FERMENTED MILK PRODUCTS

Milk products prepared by lactic acid fermentation (e.g. yoghurt) or a combination of this and yeast fermentation (e.g. Kefir) are called fermented or cultured milks. The term fermented will be used in this chapter.

Fermented milk is the collective name for products such as yoghurt, laban, kefir, cultured buttermilk, filmjölk (Scandinavian sour milk), cultured cream and koumiss (a product based on mares’ milk). The generic name of fermented milk is derived from the fact that the milk for the product is inoculated with a starter culture which converts part of the lactose to lactic acid. Depending on the type of lactic acid bacteria used, carbon dioxide, acetic acid, diacetyl, acetaldehyde and several other substances can also be formed in the conversion process, and these give the products their characteristic fresh taste and aroma. The microorganisms used in the production of kefir and koumiss also produce ethyl alcohol.

Lactic acid produced during fermentation causes a decrease in pH in the milk. Milk protein, specifically casein, reacts to the drop by aggregating. If the correct heat treatment has been applied to the milk before fermentation, it will result in the formation of a protein network, also known as “coagulum”. To the consumer, this is perceived as the soft gel texture characteristic of fermented milk products.

The conversion of lactose into lactic acid has a preservative effect on the milk in that the resulting low pH of the milk prevents spoilage and the growth of detrimental bacteria, thereby prolonging the shelf life of the product. On the other hand, acidified milk is a very favourable environment for yeasts and moulds, which cause off-flavours, blown packages, etc. if allowed to infect the products.

Fermented milk originated in the Near East and subsequently became popular in Eastern and Central Europe. The first example of fermented milk was presumably produced accidentally by nomads. This milk turned sour and coagulated under the influence of certain microorganisms. As luck would have it, the bacteria were of the harmless, acidifying type and were not toxin-producing organisms.

General requirements for fermented milk production

The quality of fermented milk products is assessed in terms of:

- Microflora – Does it contain the right type and number of microorganisms? (Legislation in many countries specifies a minimum amount of specific micro-organisms for specific products.)

- Does it contain any contaminating microorganisms (yeast or mould in the case of yoghurt)?

- Appearance – How does it look?

- Body and texture – How does it behave when poured or spooned? How does it feel in the mouth?

- Flavour – How does it smell and taste?

The “correct” final product quality is defined uniquely for each product and can therefore differ from producer to producer, country to country or even region to region. The range of fermented milk products today includes products that are thick, thin, sweet, sour, firm or liquid. The one common aim of all producers of fermented milk products is to produce attractive products with the same quality every day, and that these should not be microbiologically contaminated.

A central challenge is how long the product can maintain its desired properties, i.e. its shelf life. Again, this is to a large extent a subjective assessment made by the producer, based on market expectations on the specific type of fermented milk product. The shelf life and the limiting factor will vary accordingly. For example, modern production lines with highly hygienic design will support a shelf life of 21 to 30 days for traditional stirred or set yoghurt (see type descriptions in next section) when keeping the product below 8 °C. The shelf life of the yoghurt is then typically limited by physical instability (a watery layer, often referred to as “whey separation”, is formed on top of the product in the package) or changes in flavour.

In the production of fermented milk, the best possible growth conditions must be created for the starter culture. These are achieved by heat treatment of the milk to destroy any competing microorganisms. In addition, the milk must be held at the optimum temperature for the relevant starter culture during fermentation. When the best possible flavour has been achieved, the milk must be cooled quickly to stop the fermentation process. If the fermentation time is too long or too short, the flavour will be impaired and the texture wrong. Correct appearance and texture are mainly determined by the choice of milk processing parameters. Adequate heat treatment and homogenization of the milk, sometimes combined with methods to increase the protein content, as for milk intended for yoghurt, are essential “cornerstones” for the creation of the coagulum (protein network) during the incubation period.

Some of the most common fermented milk products are described below, with an emphasis on yoghurt. The production techniques for other fermented products have many similarities; the pre-treatment of the milk, for example, is almost the same. The process descriptions for other products therefore concentrate primarily on the production stages which differ from those in yoghurt production.

Yoghurt

Yoghurt is the best-known of all fermented milk products, and the most popular worldwide. According to Codex Alimentarius, yoghurt is defined as milk fermented by two bacteria, Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus. Due to this, the flavour of yoghurt differs from that of other fermented milks, and the volatile aromatic substances include small quantities of acetic acid and acetaldehyde.

Yoghurt is produced and sold in consistencies ranging from a firm but soft gel to low viscous liquid or even a thick, almost mouldable texture. To a large extent, these variations are a result of varying production processes.

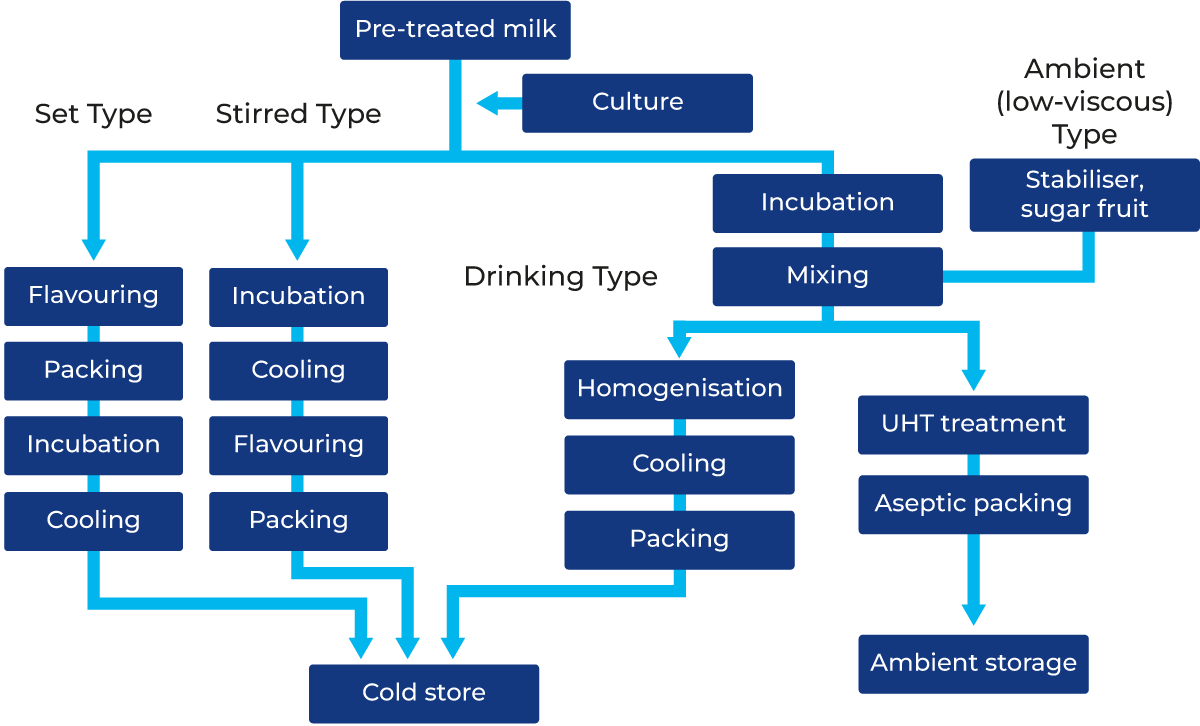

Yoghurt can be classified based on how it is produced:

- Set type: fermented and cooled in the package, Figure 13.2

- Stirred type: fermented in tanks and cooled before packing, Figure 13.3

- Drinking type: similar to stirred type, but the coagulum is broken down to a liquid before being packed, Figure 13.4

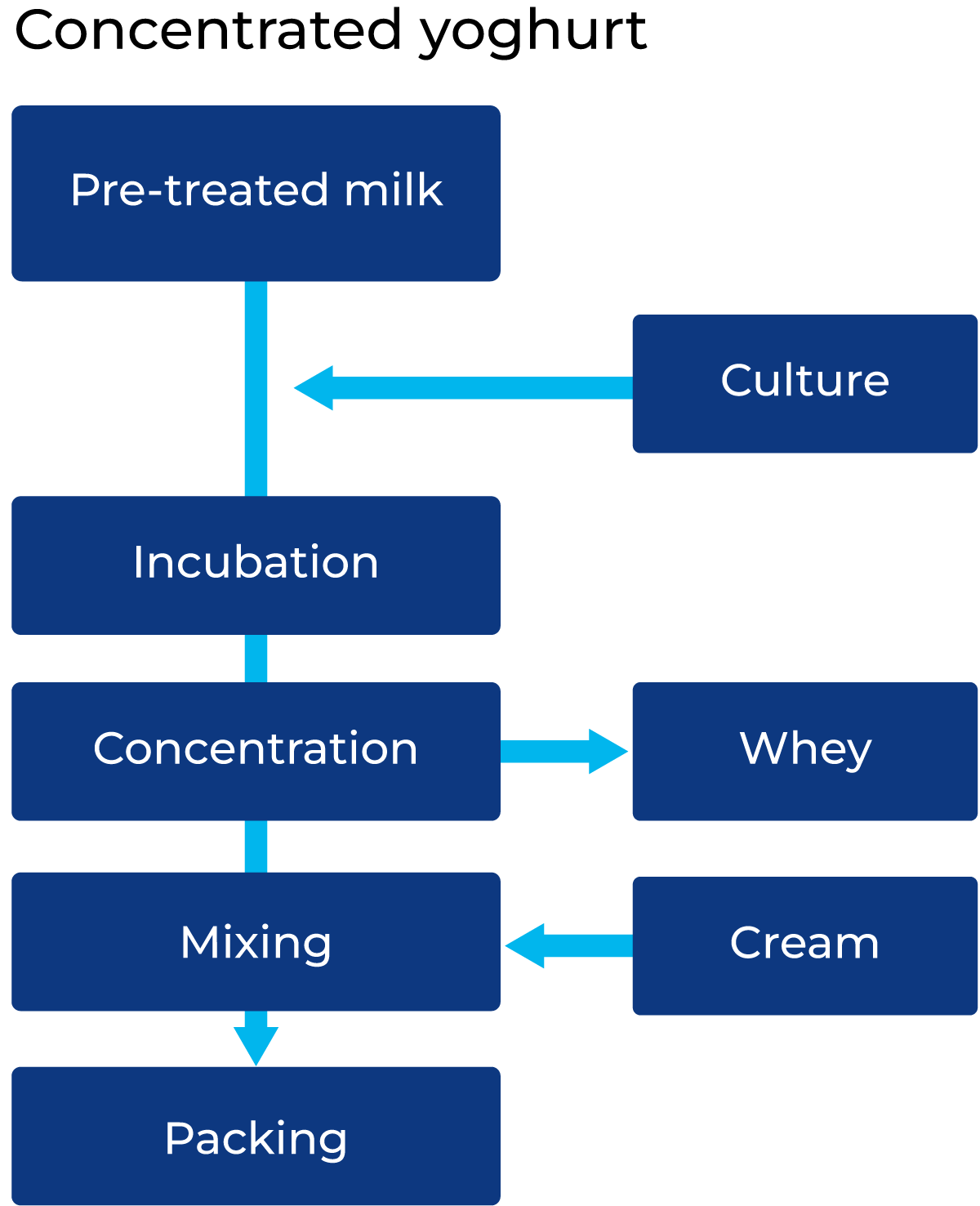

- Concentrated: fermented in tanks, concentrated and cooled before being packed. This type is sometimes called Greek yoghurt or strained yoghurt, sometimes labneh or lakaneh, Figure 13.5

- Ambient: heat treated after fermentation (which can take place inside the tank or package) to create a product that can be stored and distributed at ambient conditions.

Fruit and flavoured yoghurts

Yoghurts with various added fruits, aromas or particles are very popular worldwide. Fruit and berries are added as “fruit preparations”: fruit purée, fruit pieces in a syrup or a mixture of both. The fruit preparation often also includes aroma, sugar/sweetener and a stabiliser to ensure that the preparation remains homogenous during storage. The proportion of fruit preparation added is usually less than 10%, of which about 50% is sugar. The fruit is mixed with the yoghurt before or in connection with filling.

The fruit can also be filled in the bottom of the package before the latter is filled with yoghurt. Alternatively, the fruit can be separately packed in a twin cup integrated with the basic cup.

Sometimes yoghurt is flavoured with aroma only, like vanilla, coffee essences, etc. Colouring and sugar or sweeteners are often added together with the aroma.

Milk for yoghurt production must:

- Have a low bacteria count

- Not contain enzymes and chemical substances which may slow down the development of the yoghurt culture

- Not contain antibiotics and bacteriophages

The additives increase the DM (dry matter) content of the finished yoghurt. A typical composition for fruit yoghurt is:

- Fat 0.5 – 3.0%

- Lactose 3.0 – 4.5%

- Protein 3.2 – 4.5%

- Stabiliser (if used) 0.3 – 0.5%

- Fruit preparation 7.0 – 15.0%

Lactose-free yoghurts

The digestive systems of some people partly or completely lack the lactase enzyme. As a result, lactose is not broken down by the digestive process into simpler types of sugars. These people can consume only very small volumes of ordinary milk without discomfort (this is described in Chapter 11). They can, however, often consume fermented milk, in which the lactose is already partly broken down by bacterial enzymes during fermentation.

It is also possible to create completely lactose-free fermented milk by adding a lactase enzyme that hydrolyses the lactose into glucose and galactose. Hydrolysis of yoghurt milk can be performed during the fermentation by the addition of lactase to the fermentation tank. Some lactase enzymes are sensitive to low pH. Their activity decreases as fermentation progresses and the pH drops. What type and dosage of lactase enzyme to use therefore depends on how quickly the starter cultures ferment the milk.

