Evaporators

Removal of water

The concentration of a liquid involves the evaporation of a solvent, in most cases water. Concentration is distinguished from drying in that the final product – the concentrate – is still liquid.

There are several reasons for concentrating food liquids:

- Reduce costs for storage and transportation

- Induce crystallisation

- Reduce the cost of drying

- Reduce water activity to increase microbiological and chemical stability

- Recover valuable substances and by-products from waste streams.

The concentration of a liquid by evaporation under vacuum was introduced in 1913. The process was based on a British patent by E.C. Howard, which covered a steam-heated, double-bottomed vacuum pan with a condenser and vacuum pump.

Concentration

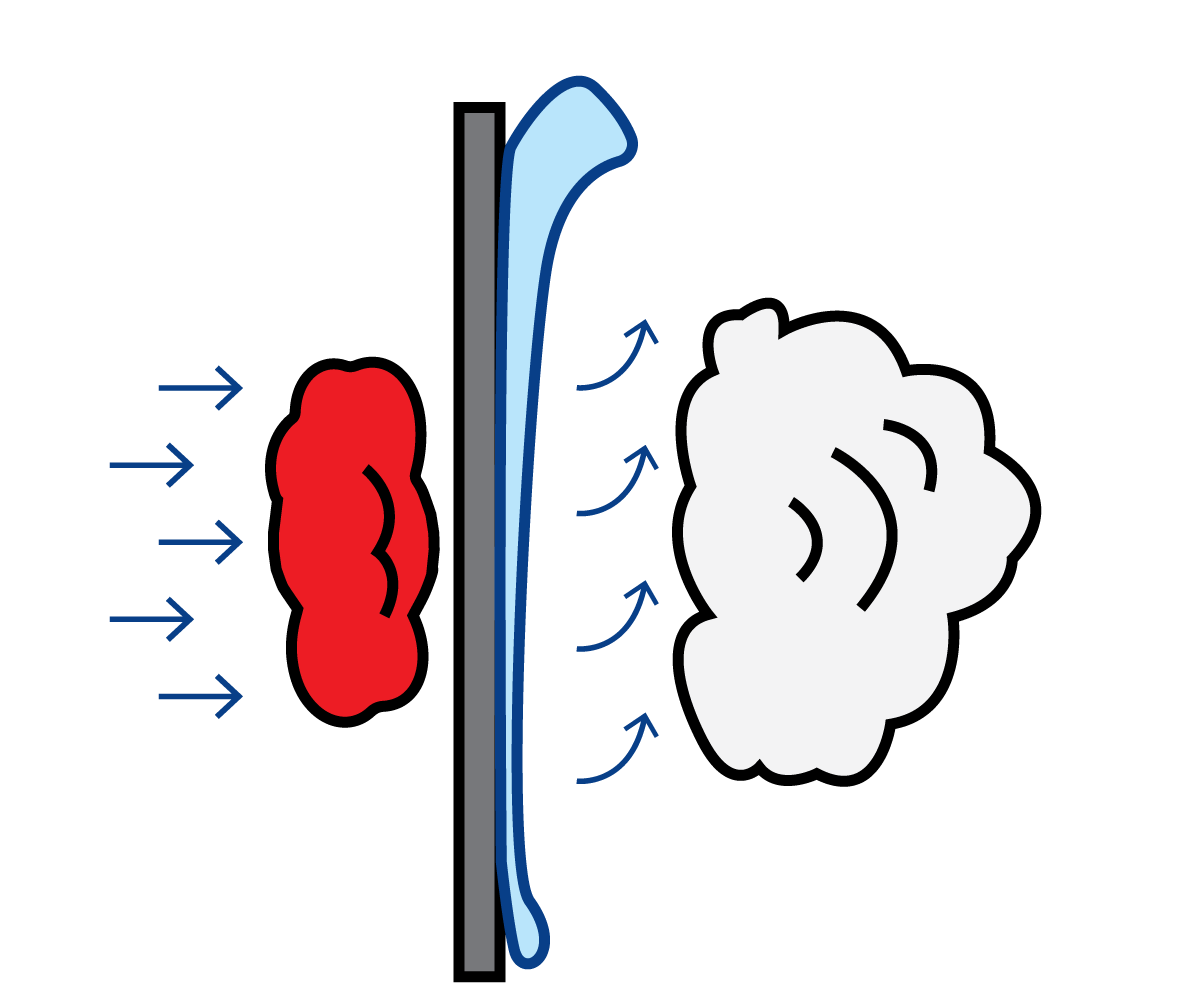

In the dairy industry, evaporation is used to concentrate milk, whey, whey- and milk protein concentrate and permeate from membrane filtration modules. Water is evaporated by means of indirect heating. The product and heating medium (steam) are kept separate from one another using a sheet of special steel. The heat released during the condensing of the steam is transferred to the product via the partition.

Evaporation also constitutes the preliminary stage of the drying of the said products.

