hair and in the soil. It is common to filter the milk before it enters the milk tank. Efficient cooling of the raw milk after milking is the best way to prevent bacterial growth (Figure 1.9). Various cooling systems are available; the choice depends on the produced volume of milk. An in-can cooler, shown in Figure 1.10, is suitable for small producers. It is much favoured by users of chilled water units and producers using direct-to-can milking equipment. An immersion cooler is designed for direct cooling of the milk in churns as well as in tanks.

The condensing unit is mounted on a wall (Figure 1.11). The evaporator is located at the lower end of the immersion unit. The immersion cooler can also be used for indirect cooling, i.e. for cooling water in insulated basins. The milk is then cooled in transport churns immersed in the chilled water. Insulated farm tanks for immersion coolers are available in both stationary and mobile types (Figure 1.12). When road conditions prevent access by tanker trucks, a mobile tank can be used to bring the milk to a suitable collection point. Mobile tanks are easy to transport and thus suitable for milking in the fields. Direct expansion tanks, as shown in Figure 1.13, can also be used for cooling and storage of the milk. Careful attention must be paid to hygiene in order to produce milk of high bacteriological quality. However, despite all precautions, it is impossible to completely exclude bacteria from milk. Milk is an excellent growth medium for bacteria; containing all the nutrients they need. Thus, as soon as bacteria get into milk, they start to multiply. On the other hand, the milk leaving the teats contains certain original bactericides which protect the milk against the action of microorganisms during an initial period after extraction. It also takes some time for infecting microorganisms to adapt to the new medium before they can begin to grow.

