Homogenizers

The technology behind disruption of fat globules

Homogenization has become a standard industrial process, universally practised as a means of stabilising fat emulsions against gravity separation. Gaulin, who invented the process in 1899, described it in French as “fixer la composition des liquides”.

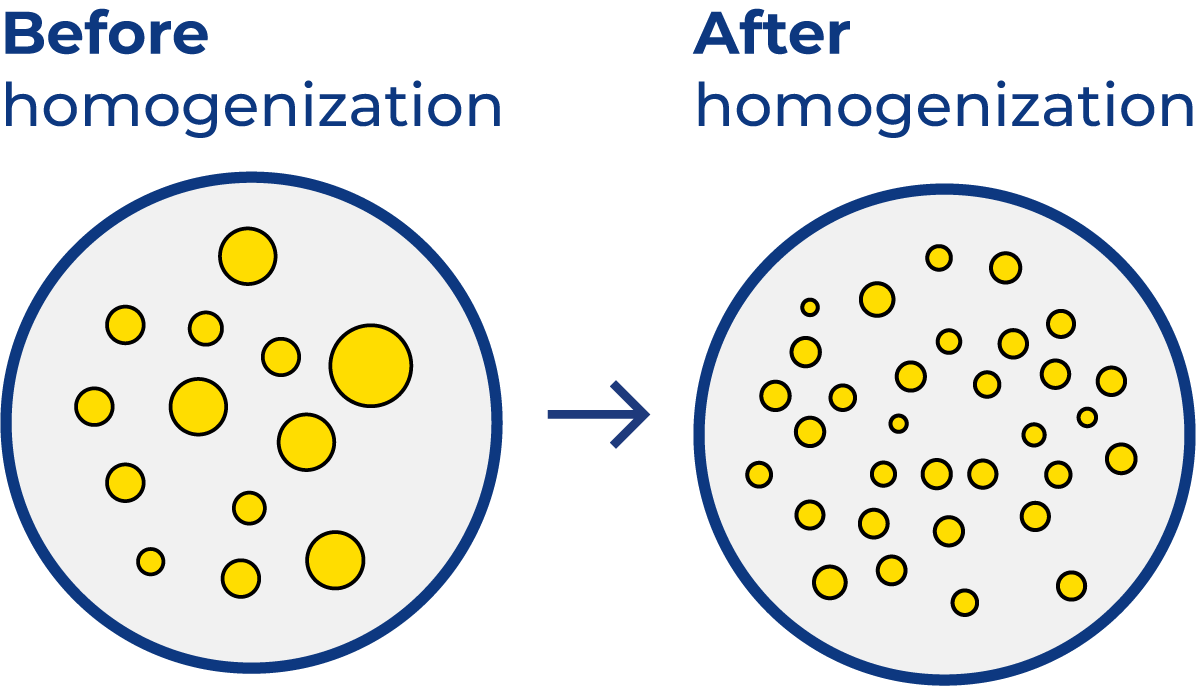

Homogenization primarily causes disruption of fat globules into much smaller ones (Figure 7.3.1). Consequently, it diminishes creaming and may also diminish the tendency of globules to clump or coalesce. On an industrial scale, all homogenized milk is produced by mechanical means where milk is forced through a small gap at high velocities.

The disintegration of the original fat globules is achieved by turbulent eddies. Homogenization reduces fat globule size from an average of 3.5 μm in diameter to below 1 μm. This is accompanied by a four- to six-fold increase in the fat/plasma interfacial surface area. The newly created fat globules are no longer completely covered with the original membrane material. Instead, they are surfaced with a mixture of proteins adsorbed from the plasma phase, primarily casein.

Effect of homogenization

The effect of homogenization on the physical structure of milk has many advantages:

- Smaller fat globules lead to slower cream-line formation

- Whiter and more appetising colour

- Reduced sensitivity to fat oxidation

- More full-bodied flavour, and better mouthfeel

- Better stability of cultured milk products

However, homogenization also has certain disadvantages:

- Somewhat increased sensitivity to light can result in “sunlight flavour” (see also Chapter 9, Pasteurized and ESL dairy products).

- The milk might be less suitable for the production of semi-hard or hard cheeses because the coagulum will be too soft and difficult to dewater.

The homogenizer

A high-pressure homogenizer is a pump with a homogenization device. A homogenizer is generally needed when a high-efficiency break-up of the fat globules is required.