How far the concentration process can be forced is determined by product properties such as viscosity and heat stability.

Heat treatment is often an integral process step of an evaporator in order to achieve specific properties in the finished powder. As some products are sensitive to heat, the design of these systems has to be considered carefully with respect to temperature and holding time in order to achieve the desired effects on the one hand, but without causing heat damage on the other.

To minimise the thermal impact on the products from the heat applied, evaporation takes place in a vacuum at pressures of 160 – 320 hPa, equivalent to water boiling temperatures of 55 – 70 °C.

The following aspects must be taken into account when planning an evaporator station:

- Quality of the final product

- Energy costs

- Heat treatment

- Heat recovery

- Condensate quality

- Cleaning duration and cleaning costs

- Cost of premises

- Environmental conditions

- Investment costs

Evaporator design

It takes a large amount of energy to boil off water from a solution. This energy is often supplied as steam. To reduce the amount of steam needed, the evaporator is normally designed as a multiple-effect evaporator. Two or more effects operate at progressively lower vacuums and thus with progressively lower boiling points. In such an arrangement, the vapour produced in the first effect can be used as a heating medium in the next effect. The result is that the amount of steam needed is approximately equal to the total amount of water evaporated, divided by the number of effects.

Nowadays, electricity is used extensively as the energy source; particularly in the case of what is known as pre-concentrators, which are used to concentrate milk and whey to 32 – 40% solids content. Electricity is also used more often in the case of what is known as finishers, which concentrate milk and whey to their final solid content. To do this, an electric compressor is used which compresses the vapour evolved in the effect, thus bringing it to a temperature level 3 – 7 °C higher and using it as a heating medium in the heater. This mechanical vapour recompression (MVR) offers clear benefits in terms of operating costs.

Circulation evaporators

Circulation evaporators can be used when a low degree of concentration is required or when small quantities of product are processed.