Probiotic yoghurts

Today, many yoghurts not only contain the starter culture but also different types of probiotic bacteria, for instance, Lactobacillus acidophilus and plantarum, Lacticaseibacillus rhamnosus or casei, Bifidobacteria animalis, etc. Consuming products containing probiotic bacteria in sufficient amounts is associated with specific health benefits meaning that probiotic products are often sold at premium prices.

The probiotic bacteria are added to the yoghurt together with the starter culture milk before fermentation.

Factors affecting the quality of yoghurt

Several factors must be carefully controlled during the manufacturing process in order to produce a high-quality yoghurt with the required flavour, viscosity, texture, appearance and stability (freedom from whey separation). In this section, we will cover some of the most important factors:

- Choice of milk

- Milk standardization

- Choice of ingredients

- Milk treatment (incl. deaeration, homogenization and heat treatment)

- Choice of culture

- Plant design

Choice of milk

To be able to produce a high-quality yoghurt, the milk intended for yoghurt production must be of the highest bacteriological quality. It must have a low content of bacteria and other substances which may impede the development of the yoghurt culture. The milk must not contain antibiotics, bacteriophages, residues of CIP solution or sterilising agents, and must be very carefully analysed at the dairy.

Milk standardization

The fat and dry solids contents of the milk are normally standardized according to the principles described below.

Fat

Yoghurt can have a fat content of 0 – 10%. A fat content of 0.5 – 3.5% is, however, the most typical. Often, yoghurt is classified into different groups based on fat content:

- Yoghurt

Min. milk fat 3% - Partially skimmed yoghurt

Max. milk fat < 3% Min. milk fat > 0.5% - Skimmed yoghurt

Max. milk fat 0.5%

Dry matter (DM) content

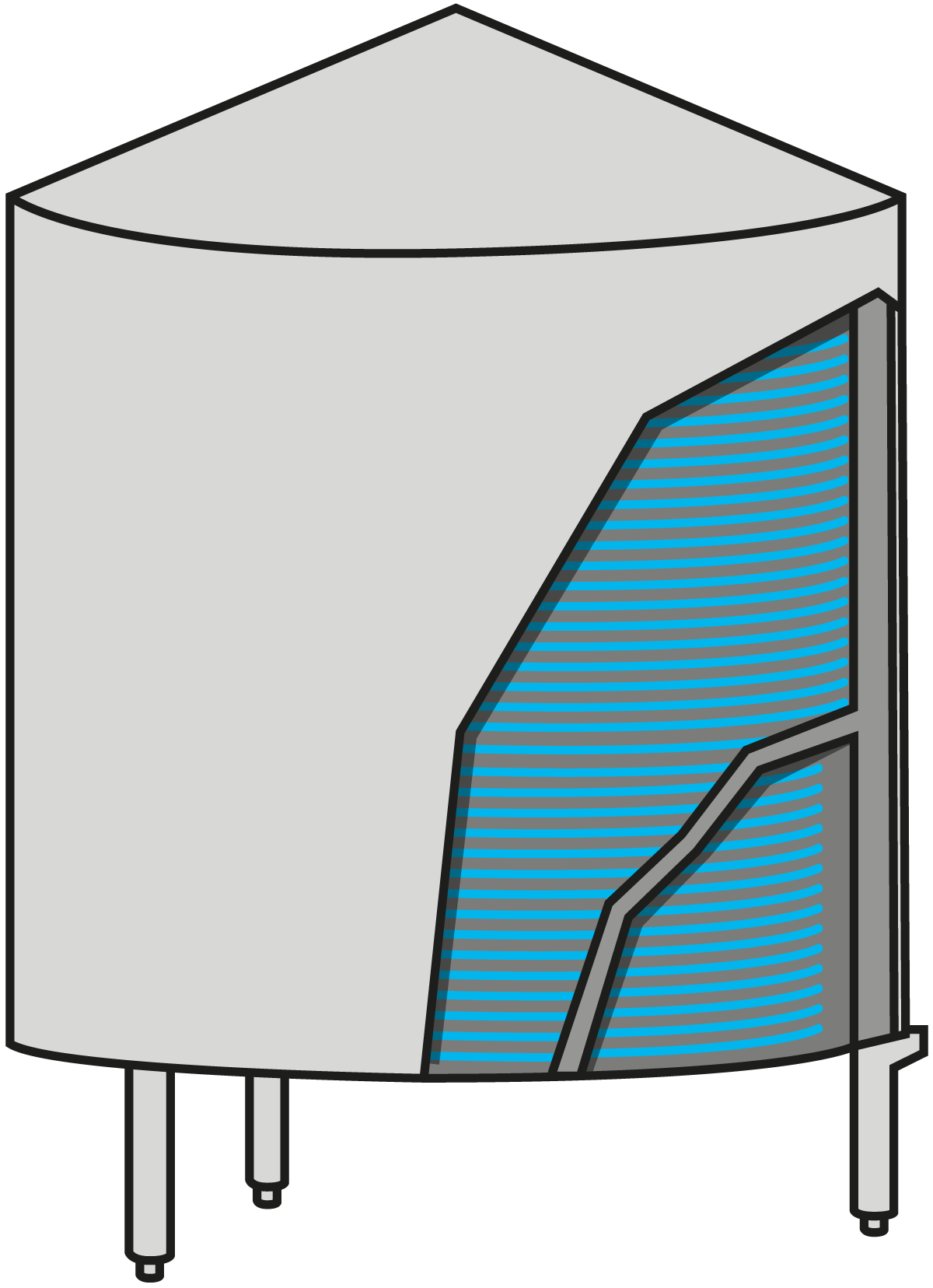

An increase in the total DM content of the milk, particularly the proportion of casein and whey proteins, will result in a firmer yoghurt coagulum, and the tendency to whey separation will then be reduced.

The most common ways to standardize the DM content are:

- Evaporation (10 – 20% of the milk volume is normally evaporated)

- Addition of skim milk powder or milk protein powder

- Addition of milk concentrate

- Concentration of the milk with membrane filtration (UF or RO)

Choice of ingredients

It is possible to produce yoghurt by simply fermenting milk with a yoghurt starter culture. In many markets, however, it is common to add other ingredients as well. This can be motivated by a need to differentiate the product range, cost optimisation or prolonging the product shelf life. At the same time, the concept of “clean label” has gained popularity. It refers to (the production of) a product using a minimum of ingredients. In many countries, “clean label” is used as a sales argument for the product, making it possible to charge a premium price.

Milk protein powder

As already mentioned in the previous section, skim milk powder (SMP) or different types of milk protein powders or concentrates can be added to increase the protein level of the milk.

Sugar or sweetener

Sugars, such as sucrose or glucose, can be added alone to sweeten the yoghurt taste or in conjunction with the addition of fruit. Alternatively, sweeteners can be used for the same purpose. A sweetener has no nutritive value, but tastes very sweet, even in very small doses.

It should be noted that adding too much sugar (more than ~8%) to the milk before the inoculation/incubation period has an adverse effect on fermentation conditions because it changes the osmotic pressure of the milk.

Stabilisers

Stabilisers in the form of hydrophilic colloids can bind water. If added to the yoghurt they can increase viscosity and help to prevent whey separation in yoghurt. The type of stabiliser and the dosage at which it should be added must be determined experimentally by each manufacturer. The product may acquire a rubbery, hard or grainy texture if the wrong stabiliser, or an excess of stabiliser, is used.

Correctly produced, natural yoghurt requires no addition of stabilisers, as a firm, fine gel with a high viscosity will occur naturally. Stabilisers can be used in fruit yoghurts and must be used in whipped/aerated and ambient yoghurt. Stabilisers (0.1 – 0.5%) such as modified starch, pectin, agar-agar, gelatine or various gums are the most commonly used substances. In some countries, the use of stabilisers is forbidden by law or is only permitted to a limited extent.

Milk treatment

Deaeration

The air content of the milk used to make fermented milk products should be as low as possible. However, some admixture of air is unavoidable if the dry matter content is increased by the addition of milk powder. If this is done, the milk should be deaerated as part of the subsequent processing.

When the dry matter content is increased by evaporation, deaeration is a part of that process.

The advantages gained through deaeration are:

- Improved stability and viscosity of the yoghurt

- Shortened fermentation time

- Improved working conditions for the homogenizer

- Less risk of fouling during heat treatment

- Removal of volatile off-flavours (deodorisation)

Homogenization

The main motives for homogenizing milk intended for fermented milk production are to prevent creaming during the incubation period and to assure uniform distribution of the milk fat.

Homogenization also improves the stability and texture of fermented milks, even those with low fat contents.

As a general recommendation, the milk should be homogenized at 200 – 250 bar and 65 – 70 °C to obtain optimum physical properties in the product. Homogenization is frequently utilised even in the production of low-fat cultured milks.

Some producers homogenize their yoghurt milk up to 600 bar and at temperatures up to 95 °C. These higher parameters can have a positive influence in terms of both viscosity and stability for certain product recipes. They may not, however, be possible to use for all recipes.

Heat treatment

The milk is heat treated before being inoculated with the starter in order to:

- Improve the properties of the milk as a substrate for the bacteria culture

- Ensure that the coagulum of the finished yoghurt will be firm

- Reduce the risk of whey separation in the end product

Optimum results are achieved by heat treatment at 90 – 95 °C and a holding time of about 5 minutes. That temperature/time combination denatures about 70 – 80% of the whey proteins (99% of the β-lactoglobulin). In particular, the β-lactoglobulin, which is the principal whey protein, interacts with the κ-casein, thereby helping to give the yoghurt a stable body.

UHT treatment and sterilisation of milk intended for fermentation do not, however, have the same favourable influence on viscosity.

Choice of culture

Starter culture producers today produce a wide range of customised yoghurt starter cultures that the dairies can choose from. During incubation the two yoghurt bacteria, Str. thermophilus and Lb. bulgaricus, multiply rapidly and ferment lactose to lactic acid. In addition to lactic acid, the culture will also produce aromatic substances such as diacetyl, acetic and propionic acids, ketones and aldehydes of various kinds. Many cultures also produce extracellular polysaccharides (EPS), a carbohydrate material that can impact the texture and stability of the final product. Thus the choice of starter culture impact many of the characteristics of the final yoghurt, such as pH, flavour, aroma and texture.

In this context, it may be mentioned that acetaldehyde is recognised (Pette and Lolkema, 1950 c; Schultz and Hingst, 1954) as the principal flavour component in the flavour of yoghurt. A principal role in acetaldehyde production is attributed to Lb. bulgaricus, although various strains of this species show considerable differences. In the associated growth of Str. thermophilus and Lb. bulgaricus, the rate of acetaldehyde production is considerably increased compared to the single Lb. bulgaricus species (Bottazzi & al., 1973). Thus, the symbiotic relationships between these species favourably influence the production of acetaldehyde in the manufacture of yoghurt. During the production of yoghurt, the formation of acet-aldehyde does not become evident until a certain level of acidification, pH 5.0, has been reached. It attains a maximum pH of 4.2 and stabilises at pH 4.0 (A.Y. Tamime & R.K. Robinson, Yoghurt: Science and Technology).

For many producers, short fermentation time is a desirable property of a starter culture as it means the fermentation tank can be emptied and used for a new batch. However, it is important to remember that also other properties (aroma, texture) of the final product can vary depending on the choice of starter. The choice of starter culture is therefore based on both desired product quality and operational efficiency.

The starter culture is typically adapted to the type of yoghurt that should be produced (e.g. stirred type, set type, drink type and concentrated).

As mentioned earlier, many producers choose to combine the yoghurt starter culture with probiotic bacteria. They can also choose to add bioprotective cultures – cultures containing bacteria that produce substances inhibiting the growth of yeast and mould that might have recontaminated the product. This can help prolong the shelf life of the product

All cultures (starter, probiotic, bioprotective) are delivered deep frozen or freeze-dried from the starter culture producer. More information on starter cultures can be found in Chapter 12, Cultures and starter manufacture.

Plant design

The coagulum formed during fermentation is sensitive to mechanical treatment. This makes the selection and dimensioning of pipes, valves, pumps, coolers, etc., as well as the plant layout, very important. This will be covered in more detail in the next section.

Production of yoghurt

Design of the plant

The quality of the yoghurt in terms of texture and flavour depends on the design of the plant, the treatment of the yoghurt milk, and the treatment of the final product. Modern plants are designed to satisfy demands for high production volumes, continuous treatment and high quality. The level of automation varies, and complete CIP systems are normally integrated into the plants.

The level of automation is usually high in large-scale production. Excessive mechanical treatment of the fermented product must be avoided, as it may cause product defects such as too soft texture and/or low viscosity and whey separation. The total amount of treatment to which the product is subjected must be taken into consideration when the plant is designed. A suitable equipment choice and the optimisation of the plant are consequently a question of achieving a suitable balance between cost and quality.

Overall, hygienic design is crucial for yoghurt production. Hygienic conditions must be maintained in all food industries, not only in the equipment coming in direct contact with the product but also in the premises where production takes place.

