CHEESE

Basic cheese facts

Since ancient times, most cultures have been making cheese in one form or another. As so many variants exist, it is impossible to formulate a strict definition of what exactly cheese is. However, in broad terms, cheese can be defined as a milk concentrate, the basic solids of which consist mainly of protein (mostly casein) and fat. Cheeses are generally formed by the coagulation of casein micelles, causing them to to interact and form a casein network. Coagulation is caused by lowering the pH (through bacterial fermentation of lactose to lactic acid or addition of chemical acids), addition of rennet (enzymes), salts or a combination thereof.

Although caseins and caseinates are completely different to cheese in terms of their applications, their production also starts with the coagulation of skimmed milk, cutting the coagulum and washing the coagulum to purify the caseins. See more at the end of this chapter.

The residual liquid from cheesemaking is called whey. Whey has many traditional uses and modern commercial applications for feed, food, special diets and pharma. It consists mostly of water, lactose, minerals and different types of smaller whey proteins, which are present in differing proportions depending on the milk source and processing technique.

Categories of cheese

A generally accepted classification of cheese is given in FAO/WHO Standard No. A 6. Each category is distinguished by several characteristics, such as structure (texture, body), flavour and appearance. These characteristics result from the type of milk used, the choice of bacteria and the manufacturing technique.

Moisture content serves to distinguish broad categories of cheeses, such as hard (low-moisture), semihard and soft cheeses. As a rule of thumb, the casein and fat in the milk are concentrated approximately 10 times in the production of hard and some semi-hard cheeses, and approximately 6 times for soft cheeses with elevated moisture contents.

Whey cheese is a type of cheese produced in e.g., Norway and Sweden (Brunost), and Italy (Ricotta). It is defined in FAO/WHO Standard No. A 7: Whey cheeses are products obtained by the concentration of whey and the moulding of concentrated whey, with or without the addition of milk and milk fat.

Cream cheese is a soft unripened cheese described in FAO/WHO Standard C 31 as “possessing a mild creamy or acid flavour and aroma typical of a milk product cultured with lactic acid and aroma-producing bacteria. It spreads and mixes readily with other foods”.

Processed cheeses differ from natural cheeses as they are not produced directly from milk. According to FAO/WHO Standard No. A 8 (b), processed cheese is a heat-treated product based on different types of cheese of varying ages.

Terminology for classification of cheese

(Source: Codex Alimentarius, FAO/WHO, Standard A6)

Cheese is the fresh or ripened solid or semi-solid product in which the whey protein/casein ratio does not exceed that of milk, obtained:

A By coagulating (wholly or partly) the following raw materials: milk, skimmed milk, partly skimmed milk, cream, whey cream, or buttermilk, through the action of rennet or other suitable coagulating agents, and by partially draining the whey resulting from such coagulation.

or

B Through processing techniques involving coagulation of milk and/or materials obtained from milk that give an end product which has similar physical, chemical and organoleptic characteristics as the product systemised under the classification of cheese.

Definitions

1.1 Cured or ripened cheese is cheese that is not ready for consumption shortly after manufacture, but which must be held for a certain time, at a certain temperature, and under certain other conditions which will result in the necessary biochemical and physical changes characterising the cheese.

1.2 Mould-cured or mould-ripened cheese is a cured cheese in which the curing has been accomplished primarily by the development of characteristic mould growth throughout the interior and/or on the surface of the cheese.

1.3 Uncured, unripened or fresh cheese is cheese that is ready for consumption shortly after manufacture.

Classification of cheese

The classification shown in Table 16.1 applies to all cheeses covered by this standard. However, this classification shall not preclude the designation of more specific requirements in individual cheese standards.

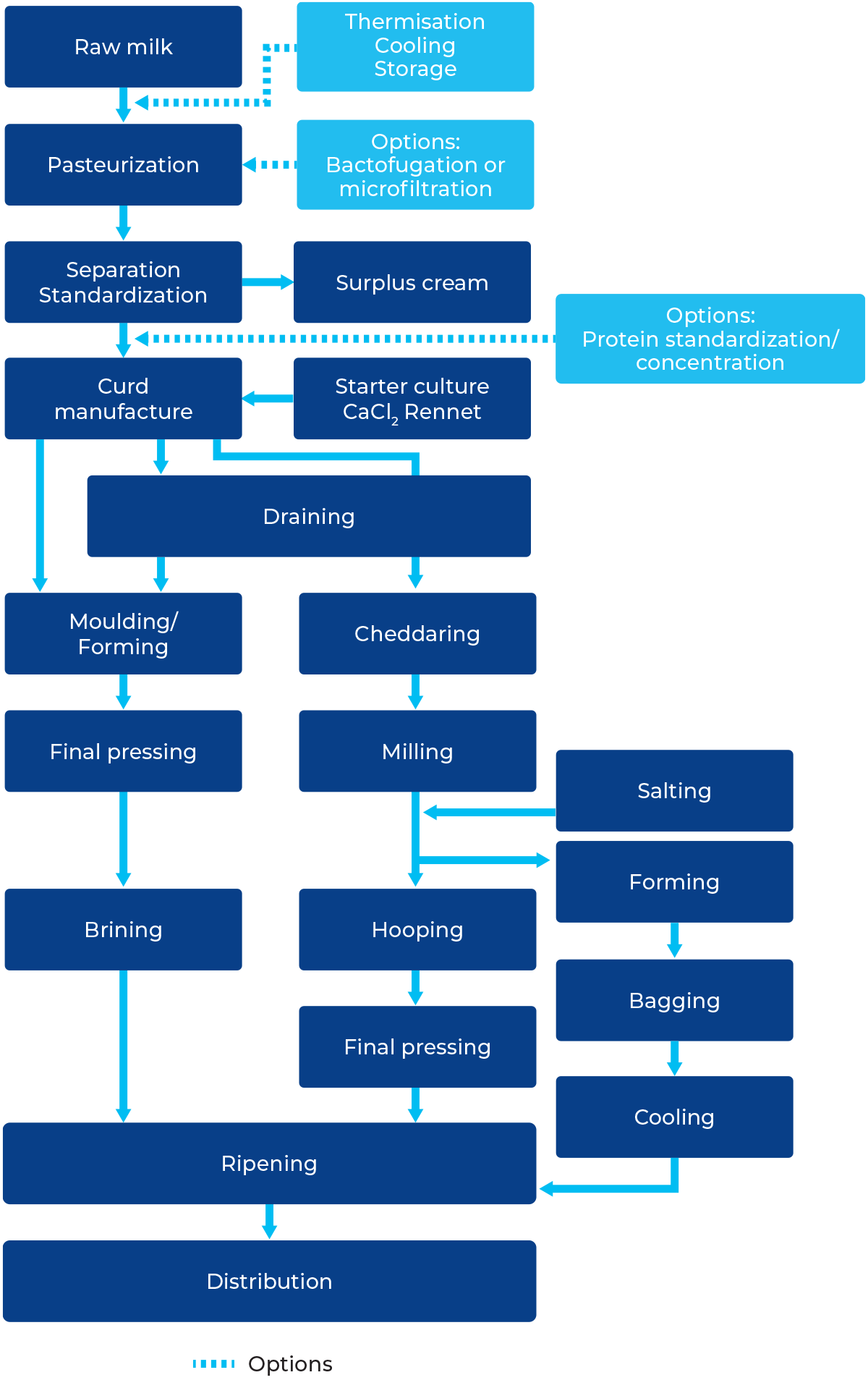

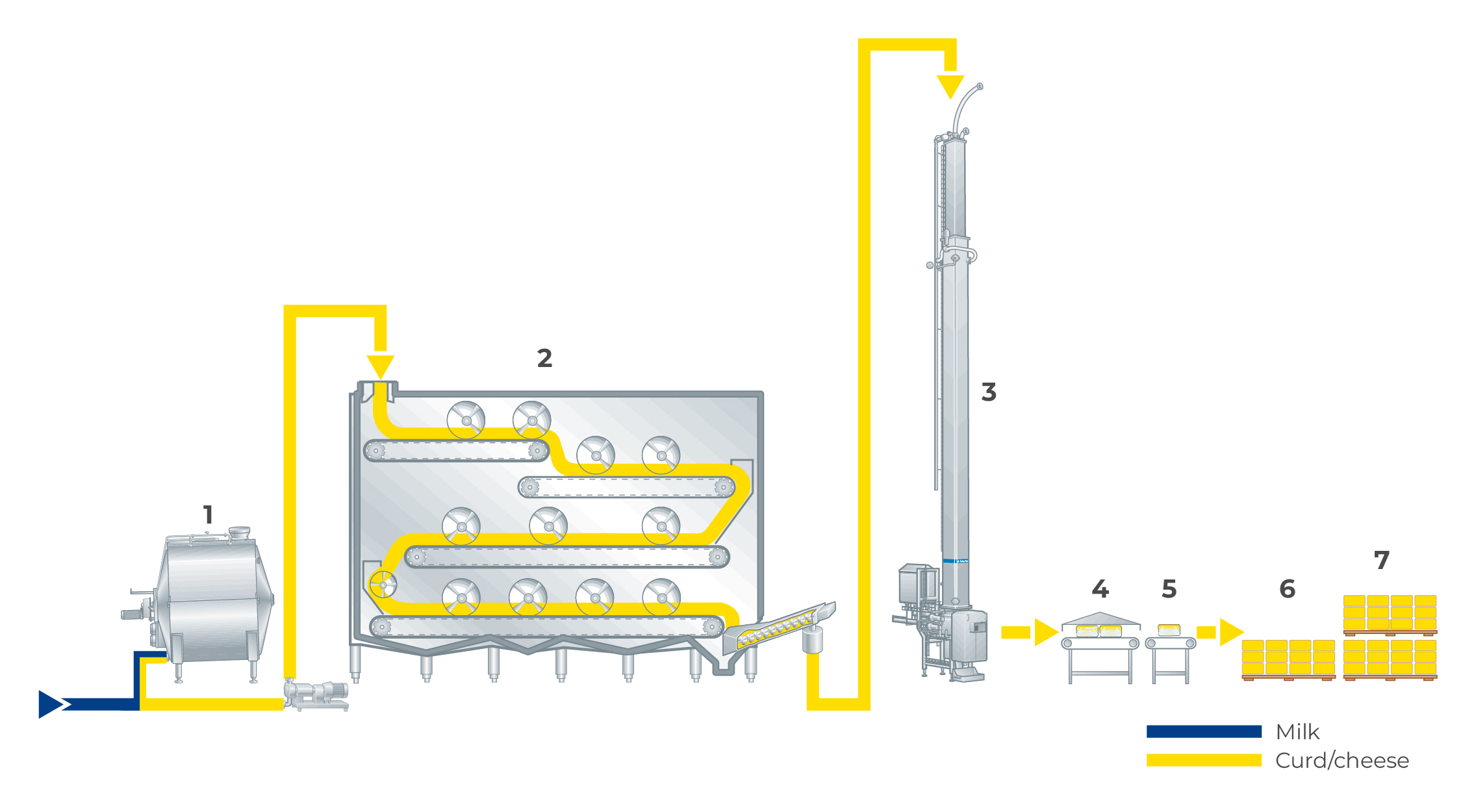

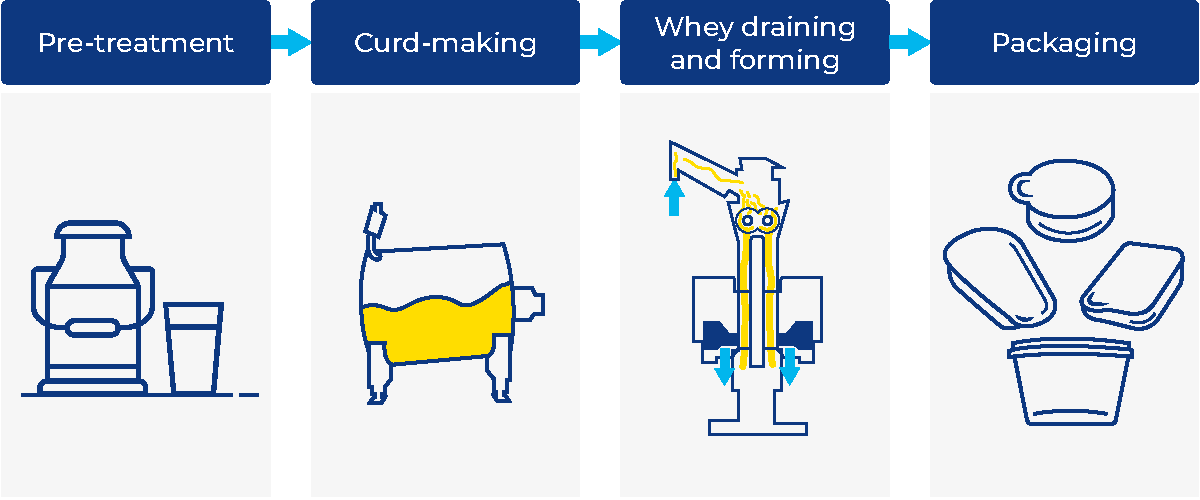

Hard and semi-hard cheese production

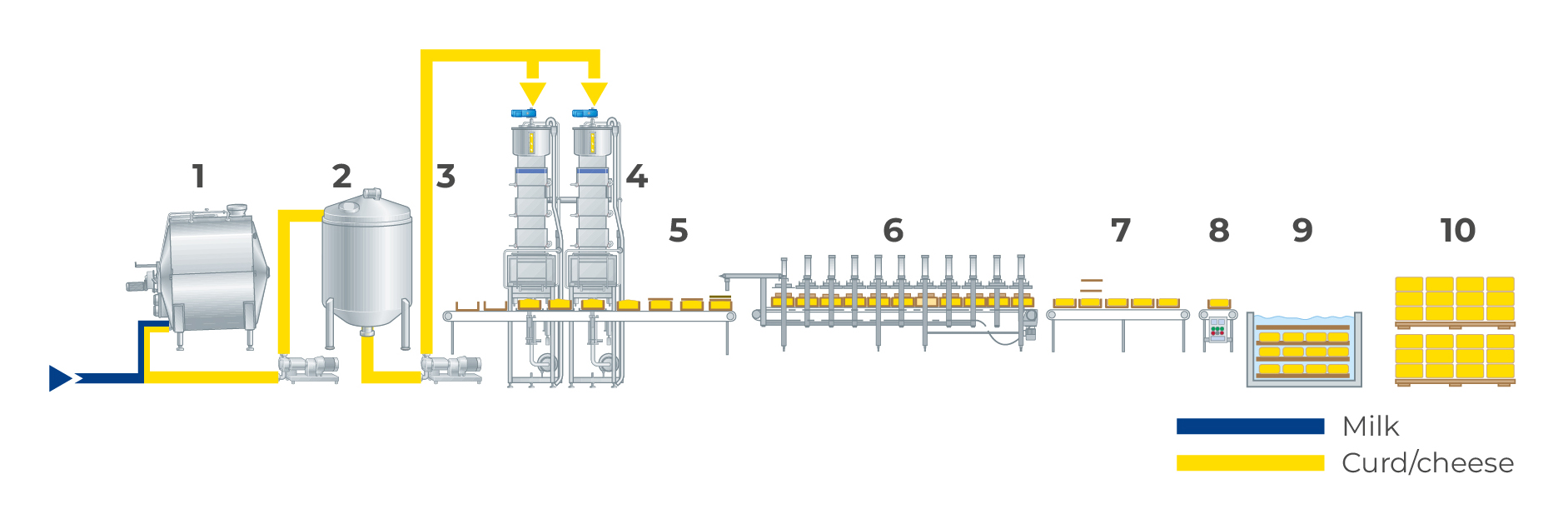

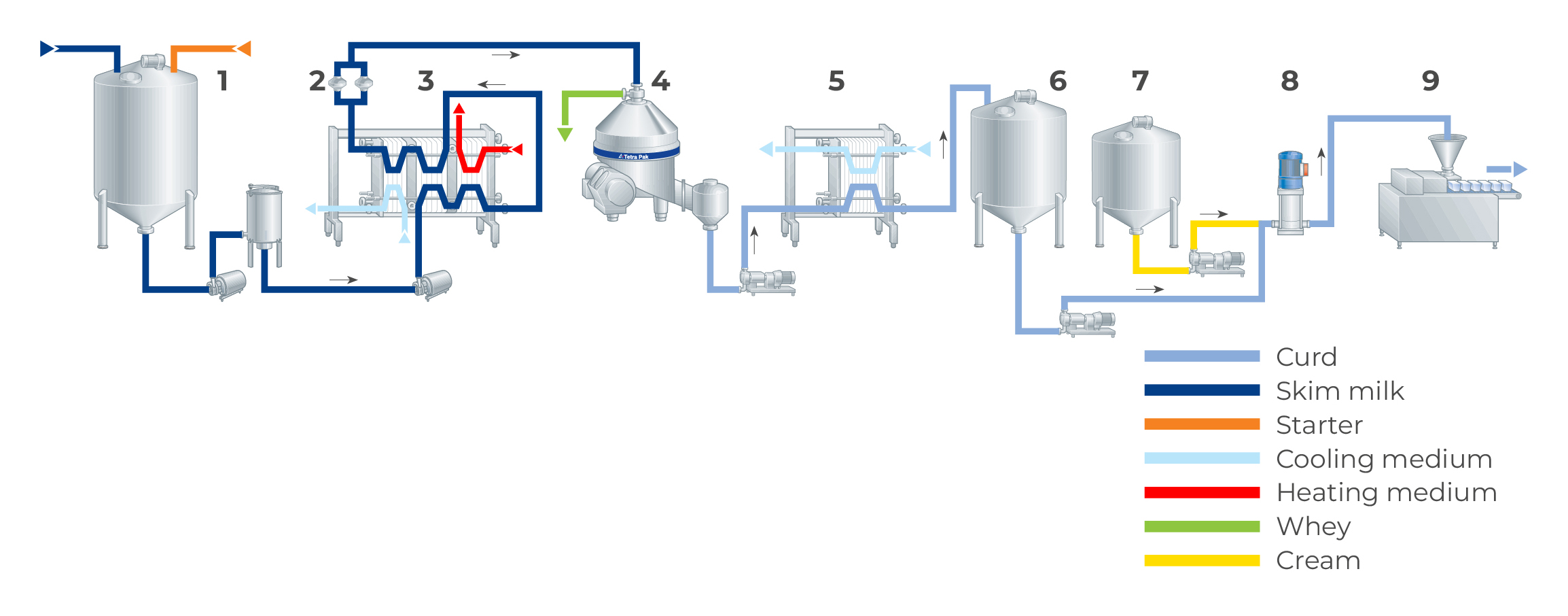

Cheesemaking involves a number of main stages that are common to most types of cheese. There are also other modes of treatment that are specific to certain varieties. The main stages for the production of hard and semi-hard cheese are illustrated schematically on the block chart in Figure 16.1.

The cheese milk is pre-treated and possibly pre-ripened after the addition of a bacteria culture appropriate to the type of cheese and mixed with rennet. The enzyme activity of the rennet causes coagulation (interlinking) of the casein micelles into a protein network entrapping fats and bacteria. As a result, the milk turns into a milk gel known as coagulum. This is cut with special cutting tools into small cubes of the desired size, called curd grains – primarily to facilitate the expulsion of whey.

During the rest of the cheesemaking process, the bacteria grow and multiply and form lactic acid from the lactose. The curd grains are subjected to mechanical treatment with stirring tools, while at the same time, the curd is cooled or heated (depending on required cheese moisture content) or optionally washed with water (to lower lactic acid content in the final cheese), according to a pre-set program. The combined effect of these three actions as a function of cheesemaking – growth of bacteria, mechanical treatment and altering the temperature profile – results in a desired rate of syneresis, i.e. the expulsion of whey from the curd grains by the shrinking/ compacting casein network. The finished curd is placed in perforated cheese moulds, mostly made of micro-perforated plastic (to allow non-bound whey to be released), which determine the shape, outer rind and size of the finished cheese.

The cheese is pressed, either by its weight or more commonly by applying pressure to the mould lids, compacting the cheese between the mould and its lid. Treatment during curd-making, curd-handling, pressing, brining, and storage (ripening) conditions, in combination with the types of bacteria or other microorganisms added to the milk or to the surface of the formed cheese determine the characteristics of the cheese. The process flow chart in Figure 16.1 also shows salting and storage. Finally, the cheese is rind-treated, coated, wrapped or packed.

In the production of cheddar cheese (dry-salted hard cheese), the whey is separated from the curd grains and the curd grains undergo a process of cheddaring to lower the pH (fermentation of lactose into lactic acid) and re-align the casein network, after which dry salt is added to the curd. After some mellowing time, the salted curd is formed into a cheese block and ripened. This is traditionally done in moulds at the time of pressing, but now mostly by forming a block of cheese in vertical forming towers and vacuum packing it in a sealed plastic bag.

Fat standardization

- Fat relative to SNF (Casein) = F/SNF (Casein)

Pasteurization

- 70-72 °C/15-20 s (not always employed)

- Cooling to renneting temperature about 30 °C

Mechanical reduction of bacteria

- Spore and bacteria removing separators

- Microfiltration

- Conditioning of cheese milk

- Additives (examples): 1/8 calcium chloride, 1/8 starter bacteria (appropriate to type), 1/8 coagulation agent (e.g. rennet)

- Cutting into grains (cured)

- Removing part of the whey

- Adding water to wash curd (semi-hard cheese production)

- Heating, scalding, directly (by wash water) or indirectly (via heating jacket), depending on type of cheese and dairy preference

- For (semi-)hard cheese, collection of curd for pre-pressing and/or final moulding/pressing and brine salting

- For cheddar cheese, cheddaring followed by milling, dry salting, block-forming, bagging. Traditional cheddar making; hooping dry salted curd and pressing.