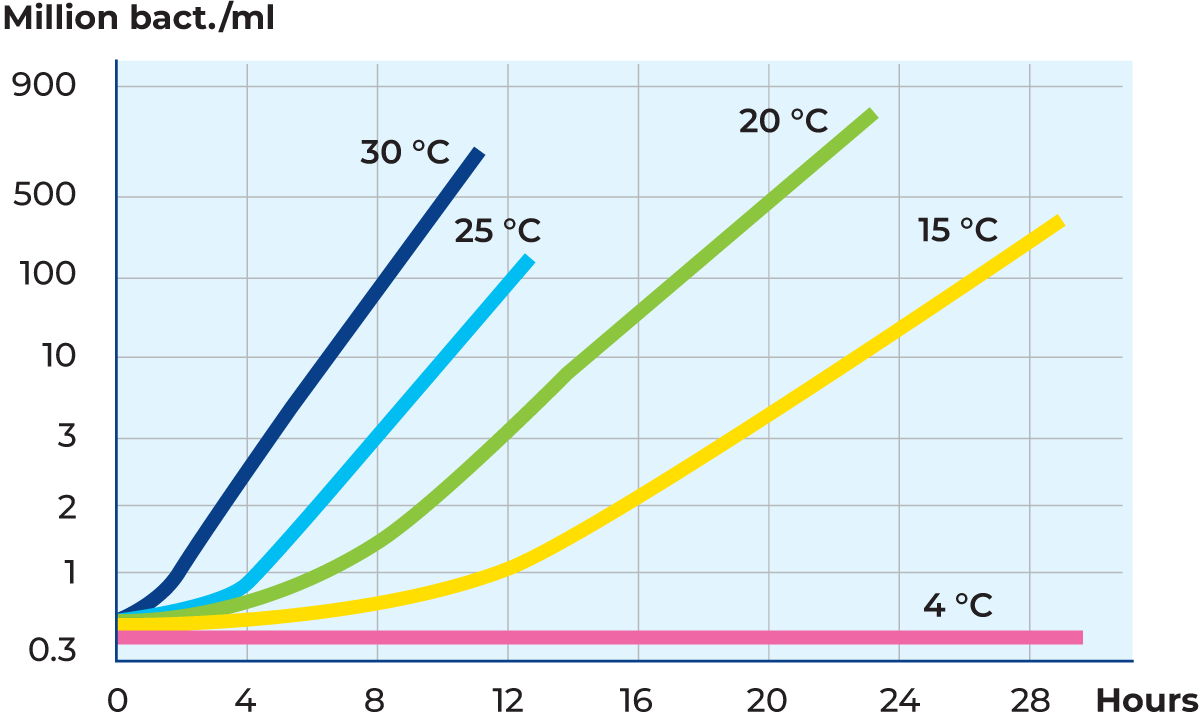

It is important to keep the milk at a low temperature during storage. The activity of the microorganisms will easily increase again if the temperature is allowed to rise a few degrees above the recommended storage temperature. Figure 1.14 shows the rate of bacterial growth at different temperatures over time. Spray or immersion coolers are commonly used on farms, which deliver milk to the dairy in cans. In the spray cooler, circulating chilled water is sprayed on the outsides of the cans to keep the milk cool. The immersion cooler consists of a coil, which is lowered into the can. Chilled water is circulated through the coil to keep the milk at the required temperature.

Where milking machines are used, the milk is commonly collected in special milk tanks at the farm. A wide range of milk tanks of various sizes are available with built-in cooling equipment designed to guarantee cooling to a specified temperature within a specified time. These tanks are in most cases equipped with equipment for automatic cleaning to ensure a uniform high standard of hygiene. On large farms, and in collecting centres where large volumes of milk (more than 5,000 litres) must be chilled quickly from 37 °C to 4 °C, the cooling equipment of the bulk tanks may be inadequate. In these cases, the tank is mainly used to maintain the required storage temperature; a major part of the cooling is carried out by means of an inline heat exchanger in the delivery pipeline (Figure 1.15).

Buffalo

The buffalo has been used in milk production for centuries. It is the most common milk producer in Asia and certain areas of Africa. There are many different species of the animal and the dominant type varies from region to region. The current world population of buffalo is some 150 million animals. 145 million of these live in Asia. Most are owned by farmers with small farms and are mainly used as a source of extra income.

In India, it is common for a family to own one or two buffaloes. In northern India, herd sizes of 10 – 15 animals are commonplace. This area also has a well-developed milk collection system. Outside large Indian cities, large farms with herds of 100 – 300 buffaloes are common. Widespread in India, Pakistan and Southeast Asia, buffaloes are also common in Egypt, Romania, Turkey and Italy. In India, Pakistan and Egypt, some 50 – 65% of all milk produced is from buffaloes. It is estimated that 17% of the world’s total milk production comes from buffaloes. Only 6% of the buffalo milk produced in India is processed and most is used by the farmer or sold untreated as “street milk”. Milk from buffaloes can be processed like milk from cows. However, its thermal stability is lower so mixed milk, a mixture of buffalo and cow milk, is preferable for ultra-high temperature (UHT) treatment.

Lactation, secretion and yield

The milk produced during buffaloes’ lactation period differs due to region and availability of feed. The buffaloes in India and China produce 450 – 500 kilograms per lactation period, while others, i.e. specialised milking farms at Indian university farms, produce more than 1,700 kilograms. In Italy they can produce up to 3,000 kilograms. The lactation period varies from 217 days in Egypt to 270 – 295 in India.

Lactating buffaloes secrete milk in the same way as other lactating domesticated animals. However the anatomy of buffalo teats is slightly different from cow teats. The muscle around the streak channel is thicker, and more force is therefore required to open the canal. This is why the buffaloes are “hard milkers”. The milk is held in the upper, glandular part of the udder, in the alveoli and in small ducts. Notably, cisternal milk fraction is only 5% in the udders of buffaloes. The composition of buffalo milk differs from that of cow milk. The biggest difference relates to fat, as buffalo milk from some breeds may contain up to 13% fat. Buffalo milk fat has a higher melting point than cow milk, due to its higher proportion of saturated fatty acids. Phospholipids and cholesterol are lower in buffalo milk, and it is more resistant to oxidative changes compared to milk from cows. Buffaloes produce colostrum during the first few days after calving. Colostrum from buffalo has a dry matter content of up to 30% and contains valuable proteins. This period usually lasts three days, during which the composition of the colostrum gradually changes, becoming more and more like ordinary milk. Colostrum is not to be delivered to dairies.

Properties

Buffalo milk is richer in most important constituents than cow milk. The content of protein, lactose and ash is somewhat higher in buffalo milk than in cow milk. Buffalo milk contains vitamin A, but lacks carotene, which is present in cow's milk.