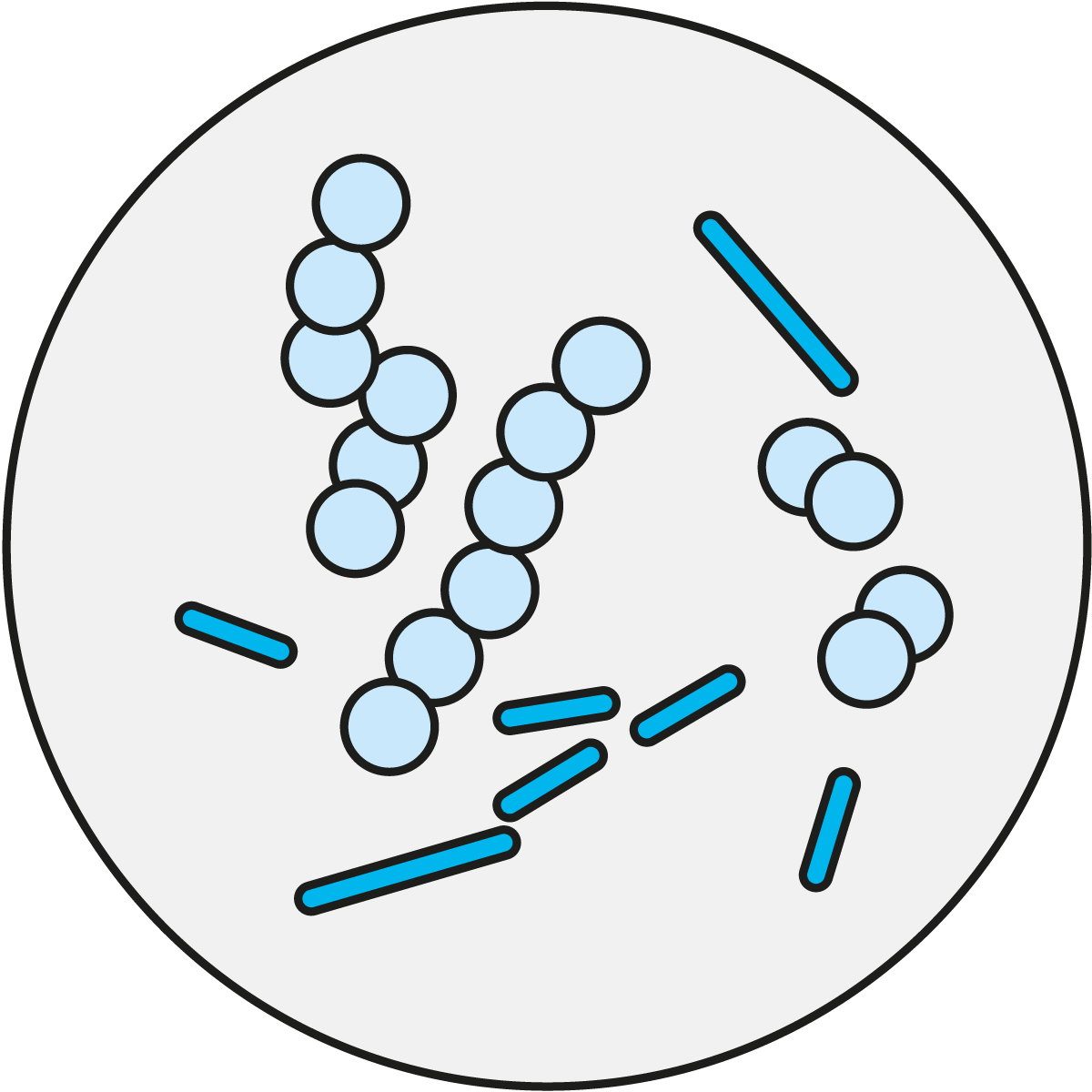

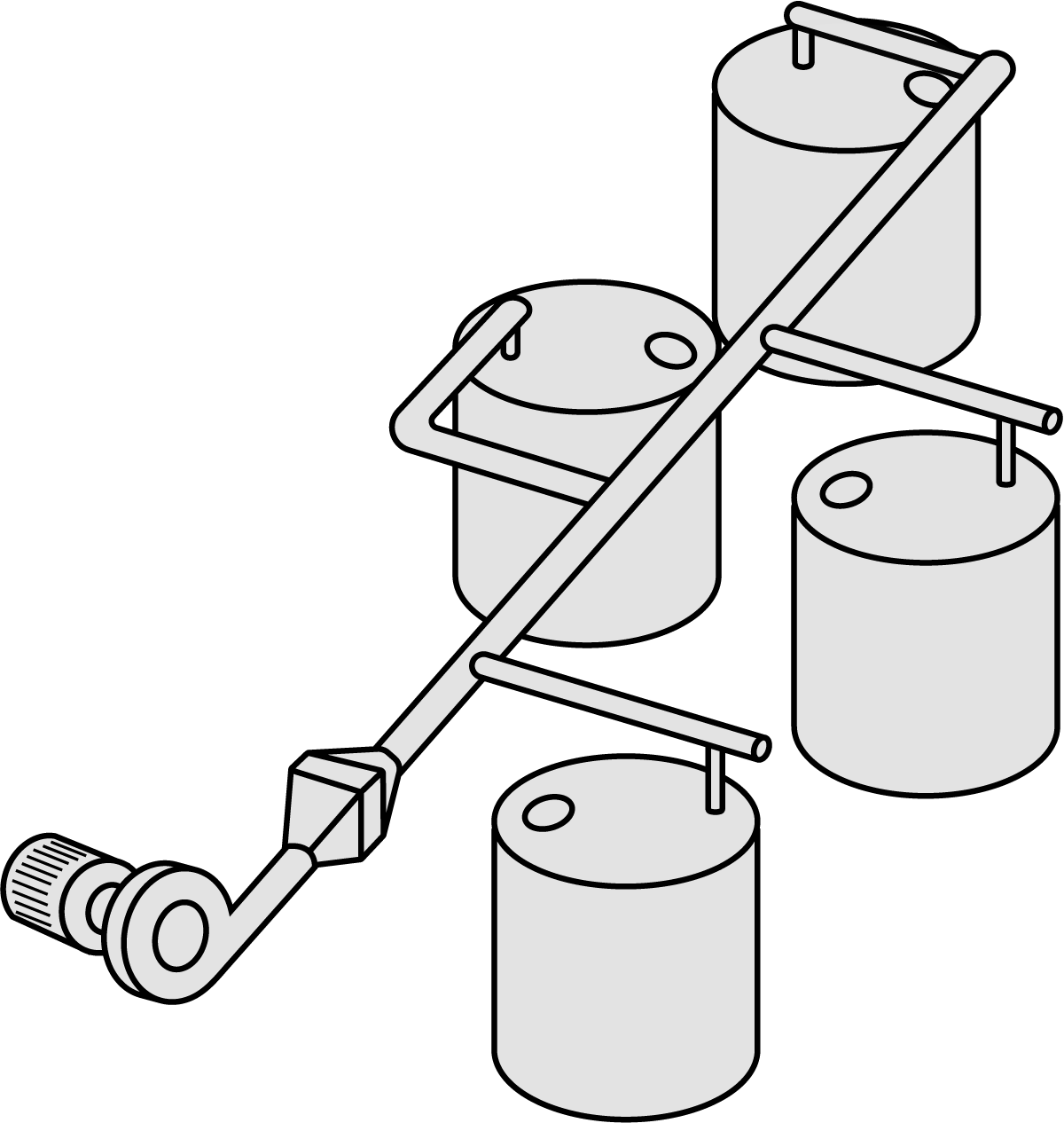

A system based on filtration of the air through sterile air filters, as shown in Figure 13.6, can be installed to clean the air in processing rooms, tanks, etc. to a high standard of purity. In this system, one main filter and a fan serve four tanks. An alternative is that each tank is equipped with a filter. A sterile air filter is capable of trapping particles larger than 0.3 microns and will capture most microorganisms, as the average diameters of cocci, bacilli, and fungi (yeasts and moulds) are 0.9, 0.25 – 10, and 3 – 15 microns, respectively.

The “clean room” conditions will improve production safety and minimise the risk of re-infection. However, the most critical areas for re-infection are fruit addition and packaging. It is therefore of high importance that contamination can be excluded during these operations and that a highly hygienic filling machine is used.

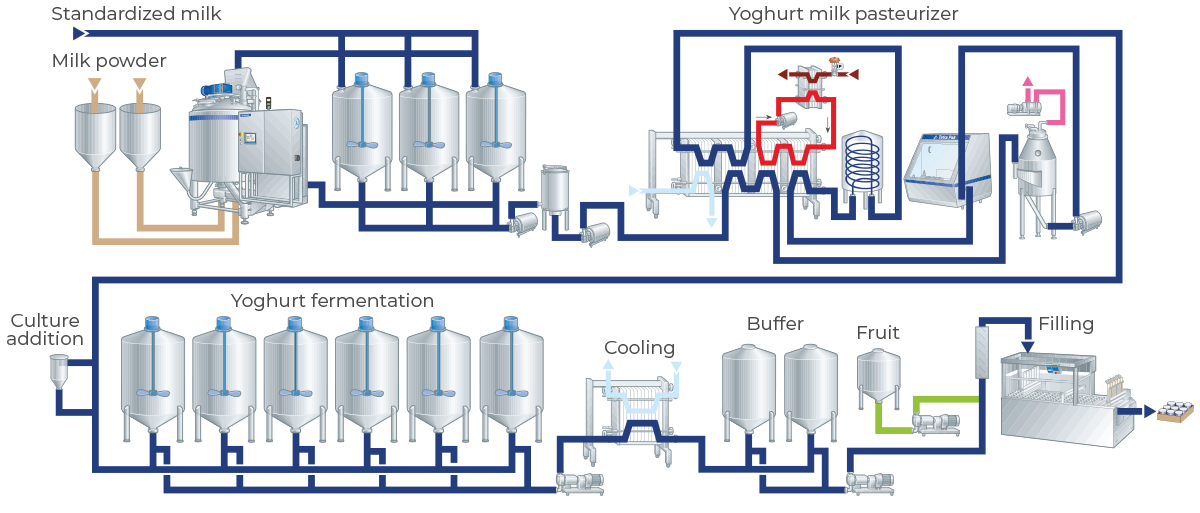

Yoghurt milk preparation

The preparation of the yoghurt milk is the same, regardless of what yoghurt type is to be produced. It includes standardization of the fat and DM contents, homogenization and heat treatment.

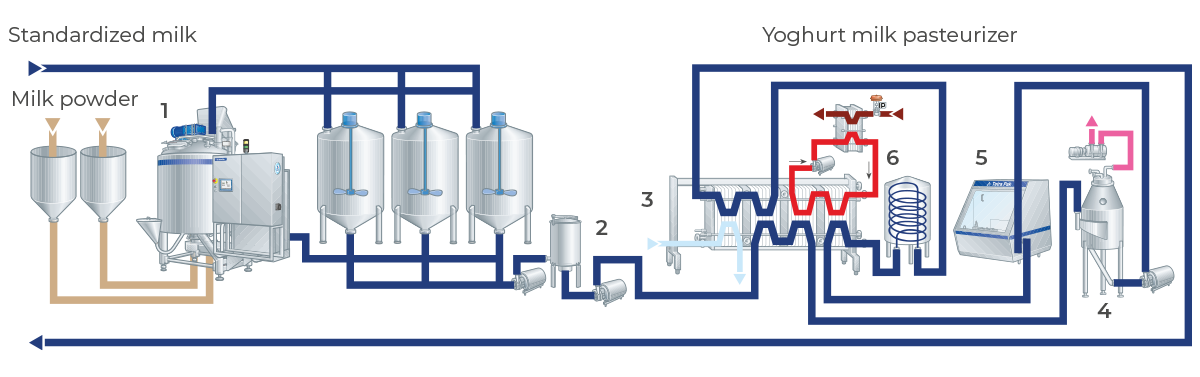

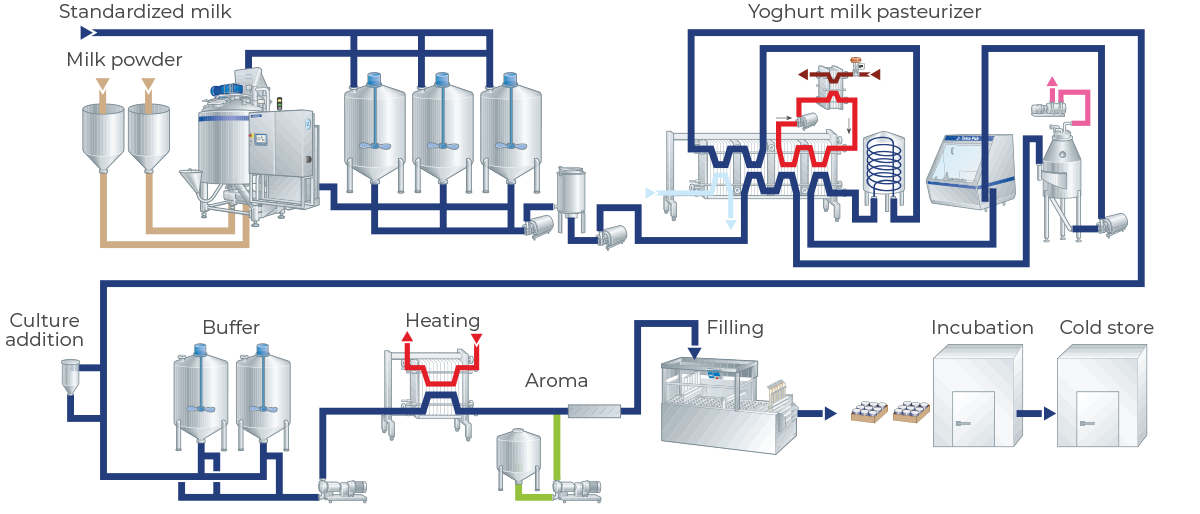

Figure 13.7 shows an example of the design of a process line for yoghurt milk preparation. The milk storage tanks, from which the milk is pumped to the process line, are not shown in the figure. It is assumed that the milk has been standardized to the required fat content and pre-pasteurized before entering the line. In the example, standardization of the DM content takes place by adding milk powder (whole milk powder or skim milk powder) or milk protein powder (like whey protein concentrates). Any additional ingredients, such as stabilisers, sugar, etc., can also be added at this step.

From the balance tank, the milk is pumped to the heat exchanger, where it is pre-heated regeneratively to about 65 °C and fed to the deaerator.

Deaeration

The milk enters the deaerator vacuum vessel at about 65 ºC. Due to the vacuum, the outlet temperature from the deaerator will be about 4 ºC lower than the inlet temperature.