- Formed, pressed, and salted cheese to ripening room storage for required time

Milk treatment prior to cheesemaking

The suitability of milk as a raw material for cheese production depends largely on conditions at the dairy farm. Quite apart from the general demand for strict hygienic conditions, milk from sick cows or other mammals undergoing treatment with antibiotics must not be used for cheesemaking or any other milk product. Antibiotics present in the milk act as growth inhibitors to the microbiological fermentation process.

Feeding animals on badly prepared silage can adversely affect the quality of several varieties of cheese.

Milk collection

With the traditional method of milk reception, i.e. morning delivery of the day’s milk in churns to the dairy, the milk was treated almost immediately after being weighed in. The fat content was then standardized in conjunction with separation and pasteurization and, after regenerative cooling to renneting temperature, the milk was pumped to the cheesemaking tanks.

These days, the practice of collecting milk from farms at intervals of two or three days is widespread. This means that particularly stringent requirements must be met regarding the way the milk is treated by the producers. In particular, a quick cooling of the collected milk to 4 °C is essential. These requirements also extend to the tanker driver, who collects the milk at the farmhouses. The driver must have the authority to refuse milk that is even slightly affected and/or impaired by off-flavours. Bovine mastitis is a common disease that causes pain to the cow and drastically alters the composition and the quality of the milk. Farmers must discard such milk, or at least not send it to the dairy.

Automatic/robotised milking systems, which help to improve milk hygiene, are widely used at larger dairy farms in developed countries. But as these systems are used for many hours around the clock each day, milk lines must be properly cleaned on a regular basis. A failure to do so may result in elevated levels of defecting bacteria in cheese and whey, of which some strains are thermoduric and survive milk pasteurization. These bacteria originate, e.g. from inline dirt filters in dairy farm milk lines. More information on milk collection can be read in Chapters 1 (Primary production of milk) and 6 (Collection and reception of milk).

Heat treatment and mechanical reduction of bacteria

Thermisation

When the collection of milk on alternate days was introduced to cheese producers, they noticed that the quality of the cheese often deteriorated. This tendency was particularly noticeable when the milk had to be stored an additional day after reception, even when it was chilled to 4 °C in conjunction with transfer from road tanker to storage tank. Even longer storage times may be expected when working weeks are limited to six or even five days. During cold storage, milk protein and milk salts change character, which tends to impair cheesemaking properties. It has been shown that about 25% of the calcium precipitates as phosphate after 24 hours of storage at +5 °C. This reduction, however, is temporary. When the milk is pasteurized, the calcium redissolves, and the coagulating properties of the milk are almost completely restored. β-casein also leaves the complex casein micelle system during cold storage, which further contributes to reducing cheesemaking properties. However, this reduction is also almost completely restored by pasteurization. Another equally important phenomenon is that psychrotrophic microflora introduced into the milk by recontamination – especially Pseudomonas spp – adapt to the low temperature at which their enzymes, proteinases and lipases, decompose protein and fat, respectively. The result is a “bitter" flavour emanating from the decomposition of the β-casein that has left the casein micelle during low-temperature storage.

The proteolytic and lipolytic enzymes formed by Pseudomonas may also cooperate to penetrate the membranes of the fat globules. This symbiotic cooperation leads to the liberation of fatty acids, especially the lower ones, by lipase action, giving the milk a rancid flavour.

So, if milk that is already at least 24 – 48 hours old cannot be processed within about 12 hours after arrival at the dairy, it is advisable to chill it to about +4 °C or, preferably, thermise it.

Thermisation means moderate heat treatment at 65 °C for 15 seconds, followed by cooling to +4 °C, after which the milk is still phosphatase positive. This technique was mainly introduced to arrest the growth of psychrotrophic flora when milk was stored for a further 12 – 48 hours after arrival at the dairy. The “critical age” of raw milk kept at +4 °C normally falls between 48 and 72 hours after milking. Figure 16.2 shows the arrangement of a milk reception station.

At many cheese dairies, separation (to lower fat content), bactofugation (to lower spore count), and/ or microfiltration (to lower microbe counts) are incorporated into the thermiser module.

Pasteurization

Before the actual cheesemaking begins, the milk usually undergoes pre-treatment designed to make the final food or feed products safe to consume or create optimum conditions for production.

National legislation or cheese-type definitions stipulate whether the milk must be pasteurized or not, and if not, how to ensure consumer safety. Most cheese types are made from pasteurized milk.

Milk intended for original Emmenthal, Gruyere, Parmesan, Grana and some extra-hard types of cheese, must not be heated to more than 40 °C, to avoid affecting flavour, aroma and whey expulsion. Milk intended for these types of cheese normally comes from selected dairy farms with frequent veterinary inspection of the herds.

Although cheese made from unpasteurized milk is considered to have a better flavour and aroma, most producers (except makers of the extra hard types) pasteurize the milk, because its quality is seldom so dependable that they are willing to take the risk of not pasteurizing it. Pasteurization equalises the bacterial composition of the milk from one day to the next, eliminating disturbances in an automatic or time-controlled process.

Pasteurization must be sufficient to kill pathogenic bacteria. It must also kill the bacteria capable of affecting the quality of the cheese, e.g. Coliforms, which can cause early “blowing” and a disagreeable taste.

Regular pasteurization at 72 – 73 °C for 15 – 20 seconds is therefore most commonly applied.

However, thermoduric or spore-forming microorganisms in the spore state survive pasteurization and can cause serious problems during the ripening process. One example is Clostridium tyrobutyricum, which forms butyric acid and large volumes of hydrogen gas by fermenting lactic acid. The butyric acid has an unsavoury taste, and the gas destroys the texture of the cheese completely.

More intense heat treatment would reduce this particular risk but would also seriously impair the general cheesemaking properties of the milk, as it increases the level of denatured whey proteins. This is unacceptable in terms of both quality and legal requirements and limits the functionality of whey for further processing where native whey proteins (still having original functional properties) are often key. Other means of reducing thermo-tolerant bacteria are therefore used.

Traditionally, certain chemicals have been added to cheese milk (or added to the curd-whey mixture during curd making) prior to production to prevent “blowing” and the development of the unpleasant flavour caused by heat-resistant and spore-forming bacteria (principally Clostridium tyrobutyricum). The most used chemical is sodium nitrate (NaNO3), but in the production of Emmenthal cheese, hydrogen peroxide (H2O2) is also used. However, as the use of chemicals has been widely criticised, mechanical means of reducing the number of unwanted microorganisms have been adopted, particularly in countries (of cheese/whey production or consumption) where the use of chemical inhibitors is banned. These inhibitors can also affect some of the added bacteria in the starter culture and residues will end up in the whey where it may be critical to the application.

Mechanical reduction of bacteria

Spore-removing separators (bactofuge)

As discussed in Chapter 7.2, specially designed hermetic separators for spore and bacteria removal are used to separate the spores formed by specific bacteria strains from the milk.

The use of spore-removing separators has proved to be an efficient way of reducing the number of spores in milk since their density is higher than that of milk. These separators normally separate the milk into a fraction that is more or less free from bacterial spores, and a concentrate (called bactofugate), which contains separated spores and some bacteria.

In applications where quality milk for cheese and powder production is the objective, the spore-removing separator is installed in series with the milk separator.

The same temperature is often chosen for spore removal as for separation, typically 50 – 55 °C.

There are two types of spore-removing separators:

- Two-phase type

- One-phase type

The two-phase type has two outlets at the top:

- One for continuous discharge of the heavy phase (bactofugate) via a special top disc

- One for the spore- and bacteria-reduced phase

The one-phase type has one outlet at the top of the bowl for bacteria-reduced milk. The bactofugate is colected in the sludge space of the bowl and discharged at pre-set intervals through ports in the bowl body.

These two types make it possible to choose various combinations of equipment to optimise the spore count of milk used for both cheesemaking and other purposes.

Process alternatives

There are many possible ways to configure a line with spore-removing separators. Three examples are given here:

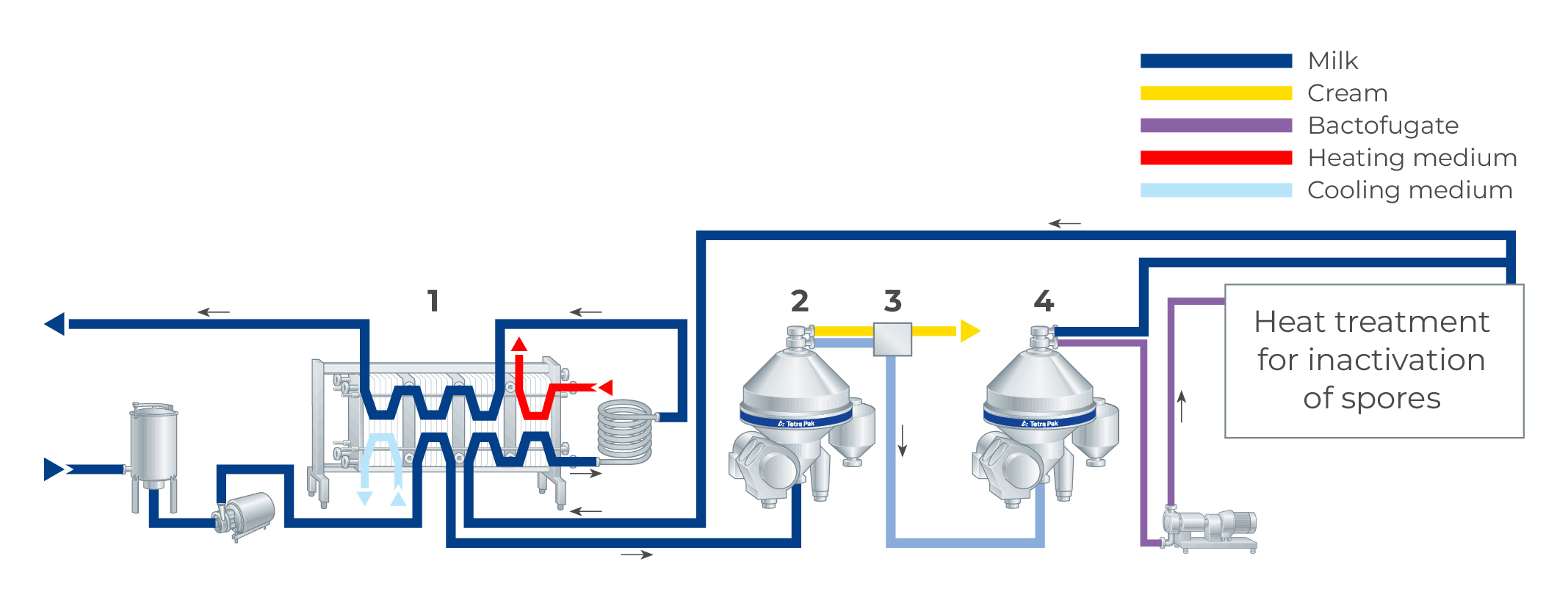

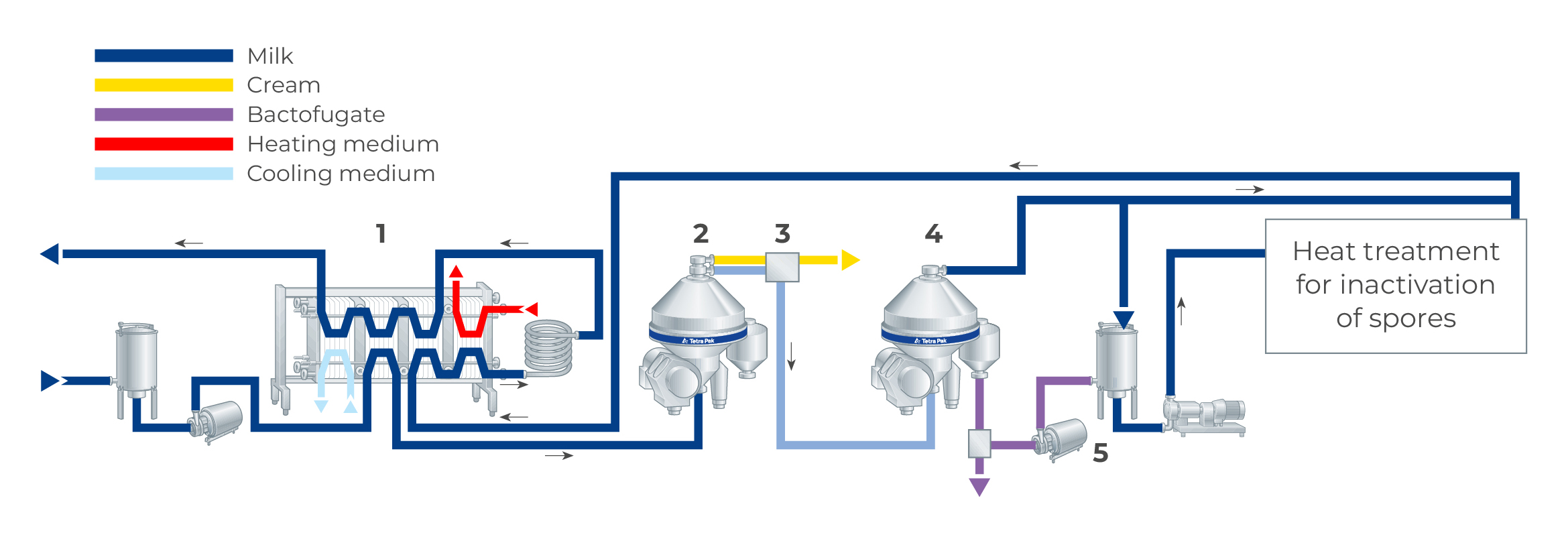

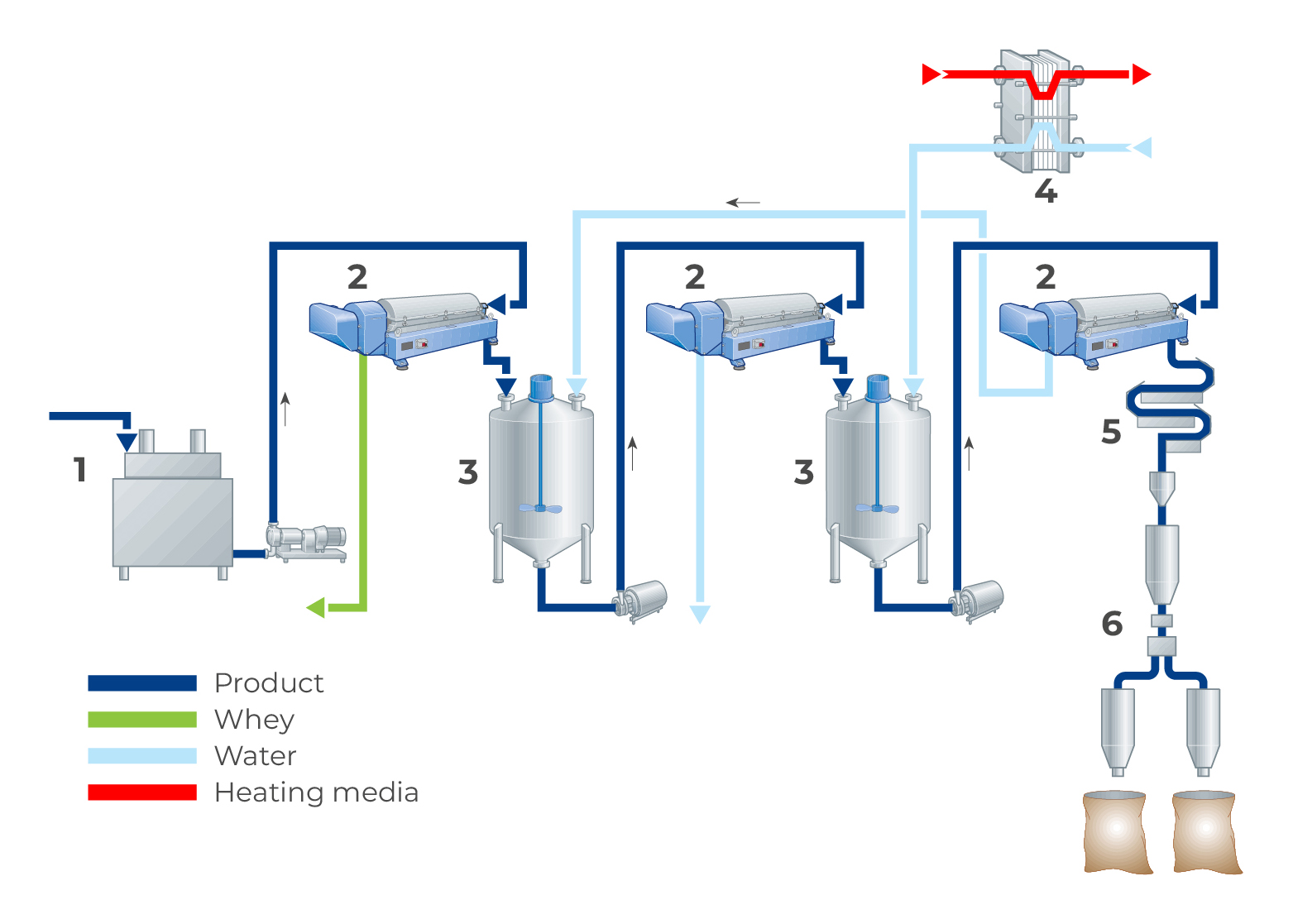

Two-phase spore-removing separator with continuous discharge of concentrate

This concept, shown in Figure 16.3, works under hermetic conditions and produces a continuous flow of air-free spore/bacteria bactofugate as the heavy phase. This phase, comprising 3 – 10% of the feed flow (adjusted by an external pump with variable speed control) is often sterilised and remixed with the main flow. The steriliser can be of different types: plate heat exchanger, tubular or infusion heater. Typical heat treatment is 120–130 °C for a few seconds up to one minute, which is sufficient to inactivate spores from Clostridia microorganisms. After cooling, the bactofugate can be remixed with the clarified milk before it is pasteurized at 72 °C for 15 seconds, followed by regenerative cooling to the renneting temperature.

A spore-removing separator with continuous discharge of concentrate is used in applications where:

- Remixing of sterilised bactofugate is possible.

- There is an alternative use for the bactofugate in a product where the heat treatment is strong enough to inactivate the microorganisms.

At nominal capacity, a spore-removing separator reduces approximately 98% of Clostridia spores and 95% of aerobic spores.

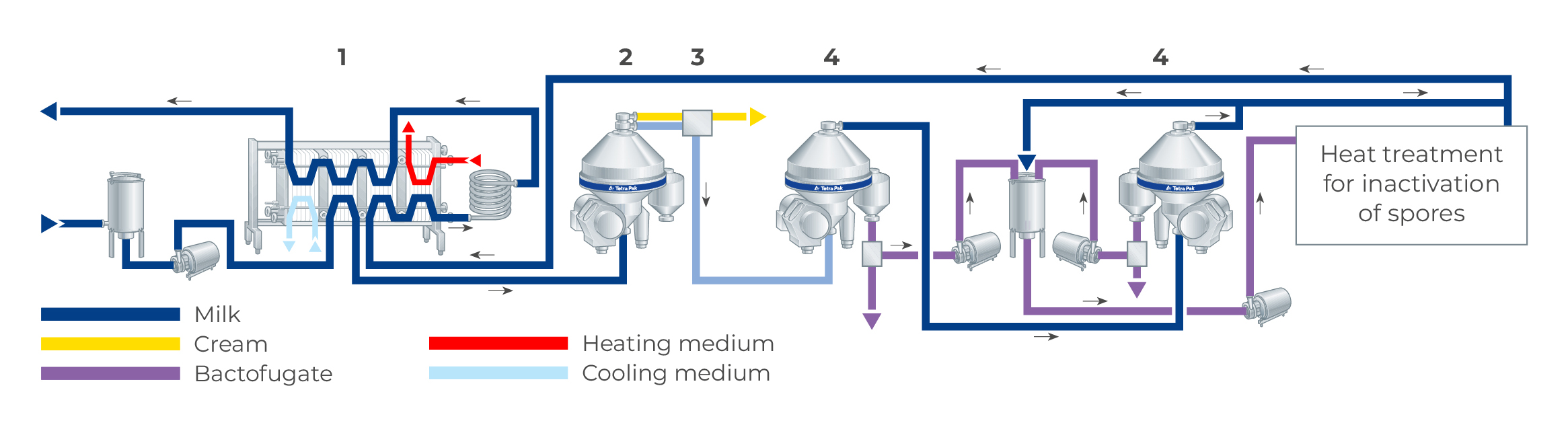

One-phase spore-removing separator with intermittent discharge of concentrate

To achieve the same reduction effect as mentioned above, nominal capacities are likewise recommended. The bactofugate from a one-phase spore-removing separator is discharged intermittently through ports in the bowl body at pre-set intervals of 15 – 20 minutes, which means that the collected bactofugate will be very concentrated and thus also low in volume, 0.15 – 0.2% of the feed. When the bactofugate is to be reintroduced into the cheese milk, it must be sterilised. This is illustrated in Figure 16.4, which also shows that before being pumped to the steriliser, the bactofugate is diluted with clarified milk (about 1.8% of the feed) to obtain a sufficient volume for proper sterilisation. Starting and stopping of the discharge pump (5) are linked to the operation mode of the discharge system of the centrifuge.

Where legislation does not permit the reuse of the bactofugate, it can be discharged to the drain or collected in a tank.

Another possibility is to use a continuous discharging spore-removing separator where the spore-concentrated phase is re-added to the inlet of the separator. The spores are thus collected in the sludge of the separators and discharged at intervals. This method reduces the volume of the spore-concentrated phase to be heat treated before reuse or limits the volume of milk losses when not reusing the sludges.