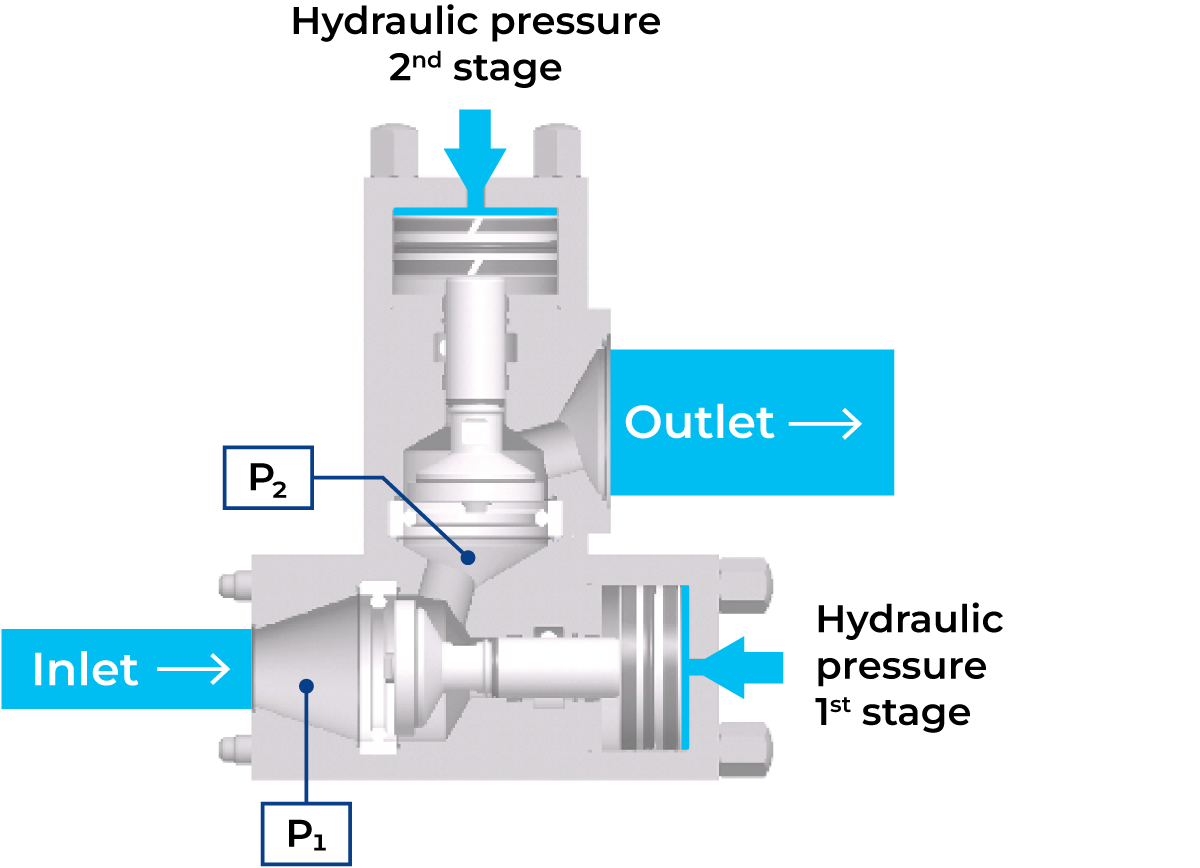

The product enters the pump block and is pressurised by the piston pump. The resulting pressure is determined by the counter-pressure given by the distance between the forcer and seat in the homogenization device. This pressure P1 (Figure 7.3.4) is designated the homogenization pressure. P2 is the backpressure to the first stage.