Milking techniques

Milking buffaloes is not a difficult task. One should, however, take care not to simply apply cow-milking techniques, as buffaloes require slightly different milking methods. Hand-milking is the method most often used on small, family-run farms. It is important to use a smooth and comfortable milking technique. In hand-milking, it is necessary to overcome the higher resistance in the teat sphincter. Buffaloes have been successfully milked with machines for decades, most notably in southern European countries like Italy, where dairy products made from buffalo milk, such as mozzarella cheese, are part of daily diets. Machine milking has during recent years become more interesting for Asian and African farmers. The udder and teats of buffaloes are different to those of cows, so a heavier cluster, higher operation vacuum and faster pulsation rate are required. Studies have shown that it is possible to reduce the cluster weight and the frequency of liner slip by applying an appropriate combination of liner design and cluster weight. It is not only the total weight of the cluster that is important, but also the distribution of its weight on the udder.

Sheep

Among the numerous breeds of sheep, some are mainly kept for meat and wool production but are occasionally also milked. There are breeds that are considered dairy breeds, but their production per lactation does not exceed 100 kilograms due to the conditions under which they are kept. On the other hand, milk production of some meat breeds can be as much as 150 – 200 kilograms per lactation.

There are, however, some breeds that can be classified as dairy breeds due to their high production of milk and good “milkability”. They include the Lacaune of France, East Friesian of Germany, Awassi of the Near East and Tsigai in the CIS, Romania, Hungary and Bulgaria. Production figures of 500 – 1 000 kg of milk per lactation have been reported for East Friesian and Awassi ewes.

It is estimated, all other factors being equal, that 8 – 10 dairy ewes equal the average production capacity of one dairy cow. Flock sizes of up to 200 ewes are common among intensive family farms, while flocks of 300 – 400 ewes can act as production units. Large-scale enterprises may have many thousands of sheep each. Well-functioning and robust milking equipment and a high efficiency of milking are of utmost importance as is the quality of the management of the sheep.

An ewe is kept for 4 – 5 years in a flock. The gestation period is about five months, and most breeds average 1.5 – 2 lambs per year. In developing countries, this figure is lower than one. Ewe

Lactation, secretion and yield

Different data on yield and lactation periods show wide fluctuation between the various breeds as well as within the same breed. Figures of 0.4 – 2.3 kilograms per ewe per day for yield and 100 – 260 days for the length of lactation should therefore be understood as a rough guide to low and high averages.

Lactating ewes secrete milk in the same way as other lactating domestic animals. Sheep milk is richer in all its important constituents compared to cow milk and with nearly 30% more dry matter. Variations in sheep milk composition are due to most of the same factors as for dairy cows, i.e. breeds, individuals and stage of lactation. Ewes produce colostrum during the first few days after lambing. Colostrum has a dry matter content of up to 40% and contains the important proteins albumin and immunoglobulin. This period lasts 3 – 4 days, during which the composition of the colostrum gradually changes to become more and more like ordinary milk. Colostrum should not be delivered to dairies.

Properties

Fat globules in sheep’s milk range in size from 0.5 – 25 microns. The largest fraction is 3 – 8 microns, nearly twice as big as the fat globules in cow’s milk. The fat in sheep milk has a higher content of caprylic and capric acid than the fat in cow milk. This is the main reason for the particular taste and aroma of milk products from sheep.

It contains on average 4.5% casein and only around 1% whey proteins. The ratio of casein to whey protein of sheep milk thus differs somewhat from that of cow’s milk, that is, 82:18 versus 80:20. Specific gravity is 1,032 – 1,040. This is due in part to its high content of solids-non-fat. Acidity is high due to a high percentage of proteins. The pH normally varies between 6.5 and 6.8.