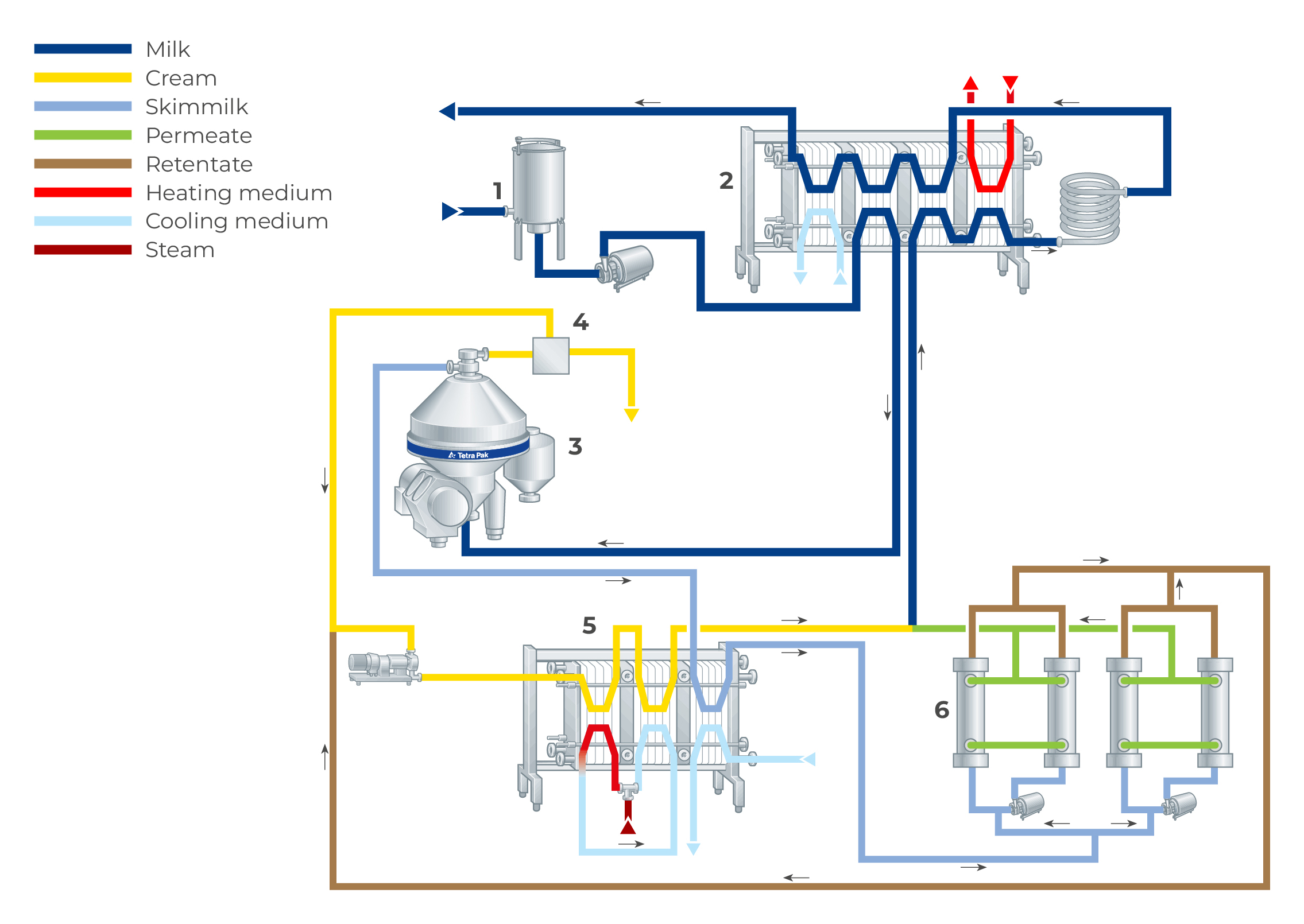

Two one-phase spore-removing separators in series

Processing the milk once through a spore-removing separator is not always sufficient, particularly with high spore loads in the milk or when producing spore-sensitive cheese types, e.g. cheese types with a low salt content, high moisture content and ripened at elevated temperatures, such as Maasdam and similar cheeses. With two of these types of separators in series, reduction of Clostridia spores reaches more than 99%. Figure 16.5 illustrates a plant with two one-phase type machines in series serving one sterilising unit. This can also be done with continuous discharging mode separators.

The concentrate treatment procedure mentioned above applies here too. Two spore-removing separators in series are sufficient (in most cases) to produce cheese without the addition of bacteria-inhibiting chemicals. However, for safety reasons, during periods when very high loads of spore-formers are expected, some dairies may still add small amounts of chemicals if legally allowed in the country where the cheese or whey is consumed.

Microfiltration

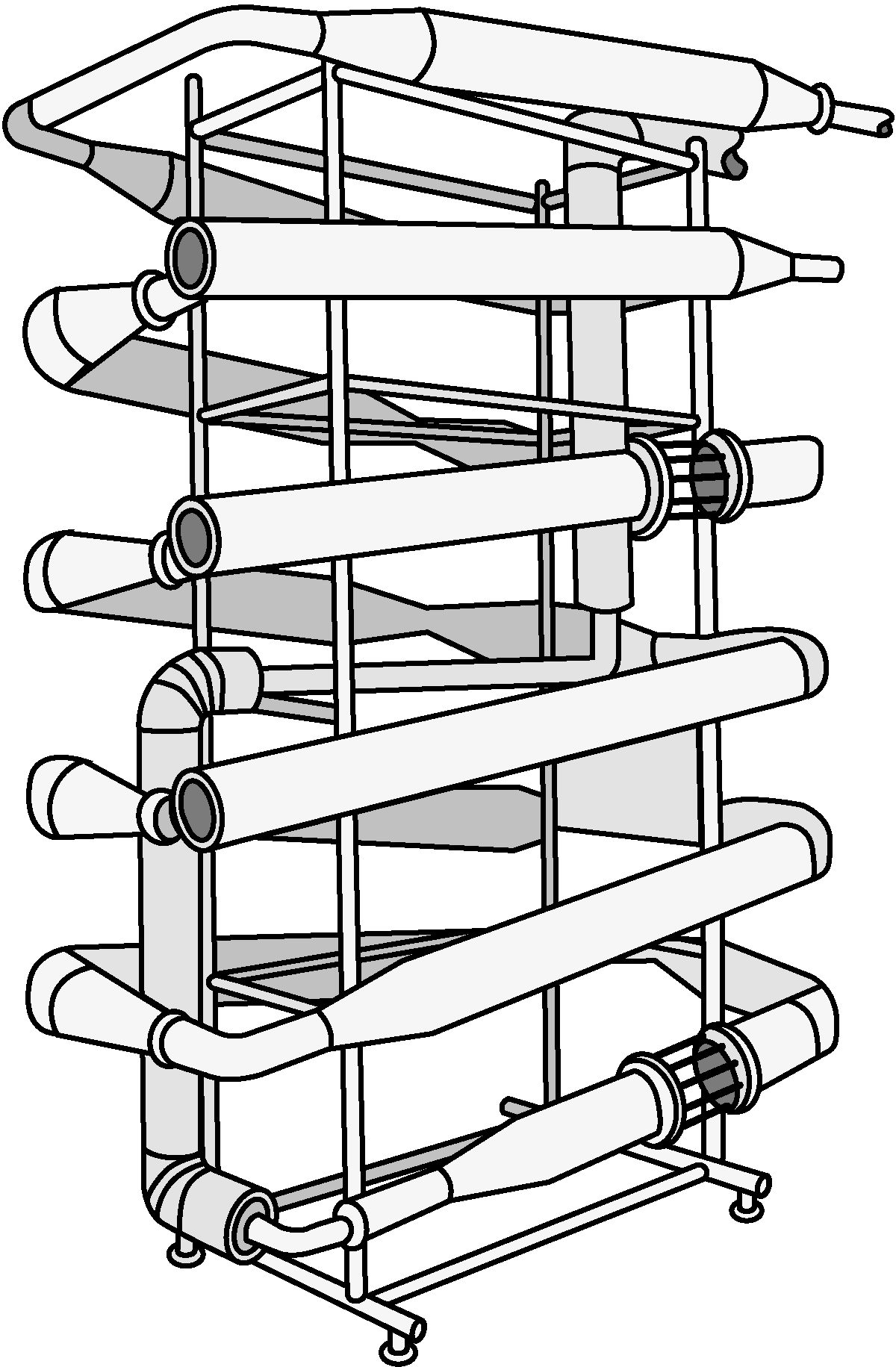

It has been known for a long time that a membrane filter with a pore size of approximately 0.2 microns can filter bacteria from a water solution.

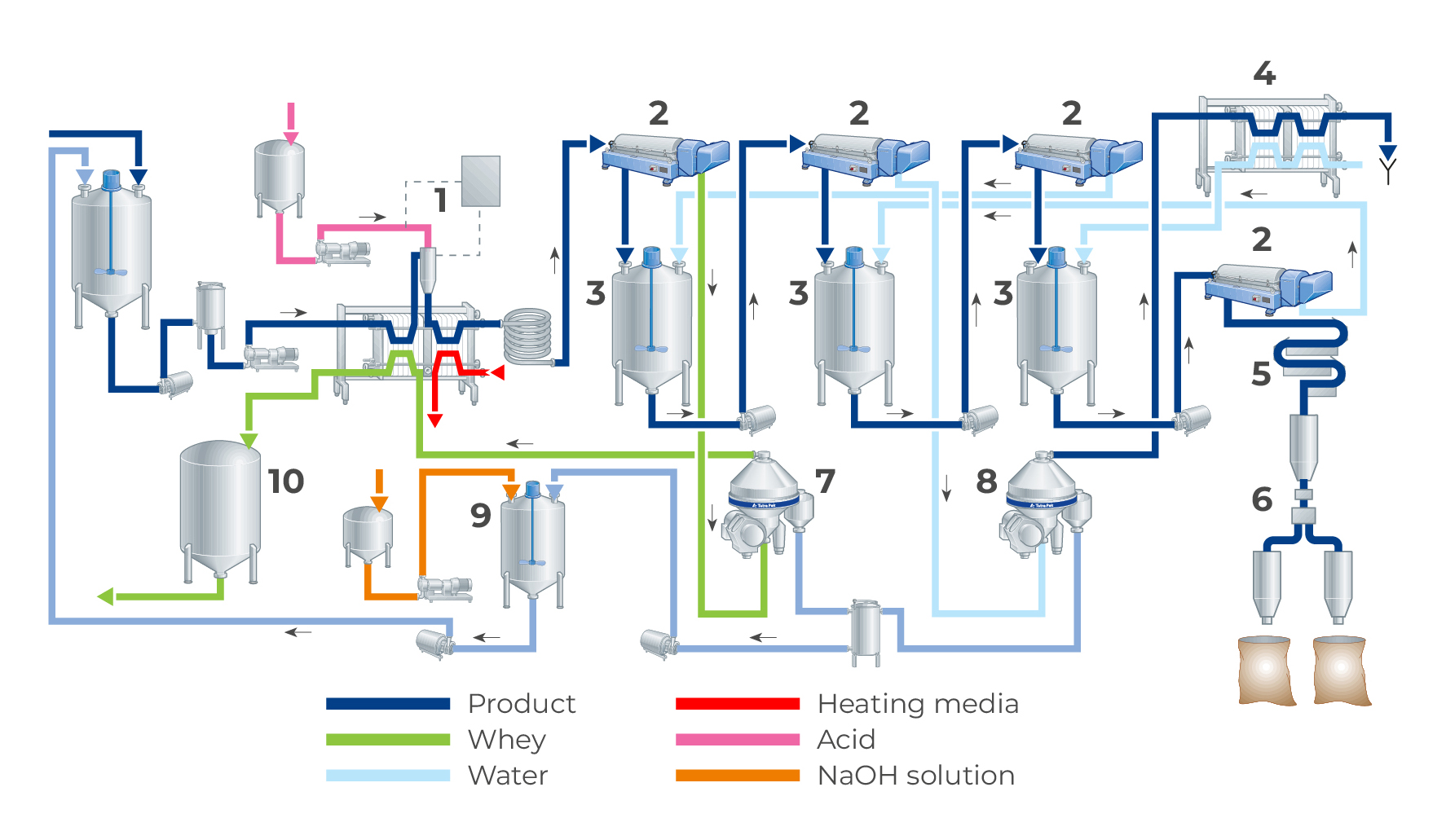

In the microfiltration of milk, the problem is that most of the fat globules and some of the proteins are as large as, or larger than, the bacteria. This results in the filter fouling very quickly when membranes with such a small pore size are chosen. Thus, it is the skim milk phase that is microfiltered, while the cream (separated upstream from skim milk) needed for standardization of the fat content is typically sterilised together with the bacteria concentrate retentate obtained by simultaneous microfiltration. The principle of microfiltration is discussed in Chapter 7.4, Membrane filters. In practice, membranes with a pore size of 1.4 microns are mostly chosen to lower the concentration of protein in the retentate.

In addition, the protein forms a dynamic membrane that contributes to the retention of microorganisms.

The microfiltration concept includes an indirect sterilisation unit for combined sterilisation of an adequate volume of cream for fat standardization and of retentate from the filtration unit.

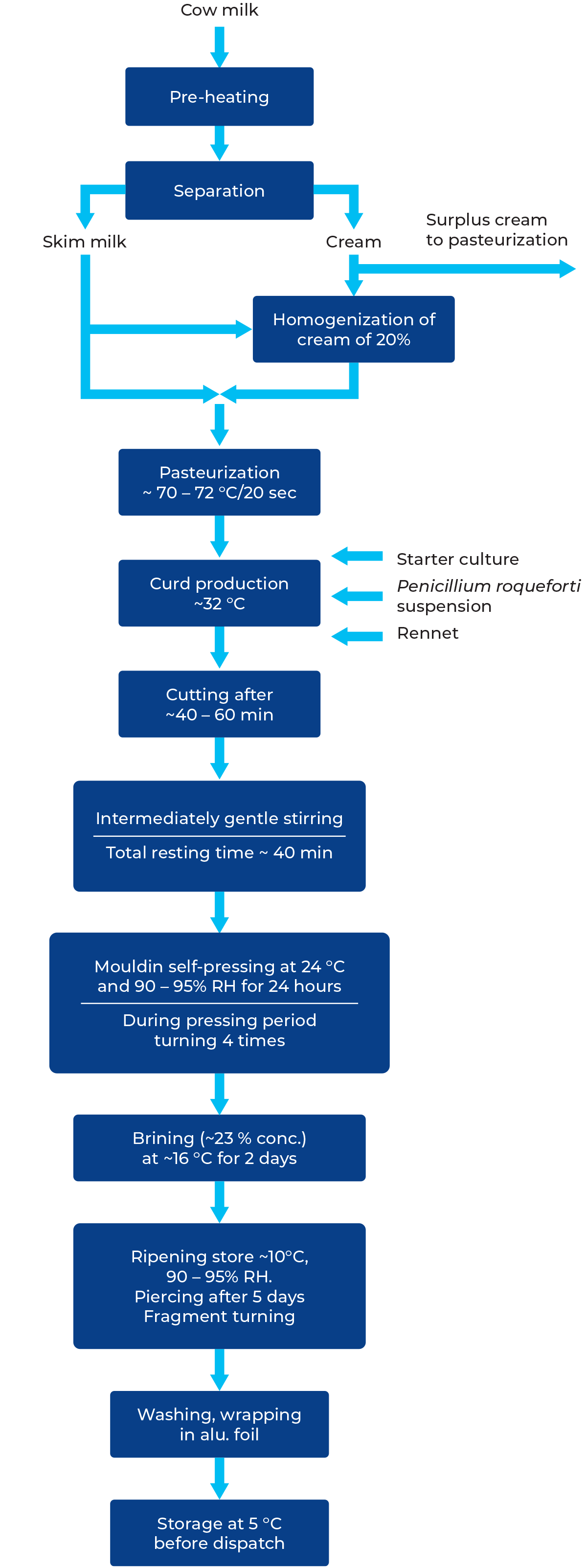

Figure 16.6 shows a milk treatment plant with microfiltration. The microfiltration plant is provided with two loops working in parallel. The raw milk entering the plant is pre-heated to a suitable separation temperature, typically about 60 – 63 °C, at which it is separated into skim milk and cream. A pre-set amount of cream, enough to obtain the desired fat content in the cheese milk, is routed to the sterilisation plant by a standardization device.

In the meantime, the skim milk is piped to a separate cooling section in the sterilising plant to be cooled to 50 °C, the normal microfiltration temperature, before entering the filtration plant.

The flow of milk is divided into two equal flows, each of which enters a loop where it is fractionated into a bacteria-rich concentrate (retentate), comprising about 5% of the flow, and a bacteria-reduced phase (permeate).

The retentates from both loops are then united and mixed with the cream intended for standardization before entering the steriliser. Following sterilisation at 120 – 130 °C for a few seconds, the mixture is cooled to about 70 °C before being remixed with the permeate. Subsequently, the total flow is pasteurized at 70 – 72 °C for about 15 seconds and cooled to renneting temperature, typically 30 °C.

Due to its high bacteria-reducing efficiency, microfiltration allows the production of hard and semi-hard cheese without requiring chemicals to inhibit the growth of Clostridia spores.

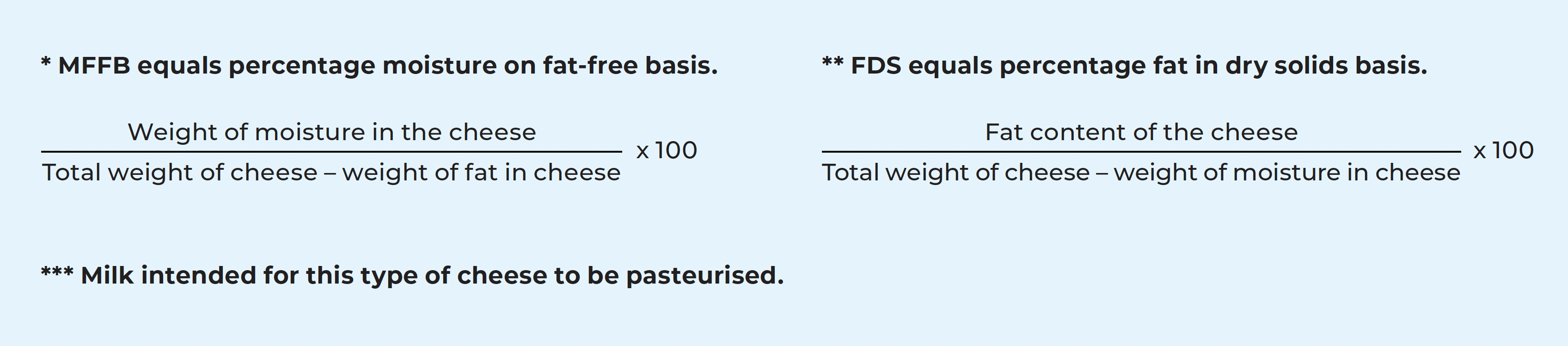

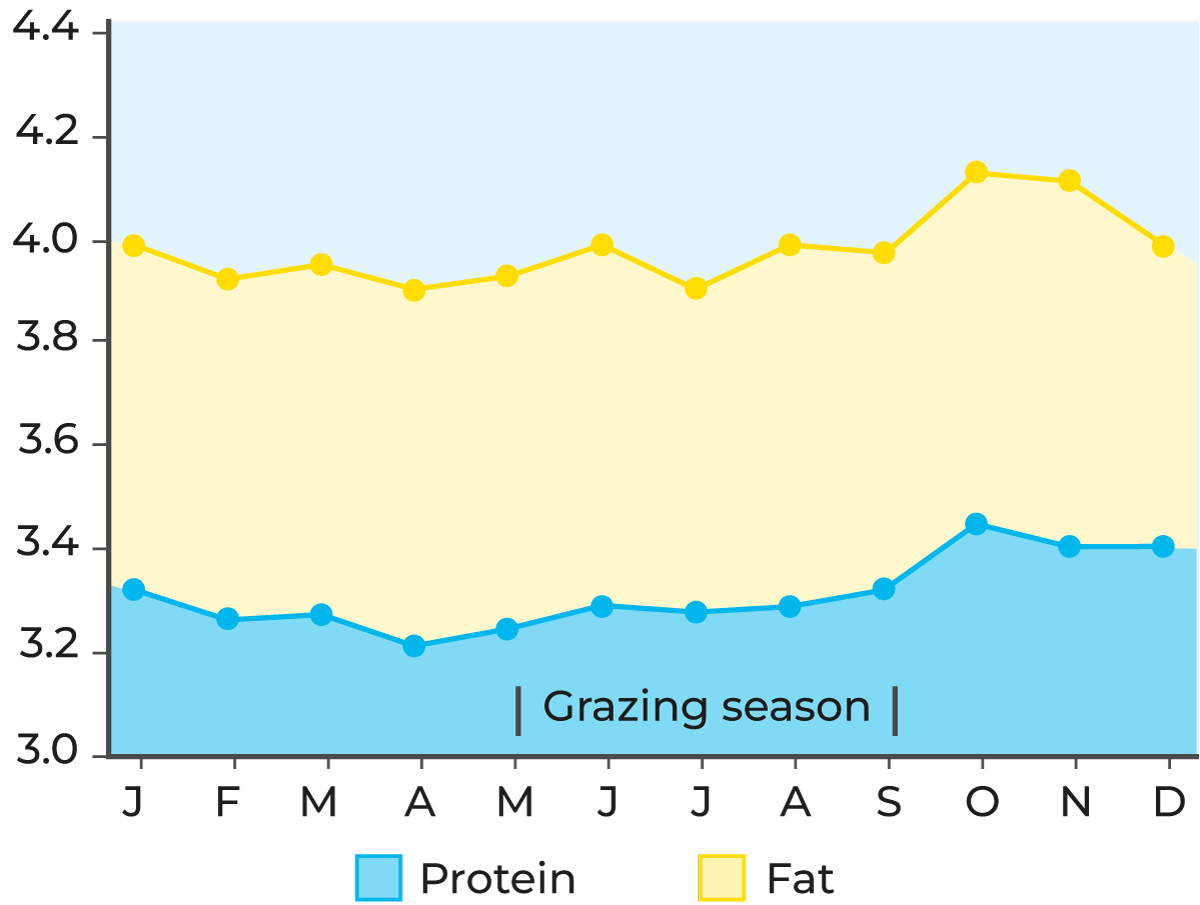

Standardization

Types of cheese are often classified according to a fat-in-dry-solids basis, FDS (or FDM = fat in dry matter). The fat to protein ratio of the cheese milk must therefore be adjusted accordingly by removing a part of the fat (in the form of cream). The protein content of the cheese milk can also be standardized in some cases. For this reason, the protein and fat contents of the raw milk should be measured throughout the year and the ratio between them standardized to the required value. Figure 16.7 shows an example of how the fat and protein content of milk can vary over a year. The final fat, protein and dry solids ratios are important factors in the yield and quality of the cheese.