The high-pressure pump

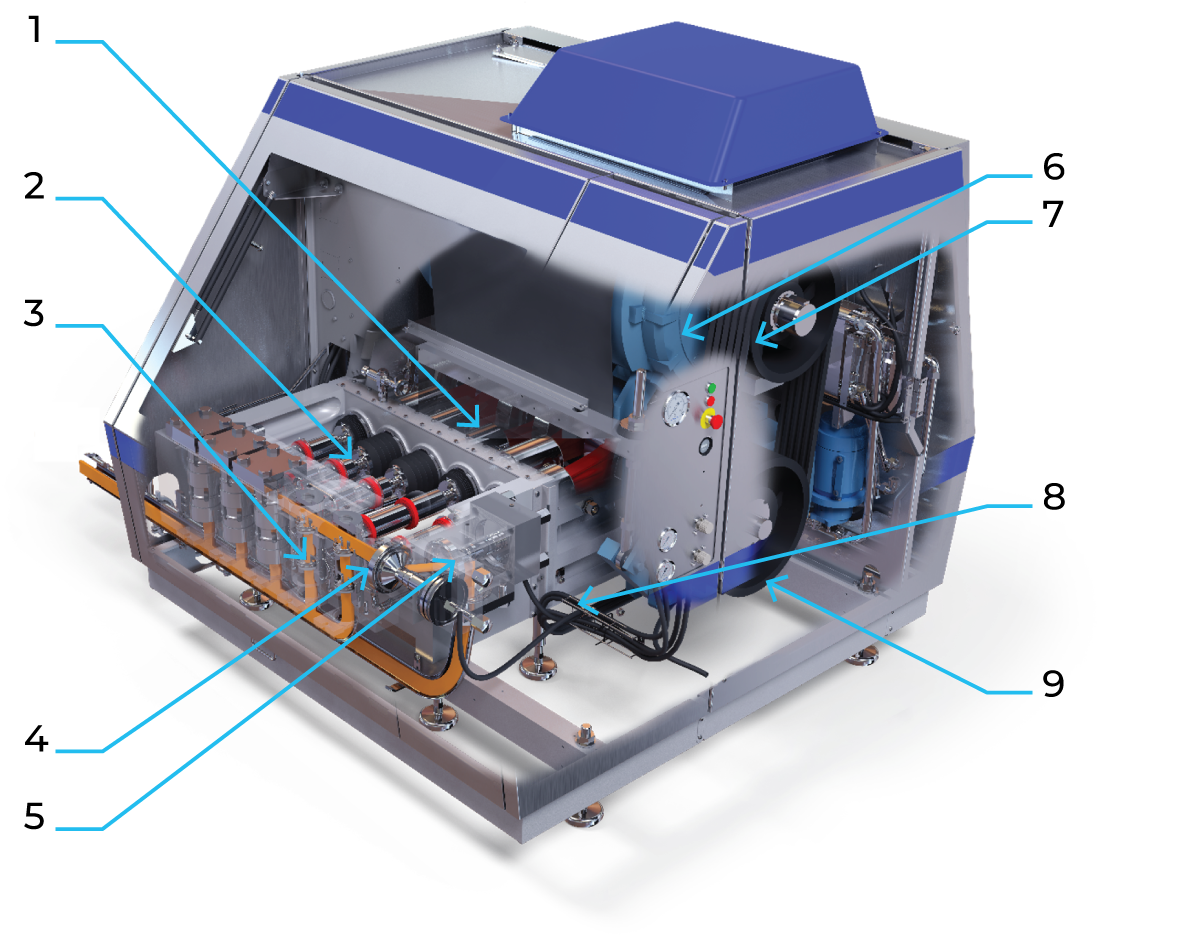

In Figure 7.3.2, the piston pump is driven by a powerful electric motor (6), via belts (7) and pulleys through a gearbox (9) to the crankcase (1) and connecting rod transmission, which converts the rotary motion of the motor to the reciprocating motion of the pump pistons (2).

A piston pump is a positive displacement pump, and its capacity can only be adjusted by changing the speed of the motor or changing the size of the pulleys. To handle higher pressures, pistons with a smaller diameter are installed. This will reduce the maximum capacity, as each machine size has a maximum crankshaft speed. A larger machine has a longer stroke length and/or more pistons. In many cases, these pistons also have a larger diameter.

A high-pressure pump block normally has three to five pistons (2) running in cylinders in a high pressure pump block (3). They are made of highly resistant materials.

The machine is fitted with double piston seals. Water is supplied to the space between the seals to lubricate the pistons. A mixture of hot condensate and steam can also be used to prevent recontamination when the homogenizer is placed downstream in aseptic processes.

A piston pump will always generate a pulsating flow. The acceleration and deceleration of the liquid will create a pulsating pressure in the suction pipe. To avoid cavitation in the pump, there is always a damper on the suction pipe to reduce the pulsation. On the outlet side, the pulsation might create vibrations and noise, which is why the outlet pipe is equipped with a damper.

As it is a positive displacement pump, a piston pump should not operate in a series of other positive pumps unless there is a bypass – otherwise the result can be extreme pressure variations and damaged equipment. If the flow can be stopped downstream of a high-pressure pump, a safety device that opens before the pipe bursts must be installed.

The homogenization device

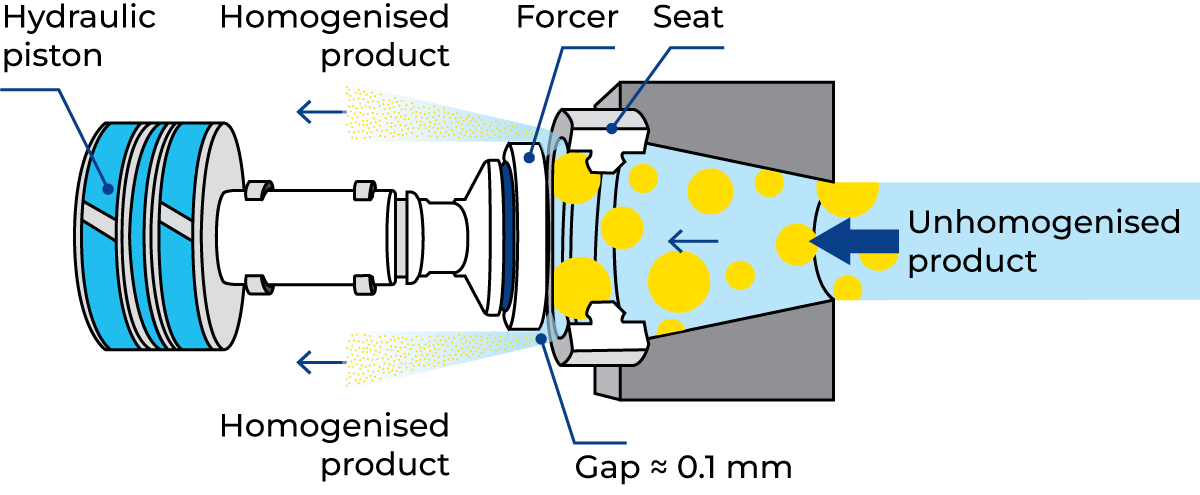

Figure 7.3.3 shows the homogenization device. The piston pump boosts the pressure of the milk from about 0.3 MPa (3 bar) at the inlet to the required homogenization pressure, depending on the desired shelf life of the products. This is often in the range of 10 – 25 MPa (100 – 250 bar) but can also be lower or higher. With the use of a multi-piston pump the pressure to the first stage before the device (the homogenization pressure) is kept constant. The oil pressure on the hydraulic piston and the homogenization pressure on the forcer balance each other. The hydraulic unit can supply both the first and second stages with an individually set pressure. The homogenization pressure is set by adjusting the oil pressure. Actual homogenization pressure can be read on a pressure gauge.

The parts in the homogenization device are precision-ground. Its seat is at an angle that makes the product accelerate in a controlled way, thereby reducing the rapid wear and tear that would otherwise occur.