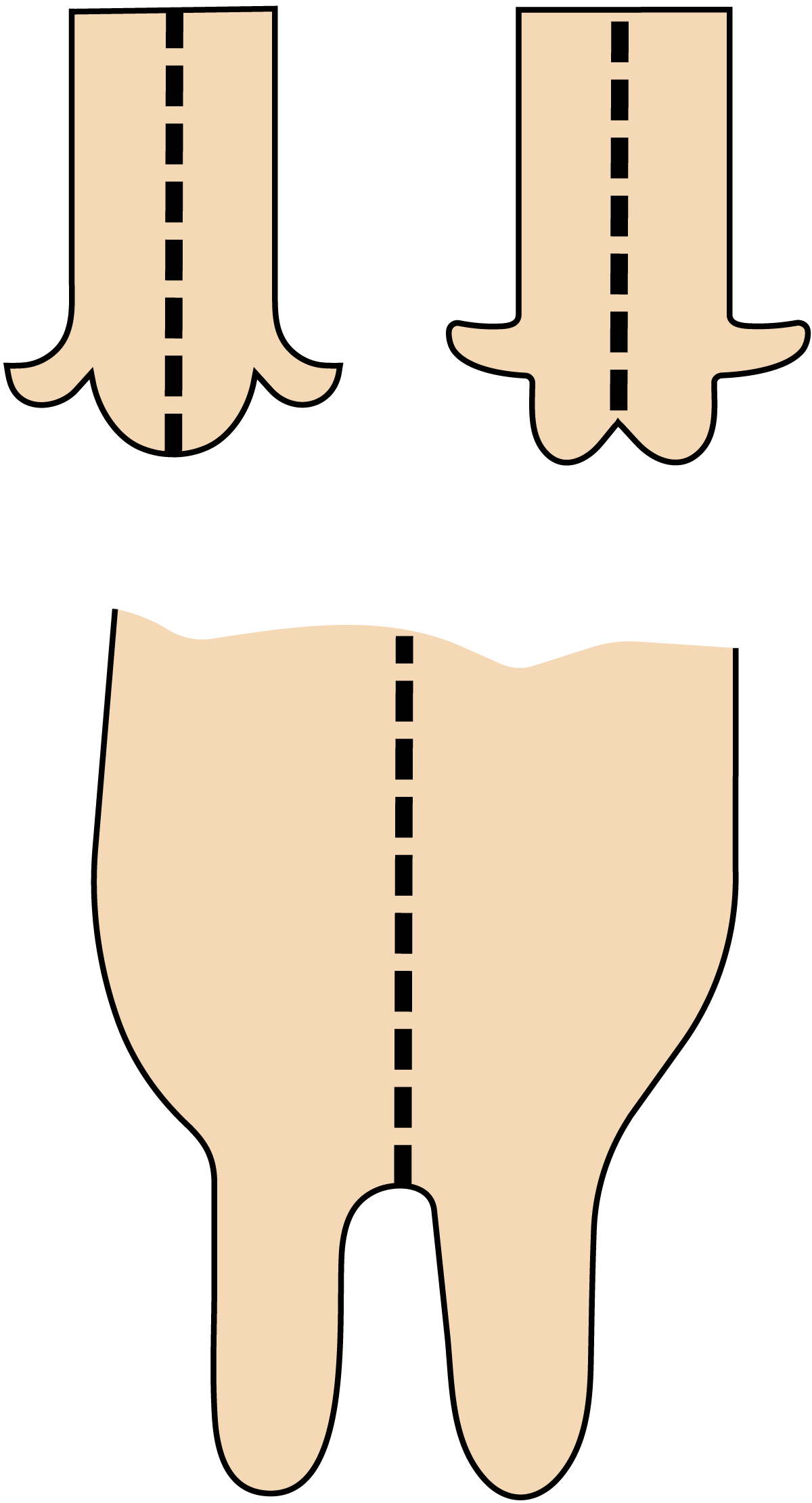

Milking techniques

The anatomy of the udder of the ewe is different to that of the cow. The udder of the ewe consists of two halves with one teat each. While the cow is normally easy to milk, both manually and by machine, sheep are more difficult to milk compared to cows, regardless of method. One important reason is that the teats of many ewes are horizontally oriented. An ideal udder is one with the teats at the lowest points of the udder halves. Figure 1.16 shows examples of various udder configurations of sheep.

As with cows, the release of milk is initiated by the hormone oxytocin which causes the muscle-like cells to compress the alveoli. This generates pressure in the udder and facilitates the transport of milk from the alveoli to the cisternal compartment of the udder. Compared to cows, the cisternal fraction of milk in sheep is considerably higher and represents more than 50%. In practice, this means that sheep can be milked without extensive pre-stimulation before the milking machine is attached.