Homogenization

The deaerated milk continues to the homogenizer and is homogenized.

Due to the energy applied during homogenization (200 – 250 bar), the outlet temperature from the homogenizer will be 3 – 5 ºC higher than the inlet temperature.

Pasteurization

The homogenized milk is then further heated in a second regenerative section before going to the final heating section and heated to 90 – 95 °C. The milk then flows to a holding cell dimensioned for a holding time of 5 minutes.

Cooling the milk

After pasteurization, the milk is cooled in the downstream regenerative section followed by a section cooled by water. The desired outlet temperature is the inoculation temperature (typically 40 – 45 °C) and is controlled either by bypassing some of the milk over the regenerative section or by cooling in a separate section with cooling water. Alternatively, if set yoghurt is to be produced, the milk is cooled to a temperature below 10 °C (preferably 5 °C).

An alternative yoghurt milk preparation concept

It is possible to feed raw milk directly into the yoghurt milk pasteurizer instead of using standardized milk, saving resources by avoiding the repetition of many processing steps. This unit will then need to be equipped with a cream separator and inline standardization unit as well as a deaerator, homogenizer and long holding cell. The addition of milk additives can be done in powder form through an integrated mixing unit or by creating a liquid powder slurry that is dosed into the milk after the cream separator.

When the yoghurt milk has been pre-treated and cooled to inoculation (culture addition) temperature, the procedure for further treatment depends on whether set, stirred, drinking, concentrated or ambient yoghurt is to be produced. The block diagrams in Figures 13.9 – 13.10 show the various production stages for each process.

In modern plants, stirred and set types of yoghurt are often produced concurrently. In the production of set yoghurt, the product flow is continuously controlled from the point where the milk is accepted in the pre-treatment section to the packaging of the product. In the production of stirred yoghurt, the pre-treatment of the milk is continuous up to the point at which it is pumped into the fermentation tanks (sometimes also called incubation tank, maturation tank, etc.) to which the culture is added. Continuity is interrupted by fermentation, which can be quite time-consuming.

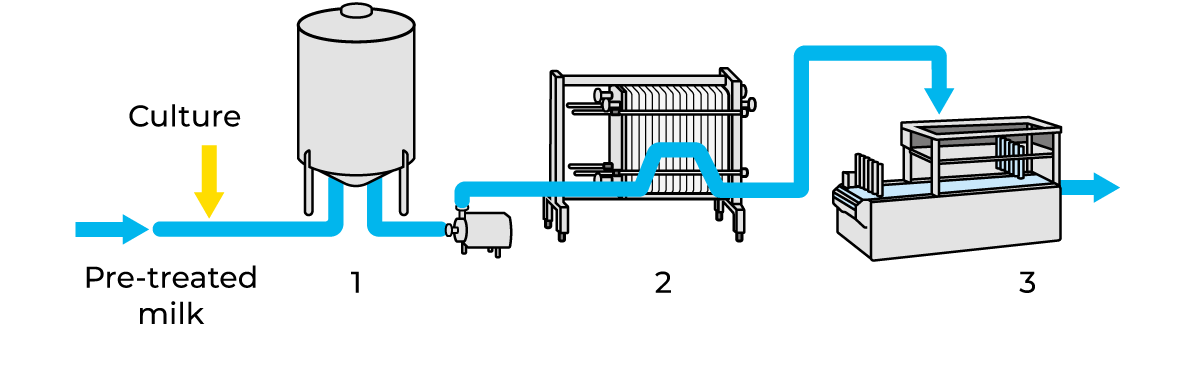

Stirred yoghurt

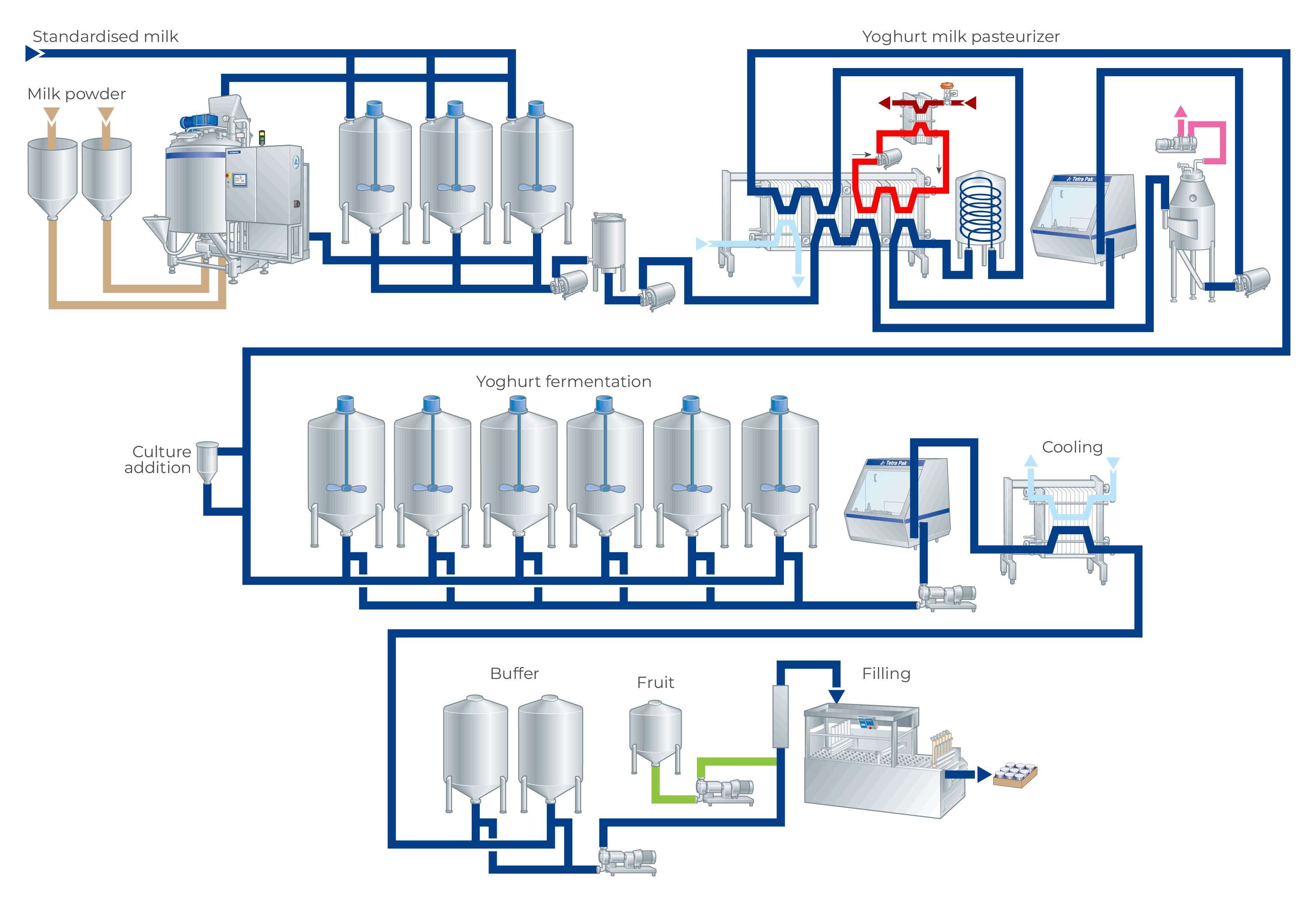

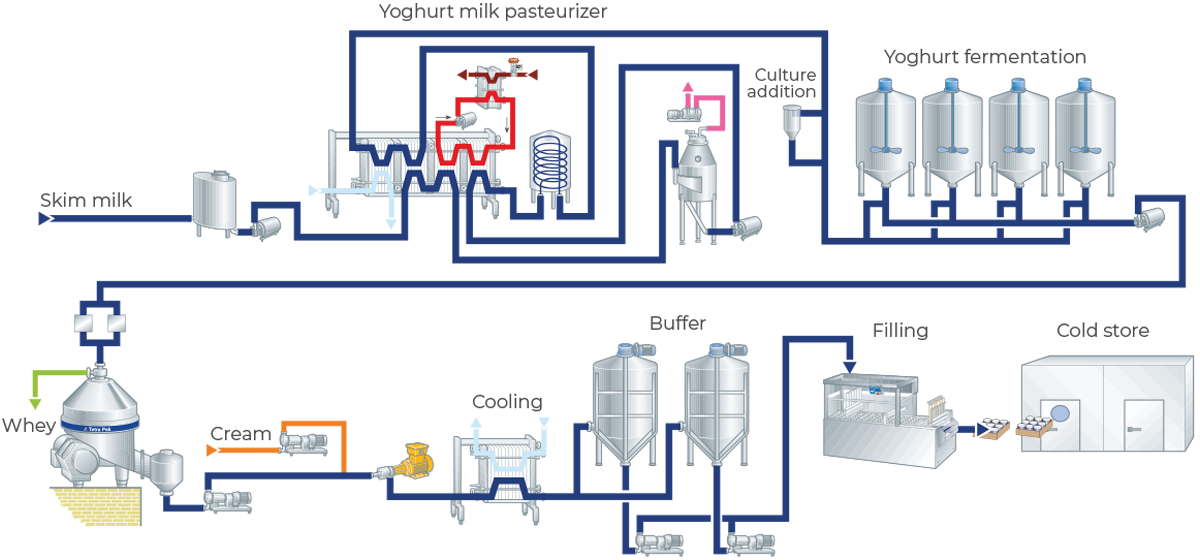

A typical plant for continuous production of a relatively large volume of stirred yoghurt is shown in Figure 13.11.

The pre-treated yoghurt milk, cooled to fermentation temperature, is pumped to the fermentation tanks in succession. Simultaneously, freeze-dried or deep-frozen culture is dosed into the milk stream. After a tank has been filled, agitation commences and continues for a short time to ensure uniform distribution of the starter culture.

The fermentation tanks are insulated, to ensure that the temperature remains constant during the fermentation period. Samples are taken for pH measurement to track the development of acidity.

In typical production of stirred yoghurt, the fermentation period is 4 – 5 hours at 42 – 43 °C.

Cooling the yoghurt

When the required pH (normally about 4.2 – 4.5) has been reached, further increase in acidity is slowed down by cooling the yoghurt to 15 – 22 °C. At the same time, the coagulum must be subjected to gentle mechanical treatment, so that the final product will have the correct texture. In some cases, a smoothing device (slot strainer, back pressure valve or dynamic texturiser) is built into the line before the cooler in order to make the product more homogenous, smooth and shiny.

Cooling takes place in a plate heat exchanger, which is designed to give a gentle mechanical treatment of the product. The capacities of the pump and cooler are often dimensioned to empty a tank in about 30 minutes in order to maintain a uniform product quality. However, some cultures are specially adapted to stop when reaching the target pH by themselves. These cultures are fermenting very slowly in this pH area and thus a longer tank emptying time and cooling time can be accepted.

The cooled yoghurt is pumped to buffer tanks before being routed to the filling machine(s).

Flavouring

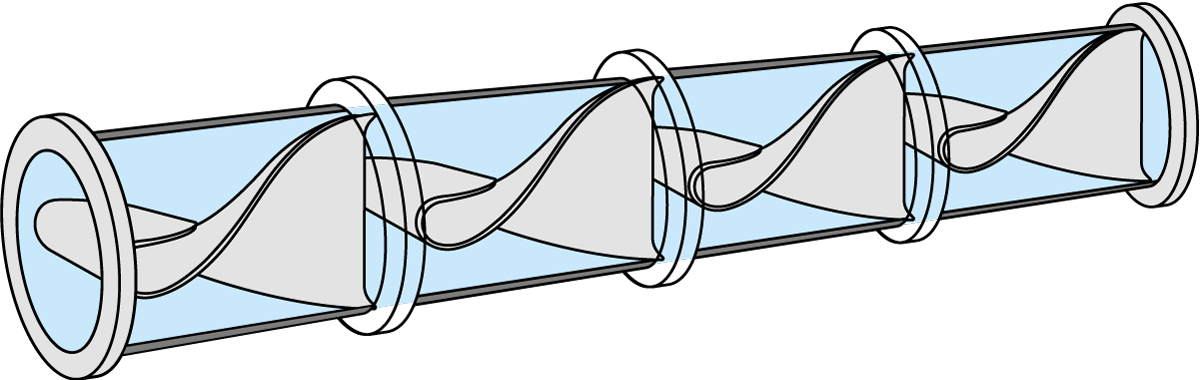

After cooling, the yoghurt is ready for packing. Fruit and various flavourings can be added to the yoghurt when it is transferred from the buffer tanks to the filling machines. This is done continuously with a variable-speed metering pump, which feeds the ingredients into the yoghurt in the fruit-blending unit. The blending unit is often a static mixer (Figure 13.12) but can also be a dynamic mixer. In both cases, the unit is designed to guarantee that the fruit is thoroughly mixed into the yoghurt. The fruit metering pump and the yoghurt feed pump operate synchronously.

The fruit additives can be:

- Sweet; normally 50 – 55% ordinary sugar content

- Natural; unsweetened

As the fruit preparation/aroma is added directly into the yoghurt, it is crucial that it has been heat treated properly (normally this is done by the supplier, but some yoghurt producers also produce their own fruit preparations, doing the heat treatment as well). The temperature programme should be such that all vegetative microorganisms are inactivated without impairing the taste and texture of the fruit. Continuous production, with rapid heating and cooling, is therefore important concerning product quality and economic aspects. Scraped-surface heat exchangers, tubular heat exchangers or tanks with scraper units, can all be used for adequate pasteurization of whole berries or fruit with solid particles.

Following heat treatment, it is important to pack the fruit in sterilised containers under aseptic conditions. Deterioration of fermented milk products is often caused by reinfection from inadequately treated fruit.