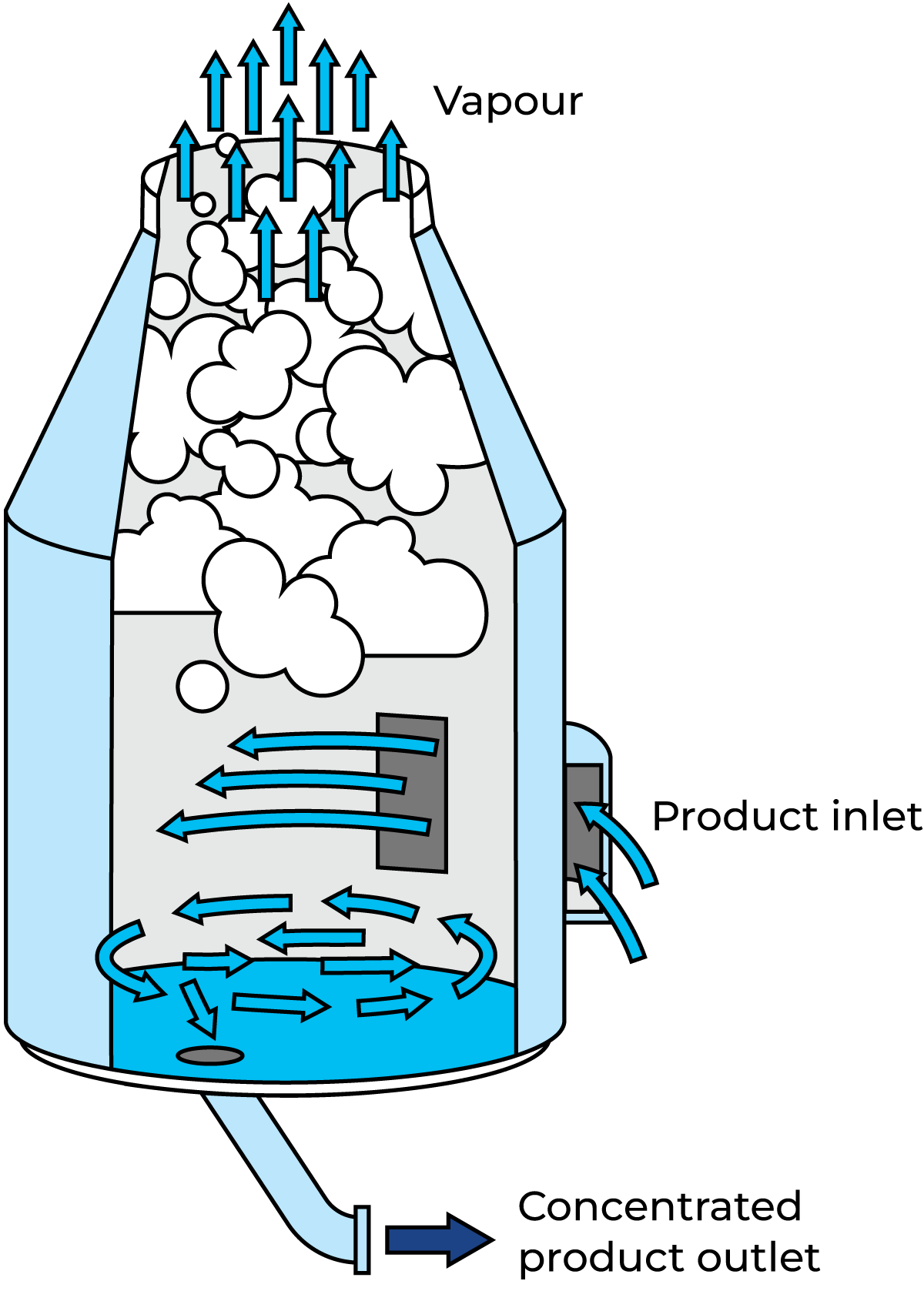

In yoghurt production, for example, evaporation is utilised to concentrate milk 1.1 – 1.25 times, or from 13 to 14.5 or 16.25% solids content, respectively. This treatment simultaneously deaerates the product and rids it from off-flavours. The circulation evaporation process line is shown in Figure 7.6.3. The milk is heated to 90 °C, enters the vacuum chamber tangentially at a high velocity and forms a thin, rotating layer on the wall surface (Figure 7.6.2). As it swirls around the wall, some of the water is evaporated and the vapour is drawn off to a condenser. Air and other non-condensable gases are extracted from the condenser by a vacuum pump.

The product eventually loses velocity and falls to the inwardly curved bottom, where it is discharged. Part of the product is recirculated by a centrifugal pump to a heat exchanger for temperature adjustment, and then to the vacuum chamber for further evaporation. A large amount of product must be recirculated to reach the desired degree of concentration. The flow through the vacuum chamber is four to five times the inlet flow to the plant.