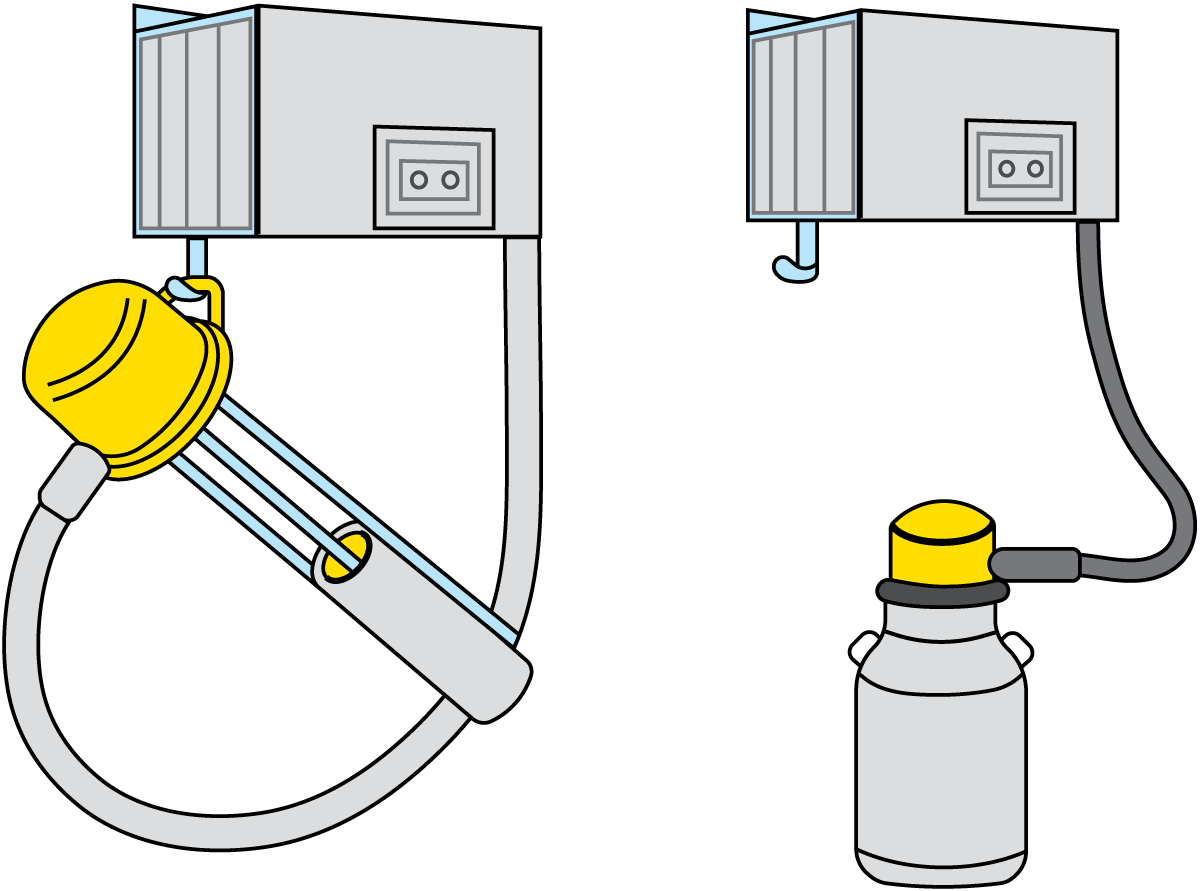

Hand-milking is the method of milking most often used in small herds. The efficiency of milking is very much dependent upon the milk let-down. A milker may be able to milk 20 – 40 ewes with slow let-down (the Lacaune breed) in one hour, while the same milker may be able to milk 40 – 100 ewes per hour of sheep with faster milk let-down (the Manech breed). Dairy farmers with more than 150 ewes generally install machine milking systems to take the hard labour out of milking. The working principle of milking machines for ewes is similar to that described for cows, except that the milking vacuum is lower and the pulsation rates are much higher. The most common types of machine milking installations are churn, mobile and pipeline systems (see Figures 1.18, 1.19 and 1.20). In a churn installation, the vacuum system is fixed, and the churn unit is movable. The churn, which holds 20 – 40 litres, is used for manual transport of milk to the storage tank.