Fat standardization

Standardization of fat can be accomplished either by in-line remixing part of the cream with the skim milk after the separator (see Chapter 7.2, section on automatic in-line standardization systems), or, for example, by mixing whole milk and skim milk in tanks followed by pasteurization. This mixing can also be done later in the cheese vats instead of standardizing beforehand, improving production flexibility. The fat content must be adjusted to the protein content (or even better to the casein content) to achieve the desired fat in dry solids ratio. For accurate standardization, cheese dairies keep tight track of the retention figures of fat and protein from milk into cheese. These retention figures are seasonally influenced (e.g. due to a varying casein content) and differ between milk types (e.g. between cow breeds) and cheese types.

Protein standardization

The protein level of the milk can be adjusted by membrane filtration techniques (commonly ultrafiltration) or by adding skim milk powder. For example the protein content can be levelled up to a constant value corresponding to the maximum level of the year.

When the protein content is increased by ultrafiltration, the level of total dry solids in the milk increases, including whey proteins. This affects the cheesemaking process and ultimately the quality of the cheese. It is also possible to standardize the casein fraction by microfiltration of skim milk, allowing the majority of whey proteins to pass to the permeate phase to increase the casein content instead of raising the total protein content.

Microfiltration of skim milk is not only favourable for cheesemaking but also for whey processing. MF permeate can be processed by ultrafiltration to a UF retentate phase (called native whey or ideal whey) containing mostly native whey proteins, without fat, micro-organisms and typical residues of cheesemaking ingredients. These include casein-macro-peptides, colouring agents, CaCl2, cultures, rennet and curd fines etc., which are not desired in many whey-based products.

Additives in cheese milk

The essential additives in the cheesemaking process are, for most cheese types, the starter culture and the rennet. For some cheese types, it may also be necessary to supply additional or other components such as calcium chloride (CaCl2) and acids.

An enzyme, Lysozyme, is also occasionally introduced to inhibit Clostridia organisms.

Starter

The starter culture is a very important factor in cheesemaking; it performs several duties.

Three principal types of culture are used in cheesemaking:

- Starter cultures, to start fermentation of lactose into lactic acid to lower pH. In many cases, these starter cultures also have functionality later during ripening of the cheese, altering the texture and adding taste formation. The starter cultures can be added as a bulk culture (created at the cheese dairy by inoculating a volume of skimmed milk in culture propagation tanks) or as a direct starter (concentrated deep-frozen pallets or freeze-dried powders) purchased from specialist suppliers.

- Adjunct cultures – a typical version of direct starters – are added to create specific taste or texture. In many cases, it is the enzymes created by these bacteria that give these properties.

The above cultures can be based on 2 main types of bacteria strains:

- Mesophilic cultures with a temperature optimum between 25 and 40 °C

- Thermophilic cultures, which develop at up to 50 °C

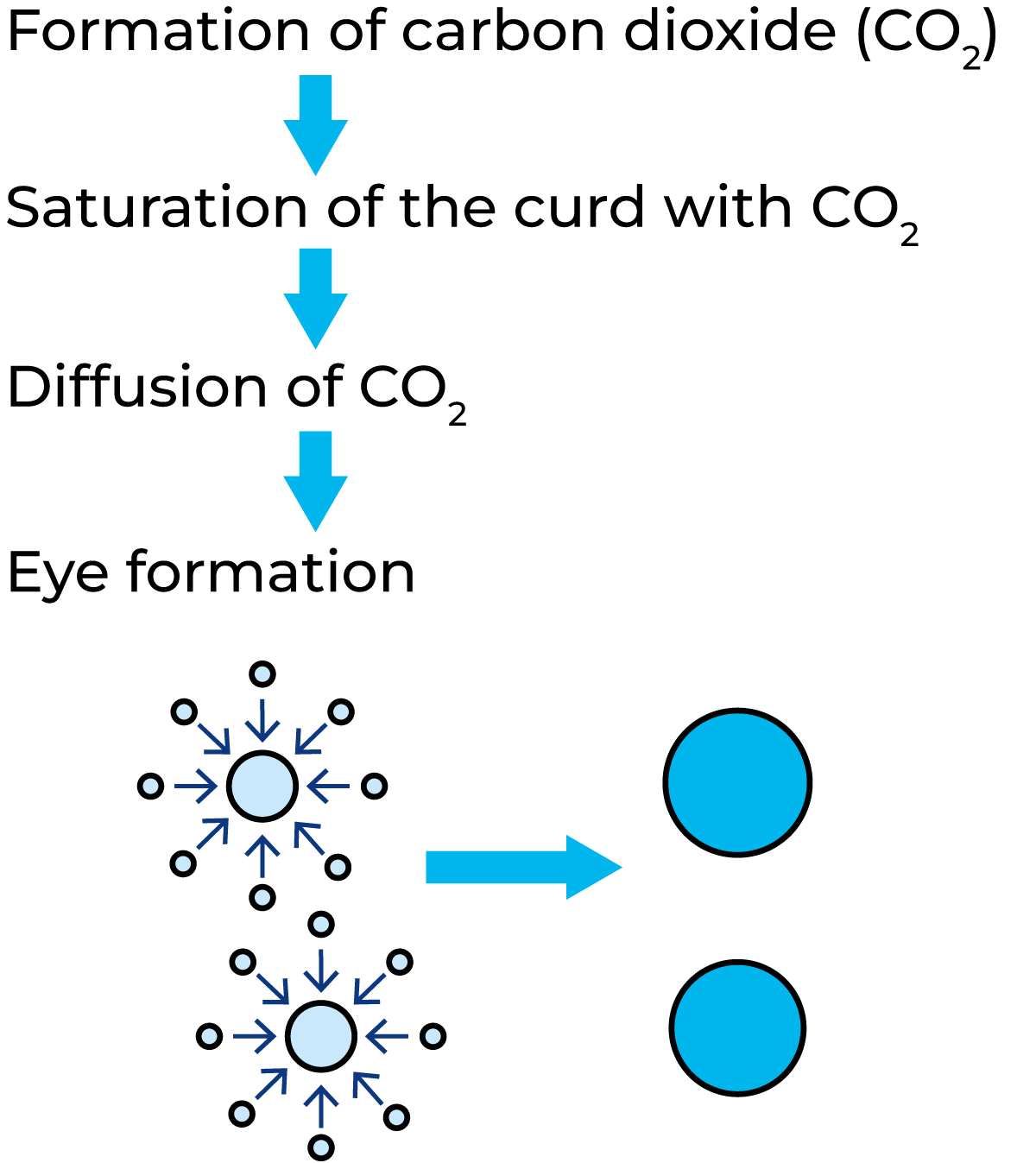

The most frequently used cultures are mixed strain cultures, containing two or more strains of bacteria, which can support each other in their functioning. Mixed strain cultures often consist of either a cocktail of mesophilic bacteria or thermophilic bacteria or sometimes a combination of both. These cultures not only produce lactic acid but can also form gas (H2, CO2) and aroma components. Carbon dioxide is essential for creating holes in round-eyed cheeses and supports the openness of granular types of cheese. Gouda, Manchego and Tilsiter are for example based on mesophilic cultures, and Emmenthal and Gruyère are examples of cheeses based on thermophilic cultures.

Single-strain cultures are mainly used where the object is to develop acid and contribute to protein degradation, e.g. in Cheddar and related types of cheese. To limit phage (culture-specific virus) sensitivity, more mixed strain cultures are also used.

Three characteristic abilities of starter cultures are of primary importance in cheesemaking:

- Producing lactic acid

- Breaking down protein and fats

- When applicable, producing carbon dioxide (CO2)

The first task of the culture is to develop lactic acid in the curd to lower the pH, influencing taste and texture formation and, above all, increasing shelf life.

When milk coagulates, bacteria cells are concentrated in the coagulum as the formed casein network entraps the bacteria cells. But some bacteria cells are lost to the whey when cutting the coagulum into curd grains. This can negatively affect the whey, as the bacteria may continue to ferment the lactose in lactic acid unless the whey is quickly cooled or pasteurized.

Formation of acid lowers the pH, which is important in assisting syneresis (contraction of the coagulum accompanied by expelling of whey). Furthermore, salts of calcium and phosphorus are released, which influence the consistency of the cheese texture and help to increase the firmness of the curd.

Another important function performed by acid-producing bacteria is to suppress the growth of undesired bacteria which either need lactose or cannot tolerate lactic acid or elevated acidity.

Production of lactic acid stops when all the lactose in the cheese (except in some soft cheeses) has been fermented. Lactic acid fermentation is normally a relatively fast process. For some types of cheese, such as Cheddar or Gouda, it must be completed before the cheese is salted as most cultures are sensitive to salt.

If the starter also contains H2 and CO2-forming bacteria, acidification of the curd is accompanied by the production of hydrogen and carbon dioxide gas through the action of citric acid-fermenting bacteria. Hetero-fermentative bacteria in a mixed strain starter culture can develop CO2 and are essential for the production of cheese with a texture of round holes/eyes or irregularly shaped eyes. The evolved gas is initially dissolved in the moisture phase of the cheese. When the solution becomes over-saturated, the gas is released and creates the eyes.

For some fresh cheese types (e.g. Tvorog) gas-formation during acidification may lead to reducing curd densities resulting in floating curd on top of the whey in the cheese vats.

The ripening process in hard and certain semi-hard cheeses is a combined glycolytic, proteolytic, and effect in which the original enzymes of the milk and those of the bacteria in the culture, together with rennet enzymes cause, for example, the breakdown of the protein into peptides and amino acids.

Disturbances in cultures

Disturbances in the form of slow acidification or failure to produce lactic acid can sometimes occur. One of the most common causes is the presence of antibiotics used to cure udder diseases. Another possible source is the presence of bacteriophages, thermo-tolerant viruses found in the air and soil.

The detrimental action of both phenomena is discussed in Chapter 12, Cultures and starter manufacture. A third cause of disturbance is the use of detergents and sterilising agents used in the dairy. Carelessness, especially in the use of sanitisers, is a frequent cause of culture disturbances.

Disturbances in the form of slow acidification or failure to produce lactic acid can depend on:

- Antibiotics

- Bacteriophages

- Detergent residues

Calcium chloride (CaCl2)

A low concentration of Ca+ ions in the cheese milk causes a soft coagulum. This results in heavy losses of fines (casein) and fat, as well as poor syneresis during cheesemaking.

Between 5 – 20 g of calcium chloride per 100 kg of milk is normally enough to achieve a constant coagulation time and result in sufficient firmness of the coagulum. By adding more CaCl2, the amount of rennet used can be reduced, as the CaCl2 supports the interconnection of casein micelles to a casein network, entrapping fat globules and bacteria.

However, excessive addition of calcium chloride may make the coagulum so hard that it is difficult to cut. Furthermore, overdosing calcium chloride will release it into the whey, and during whey processing it can cause scaling on the evaporators, shortening runtime and reducing thermic efficiencies.

Carbon dioxide (CO2)

The addition of CO2 is a method of improving the quality of cheese milk, as the carbon dioxide acts as an inhibitor. Carbon dioxide occurs naturally in milk, but most of it is lost in the course of processing.

Adding carbon dioxide by artificial means lowers the pH of the milk. This will then result in a shorter coagulation time, the release of some bound calcium from the casein and a reduction in the amount of rennet.

Colouring agents

The colour of cheese is to a great extent determined by the colour of the milk fat and undergoes seasonal variations. Colours such as carotene and orleana, an anatto dye, are used to correct these seasonal variations in countries (either the country of cheese production or cheese consumption) where colouring still is permitted.

Green chlorophyll (contrast dye) is also sometimes used, for example in blue-veined and feta cheeses, to obtain a “pale” colour as a contrast to the blue mould.

Rennet

Except for some fresh cheese types such as cottage cheese and quark, in which the milk is clotted mainly by lactic acid, or white cheese and paneer cheese, in which acid is used as a clogging method, most cheese manufacture depends upon the formation of curd through the enzymatic destabilisation of casein micelles. This process in caused by rennet (concentrated solution of enzymes, primarily chymosin) or similar enzymes and allows the micelles to interlink into a casein network.

Coagulation of casein is the fundamental process in cheesemaking. It is generally done with rennet, but other proteolytic enzymes can be used, often in combination with the addition of calcium chloride, which accelerates the casein network formation. An alternative method is acidification of the casein to the iso-electric point (pH 4.6 – 4.7, at which casein micelles do not repel each other) by adding acids or fermenting lactose to lactic acid. Combinations of both principles also exist.

The active principle in rennet is an enzyme called chymosin, and coagulation takes place shortly after the rennet is added to the milk. The renneting process operates in several stages; it is customary to distinguish these as follows:

- Transformation of casein to paracasein under the influence of rennet

- Interlinking paracasein to a casein network in the presence of calcium ions

The whole process is governed by the temperature, acidity, and calcium content of the milk, as well as other factors. The optimum temperature for rennet is in the region of 40 °C, but lower temperatures (31 – 33 °C) are normally used in practice, principally to enable control of the coagulum’s hardness.

Rennet is traditionally extracted from the stomachs of young calves and marketed in the form of a solution with a strength of 1:10,000 to 1:15,000, which means that one part of rennet can coagulate 10,000 – 15,000 parts of milk in 40 minutes at 35 °C. Bovine and porcine rennet are also used, often in combination with calf rennet (50:50, 30:70, etc.). Rennet in powder form is normally 10 times as strong as liquid rennet.

Substitutes for animal rennet

The search for substitutes for animal rennet was carried out primarily in India and Israel, on account of the refusal of vegetarians to accept cheese made with animal rennet. In the Muslim world, the use of porcine rennet is out of the question, which is another important reason to find adequate substitutes.

Interest in substitute products has grown more widespread in recent years due to a shortage of good quality animal rennet.

There are two main types of substitute coagulants:

- Coagulating enzymes from plants

- Coagulating enzymes from microorganisms

Investigations have shown that coagulation ability is generally good with preparations made from plant enzymes. A disadvantage is that the cheese very often develops a bitter taste during storage. Various types of bacteria and moulds have been investigated, and the coagulation enzymes produced are known under various trade names.

DNA technology has been utilised in recent times, and a DNA rennet with characteristics identical to those of calf rennet has been thoroughly tested and is now widely used in the cheesemaking industry.

Other enzymatic systems

Several research institutions and ingredient suppliers are working and supplying isolated enzymatic systems and bacteria strains (carriers/providers of ripening enzymes) that can be used to accelerate the ageing of cheese or to counter undesired side effects of ripening, e.g. bitterness.

Whey components

Depending on cheese type and legislation it is common practice to re-introduce some components from the whey or exchange thermal energy from the whey to the milk. See chapter 18, Whey pre-treatment.

Cheesemaking modes

Cheese of various types is produced in several stages and according to principles that have been worked out by years of experimentation. Each type of cheese has its specific production formula, often with a local touch. Some basic processing alternatives are described here:

Curd production

Milk treatment

As discussed above, the milk intended for most types of cheese is standardized to the appropriate fat-to-protein ratio and preferably pasteurized just before being pumped into the cheese vat. Milk intended for raw milk cheese types, such as traditional Swiss Emmenthal or Parmesan is an exception to this rule.

Milk intended for cheese is normally not homogenized, unless it is recombined. The losses of fat in the whey will also increase as the fat globule size becomes smaller, so fats are less entrapped by the formed casein network. Homogenization also damages the protective membrane of the fat globule, which can result in off-taste formation in ripened cheese.

However, in the special case of blue and white cheeses made from cows’ milk, the fat is homogenized in the form of 15 – 20% cream. This is done to make the product whiter and, more importantly, to make the milk fat more accessible to the lipolytic activity by which free fatty acids are formed; these are important ingredients in the flavour of these two types of cheese.

Filling

In all cheesemaking, air pickup should be avoided when the milk is fed into the cheesemaking vat. This is because it causes a foam layer on the coagulum or air pockets in the coagulum. This causes additional losses of fat and protein due to increased curd fines in the whey.

The milk is therefore fed into the tank via a combined bottom inlet/outlet pipe, separate bottom inlet or a foam-repressing top inlet.

Air entrapment in the milk feedline must be avoided, e.g. by avoiding vortex-formation in milk silos and balance tanks, too high pressure drops, too intensive cavitation, non-airtight/broken seals or pipe couplings.

Fat, % 3.4

Protein, % 3.3

Lactose, % 4.7

Total solids, % 12.5

Starter addition

The starter is normally added to the milk at renneting temperature while the cheese vat is being filled. There are two reasons for early dosage of the starter:

- To achieve good and uniform distribution of the bacteria

- To gain more acidification time to achieve proper pH in the downstream process

- To give the bacteria time to become acclimatised to the new medium

The time needed from inoculation to the start of growth, also called the pre-ripening time, is about 30 to 60 minutes, especially in the case of adding a deep-frozen starter.

The quantity of starter needed varies with the type of cheese. Further information about various starters can be found in Chapter 12, Cultures and starter manufacture.

Additives and renneting

Most factories also dose calcium chloride during milk filling to strengthen the coagulation properties of the milk (added before the rennet). Anhydrous calcium chloride salt can, for example, be used in dosages of 20 g/100 kg of milk.

The rennet dosage is up to 30 ml of liquid rennet with a strength of 1:10,000 to 1:15,000 per 100 kg of milk. To facilitate proper distribution, the rennet volume is increased by diluting with at least double the amount of water. After the rennet dosage, the milk is stirred thoroughly for approximately 5 minutes. The milk needs to come to a full standstill within 5 – 7 minutes after rennet is added to avoid disturbing the coagulation process and causing loss of casein in the whey.

To further facilitate equal rennet distribution throughout the whole milk volume, automatic dosage systems are available. These systems dilute the rennet with an adequate amount of water by sprinkling it over the surface of the milk via multiple inlets distributed over the length of the cheese vat.

Cutting the coagulum

The renneting or coagulation time is typically about 30 minutes but differs between cheese types, rennet strength, milk temperature and milk composition.

Before the coagulum is cut, a simple test is normally carried out to establish the correct coagulum strength. Typically, a blade is stuck into the clotted milk surface by the cheesemaster and then drawn slowly upwards until proper breaking occurs. The curd may be considered ready for cutting as soon as a glass-like splitting flaw can be observed. This is more of a qualitative confirmation of coagulum readiness.

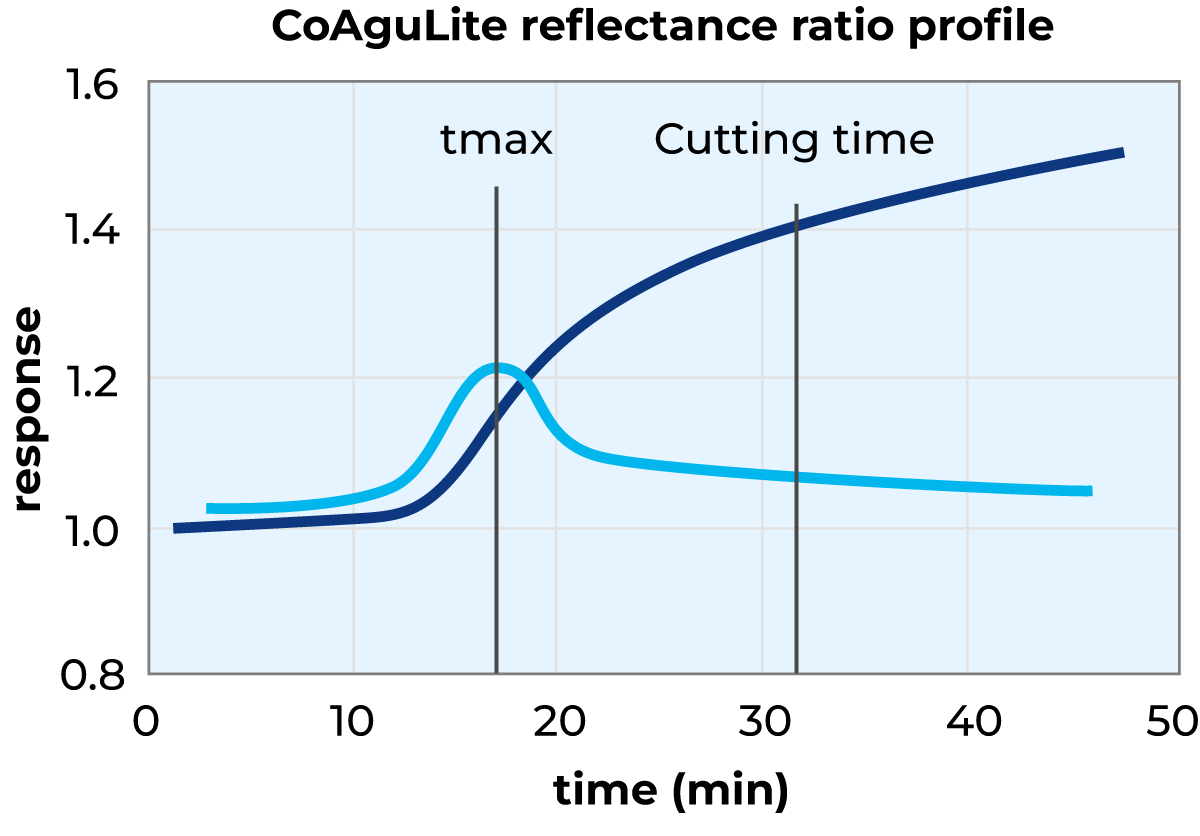

Many cheesemakers use quantitative insights and verification systems on the coagulation process by adding coagulation sensors to the cheese vat for automatic measurement of the progress and readiness of the coagulation. The principle is the change in light scattering and reflection. Based on experience, the cutting-readiness point of the set can be verified by the sensor readings. Also, external factors impacting coagulation like seasonal milk effects can be measured, quantified and compensated for to gain a reliable coagulation process outcome.