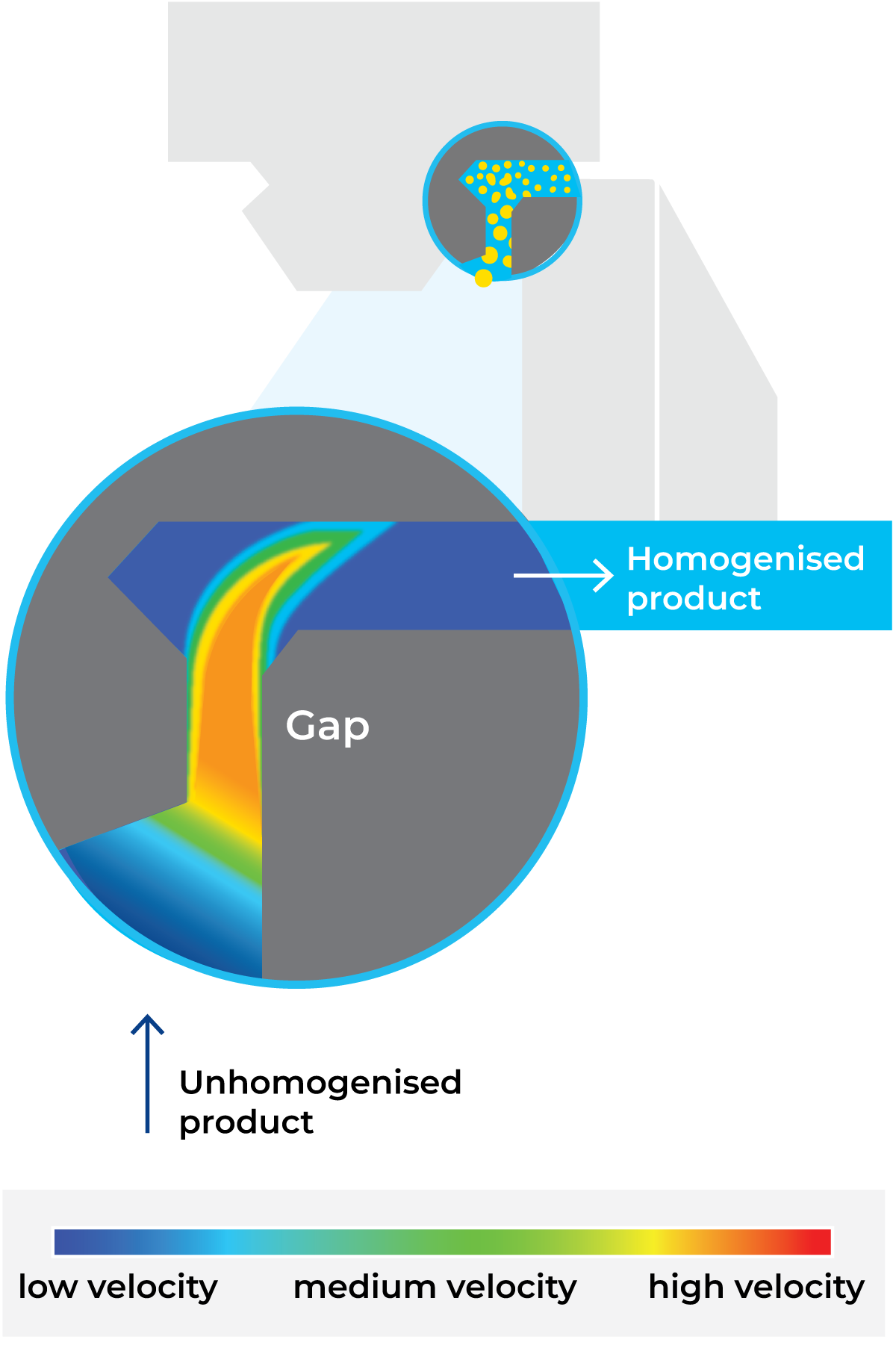

Milk is supplied at high pressure to the space between the seat and forcer. The distance between the seat and the forcer is approximately 0.1 mm or 100 times the size of the fat globules in homogenized milk. The velocity of the liquid is normally 100 – 400 m/s in the narrow annular gap. The higher the homogenization pressure, the higher the speed.