Packing

Various types of filling machines are used to pack yoghurt. The sizes of the packages vary from one market to another. In general, the total packing capacity should match the capacity of the pasteurization plant, to obtain optimal running conditions for the plant as a whole. Prolonged storage of yoghurt in buffer tanks can lead to whey separation, changes in flavour and lower viscosity in the final product. Storage time in buffer tanks should therefore be minimised.

Plant design

As mentioned, the plant design is one important factor affecting the quality of the yoghurt and, of course, all other cultured products.

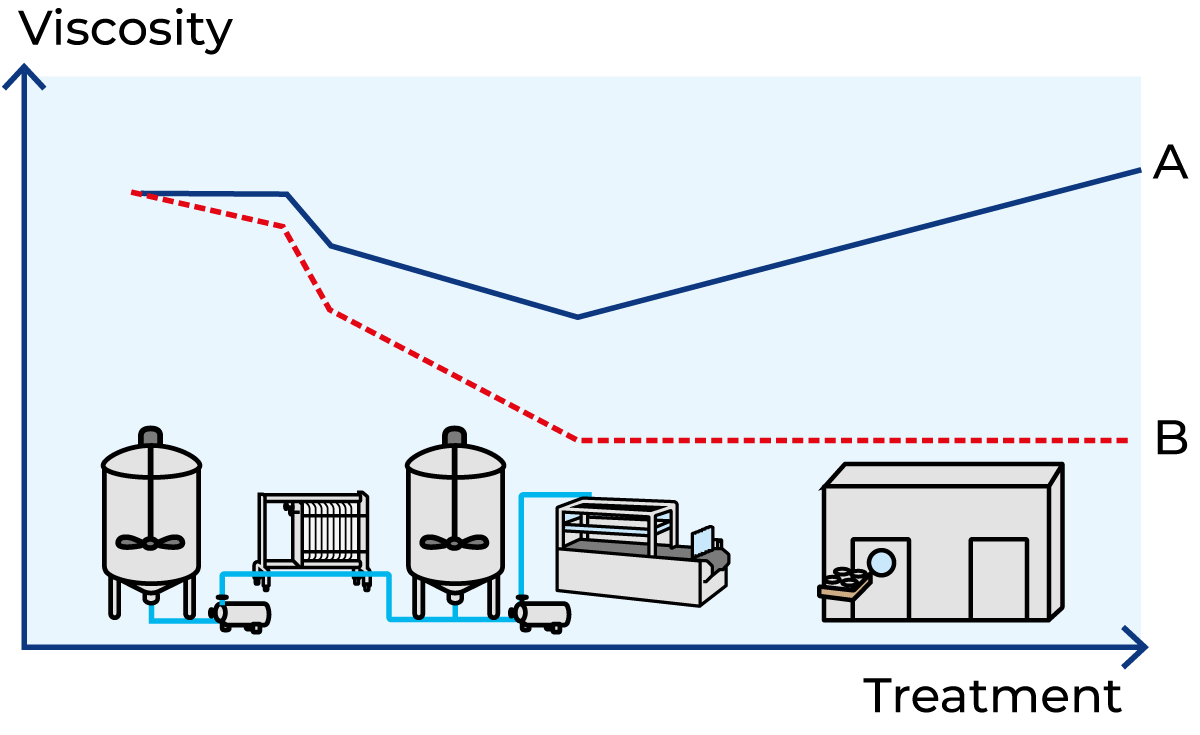

Figure 13.13 shows curves for the development of viscosity in stirred yoghurt from the moment it leaves the incubation tank, via packing and up to about 24 hours in cold storage. Curve A represents the ideal situation when all operations that influence the structure and viscosity are optimised.

The product will inevitably become less viscous while being treated since yoghurt belongs to the class of products with thixotropic flow behaviour. However, if all parameters and equipment are fully optimised, the viscosity will be almost fully regenerated during the first few days in cold storage, and the occurrence of whey separation minimised.

Curve B shows the result when the product has been maltreated on its way from the incubation tank up to packaging and cold storage. If the yoghurt coagulum has been treated too harshly, the viscosity will be too low, resulting in a liquid product with a high risk of whey separation.

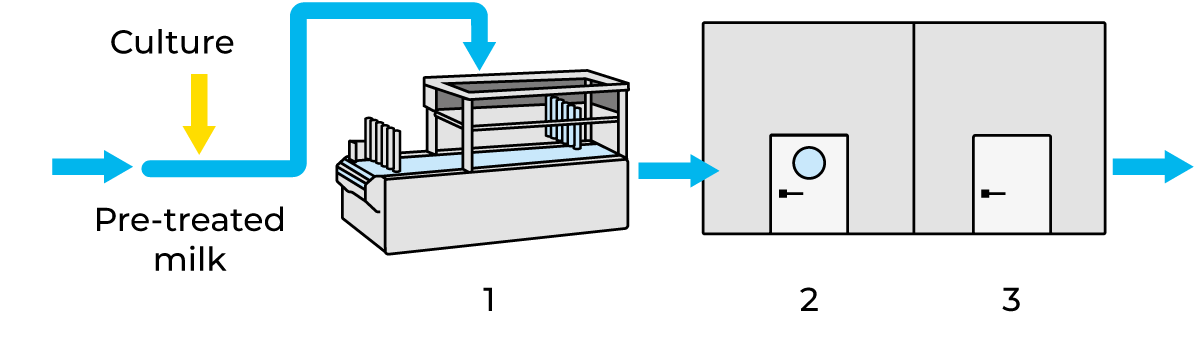

Set yoghurt

The most frequently used system for the production of set yoghurt is illustrated in Figure 13.14. This system offers flexibility in production planning because it is not necessary to match preparation capacity to packing capacity.

The milk, prepared in the same way as for stirred yoghurt, is cooled to a temperature of less than 10 °C, preferably to 5 °C, and pumped into one, two or more buffer tanks. Starter culture is added either inline (as shown in 13.14) or directly to the tank. Following culture inoculation and thorough stirring, the milk is ready to be heated in-line to the exact incubation temperature, before being packed in containers.

Flavouring/packing

Flavouring can be continuously metered into the milk stream before the filling machine. If fruit or additives with particles are added, these have to be dosed into the packages or cups first, before they are filled with inoculated milk. It is, however, important to remember that additives with low pH have a negative influence on fermentation.

Fermentation and cooling

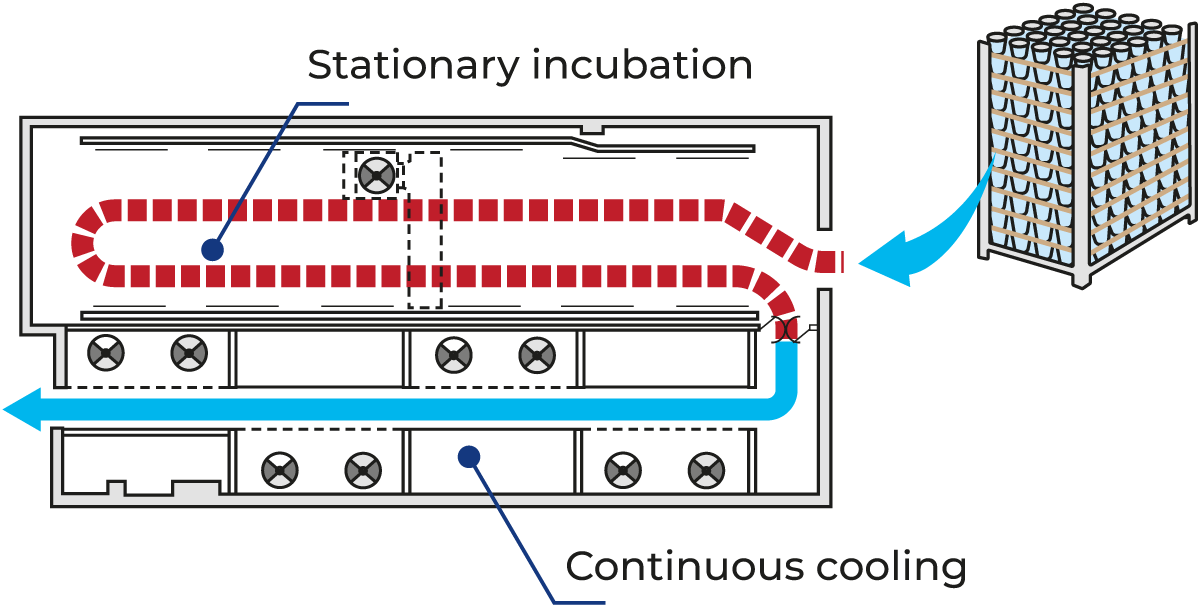

After filling, the packages are put onto pallets and transferred for incubation and cooling. There are two principal ways to do this, using namely:

- A combined incubation/cooling chamber, when the pallets are stationary through both incubation and cooling, before being trucked to the final cold store.

- An incubation room able to accommodate a large number of filled pallets. After adequate incubation, the pallets are trucked to a conveyor passing through the cooling sections enclosed in a tunnel. This system offers continuous cooling and is illustrated in Figure 13.15.

Fermentation

The filled packages/containers are placed in crates of open design, and at a certain distance from each other, so that the circulating warm/cold air for the incubation and cooling room or chamber can reach every individual container. The crates are normally stacked on pallets, which are then trucked into the incubation room. This ensures uniform quality, provided that the temperature is accurately controlled.

Cooling

When the empirically determined time to reach optimum pH (typically 4.5) has passed, it is time to start cooling. The normal target temperature is 18 – 20 °C; it is important to stop further growth quickly, which means that a temperature of about 35 °C should be reached within 30 minutes, and 18 – 20 °C after another 30 – 40 minutes.

Final cooling, normally down to 5 °C, takes place in the cold store, where the products are held to await distribution.

Cooling efficiency depends on the size of the individual package, and the design of the crates as well as the airflow and temperature.

The pallets (crates) are stationary during incubation. They are placed in the incubation room/chamber in such a way as to facilitate first-in/first-out handling. In a typical incubation period of 3 – 3.5 hours, the product must not be exposed to any mechanical disturbance during the last 2 – 2.5 hours, when it is most sensitive to the risk of whey separation.

The cooling capacity should be adequate to achieve the above-mentioned temperature programme. As a guide, the total cooling time is about 65 – 70 minutes for small packages (0.175 – 0.2 kg sizes) and about 80 – 90 minutes for large packages (0.5 kg size).

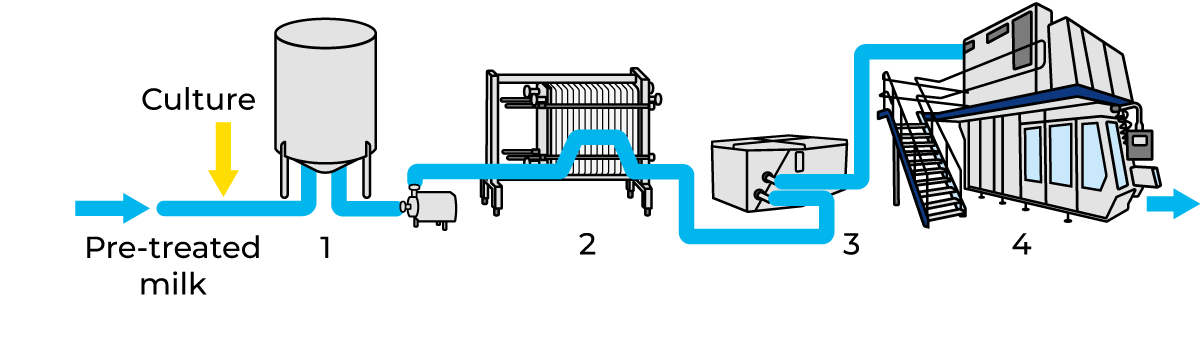

Drinking yoghurt

Low-viscosity drinkable yoghurt, normally with a low fat content, is popular in many countries. The composition can be the same as for stirred yoghurt but can also be reduced in dry matter by, e.g. dilution with water. Figure 13.16 shows a process alternative for the production of drinking yoghurt.

Yoghurt intended for the production of drinking yoghurt is produced in the typical way, by using fermentation in tanks. The viscosity of the product is intentionally reduced by homogenization or mixing after fermentation. To achieve a stable drinking yoghurt without sedimentation, a stabiliser (commonly modified starch but pectin and/or CMC are also used) is often included in the formulation.