Plate-type evaporator

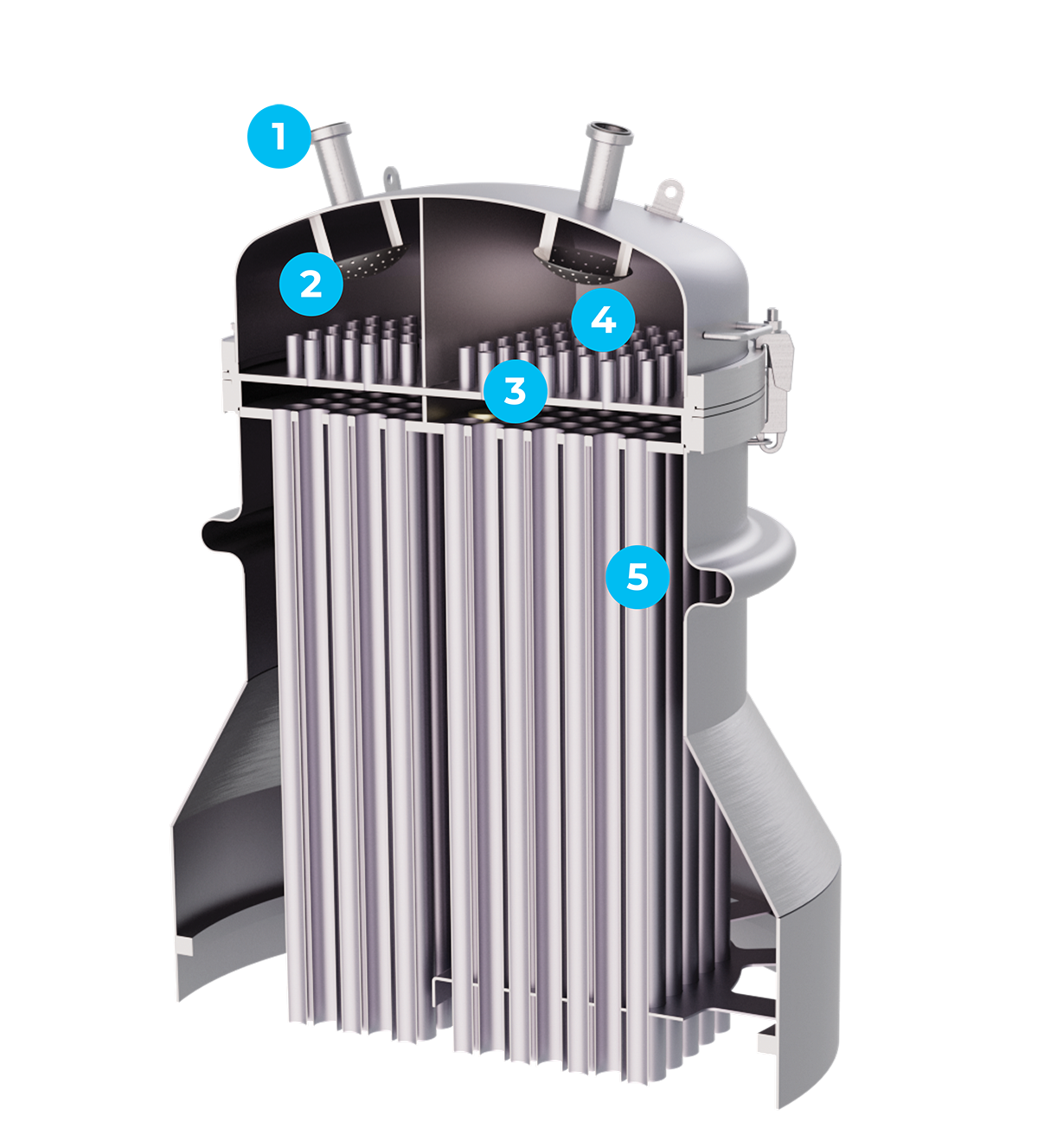

Distribution in a plate-type, falling-film evaporator can be arranged with two pipes running through the plate pack. For each product plate, there is a spray nozzle in each product pipe, spraying the product in a thin, even film over the plate surface. In this case, the product enters at evaporation temperature to avoid instant flash evaporation during the distribution phase. The water component of the thin product film evaporates rapidly as the product passes over the heating surface. A vapour cyclone separator (4, 5) is fitted at the outlet of the evaporator. This separates the vapour from the concentrated liquid.

As evaporation proceeds, the volume of liquid decreases and the volume of vapour increases. If the vapour volume exceeds the available space, the velocity of the vapour will rise, resulting in a higher pressure drop. This will require a higher temperature difference between the heating steam and the product. To avoid this, the available space for vapour must be increased as vapour volume increases.

To achieve optimum evaporation conditions, the product film needs to have approximately the same thickness over the length of the heating surface. Since the volume of available liquid steadily decreases as the product runs down the heating surface, the perimeter of the heating surface must be decreased to keep the film thickness constant. Both of these conditions are fulfilled by the plate design of the falling-film cassette evaporator. This unique solution makes it possible to evaporate using very small temperature differences at low temperatures.

The residence time in a falling-film evaporator is short compared to other types. The combination of temperature and time in the evaporator determines the thermal impact on the product. Using a falling-film evaporator with a low temperature profile (low evaporation temperatures, small temperature differences, and low heat load) is a considerable advantage for the concentration of dairy products which are sensitive to heat treatment.

Tubular evaporators

This is the evaporator type most often used in the dairy industry. The key to success with falling-film evaporators is to obtain uniform distribution of the product over the heating surfaces. Vertically arranged tubes are used for the most part, where the product flows downwards on the inner surface of the tubes and the heating steam condenses on the outer surface of the tubes.

The length of the tubes may vary up to 20 m. The length of the tubes is selected in order to find the optimal building situation (height versus footprint). The tubes are encased and can be insulated.

The overall heating surface is divided into a number of sections and the milk flows only once through each of these. Uniform distribution of the product over the heating surface is very important for the economical operation of an evaporator. Gaps in the distribution lead to local overheating. This causes the product to stick, thereby impairing the transfer of heat into the product and impeding cleaning. This reduces production uptime.

Uniform product spreading in the head section (Figure 7.6.5) of the evaporator is required for good distribution, as is the correct calculation of the sections. This is achieved using a first divider just below the inlet of the cover of the heater. Holes drilled concentrically around the downpipes lead the product into the tubes as a uniform film. Slightly superheating the product when feeding it into the spreader section makes it expand and thus ensures immediate partial evaporation and good distribution. The vapour forces the product to the inner surface of the evaporator tubes, where it flows away as a thin film.