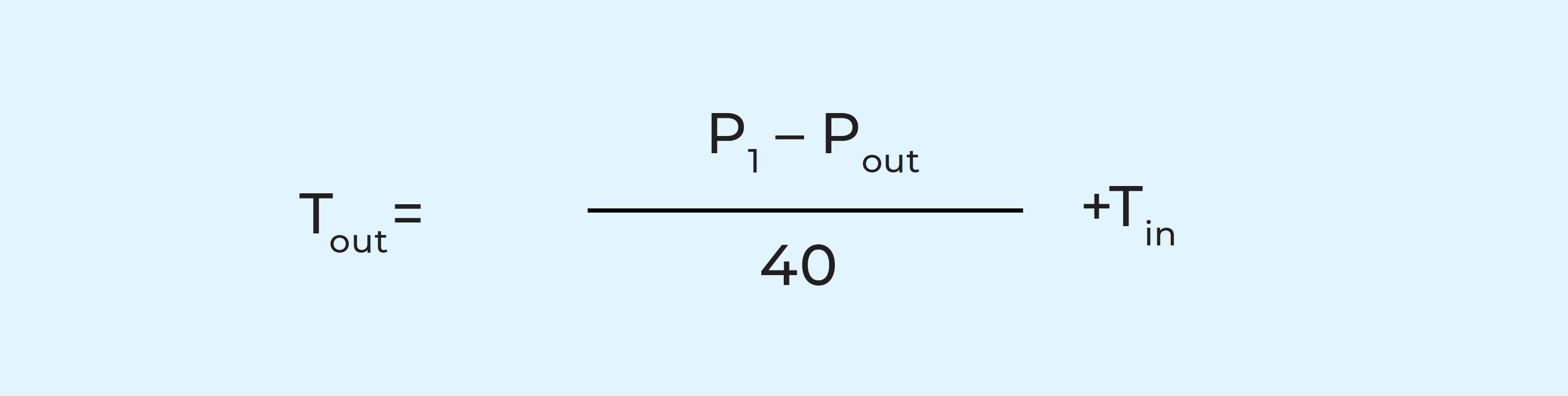

Homogenization takes 10 – 15 microseconds. During this time, all the pressure energy delivered by the piston pump is converted into kinetic energy. Part of this energy is converted back to pressure again after the device. The other part is released as heat; every 4 MPa (40 bar) in pressure drop over the device gives a temperature rise of 1 °C. Less than 1% of the energy is utilised for homogenization. Nevertheless, high-pressure homogenization is the most efficient method available.

Single and two-stage homogenization

Homogenizers may be equipped with one homogenizing device or two connected in series, hence the names single-stage homogenization and two-stage homogenization. The two-stage system is illustrated in Figure 7.3.4.

The actual homogenization always takes place in the first stage, meaning that homogenization efficiency is controlled by the magnitude of the pressure drop over the first stage. The second stage serves two basic purposes:

- Supplying a constant and controlled back-pressure to the first stage, suppressing cavitation and giving the best possible conditions for homogenization

- Breaking up clusters formed directly after homogenization

In single-stage homogenization, the back pressure (P2) is created by the process. In two-stage homogenization, the back pressure (P2) is created by the second stage. In this case, the back pressure can be chosen to achieve optimal homogenization efficiency. Using modern devices, the best results are obtained when P2 is equal to 3 MPa (30 bar) since under those conditions cavitation is sufficiently suppressed while still maintaining a large pressure drop. The second stage also reduces noise and vibrations in the outlet pipe.

When the static pressure is lower than the liquid vapour pressure, vapour bubbles are formed. When these bubbles move to a region with higher pressure, they implode and generate pressure shockwaves.

Single-stage homogenization may be used for the homogenization of products with a high fat content demanding a high viscosity (certain cluster formation).

The theory of break-up

Many theories of the mechanism of high-pressure homogenization have been presented over the years. Those include turbulence, cavitation, shear, and impact theories. For a low-viscous oil-in-water dispersion like milk, where most of the droplets are in the order of one μm (10–6 m) in diameter, only one theory has survived: the turbulence theory.

The theory of fat globule disruption by turbulence is based on the fact that a high-velocity turbulent jet is formed in the outlet chamber of the homogenizing device (see Fig. 7.3.5). As the jet is deaccelerated it is broken down and the energy is transformed into eddies (in academic literature this is referred to as the dissipation rate of turbulent kinetic energy). These eddies interact with the droplets, pull and elongate them and eventually cause break-up.

Homogenization efficiency

Homogenization efficiency is a measurement of how small the fat globules have become, thereby indicating how stable the product will be during its shelf life. How long the product can be stored without intense separation is often referred to as creaming stability.

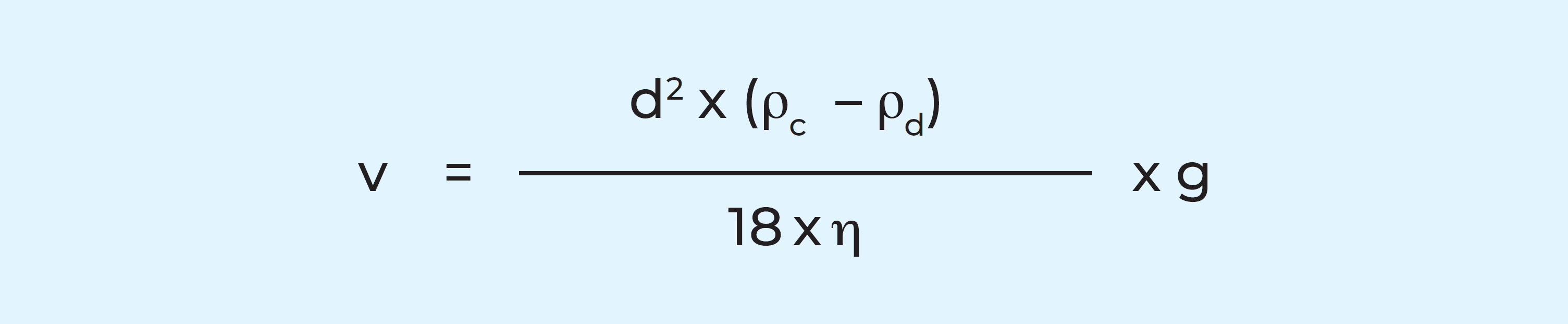

According to Stokes’ Law, the rising velocity of a fat droplet is given by:

v = rising velocity

g = force of gravity

d = fat drop size (diameter)

ρc = density of the liquid (continuous phase)

ρd = density of the fat drops (dispersed phase)

η = viscosity of the liquid (continuous phase)

In the formula:

It can be seen that reducing the particle size is an efficient way of reducing the rising velocity. Therefore, reducing the size of fat globules in milk reduces the creaming rate.