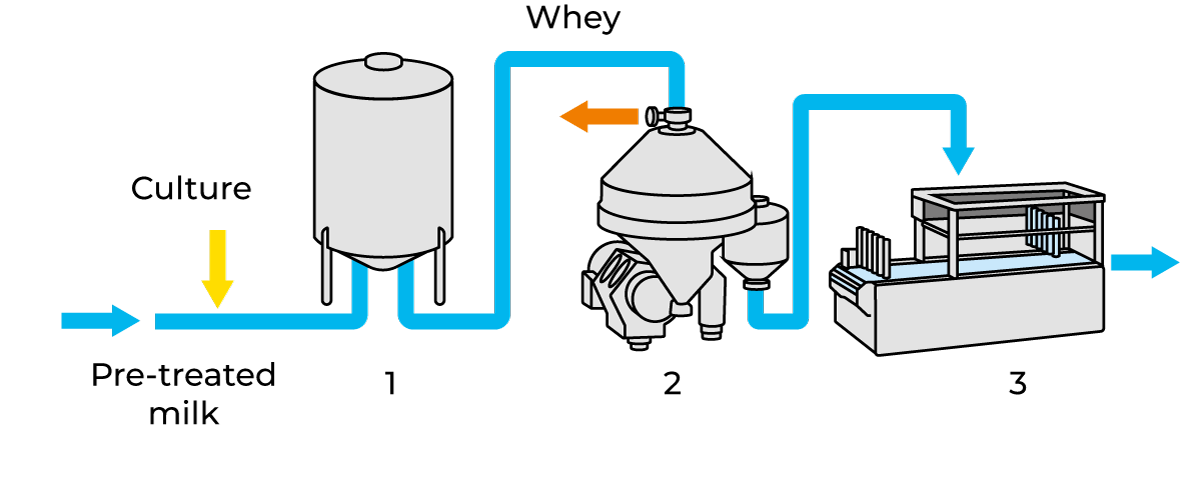

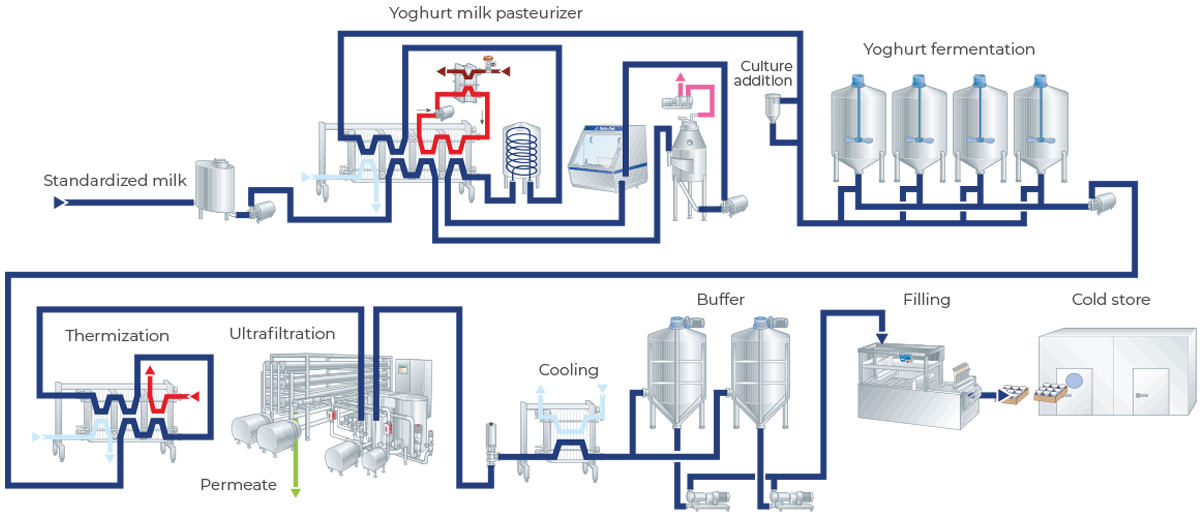

Concentrated yoghurt

Concentrated yoghurt is produced in many countries. It is also known by names like strained yoghurt, Greek yoghurt, Labneh, Skyr, etc., depending on country or region. In concentrated yoghurt, the dry matter of the product is increased after fermentation and whey is drained off from the coagulum. There are two main production methods used today: concentration by nozzle separator and concentration by ultrafiltration.

In both cases, standardized milk is heat treated at 90 – 95 ºC for 5 minutes before it may be homogenized (if required) and then cooled to fermentation temperature before it is fed to the incubation tanks. After fermentation, the yoghurt is agitated. It is then either pumped directly to a nozzle separator, or thermised at approximately 55 °C for 3 minutes and then fed to an ultrafiltration unit. There the whey/ permeate is separated and the concentrated yoghurt is pumped out for cooling and packing.

In addition to these two production methods, it is also possible to standardize the milk to final composition before fermentation. Care has to be taken when using this method, because if the protein content is increased too much there is a risk of off flavours and sandiness in the finished product. No matter which method is used to produce the concentrated yoghurt, the final product is often very viscous. Compared to a stirred yoghurt line, extra care has to be taken in the design and dimensions of the buffer tanks and surrounding equipment to make sure that the thick product can be emptied from the tanks.

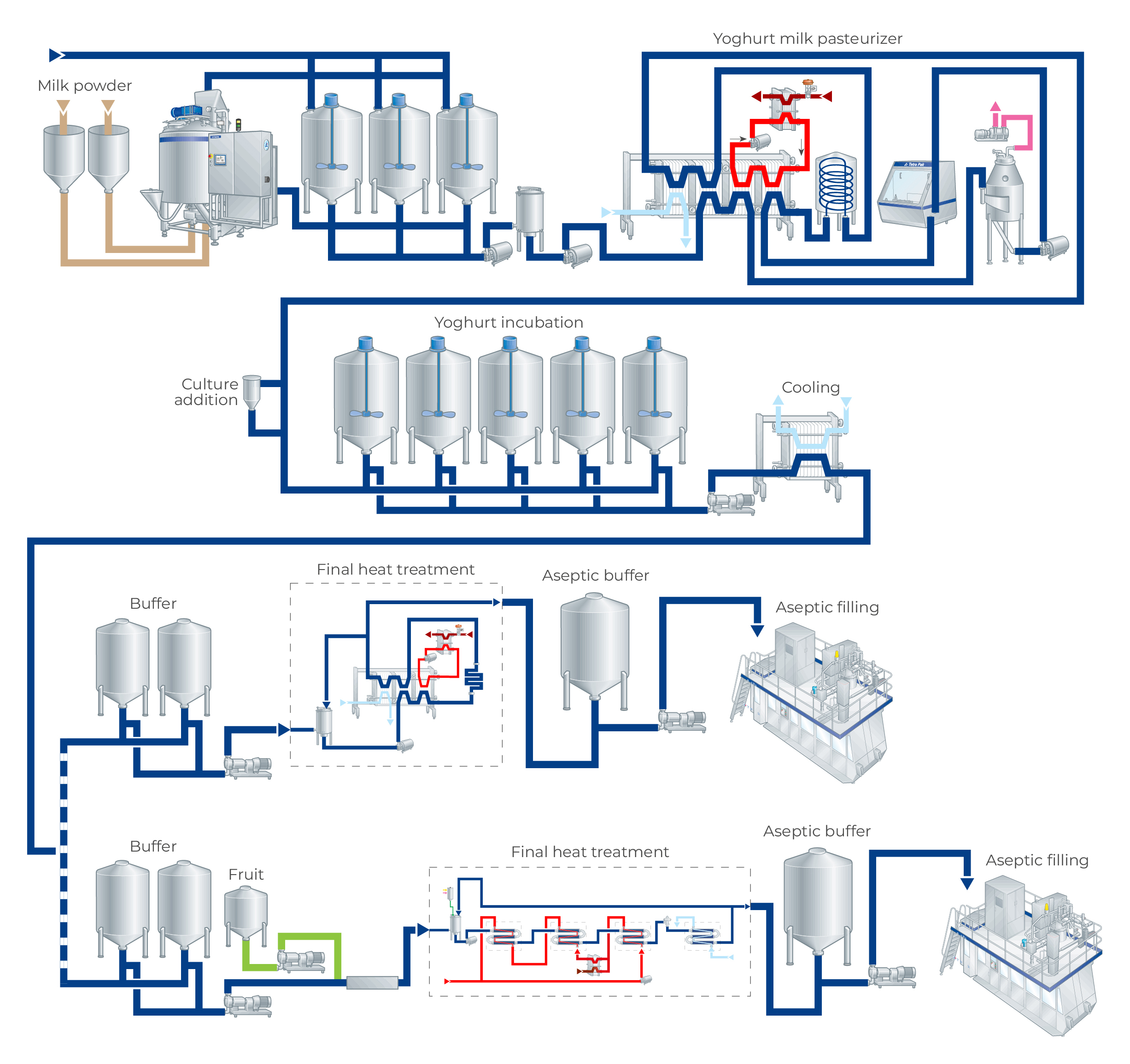

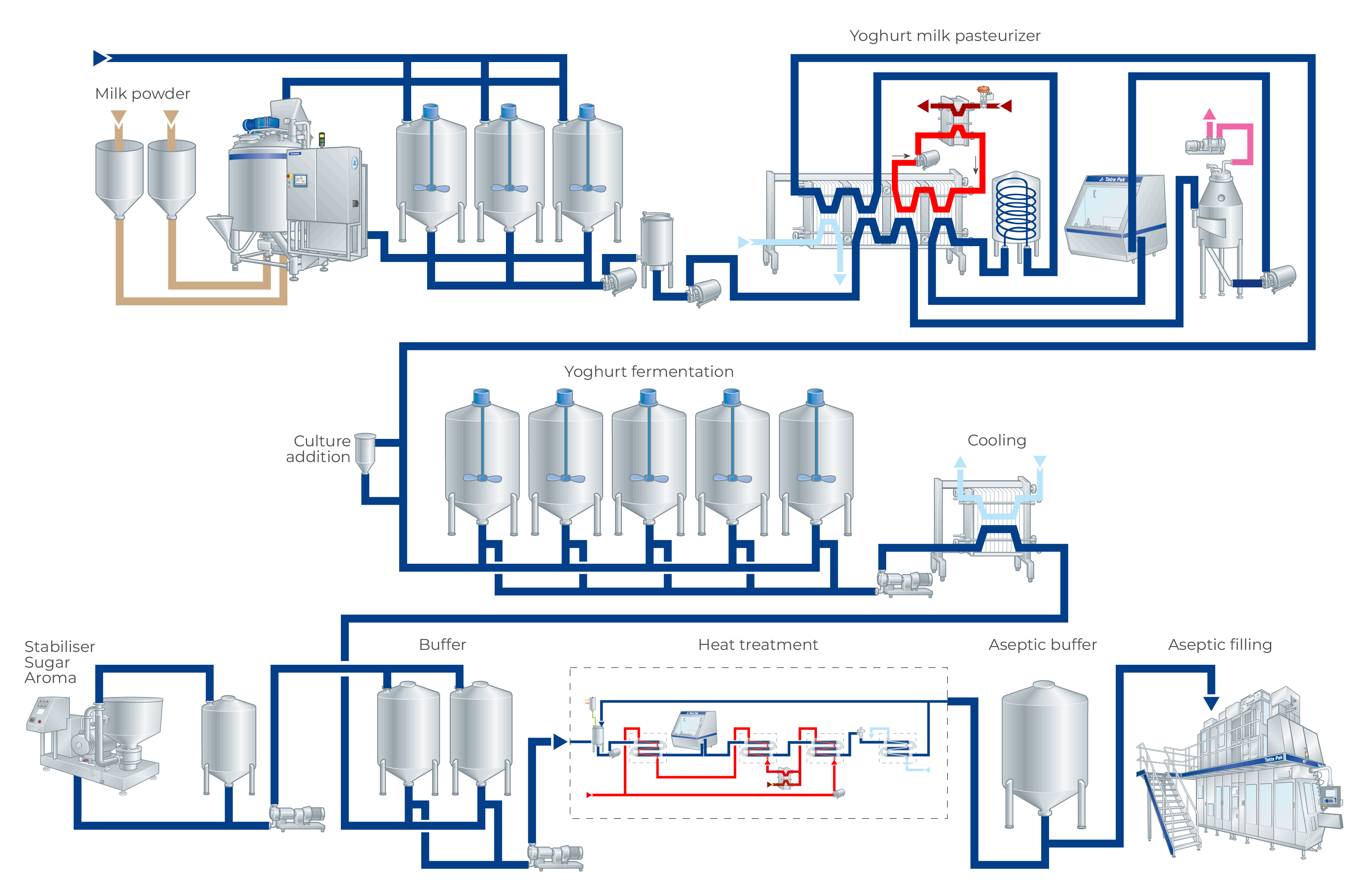

Ambient yoghurt

In some countries, it is difficult to maintain the integrity of the cold chain during distribution. Also, as producers are gathering their production in more centralised production units, markets are becoming geographically larger and transport distances longer. This has led to the development of new variants of yoghurt.

The shelf life of fermented milk products can be extended by:

- Heat treatment of the finished product either immediately before filling or in the package

- Production and packaging under aseptic (or ultra-high hygienic) conditions

By applying a heat treatment to the yoghurt after fermentation, a “thermised yoghurt” that is less sensitive to fluctuations in the cold chain can be created. By applying heat treatment as well as aseptic or ultra-high hygienic processing and filling a product that is possible to store and distribute at ambient temperature, ambient yoghurt – also referred to as “UHT-yoghurt”, “post-pasteurized yoghurt” or “sterilised yoghurt”– can be produced. In both products, stabilisers are added to counteract the negative effect of the heat treatment on the texture and stability of the product, as well as ensure the quality of the product throughout its shelf life.

It should be noted that if the microorganisms in the yoghurt are killed by heating, the product is then, according to the definition in many countries, not allowed to be called yoghurt. They can, however, often be called "yoghurt-based".

Heat treatment of yoghurt

The shelf life of all types of yoghurt (stirred, set, drinking and concentrated) can be prolonged by heating.

Heat treatment of yoghurt prolongs its shelf life by:

- Inactivating the starter bacteria and their enzymes

- Inactivating contaminants such as yeasts and moulds

Production under aseptic conditions

In aseptic production, measures are taken to prevent the yoghurt from being infected by yeast and moulds after the final heat treatment. These microorganisms would destroy the product, as they can survive and multiply in an acid environment and can cause off-flavours and whey separation. The prime measure is thorough cleaning and sterilisation of all surfaces in contact with the product. The special feature of aseptic production is, however, that it takes place under aseptic conditions; using aseptic tanks which are permanently pressurised with sterile air, remote-controlled aseptic valves, aseptic dosing devices for fruit and aseptic filling machines. Infection by airborne microorganisms can thus be prevented.

Heat treatment before filling

In the production of thermised yoghurt, the yoghurt is heat-treated at 60 – 70 °C for a few seconds. This heat treatment will minimise post-acidification, giving the yoghurt a bacteriological shelf life in cold storage of 1 – 2 months if packed under high-hygienic conditions.

If the aim is to produce a yoghurt for ambient storage with a shelf life of 4 – 12 months, the heating temperature is in the range of 75 – 110 °C for 5 – 20 seconds, depending on factors such as milk formulation, milk treatment, pH of yoghurt, etc. The product is then packed in an aseptic or ultra-high hygienic filling machine to prevent reinfection.