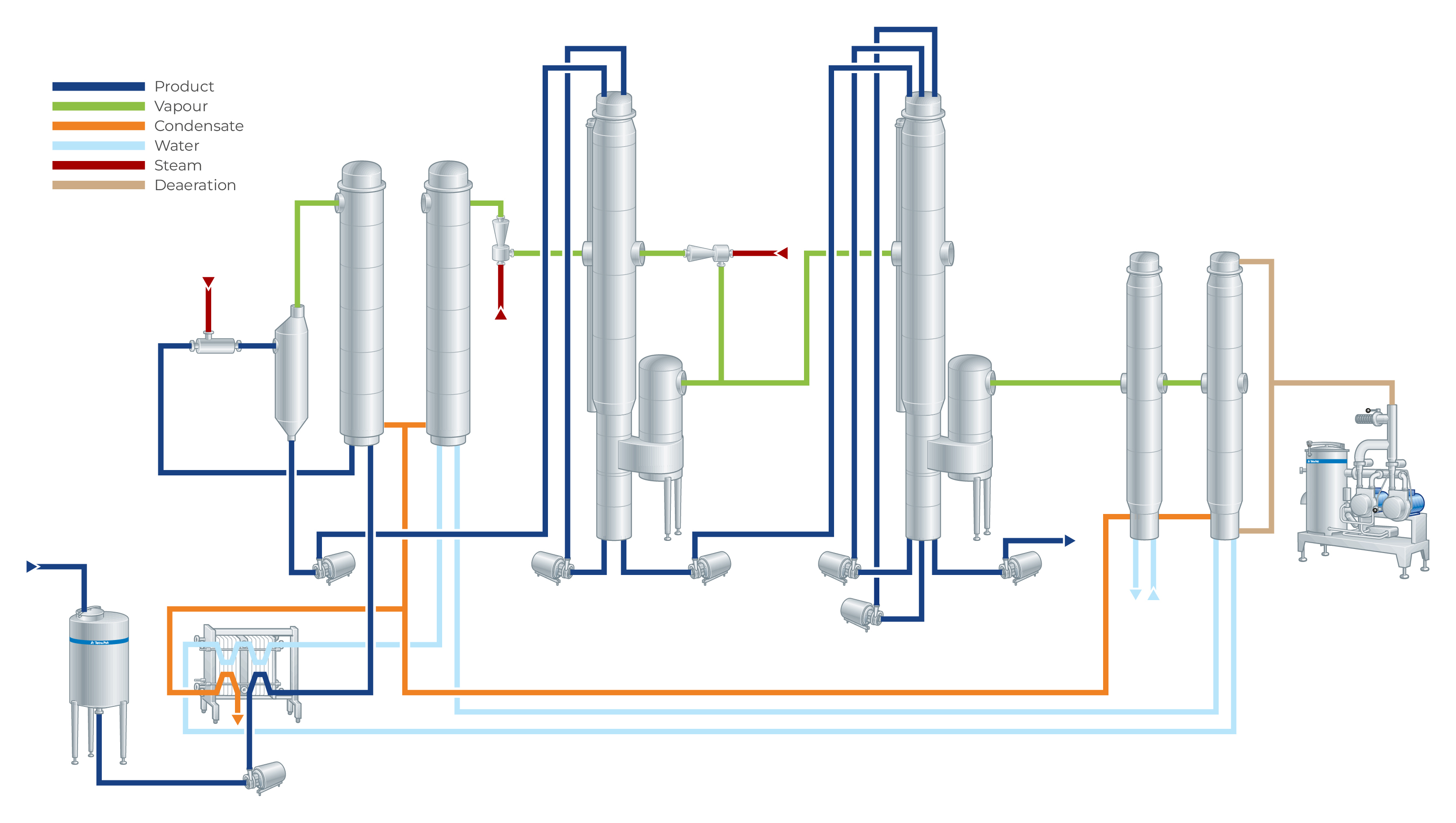

Process flows

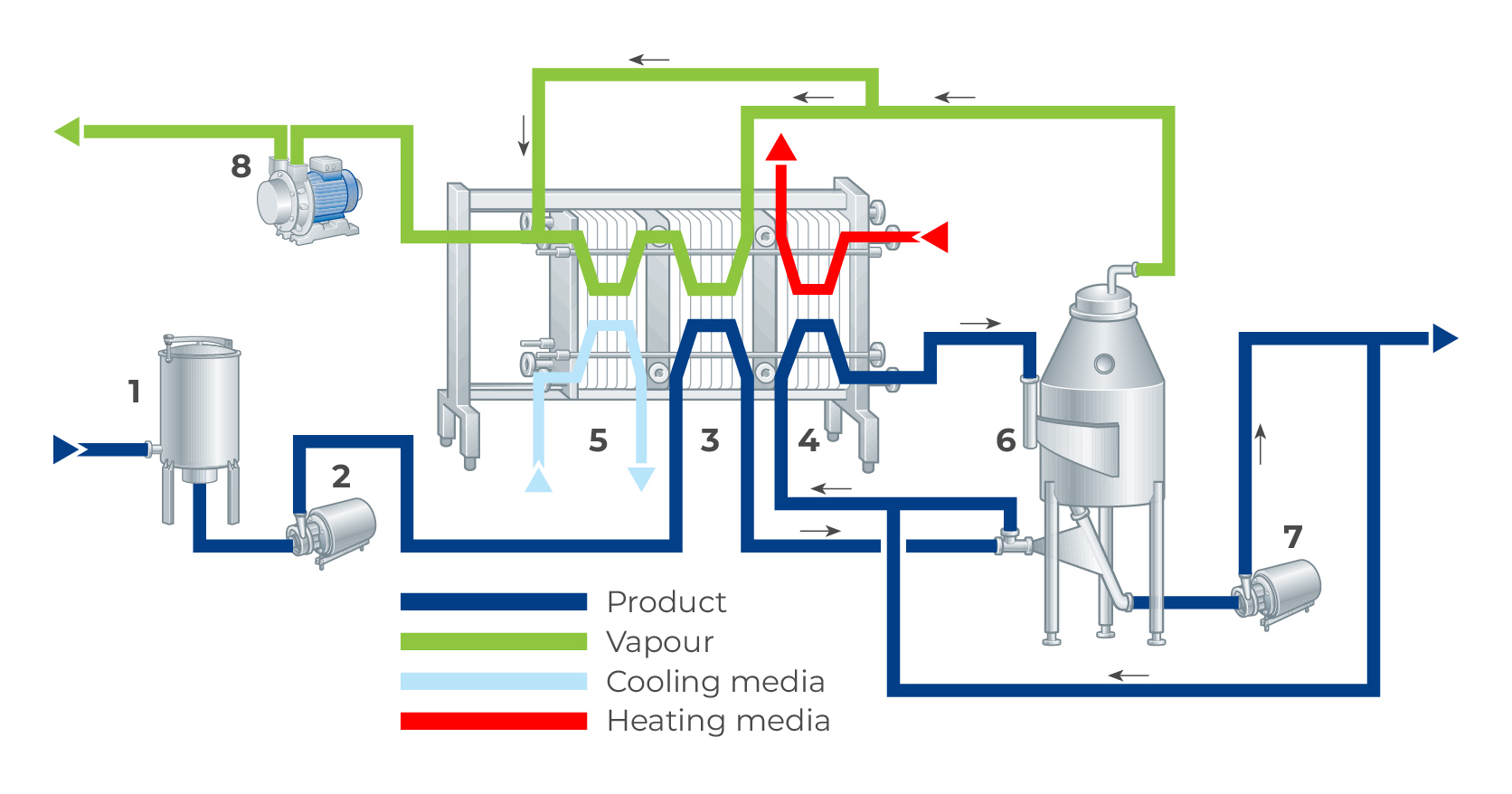

A process line for a two-effect falling-film tubular evaporator is shown in Fig 7.6.7. The milk is pumped from a balance tank (1) via the pre-heating (2, 3, 12 and 13), where it is pasteurized and heated to a temperature slightly above the boiling point of the first evaporator effect. The milk then continues to the first effect (4) of the evaporator, which is under a vacuum corresponding to a boiling temperature of 68 °C. The water evaporates and the milk is concentrated as the thin film of milk flows downwards in the tubes.

The concentrate is separated from the vapour in the bottom part of the calandria and the vapour separator (5) and pumped to the second effect (6). The vacuum is lower in this effect, corresponding to a boiling temperature of 58 °C. After further evaporation in the second effect, the concentrate is again separated from the vapour in the bottom part of the calandria and the vapour separator (5) and pumped out of the system for further treatment (10).

The injection of high-pressure steam into the thermocompressor (7) increases the pressure of the vapour from the first effect. The live steam/vapour mixture is then used to heat the first effect (4).

Multiple-effect evaporators

Multiple-effect evaporators were usually used. The theory is that if two evaporators are connected in series, the second effect can operate at a higher vacuum (and therefore at a lower temperature) than the first. The vapour evaporated from the product in the first effect can be used as the heating medium for the next effect, which operates at a lower boiling temperature due to the higher vacuum. One kilogram of water can be evaporated from a product with a primary steam input of 0.6 kg, even allowing for heat losses. It is also possible to connect several evaporator effects in series to further improve steam economy. However, this makes the equipment more expensive and involves a higher temperature in the first effect. The total volume of product in the evaporator system increases with the number of effects connected in series. This is a drawback in the treatment of heat-sensitive products. However, evaporators with four to seven effects and additional finishers have been used in the dairy industry for a long time now in order to save energy.

Thermal vapour recompression (TVR)

The vapour evaporated from the product can be compressed and used as a heating medium. This improves the energy balance of the evaporator. A thermocompressor is used for this purpose.