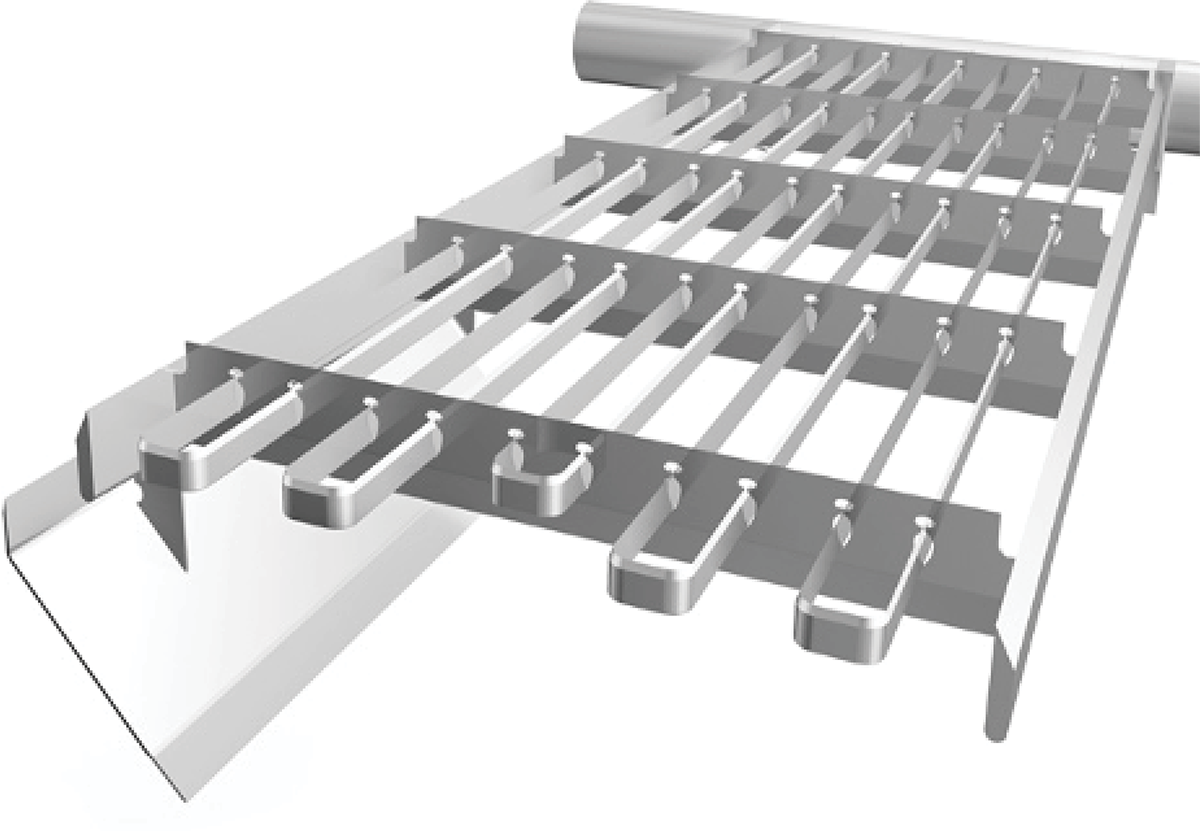

Cutting gently breaks the curd up into grains with a size distribution between 1 and 15 mm, depending on the type of cheese. Generally, the finer the cut, the lower the moisture content in the resulting cheese – but also the more fat and protein losses to the whey (due to a higher ratio of curd grain skin area versus curd grain volume). The coagulum is cut up to accelerate the sequential syneresis process (by shortening the way to the rind of the coagulum/curd grain).

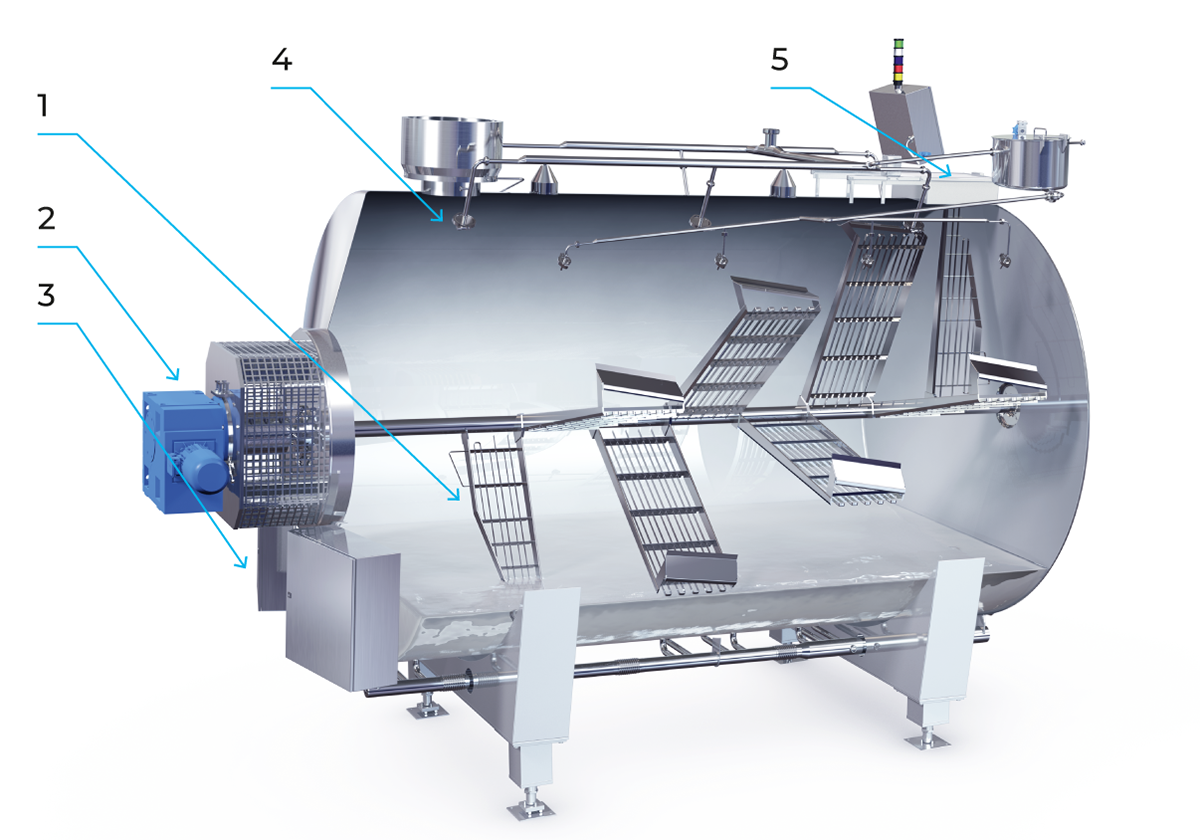

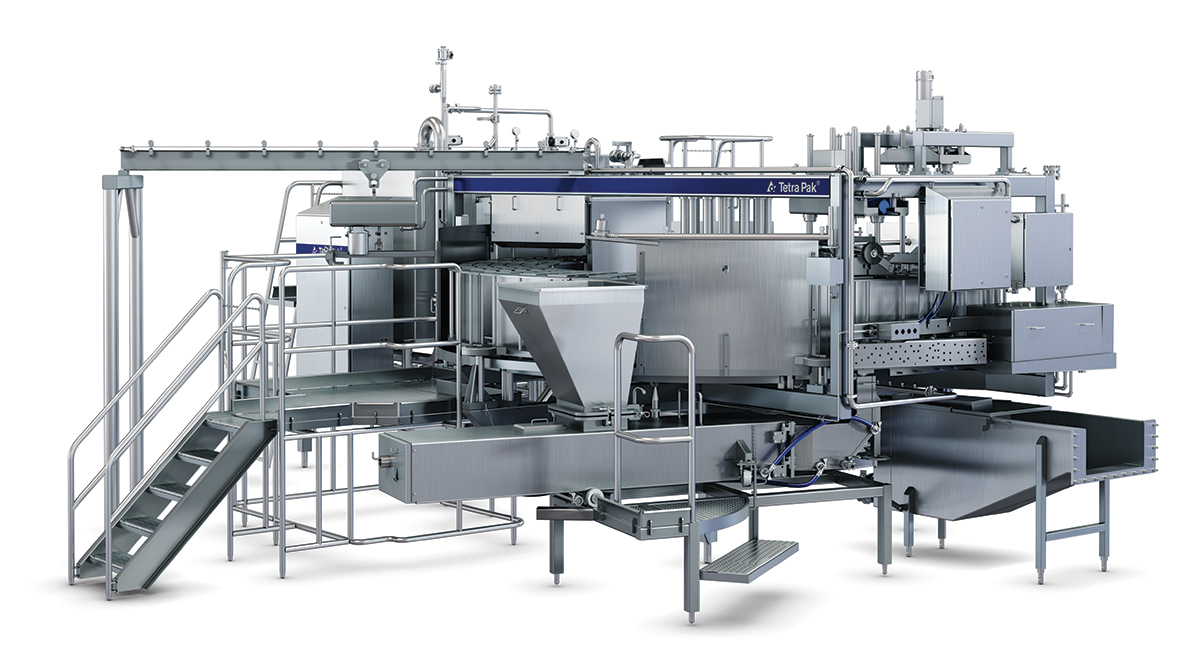

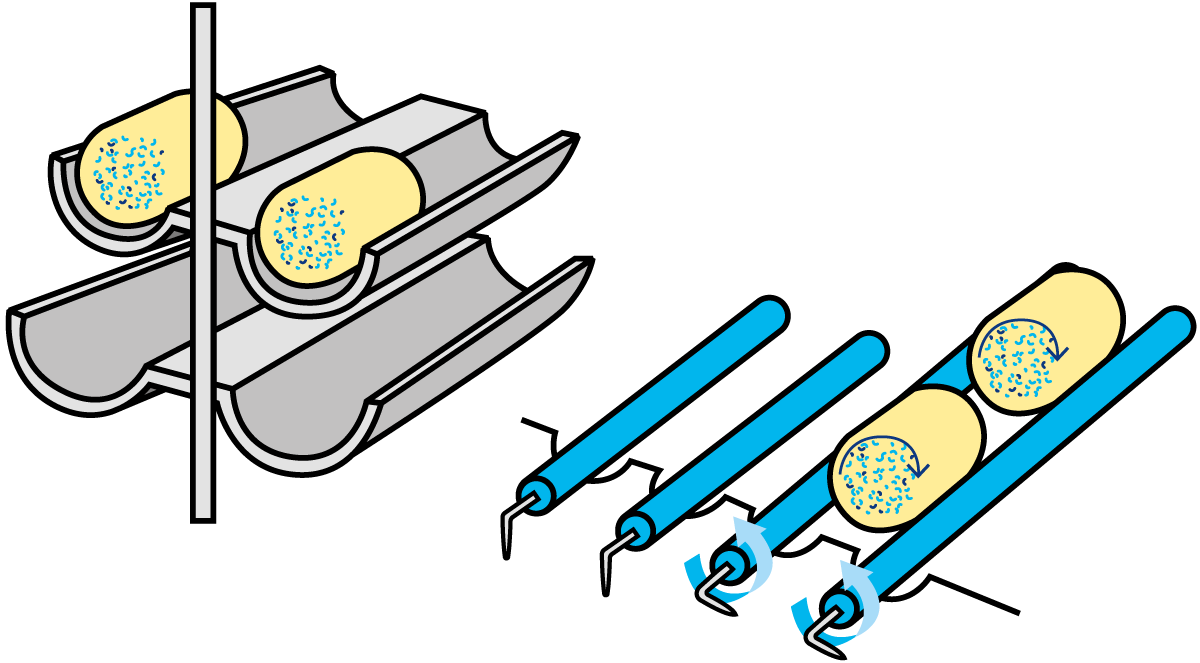

Syneresis is the process by which the shrinking casein network expels milk serum (whey) containing soluble components, lactose, whey proteins, minerals, spore elements and mainly water. The cutting tools can be designed in different ways. In a modern, enclosed, horizontal cheesemaking tank (Figure 16.10) stirring and cutting are done with cutting and stirring frames welded to a horizontal shaft powered by a drive unit with a frequency converter. The dual-purpose frames cut or stir depending on the direction of rotation; the coagulum is cut by razor-sharp radial stainless steel knives. Stirring blades mounted on the tip-ends of the tools, in combination with the rounded backside of the knives, provide gentle and effective stirring to the curd.

In addition, the cheese vat can be provided with:

- Rennet distribution pipes, inlets and optional hopper for proper distribution of coagulant (rennet)

- Temperature and volume sensors

- A coagulation sensor

- An automatically operated whey strainer to remove a part of the whey (milk serum expelled from the curd grains) to suit the capacity of downstream equipment or to make space to add wash water

- An alternative, in case of low whey discharge volumes, is to add outlets at certain levels at the cone-end of the cheese vat, provided with discharge valves and return piping.

- Nozzles to add curd wash water to the cheese vat (often also partly via the whey strainer) to support final rinse-out at final emptying and to be connected to a cleaning-in-place (CIP) system

Pre-stirring

Immediately after cutting, the curd grains are very sensitive to mechanical treatment, therefore the stirring must be gentle. It must, however, be fast enough to keep the grains suspended in the whey. Sedimentation of curd in the bottom of the vat causes the formation of lumps. The curd of low-fat cheese has a strong tendency to sink to the bottom of the tank, which means that the stirring must be more intense than for curd with a high-fat content.

Lumps negatively influence the texture of the cheese, as lumps entrap whey which can cause white and acid spots in the final cheese texture due to a higher presence of lactic acid and thus lower pH (lactose is fermented to lactic acid by the added lactic acid bacteria).

The mechanical treatment of the curd grains and the continued production of lactic acid by bacteria (lowering the pH) help to enforce the syneresis and thus expel more whey from the grains.

The cutting and initial stirring process, totalling 20 minutes, separate the coagulum into curd grains submerged in a three-fold volume of whey.

First drainage of whey

For hard and semi-hard types of cheese, such as Gouda, Havarti, Tilsiter, Maasdam and Edam, it is required to wash the curd grains to lower the lactose content in the curd texture and control the final pH of the cheese texture, which is a major factor in acquiring the typical smooth texture. Discharge of some of the expelled whey (called first whey) makes space for the added curd wash water. Typically, more first whey is discharged from the cheese vat as curd wash water is added. This is due to the high quality of the first whey (minimal presence of lactic acid and low bacteria presence) and minimises the volume of wash water to dilute the lactose in the remaining whey. Less wash water is less water to later remove from the whey and less volume to heat up or cool down.

The added wash water is typically also used to control the temperature profile at the second stage of the curd-making process. For most cheese types, the temperature will raise to accelerate the syneresis and thus expel the whey faster from the curd grains. Typically, for low-fat cheese types, the curd is cooled down a bit by wash water to achieve a higher moisture content in the cheese and soften the higher protein texture.

Some producers prefer to partly heat the curd via indirect heating with hot water added to the heating jackets (typically dimple-jacket type) mounted to some parts of the cheese vat.

For some cheese types with low wash water usage like Emmentaler, additional indirect heating of the curd grains is required. It is also important to drain off the first whey to reduce the energy consumption needed for indirect heating of the curd. For each type of cheese, it is important that the same amount of whey (typically 30 – 50% of the batch volume) is drained off every time.

Although not pictured in figure 16.10, it is possible to have a whey drainage system in an enclosed, fully mechanised cheese vat. A longitudinal slotted tubular strainer is suspended by means of a pneumatic servo cylinder for the upward and downward movement of the strainer.

The strainer is connected to the whey suction pipe via a swivel union and then through the tank wall to the external suction connection. A level electrode attached to the strainer controls the hoist device, keeping the strainer just below the liquid level throughout the whey discharge period. A predetermined quantity of whey can be drawn off, typically controlled via a flow meter in the whey discharge system.

Stirring is normally stopped while whey discharge is in progress. The whey should therefore always be drawn off at a high capacity to limit the period of no stirring (the time for curd grains to sediment) to a maximum of 8 minutes as curd lumps can form in the meantime. Discharge of the total volume of whey therefore typically takes place in two intervals, the final/second at the end of the curd-making process when another portion of the whey volume is taken.

A less sophisticated manner to get rid of whey is the “hole-in-the-wall” solution. This means that holes are positioned on the tank’s end walls at fixed levels. This is a cheaper way of draining the whey but has some disadvantages. Whey can only be discharged to fixed levels, lower discharge capacity and the losses of fines in the whey are higher compared to using a hoisted whey strainer. For Tvorog cheese (a widely produced fresh cheese type in Eastern Europe) a whey strainer cannot be used as the curd is fermented by gas-forming bacteria which cause the curd grains to have a lower density than the whey. Thus when stirring is stopped the curd will rise to the top of the whey. Here the whey must be discharged via holes in the tank wall underneath the floating curd level.

Heating/cooking/scalding

Heat treatment is required during cheesemaking to regulate the rate of syneresis (expelling of whey, highly impacting the final cheese moisture content), the grain size, grain rind formation and acidification of the curd. The growth of acid-producing bacteria depends on the temperature profile which thus also regulates the formation rate of lactic acid. Apart from the bacteriological effect, the heat also promotes shrinking (contraction) of the curd, accompanied by the expulsion of whey (syneresis).

Depending on the type of cheese, heating (or cooling) can be done in the following ways:

- By temperature-controlled addition of wash water to the curd/whey mixture

- By cold/hot water in the tank jacket

- By a combination of wash water addition and indirect cooling/heating via vat jacket

The time and temperature program for heating is determined by the method of heating and the type of cheese. Heating to temperatures above 40 °C, sometimes also called cooking, normally takes place in two stages. Significant heating will impact the added cultures. Above 38 °C, the activity of the mesophilic lactic acid bacteria is slowed. Above 44 °C, the mesophilic bacteria are completely deactivated, and they are killed if held at 52 °C for between 10 and 20 minutes. Cheese types made using higher heating temperatures and/or only thermophilic cultures can benefit from these elevated temperature profiles.

Cheddar cheese is cooked with hot water (traditionally steam) in the jacket. The heating slope is normally 0.2 – 0.5 °C/min. Heating above 44 °C is typically called scalding. Some types of cheese, such as Emmenthal, Gruyère, Parmesan and Grana, are scalded at temperatures as high as 50 – 56 °C. Only the most thermophilic lactic acid-producing bacteria survive this treatment. One that does so is Propionibacterium freudenreichii ssp. shermanii, which is very important to the formation of the character of Emmenthal cheese.

Final stirring

The sensitivity of the curd grains decreases as heating and stirring proceed. More whey is expelled from the grains during the final stirring period, primarily due to the set temperature profile, the continuous development of lactic acid, as well as the mechanical effect (“massage”) of stirring.

The duration of the final stirring depends on the desired acidity and moisture content of the cheese. Typically, the total period of curd-making (the time from adding the rennet to the milk until starting to empty the cheese vat into the downstream processes) takes 90 – 120 minutes for most hard and semi-hard cheese types, but shorter or significantly longer times are also seen, depending on cheese line setup and preferences of the cheesemaster.

Discharge of whey at the end of the curd preparation process

In many curd-making processes, a second or final removal of whey is recommended shortly before emptying the cheese vat to downstream processes, as it reduces the required drainage capacity of downstream equipment.

Fresh cheese types

Some fresh cheese types have a different curd-making procedure which either takes less time or much more time.

Queso fresco is a non-fermented cheese type where no cultures are added to the milk, so the lactose is not fermented to lactic acid. The coagulation is rennet-based and as the moisture content in the final cheese is high, the curd grains do not need to be cut into small grains and need limited syneresis time. The curd-making time may take up to one hour.