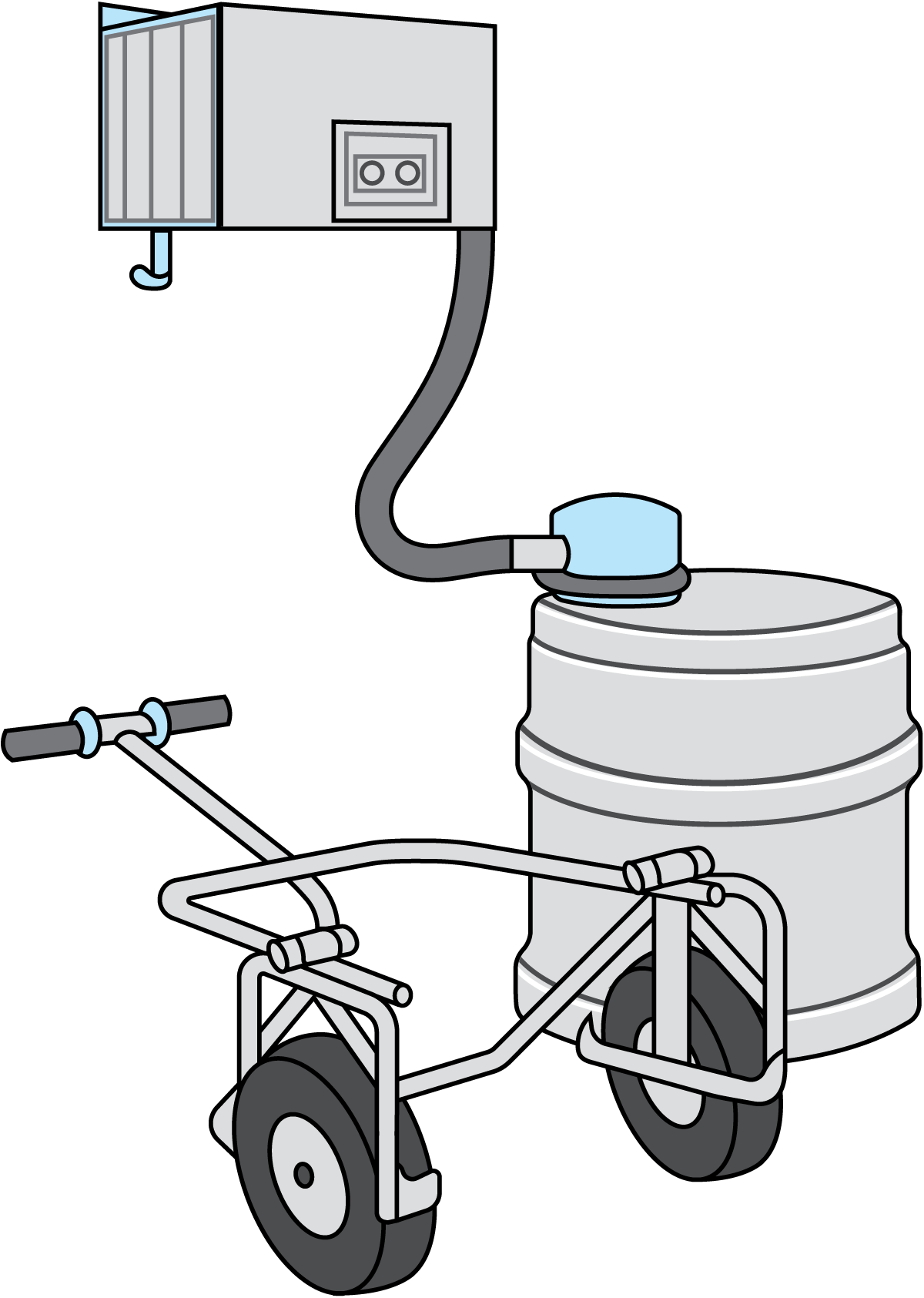

The pulsator can be mounted on the churn lid. A non-return valve in the lid allows air to be sucked from the pail. A churn plant can have one to three churns per operator. The normal capacity of an operator with two churns is 70 ewes per hour. This type of installation is suitable for small flocks of up to 140 animals. In a pipeline milking installation, the milk line can be installed at a high or low level in the parlour. Milking capacity depends on the design of the parlour. The mobile milking unit is suitable for small flocks and outdoor milking, and when ewes must be milked in different places. The installation has the same capacity as that of a churn milking installation. The unit consists of a complete vacuum system, power unit (electric motor or combustion engine), cluster assemblies, milk container (churn) and pulsation system, all mounted on a trolley. During milking, the trolley is placed behind 4 – 8 ewes. Two pivoted bars are turned outwards behind the ewes, and the cluster assemblies are attached from the rear.