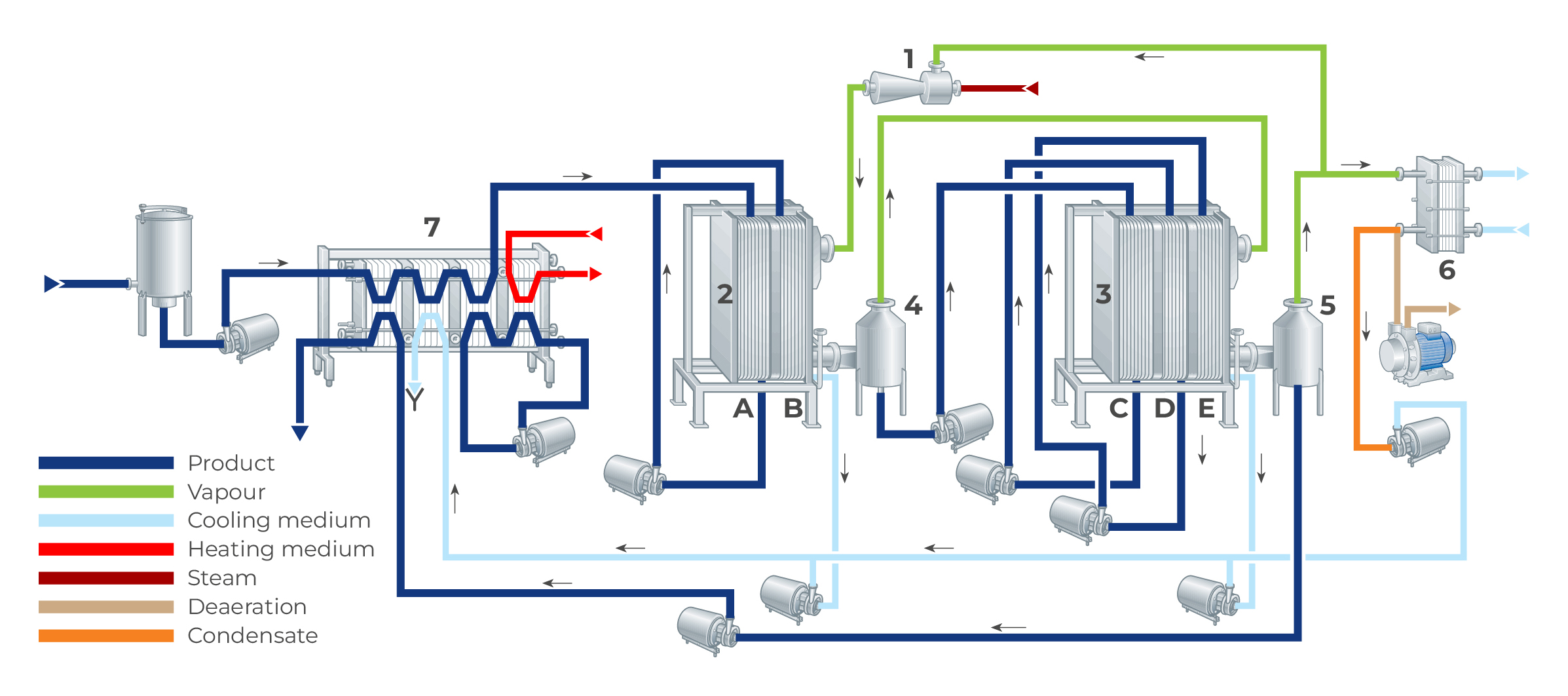

Figure 7.6.6 shows a four-effect evaporator with a thermocompressor for the evaporation of milk. Part of the vapour is supplied to the thermo-compressor, to which high-pressure steam (600 – 1,000 kPa) flows. The compressor uses the high steam pressure to increase the kinetic energy and the steam is ejected at high speed from the nozzle. This jet effect mixes the steam and the vapour from the product and compresses the mixture to a higher pressure. Using a thermocompressor together with a multiple-effect unit optimises the energy balance.

Evaporation efficiency

A two-effect falling-film evaporator with a thermocompressor requires about 0.32 kg of steam to evaporate 1 kg of water, and a five-effect evaporator requires 0.09 kg of steam. Without the thermocompressor, the specific steam consumption would be approximately 0.55 and 0.2 kg per kg of water evaporation, respectively.

Demand for lower energy consumption has led to the development of facilities with more than six effects, but certain limits must be observed in this instance. The maximum boiling temperature on the product side is normally no more than 70 °C in the first effect and 40 °C in the last.

Thus, a temperature range of between 40 °C and 70 °C makes 30 °C available for the dimensioning of the evaporator. The greater the number of effects, the lower the temperature difference in each individual effect.

Potential temperature differences are also reduced in the form of pressure drops and increased boiling temperatures. The sum of these in a multi-effect evaporator station may lead to a restriction of the temperature difference of 5 – 15 °C. This requires larger heat transfer surfaces and results in higher capital costs. Larger heat transfer surfaces then mean greater difficulties in ensuring uniform distribution of the liquid over the heat transfer surfaces. Another disadvantage is the longer residence time of the product in the system. In a six-effect evaporator with a thermocompressor, it is possible to evaporate 12 kg of water with 1 kg of steam. This is equivalent to a specific steam consumption of 0.08 kg of steam per kg of water evaporation.

How far the concentration process can be forced is determined by product properties such as viscosity and sensitivity to heat. The solids content of skim milk and whole milk can be increased to 50% and 52% respectively.