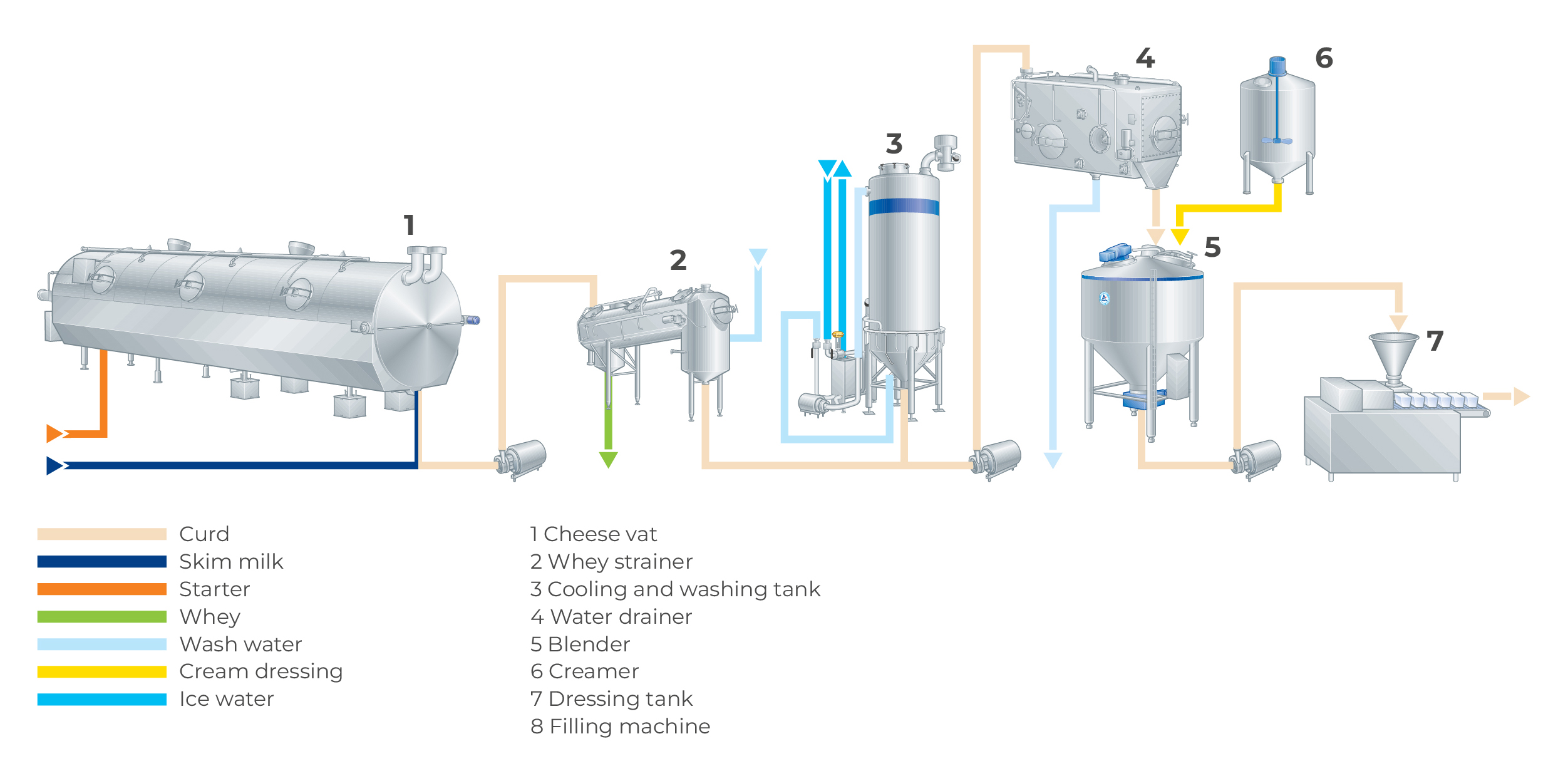

Cottage cheese is based on lactic acid coagulation, often supported with a small amount of rennet. Typically, skimmed milk is inoculated with culture and given a long time for the bacteria to ferment the lactose into lactic acid until a pH of 4.6 – 4.7 (isoelectric point of casein micelles) is reached, at which time the milk coagulates. This may take more than 6 hours. For cottage cheese, the coagulum is gently cut into uniformly sized curd grains and stirred to strengthen the grains by syneresis and heating (rind formation and inactivation of culture activity). The total curd-making process may take up to 10 hours. Depending on the final properties, the curd may be washed with water to remove some of the lactic acid. This is mostly done downstream of the cheese vat but can also be done in the cheese vat. The curd grains are the final product. Downstream processes will separate the whey, wash and cool the curd grains and blend the drained curd grains with a dressing.

Tvorog cheese is also a fresh cheese, solely based on lactic acid coagulation. Reaching the isoelectric point (pH 4.6 – 4.7) may take up to 12 hours. The coagulum is traditionally gently broken up into large curd portions. The curd is given some time for syneresis under gentle stirring and some heating to control the moisture content. At the end of curd-making, which takes a total of approximately 15 hours, some whey may be drained from below the curd level. Typically, the gas-forming cultures will lower the density of the curd making the curd to raise above the whey at standstill. Afterwards the curd will be sent downstream to separate the whey and to form the cheese.

Paneer is a fresh cheese made without the use of cultures and is based on instantaneous acid coagulation by the addition of acid to hot milk to reach the isoelectric point at which the milk coagulates. The hot milk temperature also denatures most whey proteins, which also become part of the cheese texture and help bind water and raise the moisture content. Only limited time is required for syneresis before the coagulum is ready for cheese formation in downstream processes. Curd-making time is typically less than an hour.

Some fresh cheeses, such as white cheese (a feta-like cheese), queso fresco or cream cheese may also be formed without using cheese vats; rather, the cheese package acts as a cheese vat. For these so-called liquid-filled cheeses, the cheese milk is pre-concentrated to final composition of the cheese (taking into account the effect of ingredients added to the pre-concentrated milk) by means of ultrafiltration. The pre-concentrated milk is heat treated to prolong the shelf life and sometimes acidified (e.g. white cheese). Acidification can be done either by inoculation with lactic acid bacteria and ferment overnight or shortly before filling the cheese package by addition of GDL (gluconodeltalactone). The pre-concentrated milk is directly dosed into the consumer package together, with some rennet and (if required) some salt. After a few hours in the closed package, the milk adopts a cheese texture by means of coagulation at ambient temperature.

Final removal of whey and principles of curd handling

Drainage principles

As soon as the required acidity and firmness of the curd have been attained, the residual whey has to be removed from the curd. When continuous drainage equipment such as Casomatic or Cheeseformer drainage and forming columns are utilised, the whey discharge volumes in the cheese vat must be set to achieve the right curd/whey ratio suited for the downstream units. Other types of continuous drainage equipment, such as cheddaring machines or draining and matting machines, are less critical.

The whey, when in the curd/whey mixture, is present in three forms:

- Whey between the curd particles – free whey

- Milk serum incorporated in the curd grains

- Whey bound to protein

The free whey is easily drainable by increasing the compactness of the curd block by pressing.

The milk serum inside the grains is more difficult to evacuate. However, by increasing the acidity and applying force (e.g. by stirring) on the grains, some of this serum is released and behaves as free whey.

The water bound to protein is not drainable under normal cheesemaking procedures.

It is vital to the drainage process that the discharge of whey is gentle and does not exert excessive force on the curd. During whey drainage, the curd grains deform and partly fuse together due to the static pressure in the forming column or the pre-press vat.

Depending on how the curd grains are treated after whey separation, different types of cheese are obtained.

- If the grains are separated first from the whey, filled in moulds and then turned and/or pressed, the result is a cheese with an open or granular structure, i.e. Tilsiter or Havarti

- Collecting the grains in a layer for an acidification period results in a cheese with a closed texture, i.e. cheddar, industrial mozzarella

- When the high-moisture curd grains are acidified in the cheese vat, the final product will be a type of formed or crumbled fresh cheese.

- When the high-moisture curd grains are acidified in the cheese vat, washed with water and cooled, and then mixed with cream or dressing, the final product will be a type of cottage cheese.

- When the curd is kept under the surface of the whey during the combined draining and pre-pressing sequence, the result will be a round- eyed type of cheese, i.e. Emmenthal, Maasdam, Gouda or Edam.

Related properties, essential for cheese quality, are to be controlled via the following parameters of the curd before production continues:

- Moisture content

- Temperature

- Fat content

- Acidity

- Curd grain size and size distribution

Cheese with granular texture

The curd/whey mixture is pumped across a static screen, or an alternative system consisting of a vibrating or rotating strainer. The grains are separated from the whey and discharged directly into the forming column where, under gravity, the drained curd grains interlink. They are then cut off at the bottom end from the compacted curd bed to become curd blocks, which are placed in micro-perforated moulds and pressed into to a cheese with closed rind. The resulting cheese acquires a texture with irregular or mechanical holes, also called a granular texture (Figure 16.13). As the curd grains are exposed to air before being collected and pressed, they do not fuse completely so a large number of air pockets remain in the interior of the cheese. The carbon dioxide formed and released during the ripening period fills and gradually enlarges these pockets.

Cheese with closed or round-eyed texture

Gas-producing bacteria (Sc. cremoris/lactis, L. cremoris and Sc. diacetylactis) are used in the production of round-eyed cheese (Figure 16.14). Propionic bacteria is responsible for the big eyes in Emmenthal cheese.

Studies of the formation of round holes/eyes have shown that when curd grains are collected and compacted below the surface of the whey, the curd contains microscopic cavities. The gas formed when starter bacteria start growing initially dissolves in the liquid, but as bacterial growth continues, local super-saturation occurs, which results in the formation of small holes. Later, after gas production has stopped due to lack of substrate, e.g. citric acid, diffusion becomes the most important process.

This enlarges some of the holes, which are already relatively large, while the smallest holes disappear. Enlargement of bigger holes at the expense of the smaller ones is a consequence of the laws of surface tension, which state that it takes less gas pressure to enlarge a large hole than a small one. This course of events is illustrated in Figure 16.15. At the same time, some CO2 escapes from the cheese.

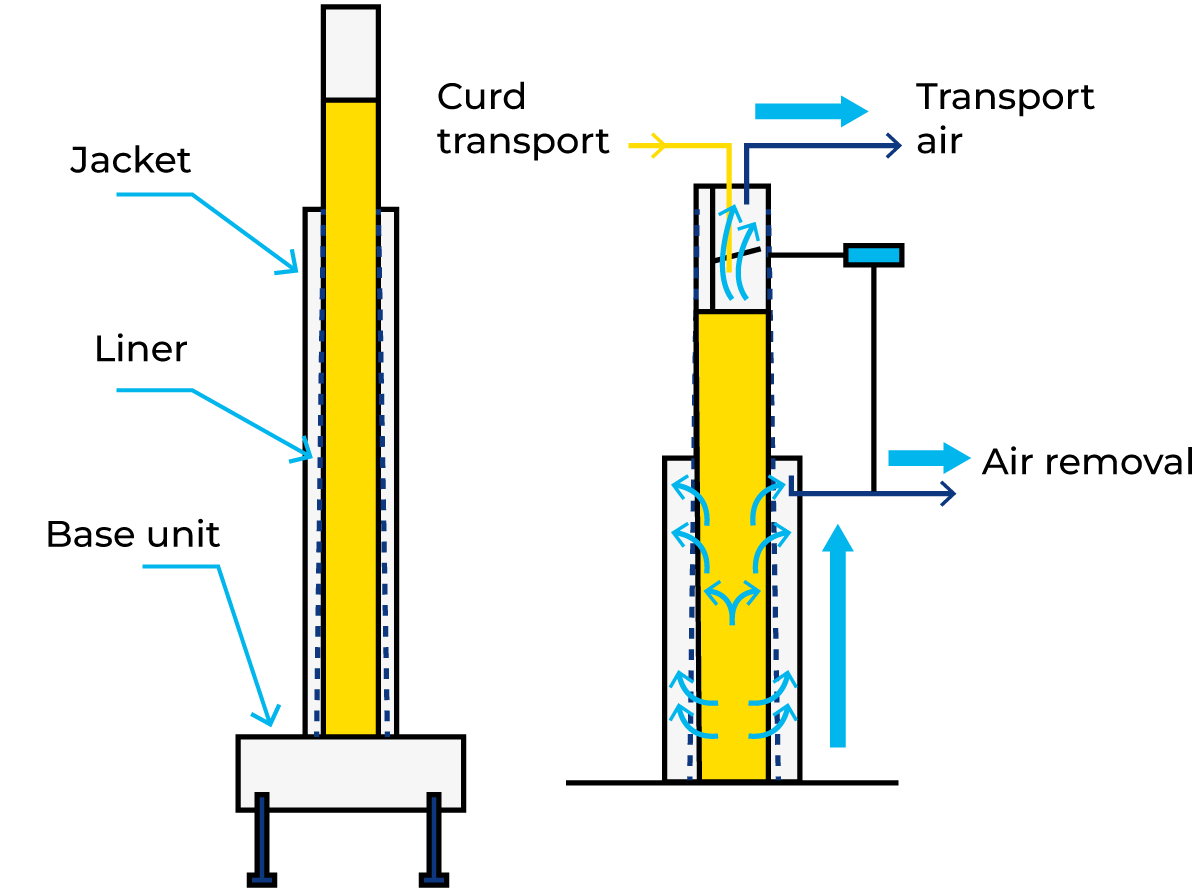

Two systems can be applied for draining the whey under its surface: the traditional horizontal pre-pressing vat or the more favoured industrial vertical drainage and forming columns. There are two main types of vertical drainage and forming columns; Casomatic systems for hard and semi-hard cheese and Cheeseformer systems for fresh cheese types.

The choice of system depends on:

- Type of cheese to be produced

- Batch or continuous production

- Plant production capacity

- Flexibility regarding cheese types and dimensions

- Addition of herbs, spices, etc. to the cheese

- Level of automation

- Level of investment

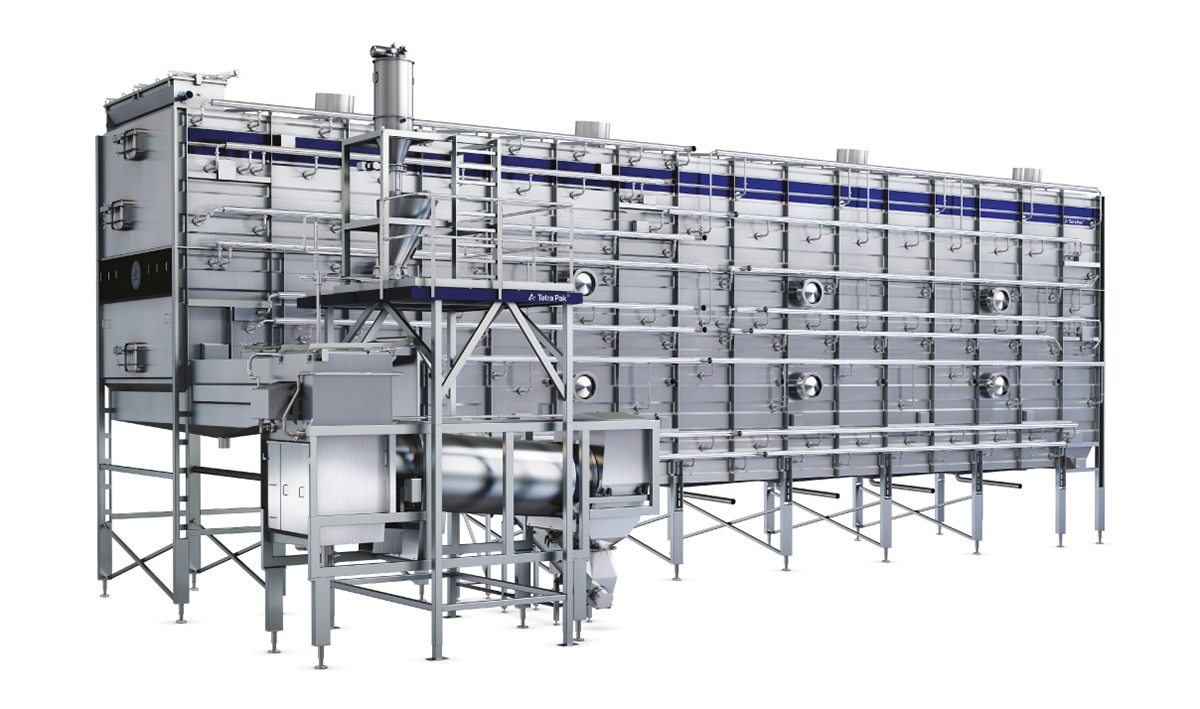

Continuous drainage system

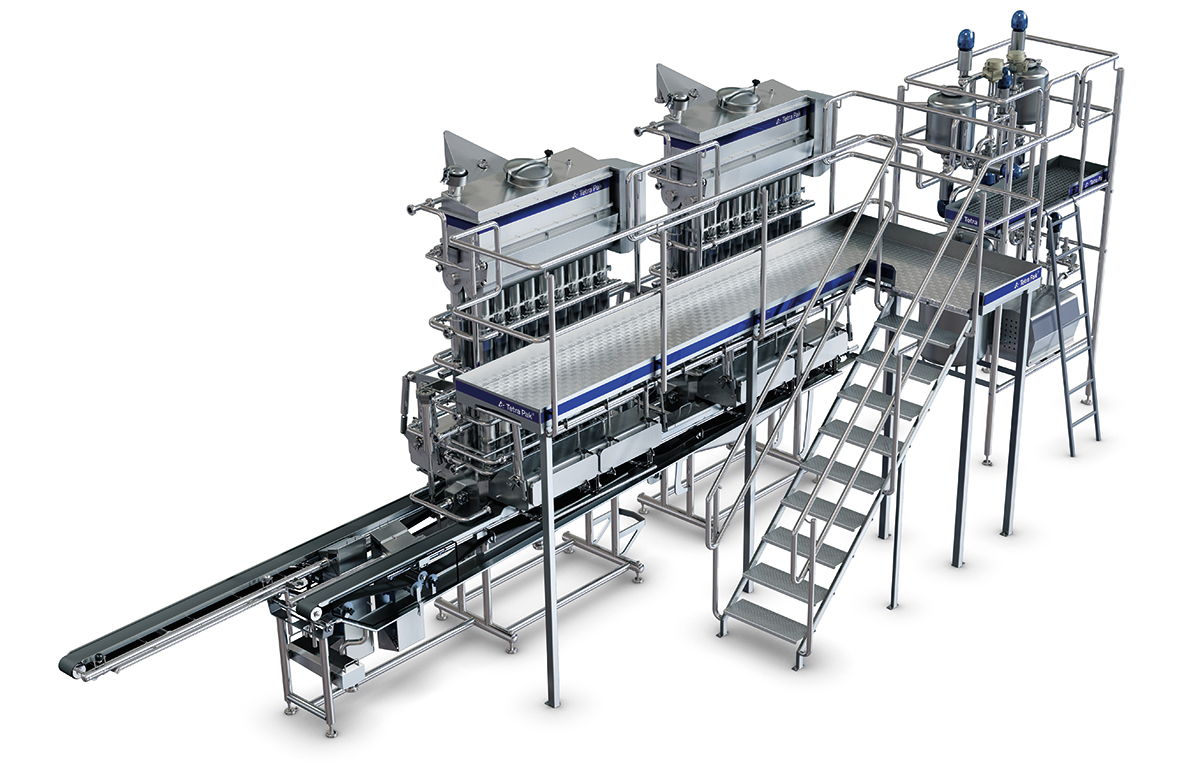

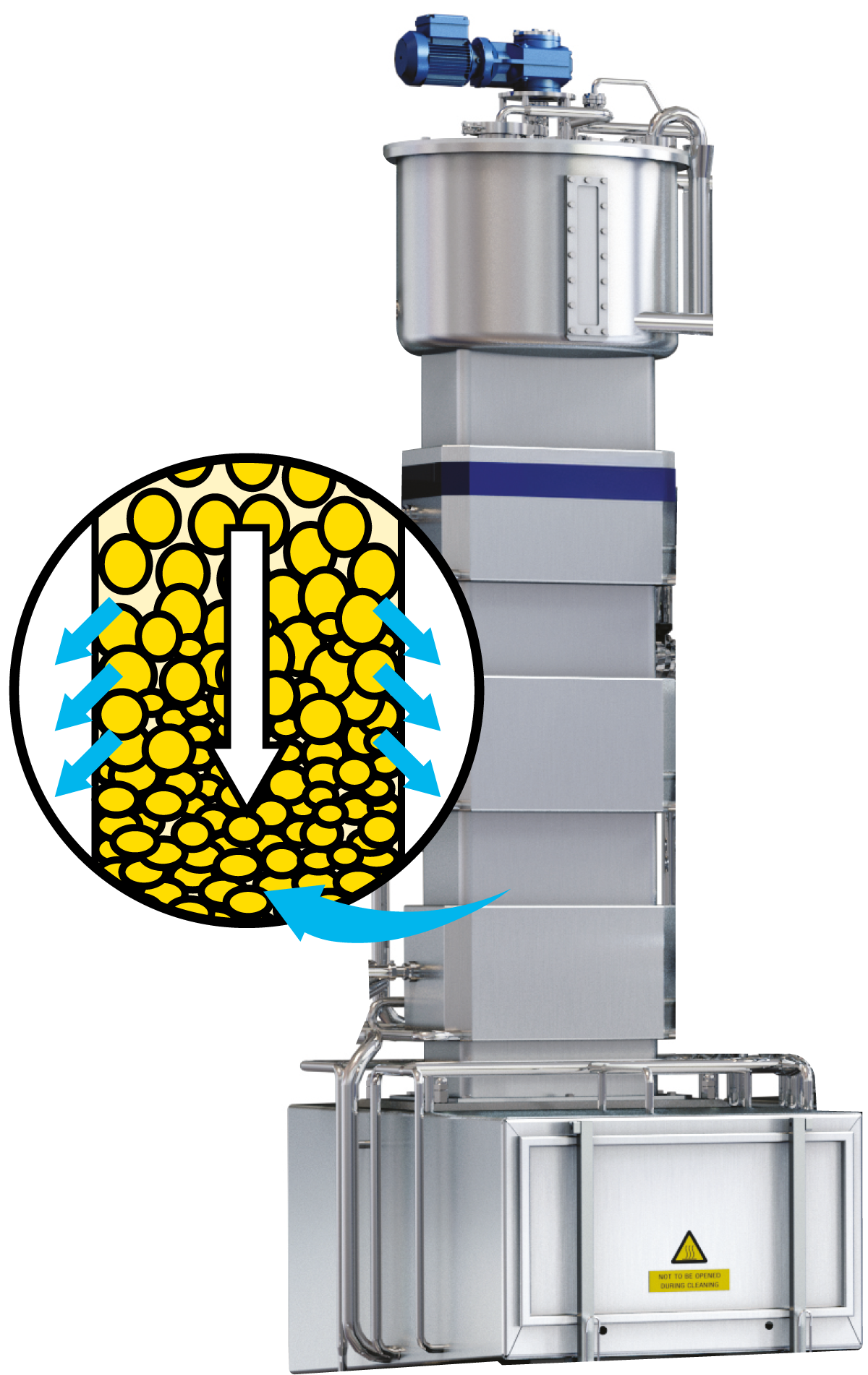

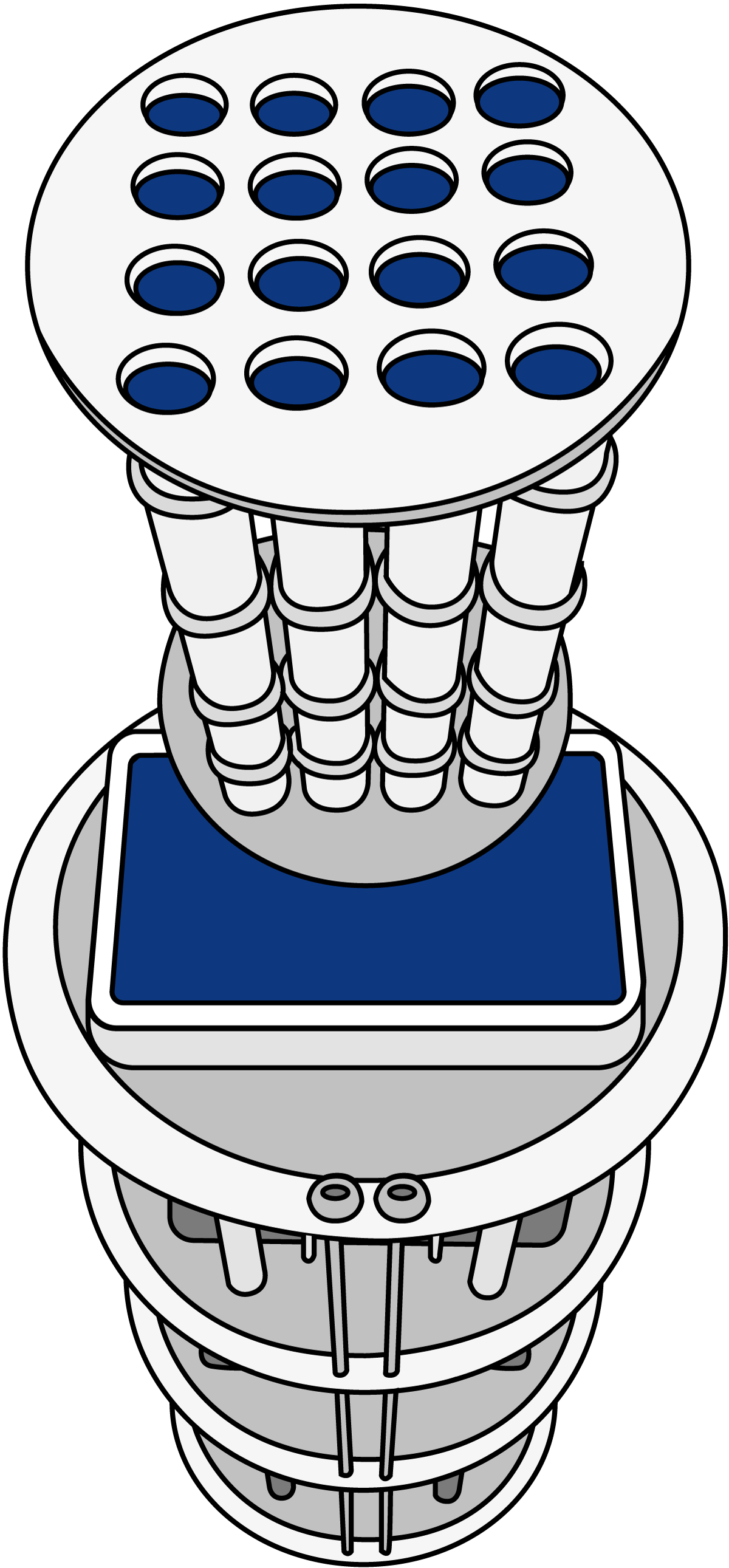

The continuous drainage, forming and mould-filling machine offers an advanced drainage system. For fresh cheese types a cheese former column system is used (see Figure 16.16). The Casomatic single-column version is shown in Figure 16.17. There is also a multi-column version available in which a changeable insert is placed (see Figure 16.17, centre). This insert contains from one up to a maximum of 16 drainage tubes, depending on the size of the formed cheeses.

Two buffer tanks (occasionally three) are also required in the automatic and continuous Casomatic system to feed a continuous ration of curd and whey. One buffer tank receives a batch of curd-whey mixture from the upstream cheese vat and has some time to de-aerate potentially entrapped air, while the other empties into the Casomatic columns. A third tank is sometimes used to optimise the production time schedule and allow more time for de-aeration.

A buffer tank must finalise the filling stage before starting to empty to ensure a constant whey/curd ratio is supplied to the columns during the whole emptying time (batch time). The stirring action in the buffer tank forms a part of the final curd-making process. The capacity per single column is approximately 1,300 kg/h depending on the cheese shape, type and weight. Several columns are usually placed in a row to suit the required line capacity and work in parallel mode filling moulds on a mould conveyor.

In the multi-column version, the capacity depends on cheese type, cheese size and number of drainage tubes in the insert. For semi-hard, round-eyed cheese, the capacity can range between 1,000 and 3,000 kg/h. Depending line capacity several columns can work in parallel.

The Cheeseformer is directly supplied with the curd-whey mixture of the upstream cheese vat. It separates the whey from the curd and forms the curd to a specific narrower cheese shape in 16 – 24 forming columns per unit. The formed fresh cheese blocks are transferred sideways and either manually or automatically positioned in consumer packages.

Buffer tanks

The buffer tank is a vertical stainless steel tank with a conical bottom equipped with a dimple jacket for cooling to limit cheese moisture content variation. Inside the tank, a stirrer is situated in the lower conical part. The stirrer speed is adjustable in correlation with the level, as the intensity of stirring is critical to maintain a constant curd/whey ratio supplied to Casomatic systems.

The buffer tank in the drainage system is intended to:

- Create a uniform feed of curd/whey mixture

- Be a link between batch curd production and continuous drainage

- Cool the curd/whey mixture for moisture accuracy control of the final cheese

- Deaerate the curd/whey mixture

- Extend the stirring period and release the cheesemaking tank for a new batch

- Mix the curd with other ingredients, i.e. herbs, spices

The curd/whey mixture, normally in a ratio of 1:3.5 – 5.0, is pumped from the buffer tank to the drainage columns by a frequency-controlled positive displacement pump.

Single-column system

The single-column system is able to make one pre-determined curd block shape (with adaptable height). The curd/whey mixture enters the column under the whey level for round-eyed cheese production. The column is filled with a so-called curd bed, but the whey level is always above the level of curd to avoid the incorporation of air into the curd.

The drainage columns can be round or rectangular-shaped to suit the cheese being produced. The whey is flowing at a controlled flow rate through the curd bed to one of the three drainage sections where the column wall is perforated so the whey can flow out. The flowrate, controlled by regulating drainage valves, and resulting curd bed compactness (measured as pressure difference over the curd bed, also called flow resistance for the whey) are regulated based on recipe settings resulting in a compacted curd bed at the lower end of the drainage column. The majority of the whey is removed at the upper drainage section, but the final compactness is reached at the lowest whey section, giving time for equal compacting of the curd bed from its centre to outer regions, ensuring proper and even cheese texture.

Optionally, a pre-drainage screen can be placed on the top of the column if producing granular types of cheese. In this case, the whey drains off over the curd bed, and a curd bed in contact with air is created in the drainage column. The compactness of the granular structure, among other things, is controlled by the adaptable curd bed height, residence time and curd grain properties.

The compacted curd bed rests on a horizontal knife. At pre-set intervals, the knife is opened, and the curd bed is lowered into the base unit to the dosing height, after which the lower end of the curd bed in the base unit is cut-off by closing of the knife.

The operating sequence is:

- A slide cassette is positioned under the column and a dosing plate is pushed up through the slide cassette until it is just underneath the knife.

- The knife opens and the curd bed rests on the dosing plate. This descends to the optimal dosing height for this dosing cycle (to achieve the required weight and height of the pressed cheese).

- The knife closes and cuts off the curd block (and the bottom of the drainage column closes).

- The curd block can be pre-pressed by the upwards-moving dosing plate.

- The dosing plate descends to its bottom position.

- The dosing plate and slide cassette with the curd block are pushed forward to a position above the presented mould.

- The dosing plate is quickly retracted and the curd block is placed into a mould.

- The slide cassette is positioned back under the column, and the dosing plate is again pushed up and ready for the next dosing and mould-filling sequence.

The combination of precise curd-bed compactness control, automatic height adjustment of the curd blocks in the base unit below the drainage column, and predictable pressing of the curd block to cheese in downstream processes results in a predictable and accurate weight of the cheeses.

Multi-column system

The Casomatic multi-column system is a vertical unit that provides higher production flexibility in terms of cheese sizes and shapes. The inner drainage insert and a few tools in the base unit can be exchanged after an intermediate rinse halfway through the CIP process for parts fitting for the next curd block dimensions.

The drainage insert can consist of one single drainage tube, round or rectangular, i.e. one Euroblock for Gouda or 16 small tubes, i.e. for Edam balls. The drainage inserts are hoisted and placed on a platform adjacent to the column when changed. One or multiple columns are normally placed beside each other using the same mould conveyor for delivering cheeses. The moulds used must all have the same outer measurements. When inserts with several drainage tubes are used, multi-moulds with the same configuration as the insert tube must be used.

The curd/whey mixture is pumped from the buffer tanks to the top of the multi-column. The inlet is tangential, and a rotating distributor ensures uniform filling of each drainage tube. The whey level is always above the curd level when producing round-eyed cheeses. When granular cheese is to be produced, a pre-drainage screen is placed on top of the column.

The discharge of whey and curd bed compacting through two (for small cheese formats) or three perforated sections is equal to that of the single-column system. The transfer of the curd block(s) to the mould is slightly different as the dosing plate will stay positioned below the drainage column and the curd blocks slide over the transfer plate towards a sluice plate assembly above the presented (multi) mould. By opening the sluice plates, the curd block(s) drop into the mould.

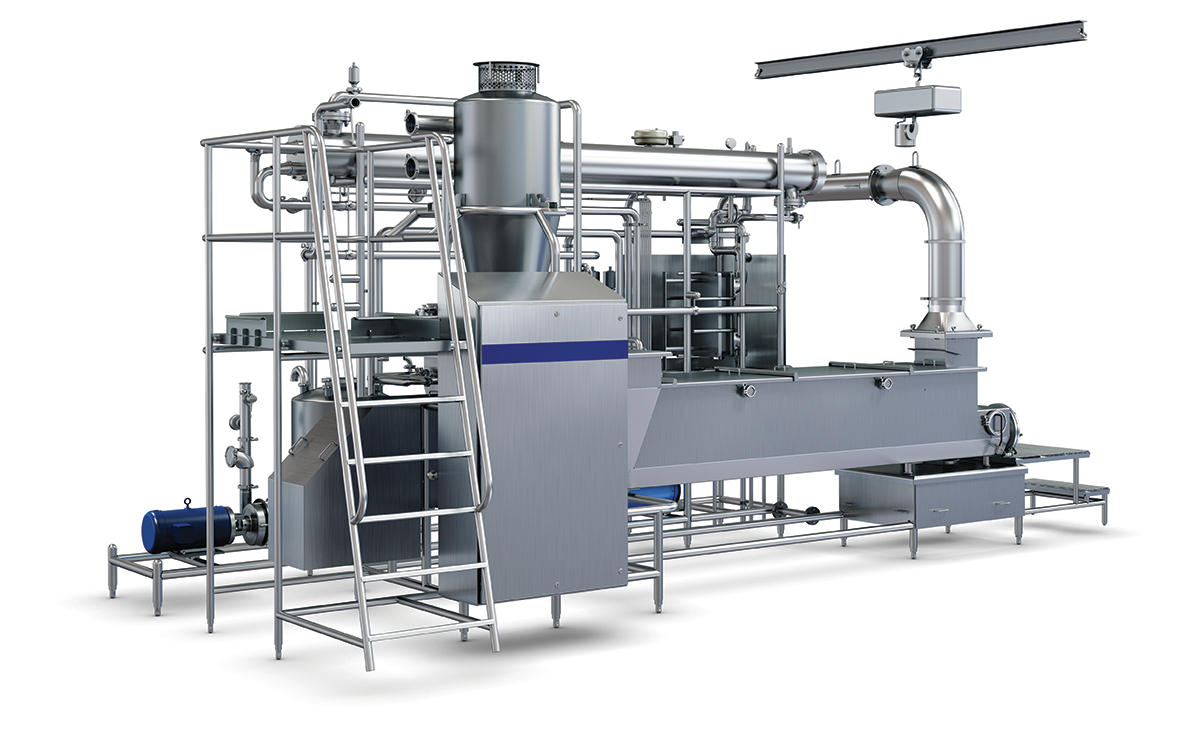

Cheeseformer

The Cheeseformer has as the Casomatic single column system pre-set drainage columns. These drainage columns share a common base unit. The curd-and-whey mixture is directly supplied by the cheese vat. At the inlet to the drainage columns at the column top, a major part of the whey can be separated by a sloped screen. The remaining curd and whey are distributed in the common column top to the positioned 2 rows of drainage columns.

The remaining whey is drained through the formed curd bed and leaves the drainage columns via the perforated walls. Final compacting is achieved by adding a partial vacuum pulling more whey from the curd bed.

The curd beds of all columns are resting on a common knife. When opening the knife, all curd beds transfer to a positioned dosing plate and the dosing plates lower to the preset dosing height. By closing the knife, the bottom side of the compacted curd bed is cut off as cheeses.

The cheeses will be dropped onto 2 conveyors and transferred to the side for manual or automatic placement of the cheeses in consumer packages. All versions of the continuous-drainage and mould-filling systems are designed and equipped for CIP cleaning.

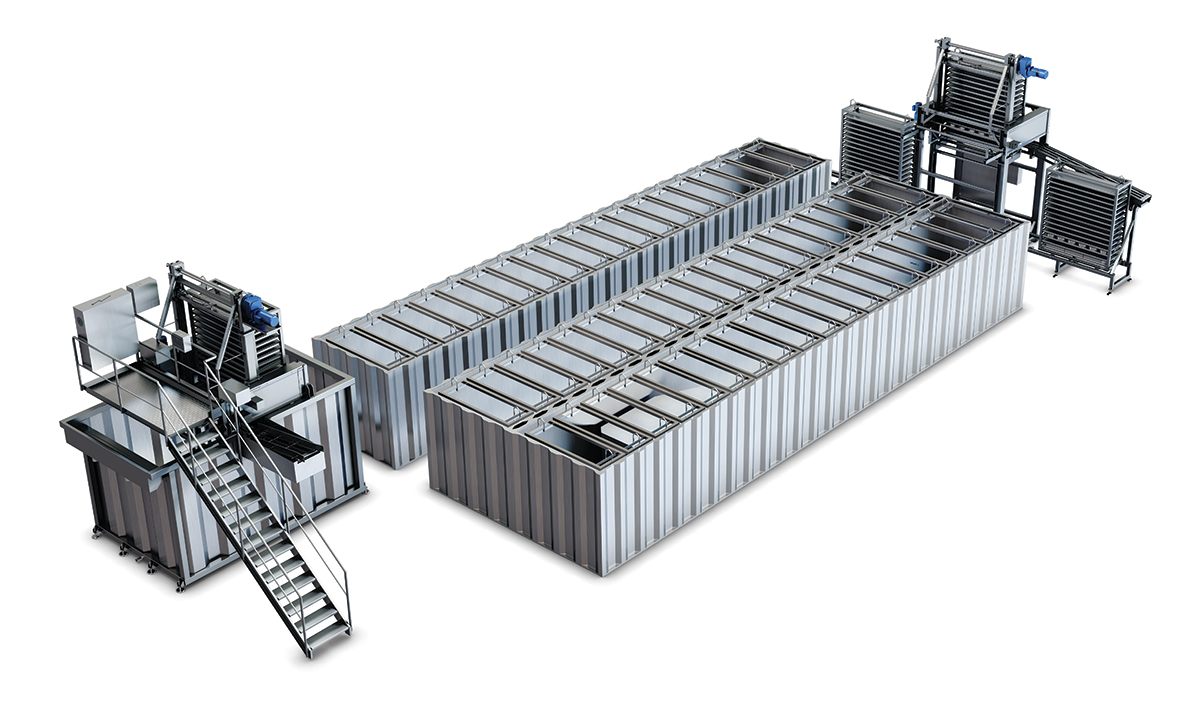

Pre-pressing vats

The whey is drained off in the batch-operated pre-pressing vat, and the curd is pre-pressed before being portioned and moulded.

The pre-pressing vat consists of a stainless steel rectangular open vat. In the front part of the vat is a door, which can be closed when the vat is filled. The end walls are covered with perforated screens for whey drainage. Their positions are not fixed and can be set depending on the type of cheese, curd amount, curd layer thickness, etc.

The bottom of the vat is covered by a draining belt that can move forward or backwards. Whey is drained through the belt, and front and end screens. The plastic belt also transports the curd bed out of the vat after drainage.

The curd/whey mixture is manually or automatically spread into a uniform layer. In the case of granular cheese production, the curd is distributed in the same way, but the whey is first strained off and collected in a tank.

The curd bed is commonly pre-pressed by a pneumatically operated pressing plate. The pressing plate is perforated for whey drainage.

After the pressing is completed, the discharge end of the vat is opened, and the plastic belt moves the complete curd bed a pre-set distance and the curd bed will be cut into rectangular curd blocks by a set of static or moveable knives so that it fits in the mould for final pressing.