As mentioned earlier, the production of heat-treated yoghurt requires the addition of stabilisers. The type of stabiliser(s) used depends on the desired characteristics of the final product and highly impacts the production line design. These characteristics, in turn, determine the heat treatment programme that can be used and how the process line needs to be designed.

For high-viscous ambient yoghurt, the additives used are typically combinations containing modified starch, pectin, and gelatine or some type of gum component to give the product a viscous texture as well as avoid whey separation and sedimentation during shelf life. The line design, as illustrated in 13.20, is focused on minimising the mechanical shear to the product to maintain its viscosity. The stabilisers are often added to the milk before yoghurt milk pasteurization.

Pectin is a common stabiliser used in low-viscous ambient yoghurt products to avoid sedimentation, whey separation and a sandy mouth feel. Other stabilisers which can be used are CMC or mixes of the two. If pectin is used, it is preferably added as a water solution to the yoghurt before the final heat treatment (See Figure 13.19). The amount of water strictly needed for this solution, often referred to as slurry, is small (maybe 10% of the total product volume). In many countries, however, it is popular to add additional water/juice at this point, making up as much as 70% of the final product. Other ingredients added to the slurry are sugar and aroma. To achieve the optimal stabilising effect of the pectin, mechanical treatment, e.g. homogenization, should take place.

If the final product contains fruit, different processing solutions can be used.

- Yoghurt and fruit are mixed and then heat-treated and cooled together before packaging.

- Yoghurt and fruit are heat-treated and cooled separately and then mixed before filling.

Heat treatment after filling

Yoghurt for ambient distribution can be heat-treated at, e.g. 60 – 70 ºC for 30 minutes in packages inside special pasteurizing chambers. The time is of course dependent on the size and shape of the package. Additionally, for this type of product, stabilisers must be used.

Kefir

Kefir is one of the oldest cultured milk products. It originates from the Caucasus region and is today produced in many countries. The raw material is milk from goats, sheep or cows.

Kefir should be viscous and homogenous and have a shiny surface. The taste should be fresh and acidic, with a slightly fizzy mouthfeel and a slight flavour of microorganisms, such as yeasts and aroma-and-lactic-acid-forming bacteria. The yeasts represent about 5 – 10% of the total microflora.

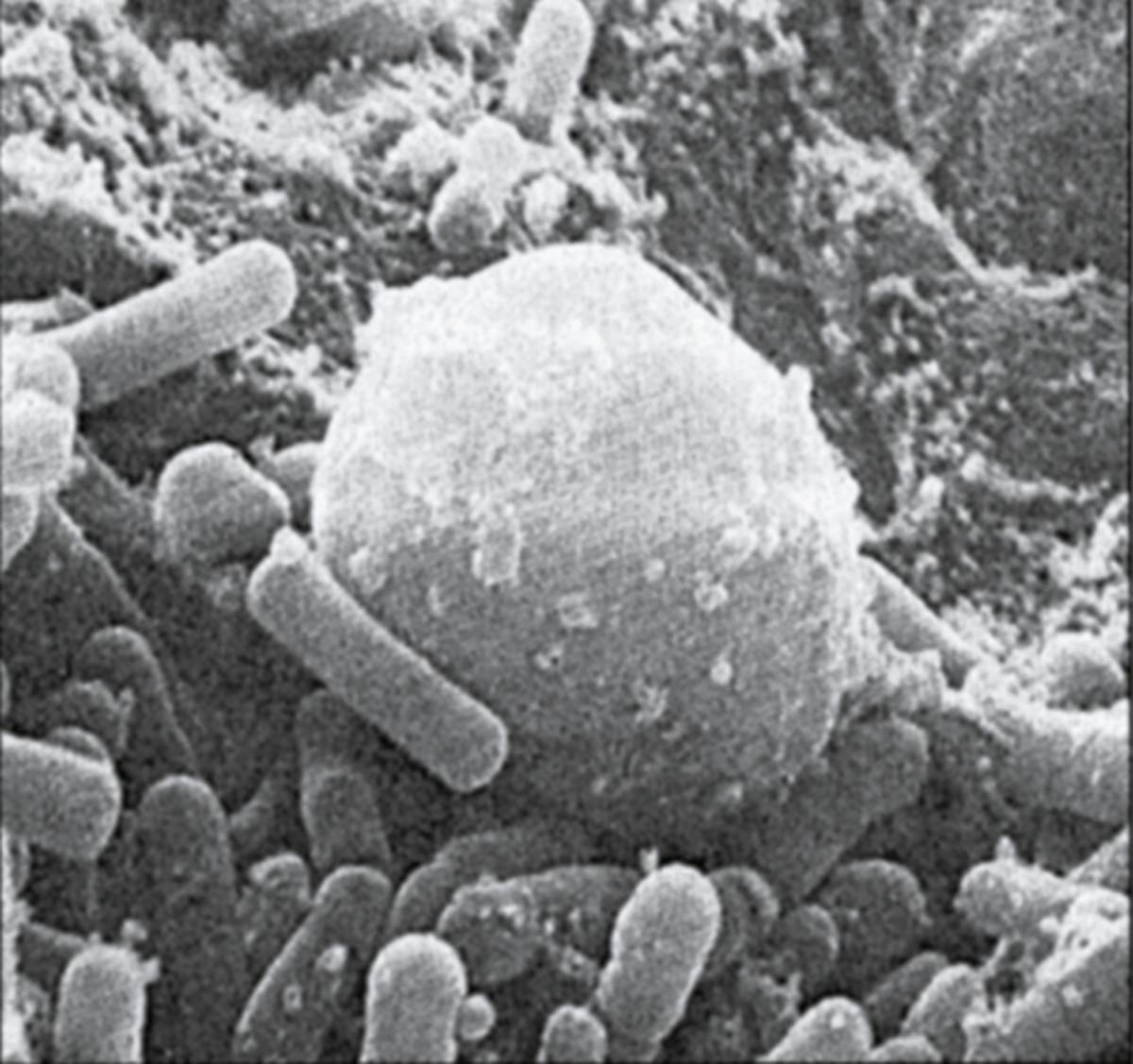

The kefir grains are yellowish and about the size of a cauliflower floret, i.e. about 15 to 20 mm in diameter. The shape of the grains is irregular, as seen in Figure 13.21. They are insoluble in water and most solvents. When steeped in milk, the grains swell and become white.

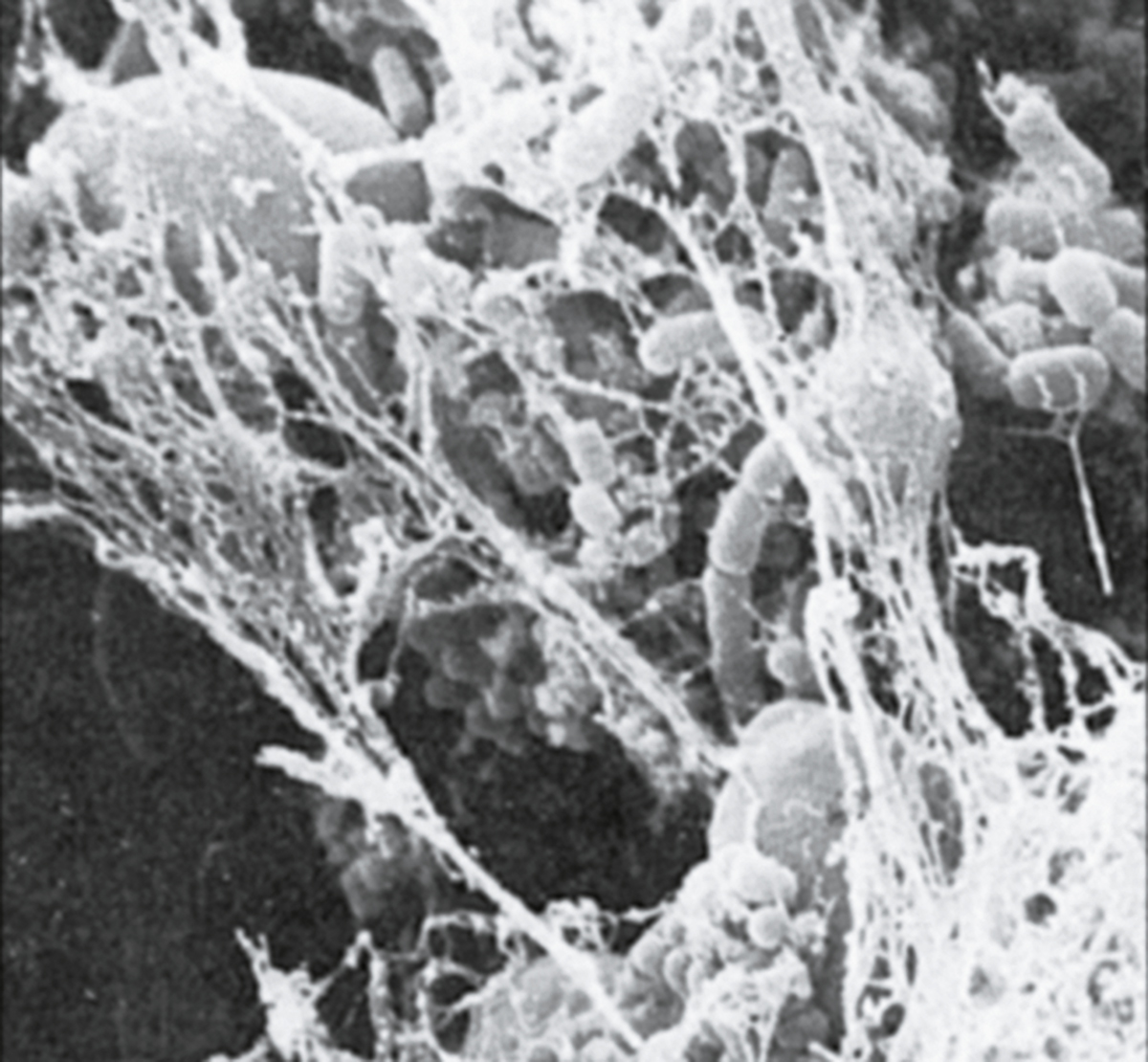

Figure 13.21 shows yeast and lactic acid bacteria at the surface of the kefir grain. The “ball” in the centre is a yeast cell and the rods are different kinds of bacteria. Figure 13.22 shows the centre of a kefir grain. Yeast and bacteria are united by a network consisting mainly of proteins and polysaccharides.

During the fermentation process, the lactic acid bacteria produce lactic acid, whereas the lactose-fermenting yeast cells produce alcohol and carbon dioxide. Some breakdown of protein also takes place in the yeast metabolism, from which Kefir derives its special yeast aroma. The contents of lactic acid, alcohol and carbon dioxide are controlled by the incubation temperature during production.

Depending on local conditions and requirements, the equipment and process variables may differ significantly from one manufacturer to another Kefir-type products can also be produced in the same way as stirred-type yoghurt by using a highly concentrated frozen or freeze-dried starter culture.

Raw materials

As with other fermented milk products, the quality of the raw material is of major importance. It must not contain any antibiotics or other bactericidal agents. The raw material for kefir manufacture can be milk from goats, sheep or cows.

Production of starter culture

Kefir culture is normally produced from milk of various fat contents, but skim milk and reconstituted skim milk can also be used.

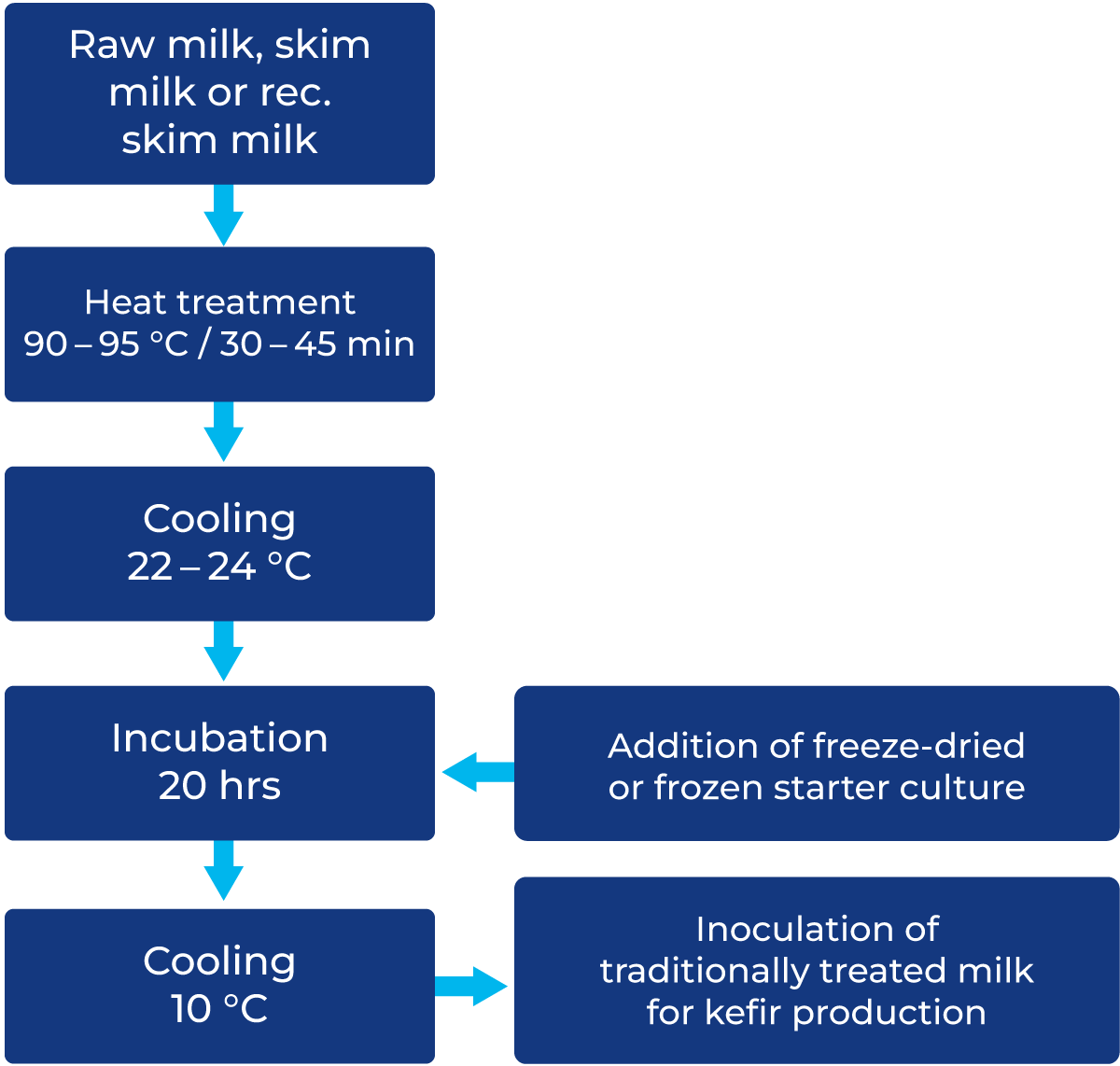

As in the propagation of starter cultures for other fermented milk products, the milk substrate must be thoroughly heat-treated to inactivate bacteriophages. Production takes place in two stages. The reason for this is that kefir grains are bulky and awkward to handle, whereas relatively small volumes of mother culture are easier to control. Figure 13.24 shows the various process stages.