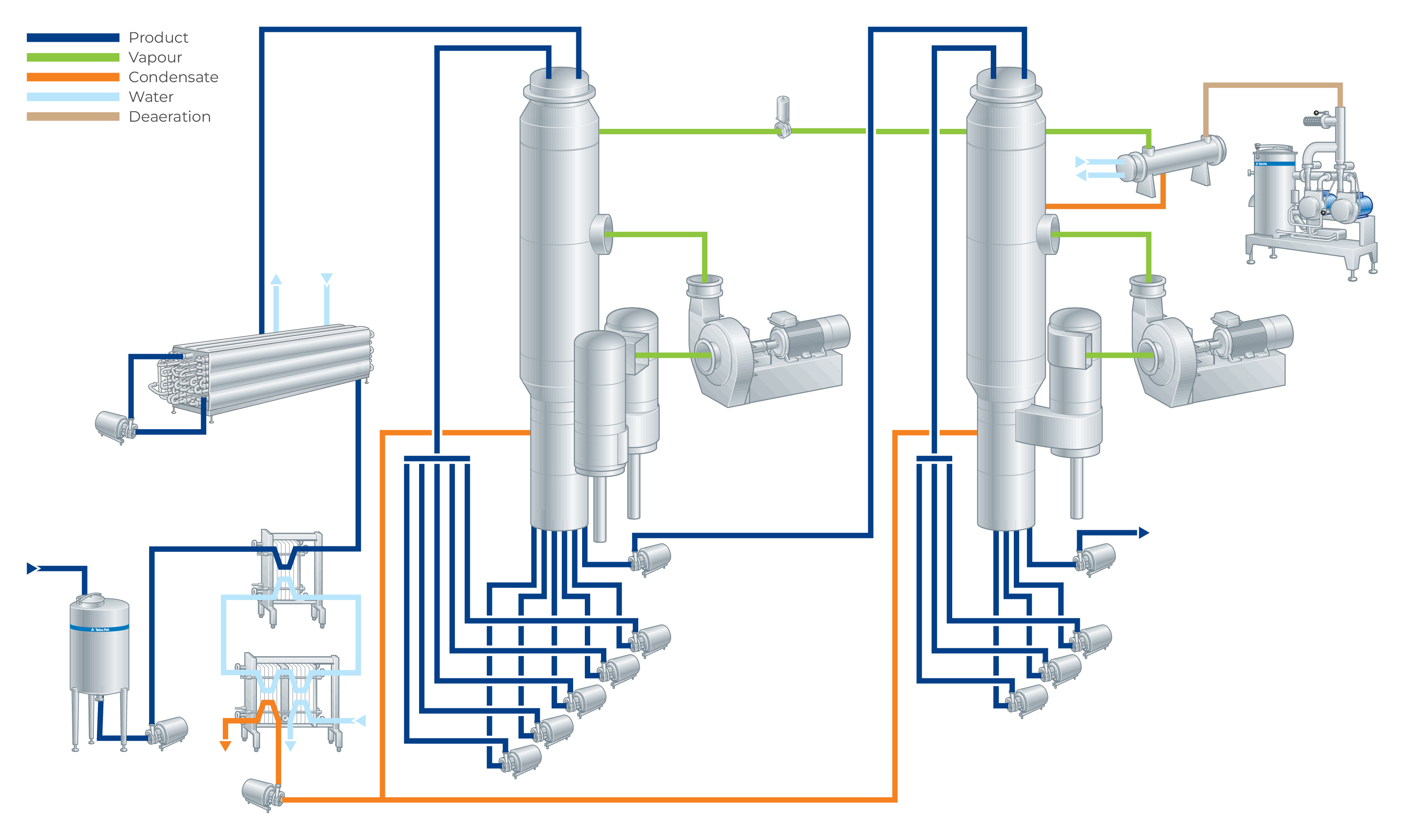

Mechanical vapour recompression (MVR)

Unlike a thermocompressor, a mechanical vapour recompression system (fan) (MVR), draws all the vapour out of the evaporator and compresses it before returning it to the heating side of the evaporator. Increasing the pressure of the vapour requires mechanical energy which drives the compressor. Thus, during production, the evaporator requires no additional thermal energy or only very little thermal energy towards the end of a production cycle, apart from the steam used for heat treatment before the first effect. Thus, there is almost no residual vapour to be condensed.

Figure 7.6.9 shows an evaporator with mechanical vapour recompression. The compressed vapour is returned from the compressor to the pre-concentrator to heat the product.

A pasteurizer heated with live steam is installed before the MVR effect in the system. Excess vapour is condensed in a separate condenser. Mechanical vapour recompression makes it possible to evaporate 80 – 100 kg of water with 1 kWh. Using an evaporator with mechanical vapour recompression can halve the operating costs compared to a conventional six-effect evaporator with a thermocompressor.

Pre-concentrators

Nowadays, falling-film tubular evaporators are mainly used for high-capacity concentration in the dairy industry. The complete calandria heating unit is made of stainless steel and divided into several sections separated from each other. Depending on the nature of the process, the calandria is divided into 4 – 6 sections in a pre-concentrator.

The product is pumped to the top end of the first heating section and distributed to its tubes. The volume of the product is reduced by the evaporation of water that takes place during the downflow. At the bottom end of the section, the vapour evolved is removed and the product is collected in a sump. The product is pumped into the next section and back to the top end of the calandria.

The heat transfer surfaces of the sections arranged one after the other become smaller and smaller due to the increasing concentration.

The compressor fan draws off the vapour from the collector and compresses it. The compressed vapour is forced into the casing of the heater, where it then condenses on the outer surface of the tubes. The condensate is pumped out and used for pre-heating the feed product.

This structure allows whey, for example, to be concentrated from a solids content of 6% to a solids content of 32%, or 20% to a solids content of 60%, and skim milk to be concentrated from a solids content of 9% to a solids content of 36%.