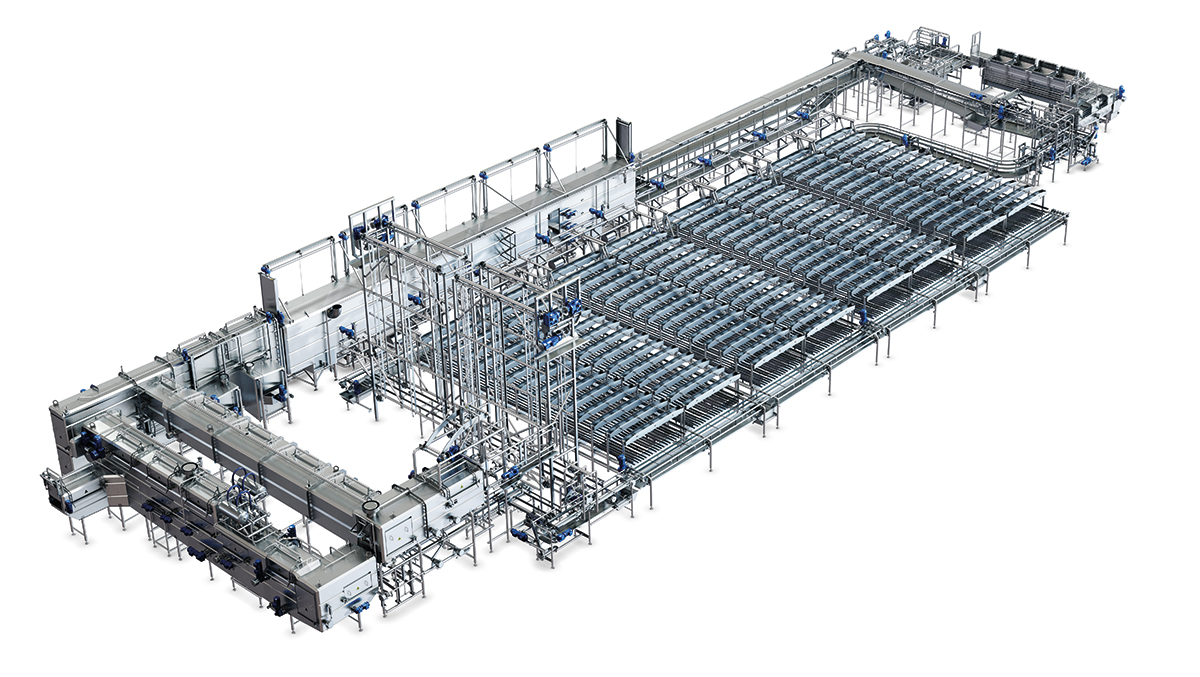

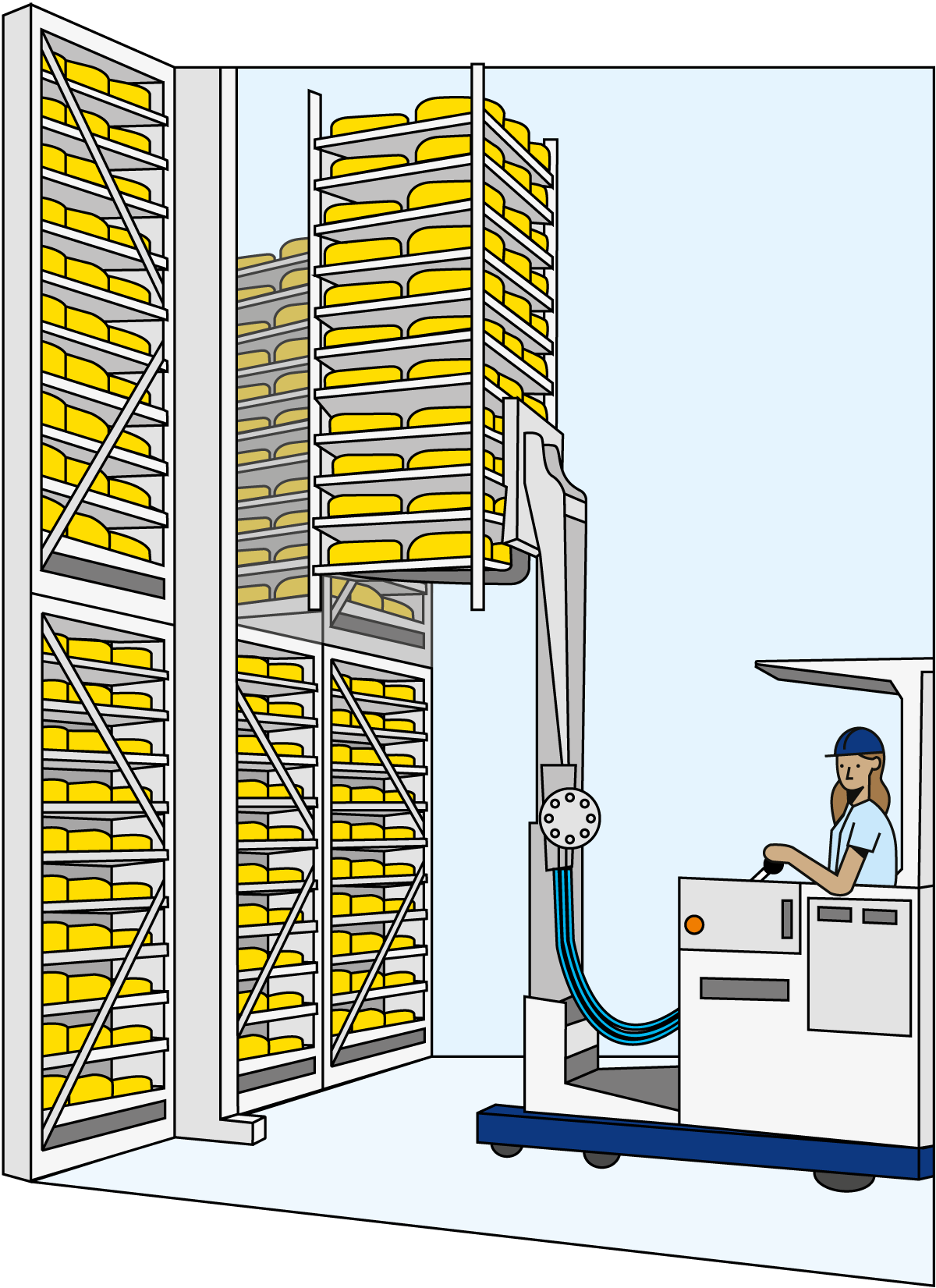

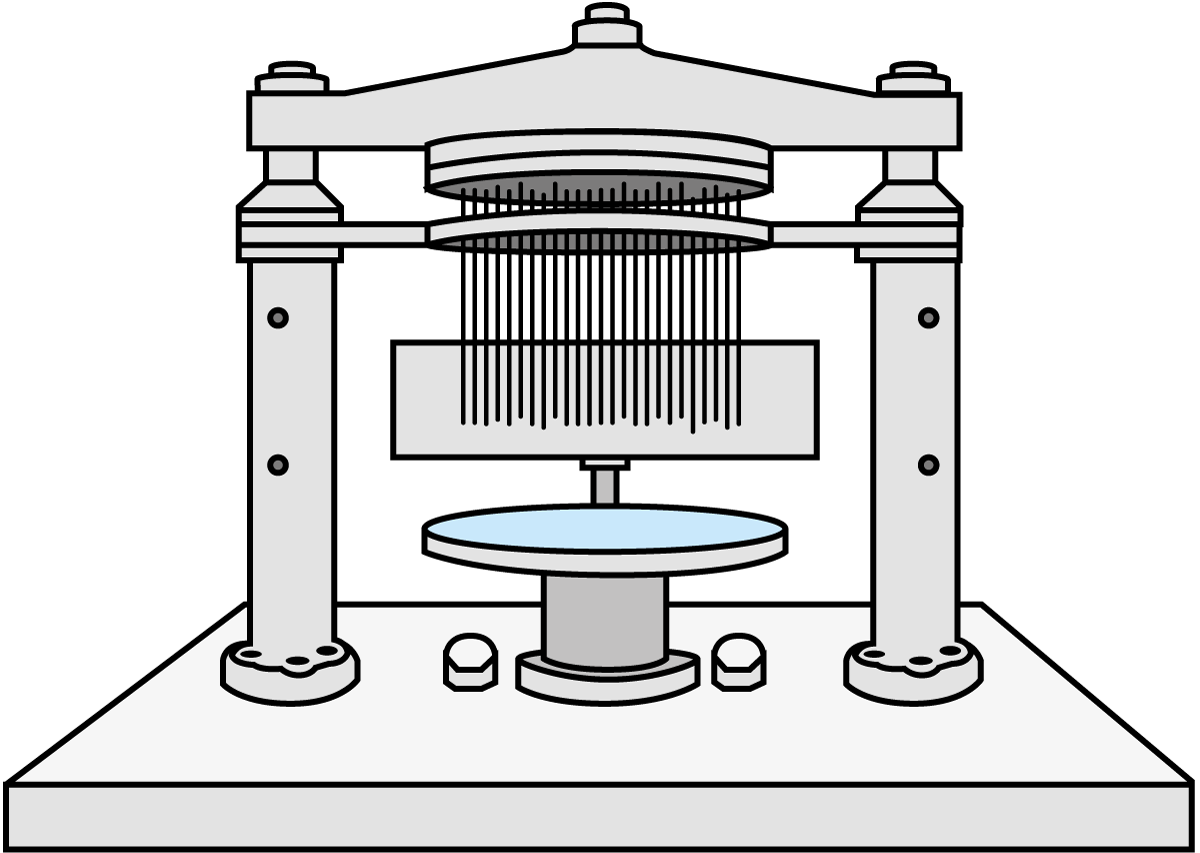

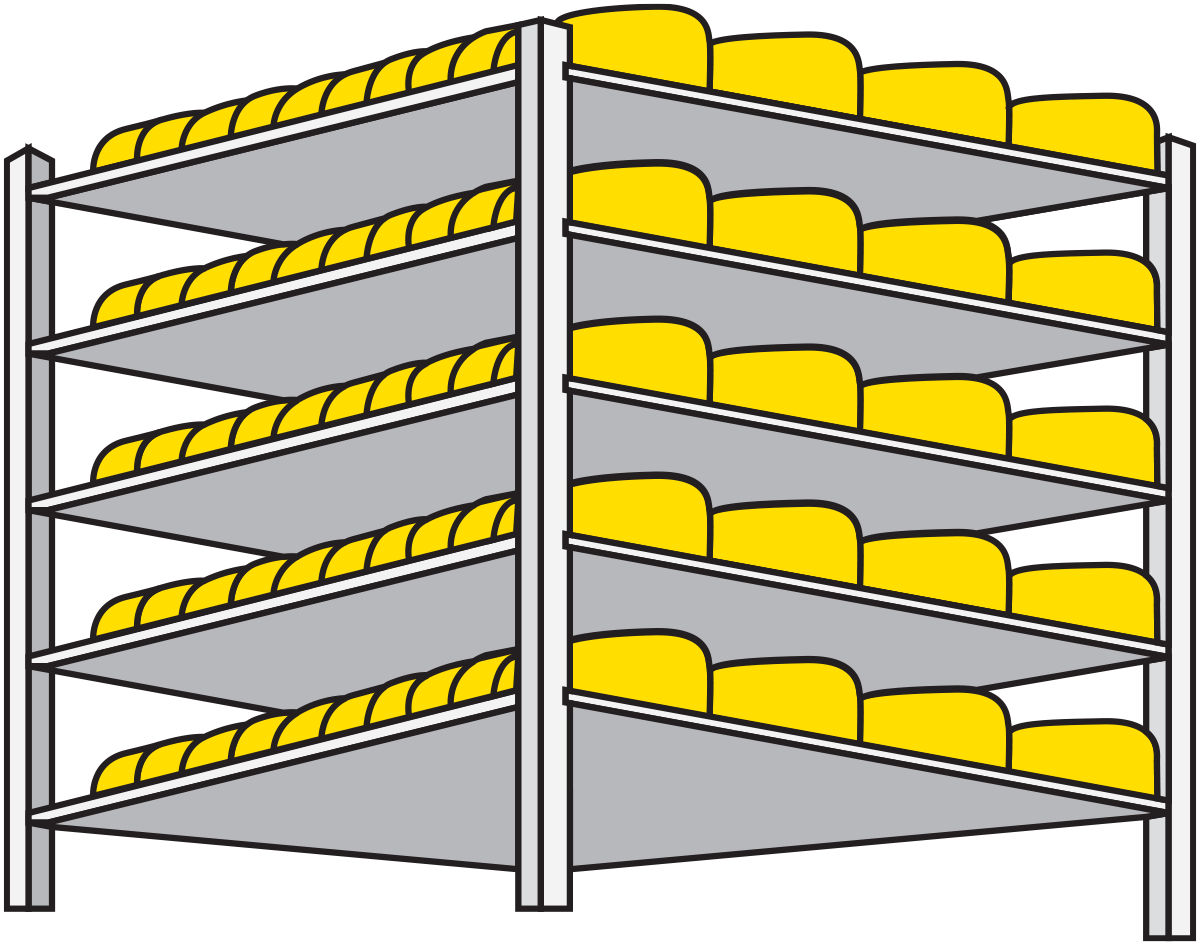

Cheese moulds

The curd blocks leaving the drainage equipment are placed in a mould for final pressing. The shape of the mould should correspond with the shape of the final cheese. After the curd block or curd blocks are placed in the mould, a lid is placed on top. The lid must precisely fit the mould opening in order to minimise uneven rims. The filled mould is conveyed to the pressing section of the plant. In the pressing section, the pneumatic operated cylinders above the moulds push the mould lid into the mould in a series of 3 to 10 pressing steps with increasing intensity.

The air pressure to the pressing cylinder is calculated to achieve an effective pressure to the cheese surface, varying between 50 up to a maximum of 450 grams per cm2, depending on the cheese type.

The moulds are used to:

- Get rid of most of the remaining whey in the curd block

- Form a stable rind on the cheese surface

- Achieve the correct, uniform shape of the cheese

- Give time for the formed cheese to acidify to the correct final pH

The total residence times of cheeses in the moulds vary but are typically between 60 – 100 minutes depending on cheese type/format/cheesemaster preferences. But shorter and longer times also are seen. The acidification time is often the critical time path.

The mould and lid are micro-perforated. Traditional moulds are fitted with a net or cloth inside. On micro-perforated moulds, grooves on the inside contribute to good rind forming and whey drainage. Most of cheese moulds are made from plastic, but in some plants, traditional stainless steel moulds are still in use. Their design must be very rigid to withstand the applied pressure, conveying and mechanised handling. Each mould and lid is in use several times during a production run and passes a mould rinsing or cleaning station before collecting the next curd block for pressing. They must thus withstand common cleaning detergents and elevated temperatures as they pass this cleaning/rinsing station in their production loop approximately every 2 hours.

Pressing

After having been moulded, the curd is subjected to final pressing. There are five aims:

- Assist final whey expulsion

- Provide texture

- Reach desired acidification

- Provide a rind on cheeses with long ripening periods

The rate of pressing and applied pressure is adapted to each particular type of cheese. Pressing should be gradual at first because initial high pressure compresses the surface layer and can lock moisture into pockets in the body of the cheese.

The pressure used depends on:

- Cheese dimensions

- Curd temperature

- Fat content

- Acidity level

- Type of mould

- Amount of residual whey in the cheese

- Available time for pressing

Pressing system

Pressing systems are available in open and closed execution. Closed CIP cleanable presses are applied in high-capacity lines with a focus on hygiene and better temperature stability for the cheese. Producers with a strong focus on whey quality and efficiency can choose an open pressing system with whey trays which carry the moulds and collect the released press whey to keep it in good hygienic condition. The whey tray press system also does not require the daily time-consuming and costly CIP cleaning of the presses and tray-conveyors.

When the press is filled, the curd blocks will be pressed into cheeses with a closed rind. The pressure and intervals between increases of pressure, as well as the total pressing time, are automatically controlled. A press system is designed for simultaneous loading and unloading, which allows optimum utilisation of the press. Downstream from the presses, the curd blocks are demoulded and transported to the brining system. Moulds and lids (and, if applicable, whey trays) are rinsed or cleaned in a washing machine and transported back to the mould-filling area.

Cheddar cheese

Cheddar cheese types are normally made with starter cultures containing bacteria that do not produce gas – typically lactic acid-producing bacteria like S. cremonis and S. lactis.

The specific processing technique may, however, result in the formation of cavities called mechanical holes, as shown in Figure 16.22.

When the pH of the curd mass has reached about 6.0 – 6.1 (about two hours after renneting), the whey is drained off, and the curd is subjected to a special form of treatment called cheddaring.

Typically cheddar curd is not washed, so no wash water addition is required to the cheese vat and therefore whey discharge from the cheese vat is mostly not required unless it suits the drainage capacity of the downstream equipment. But these whey discharge volumes at the cheese vat are fairly small and often the “hole in the wall” approach is used. Thus, typical cheddar cheese vats do not consist of whey strainer systems.

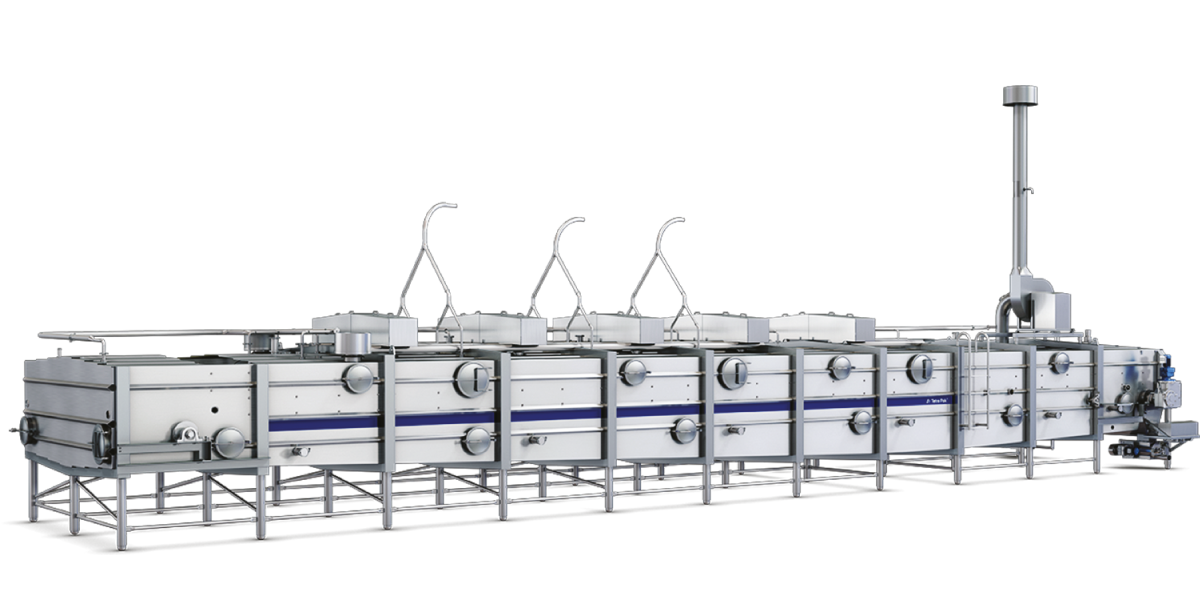

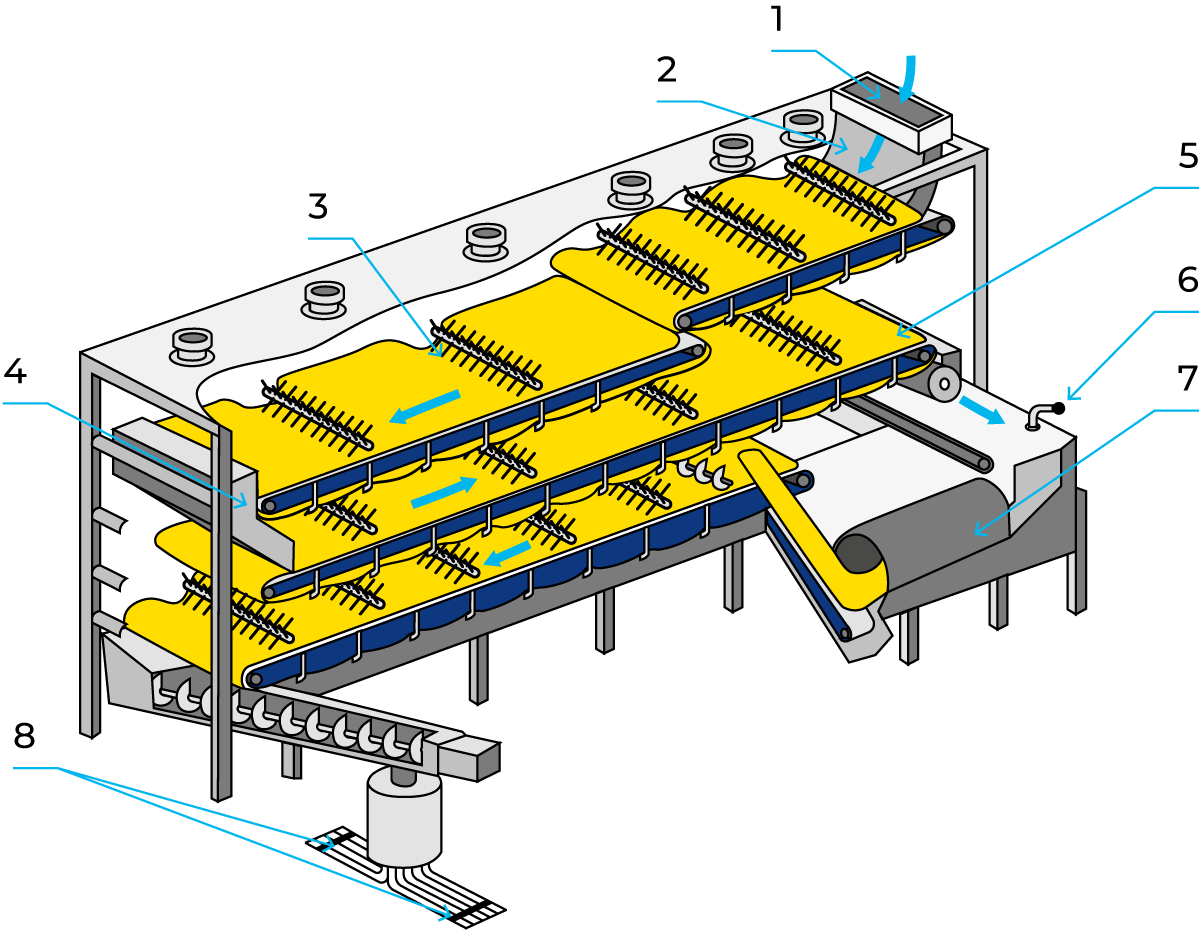

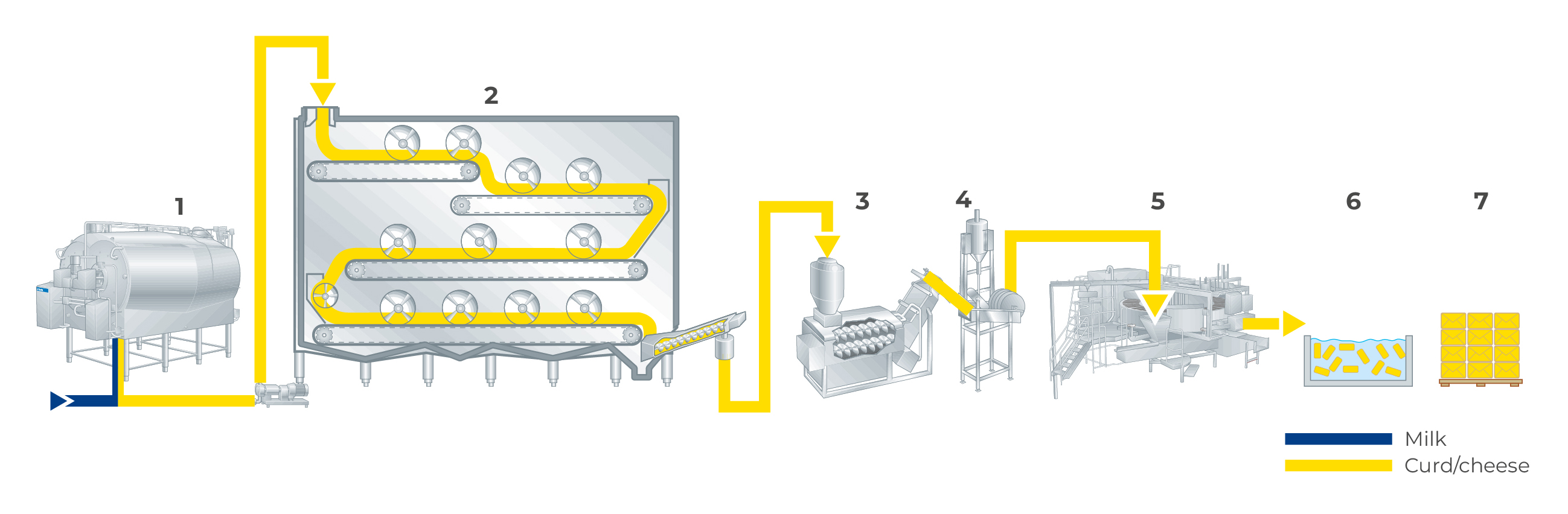

Cheddaring machine