Factors influencing homogenization efficiency

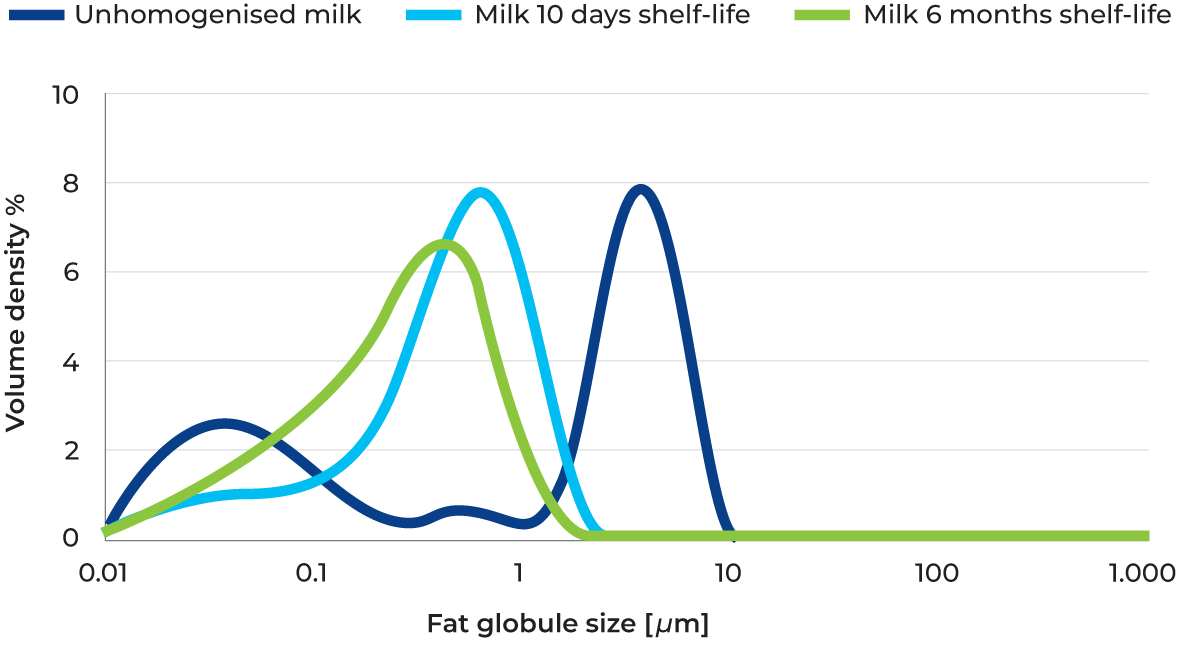

Homogenization is an energy-demanding process. It is therefore important to neither under- nor over-homogenize and be careful about using the correct homogenization conditions for each product. To achieve that, it’s important to not focus on pressure but on the desired stability of the product. A product that has a shelf life of 10 days does not have to have the same fat droplet size and creaming stability as a product with a shelf life of 6 months. With the product and machine properties in mind, the optimal pressure can be calculated. Many parameters influence homogenization efficiency and creaming stability:

- Homogenization pressure By increasing the homogenization pressure, i.e. the pressure drop over the first stage, the homogenization efficiency becomes higher. The gap height in the homogenizer decreases and the velocity increases, resulting in a more efficient jet forming in the outlet chamber of the homogenizer.

- Second-stage pressure To have the most efficient homogenization, cavitation needs to be suppressed. This is done by increasing the second-stage pressure. It’s worth noting that too high second-stage pressure will also impact the efficiency negatively by “stealing” some of the pressure drop that could have been utilised over the first stage.

- Homogenization device design and size Gap length, diameter of the device, and inlet and outlet angles are all parameters that will impact homogenization efficiency.

- Flow rate Increasing the flow rate will result in a higher gap height and in turn a lower homogenization efficiency.

- Homogenization temperature For homogenization of fat globules to be effective the fat is required to be in a liquid state. Processing at temperatures where the milk fat is partially in a solid state (i.e. below 40 °C) results in inefficient dispersion of the fat phase. Homogenization temperatures normally applied are 55 – 80 °C. Increasing the homogenization temperature decreases the viscosity of milk, influences how easily the drops are deformed by turbulence and improves the transport of membrane material.

- Fat content and other product properties, e.g. viscosity and density Products with a high fat content are more difficult to homogenize and also more likely to show evidence of aggregation because the concentration of membrane material (casein proteins) is low in relation to the fat content. Usually, cream with a higher fat content than 20% is not homogenized at high pressure because clusters are formed as a result of a lack of membrane material.

- Pre-treatment By homogenizing milk in both the pasteurizer and UHT unit, the homogenization degree will be impacted.

Analytical methods

Analytical methods for determining homogenization efficiency can be divided into two groups:

Studies of creaming rate

The straightforward way of determining the creaming rate is to take a package, store it at the recommended storage temperature until the last day of consumption, open it and check if the cream layer is acceptable or not.

The USPH method is based on this. For example, a sample of 1,000 ml is stored for 48 hours, after which the fat content of the top 100 ml is determined as well as the fat content of the rest. For pasteurized milk, homogenization is considered to be sufficient if 0.9 times the top fat content is less than the bottom fat content. However, this method is not suitable for UHT milk with a longer shelf life.