In the first stage, the pre-treated substrate is inoculated with active kefir grains. Incubation takes place at about 23 °C, and the proportion of grains is about 5% (1 part grains to 20 parts substrate) or 3.5% (1 part grains to 30 parts milk). The incubation time is about 20 hours, as the grains tend to sink to the bottom. Intermittent stirring for about 10 – 15 minutes every 2 – 5 hours is recommended. When the desired pH value, for example 4.5, has been reached, the culture is stirred before the grains are strained off from the mother culture, now also called filtrate. The strainer has holes with a diameter of 3 – 4 mm.

The grains are washed in the strainer with boiled and cooled water (sometimes skim milk). They can then be reused to incubate a new batch of mother culture. The microbial population grows by about 10% per week during incubation, so the grains must be weighed and the surplus removed before the batch is reused. In the second stage, the filtrate can be cooled to about 10 °C if it has to be stored for a few hours before being used. Alternatively, if large quantities of kefir are going to be produced, the filtrate can be immediately inoculated into the pre-treated milk intended as the substrate for the bulk starter. The dosage is 3 – 5% of the volume of the substrate. After incubation at 23 °C for approximately 20 hours, the bulk starter is ready for inoculation into the kefir milk.

Production of kefir

The process stages are much the same as for most fermented milk products. The following combination is typical for the traditional production of kefir:

- Fat standardization (not always practised)

- Homogenization

- Pasteurization and cooling to incubation temperature

- Inoculation with starter culture (here also called "filtrate")

- Fermentation in two stages (this, together with the specific culture, is characteristic of kefir)

- Cooling

- Packing

Fat standardization

The fat content of kefir is reported to vary between 0.5% and 6%. The raw milk is often used with its original fat content. However, fat contents of 2.5 – 3.5% are frequently specified.

Homogenization

Following fat standardization, if any, the milk is homogenized at about 65 – 70 °C and 175 – 200 bar.

Heat treatment

The heat treatment programme is the same as for yoghurt and most cultured milks: 90 – 95 °C for 5 minutes.

Inoculation

Following heat treatment, the milk is cooled to inoculation temperature, usually about 23 °C, after which 2 – 3% starter is added.

Fermentation

The fermentation period is normally divided into two stages, acidulation and ripening.

The acidulation stage

The acidulation stage lasts until a pH value of 4.5 is reached or, expressed as acidity until 85 – 100 °Th (35 – 40 °SH) has developed. This takes about 12 hours. The coagulum is then stirred and pre-cooled while still in the tank. At a temperature of 14 – 16 °C, cooling is stopped, and agitation is discontinued.

The ripening stage

The typical slightly yeasty flavour starts to develop during the following 12 – 14 hours. Final cooling commences when the acidity has reached 110 – 120 °Th (approximately pH 4.4).

Cooling

The product is cooled rapidly to 5 – 8 °C in a heat exchanger. This stops any further reduction in pH. It is of vital importance that the product is treated gently when cooled and during subsequent packing.

Mechanical agitation in pumps, pipes and filling machines must therefore be minimised. Air entrainment must also be avoided, as air increases the risk of whey separation in the product.

Alternative kefir production

As previously mentioned, the traditional method of preparing bulk starters for kefir manufacture is laborious. This, in combination with the complexity of the microflora, sometimes leads to unacceptable variations in product quality.

To overcome these problems, frozen or freeze-dried concentrated kefir culture, which is handled in the same way as similar forms of other cultures, has been developed at culture suppliers.

After a thorough examination of kefir grains obtained from various sources, strains of bacteria and yeasts were isolated and tested for various growth characteristics, lactic acid production, aroma formation, etc. The composition of the concentrated culture was then chosen to obtain a balance of microorganisms in the bulk starter and product comparable to that of traditional kefir manufactured with grains in a mother culture. The block chart in Figure 13.25 illustrates the processing stages when producing kefir with a concentrated frozen or freeze-dried starter culture.

Compared to traditional bulk starter production, the technique based on freeze-dried culture reduces the number of process stages, and with it the risk of reinfecting the culture.

It should however be noted that kefir produced by this type of concentrated culture is not allowed to be called "kefir" in some countries. It is instead called something like "kefir type".

Fermented cream

Fermented cream products have been used for decades in some countries, often in cooking.

Fermented cream forms the basis of many dishes in the same manner as yoghurt. It can have a fat content of 10 – 12% or 20 – 30%. The starter culture contains Lc. lactis subsp. lactis and Lc. lactis subsp. Cremoris whereas Lc. lactis subsp. lactis biovar. diacetylactis and Leuc. mesenteorides subsp. cremoris bacteria are used for the aroma.

Fermented cream has a uniform structure and is relatively viscous. The taste should be mild and slightly acidic. Fermented cream, like other fermented products, has a limited shelf life. Strict hygiene is important to ensure product quality.

Yeast and moulds can develop in packages which are not airtight. These microorganisms occur mainly on the surface of the cultured cream. In the event of extended storage, the lactic acid bacteria enzymes, which break down β-lactoglobulin, become active and the fermented cream becomes bitter. The cultured cream also loses its flavour because carbon dioxide and other aromatic substances diffuse through the packaging.

Long-life fermented cream can also be produced by heat treatment of the product before packing. Stabilisers are added in the same way as they are for other heat-treated fermented dairy products.

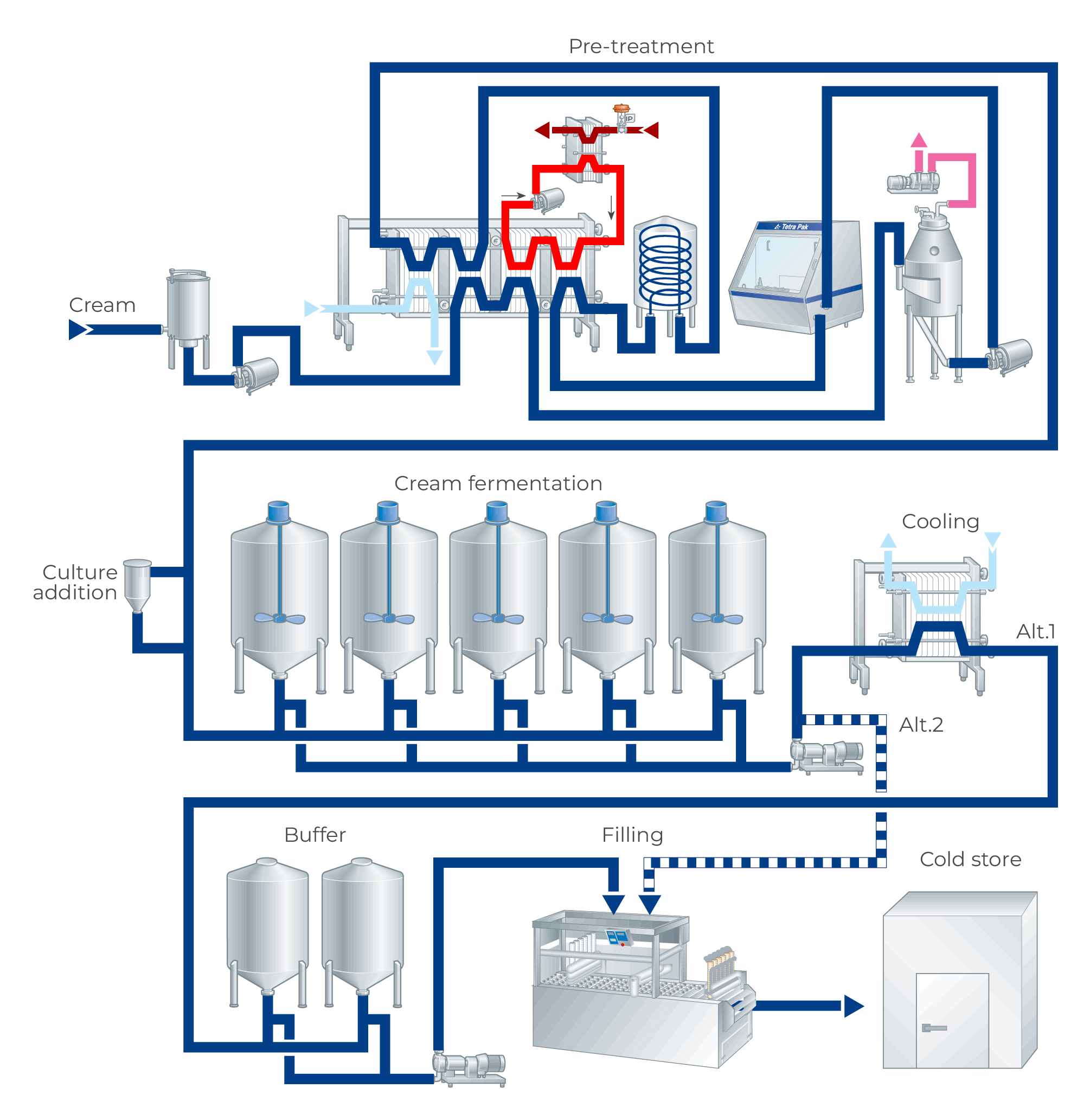

Production of fermented cream

The process line for the production of fermented cream includes equipment for standardization of fat content, homogenization and heat treatment of the cream, and also inoculation and packing.

Homogenization

The cream is homogenized. For cream with 10 – 12% fat, the homogenization pressure is normally 150 – 200 bar at 60 – 70 °C. Up to a certain point, an increase in homogenization temperature increases the texture/viscosity of the final product. For cream with 20 – 30% fat, the homogenization pressure should be lower, 100 – 120 bar, as there is not enough protein (casein) to form membranes on the enlarged total fat surface.

Heat treatment

The homogenized cream is normally heat treated for 5 minutes at 90 °C. Other time/temperature combinations can be used if the homogenization technique is carefully matched to the heat treatment.

Inoculation and packing

The pre-treated cream is cooled to an inoculation temperature of 18 – 21 °C, then 0.01% concentrated culture or 1 – 2% bulk starter culture is added. Inoculation can take place in the tank or packaging. The fermentation time is 18 – 20 hours. When fermentation is completed, the fermented cream is cooled quickly to prevent any further pH reduction. For low-fat (10 – 12%) products the cooling can take place in a plate heat exchanger as the viscosity is rather moderate. The higher the fat content, the more viscous the fermented cream is. This will make cooling in a plate heat exchanger difficult due to the high pressure drop. The fermented cream can then be fed to the packaging directly and the product is then cooled in the package (Figure 13.26).

The cream is sometimes inoculated, packaged and fermented in the packages to avoid mechanical treatment. This is especially the case when a high-fat cream is produced. After inoculation of the cream and subsequent packing, the product is stored at 20 °C until the acidity of the fat-free phase is about 85 °Th, which takes about 16 – 18 hours. The packages are then carefully transferred to the chilled store, where they are kept for at least 24 hours at a temperature of about 6 °C until distribution.

Long-life fermented cream

The shelf life of the fermented cream can be prolonged by heat treatment. Stabilisers are added either in the cream before fermentation or in the fermented cream before final heat treatment. Heat treatment of the product is often done at 85 – 90 °C for a few seconds. The viscosity of the final product is dependent on the choice of stabiliser as well as on the design of the plant.

Buttermilk

Cultured buttermilk, sometimes simply referred to as "buttermilk" is a by-product of butter production from fermented cream. The product has traditionally been sold and consumed as a drink. It has a fat content of about 0.5%, and it contains a lot of fat globule membrane material, including lecithin. The taste of the buttermilk changes fairly quickly due to oxidation of the membrane material content, giving the product a short shelf life. Whey separation is also common in buttermilk from the manufacture of butter based on fermented cream.

Today, to overcome problems such as off-flavours and short shelf life, a product called "fermented buttermilk" is commercially produced in many markets from skim or low-fat milk. Buttermilk from the manufacture of butter based on sweet cream can also be used.

In all cases, the raw material is heat treated at 90 – 95 °C for about 5 minutes before being cooled to inoculation temperature. Ordinary lactic acid bacteria are commonly used. In some cases, when the raw material is skim milk or low-fat milk, grains of butter are also added to the product to make it look more like traditional buttermilk. The product can also be flavoured with ingredients such as fruit concentrate.