Goats

The goat is considered the first ruminant to be domesticated. Goats originated in Asia and are now spread almost all over the globe. They are very hardy animals and thrive in areas where it may be difficult for other animals to live. Unlike sheep, goats are not flock animals. There are numerous breeds of goat, but no specialised dairy breed. However, Saanen, Alpine, Toggenburg and Chamois breeds have been successfully selected and bred for increased milk yields. Because of this, they have been exported around the world to be crossed with local breeds.

Lactation, secretion and yield

In a well-managed milk production herd, a goat produces 400 – 1,300 kilograms of milk per lactation of 200 – 300 days. The hard, uncomfortable work of hand milking is eased by milking by machine. However, a certain volume of milk should be produced, or a certain number of animals kept to justify switching to mechanical milking. For a family-sized goat milking operation, depending upon local conditions, at least 50 – 150 goats are required to reach an acceptable turnover. A business enterprise requires a larger number of animals, e.g. 200 – 1,000 goats. An intensive and feasible production unit, family-sized operation or business enterprise, however, requires not only appropriate milking equipment but also effective management, feeding and breeding programmes.

Goats secrete milk in the same way as other lactating domestic animals. The composition of goat milk, like that of other species, is influenced by several factors. From Table 1.1 it appears that the gross composition of goat milk is similar to that of the cow. However, the ratio of casein to whey proteins in goat milk is narrower at 75:25, compared to 80:20 for cow’s milk. The relatively higher content of whey proteins indicates that goat milk may be more sensitive to heat. The pH of goat milk normally varies from 6.5 to 6.7.

The female goat, like the ewe, has an udder with two halves (Figure 1.21) – each with one teat. Goat teats are generally somewhat longer than sheep teats and are located at the lowest point of each half. Most of the milk is stored at the cisternal part of the udder so both manual as well as machine milking is easy to perform (Figure 1.22).

Milking by hand remains a common way of milking goats in many parts of the world but machine milking is rapidly increasing. Machine milking facilitates work on large goat farms. Previous information about sheep and equipment for milking, cooling, cleaning and storage applies for the most part to goats as well.

A growing world needs a stable food supply

By 2050, the global population is expected to reach 9.1 billion, 34% higher than today. Most of this increase is likely to occur in developing countries like Brazil, China and India, where more and more people are choosing to live in urban areas with higher incomes. Total food production must therefore increase to meet the projected demands of this growing population.

Milk is one of the most nutritious foods for the human body. It makes a significant contribution towards meeting our need for calcium, vitamins B2 and B12, iodine, potassium and phosphorous. The FAO considers milk of such importance in human nutrition that it recommends 2 – 3 servings of milk or other dairy products every day.

Producing larger quantities of milk in the long term means all stakeholders in the dairy farming industry must learn to be more productive in ways that use fewer natural resources and safeguard animal well-being while producing the necessary financial returns. In other words, establishing a stable food supply requires sustainable farming techniques. The goal is to reduce the environmental footprint of farms while improving milk production, farm profitability and the well-being of the people and animals involved. All aspects of sustainability need to be considered and improved to make dairy farming more sustainable.

The dairy farming ecosystem

While dairy farmers are the primary actors in the milking of mammals such as cows, buffaloes, sheep and goats, they are part of an intricate ecosystem. Smallholder and subsistence farmers rely on the support and advice of local veterinarians and other farmers. Larger-scale dairy farmers, with herd sizes in the hundreds and thousands, have a more complex task as they must meet the demands of the market while balancing animal health and welfare, environmental concerns, regulations, equipment suppliers, labour issues, and the price of feed.