The NIZO method is based on the same principle, but with this method, a sample of 25 ml is centrifuged for 30 minutes at 350 g, 40 °C and a radius of 250 mm. The fat content of the 20 ml at the bottom is divided by the fat content of the whole sample, and the ratio is multiplied by 100. The resulting index is called the NIZO value. The NIZO value of pasteurized milk is normally 60 – 70%.

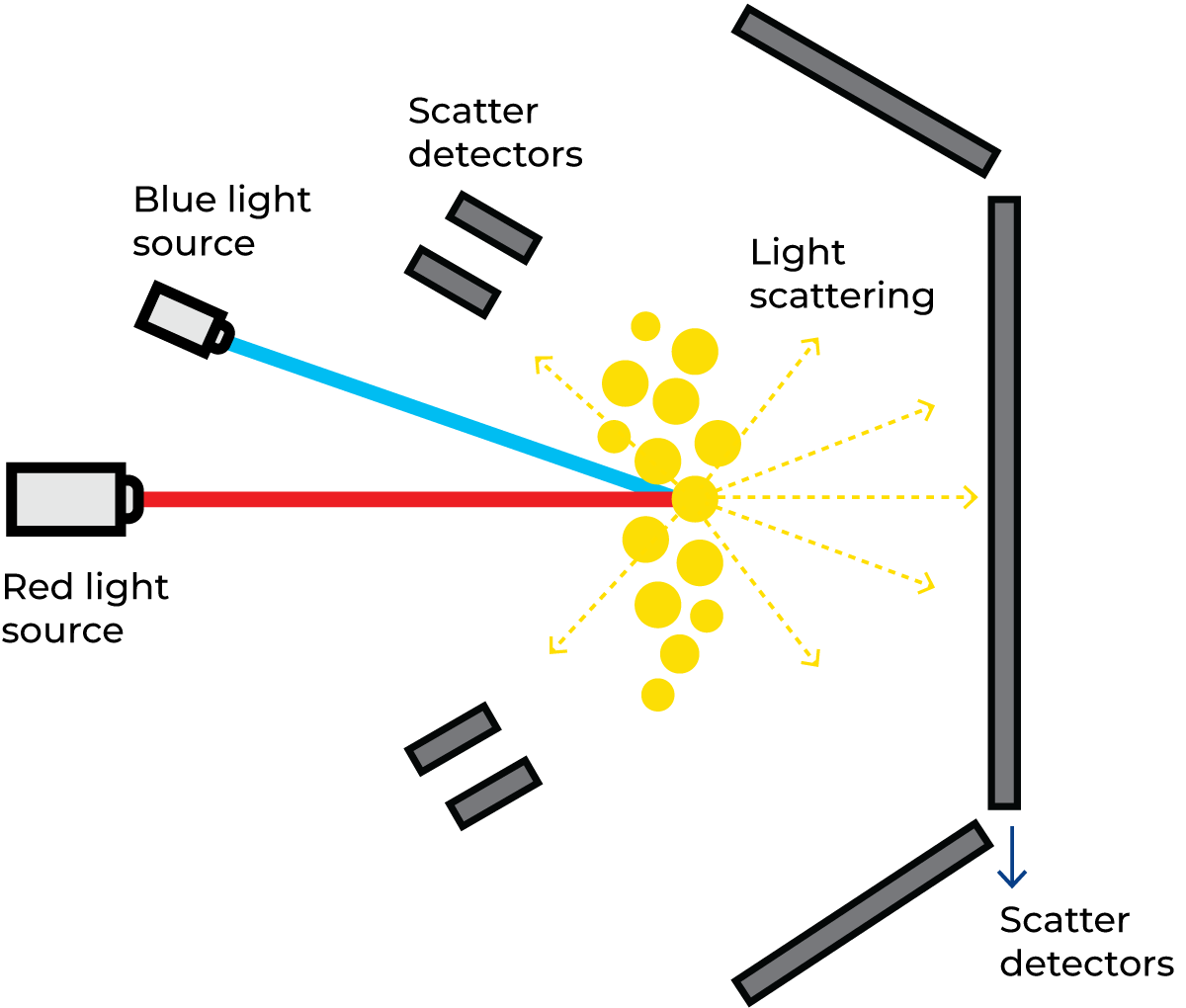

Particle size distribution analysis by laser diffraction

The size distribution of the particles or droplets in a sample can be determined in a well-defined way by using a laser diffraction unit (Figure 7.3.7), which sends a laser beam through a sample in a cuvette. The light will be scattered and absorbed, depending on the size, refractive index and number of particles in the sample.

Milk samples are always measured with the addition of a protein dissolvent. This is done to only focus on the break-up of fat globules which is what homogenization is targeting. The result is presented as size distribution curves. The percentage of the volume (fat) is given as a function of the particle size (fat globule size). Three typical size distribution curves for milk with different shelf lives are shown in Figure 7.3.6. The smaller the fat globules the slower the creaming process. Thus, to achieve a longer shelf life the milk is homogenized at different pressures to shift the particle size distribution towards smaller fat globules.

Different mean values, e.g. the volumetric mean value D[4,3], can be extracted from the particle size distributions and used to compare different homogenization conditions. The laser diffraction method has been correlated to the NIZO method discussed above with the results published in a scientific article.

Measurement of homogenization efficiency of milk by laser diffraction and centrifugation - ScienceDirect

The homogenizer in a processing line

Position in a processing line

In general, the homogenizer is placed upstream, i.e. before the final heating section in a heat exchanger. In most pasteurization plants for market milk production, the homogenizer is placed after the first regenerative section.

In the production of UHT milk, the homogenizer is generally placed upstream in indirect systems but always downstream in direct systems, i.e. on the aseptic side after UHT treatment. In the latter case, the homogenizer is of aseptic design with special piston seals, a sterile steam condenser and special aseptic dampers.

However, the downstream location of the homogenizer is recommended for indirect UHT systems when milk products with a fat content higher than 6 – 10% and/or with increased protein content are to be processed. The reason is that with increased fat and protein contents, fat clusters and/or agglomerates (protein) form at very high heat-treatment temperatures. These clusters/agglomerates are broken up by the aseptic homogenizer located downstream.

Split homogenization

An aseptic homogenizer is more expensive to operate. In some cases, it is sufficient if just the second stage is placed downstream. This arrangement is called split homogenization.

Note that the whole section, including the heat exchanger, between the first and the second stage in the homogenizer, has to withstand pressures above 3 MPa (30 bar) (second-stage pressure).

Full stream homogenization

Full stream or total homogenization is the most commonly used form of homogenization for UHT milk and milk intended for cultured milk products.

The fat content of the milk is standardized prior to homogenization, as is the solids-non-fat content in certain circumstances, e.g. in yoghurt production.

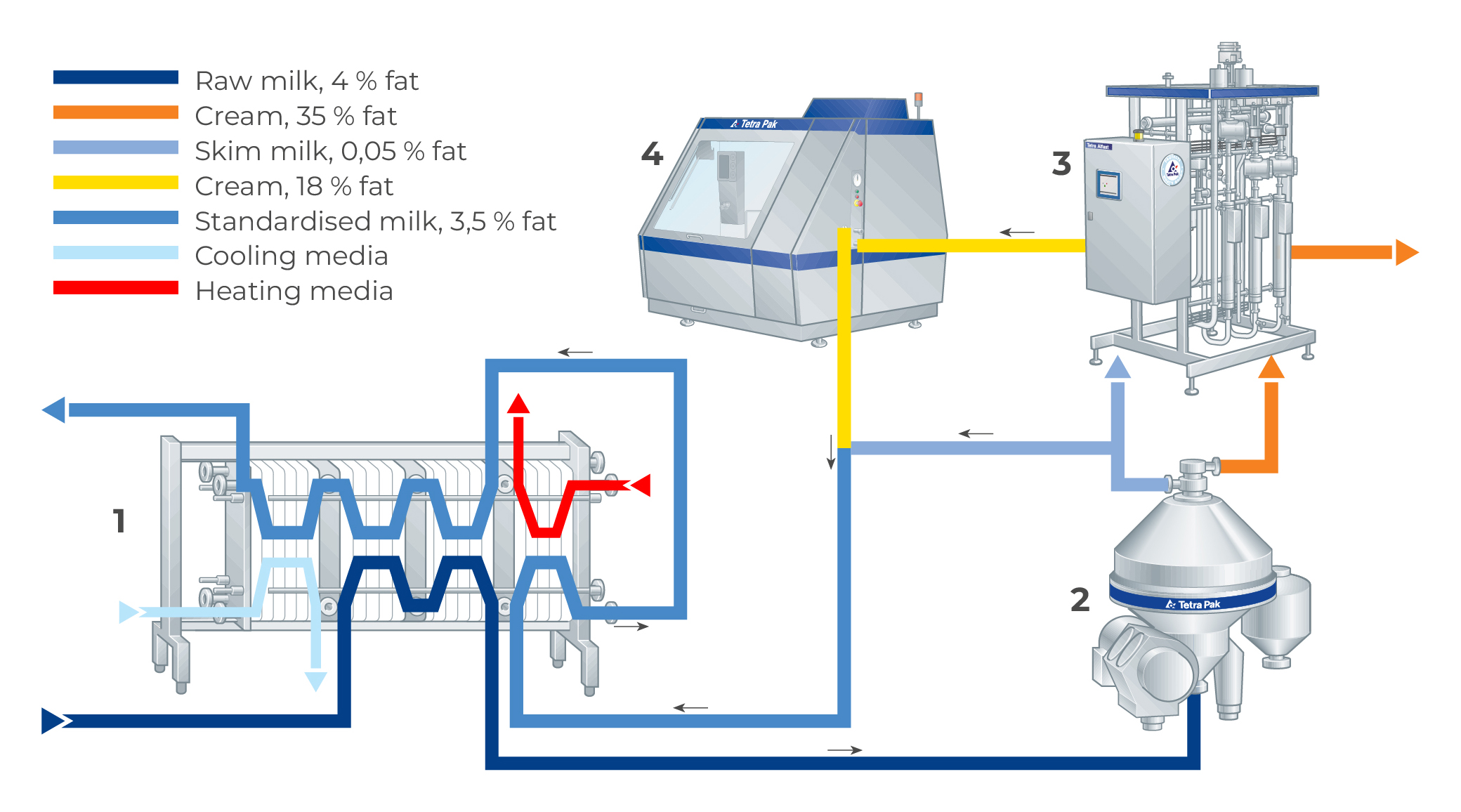

Partial homogenization

Partial stream homogenization means that the main body of skim milk is not homogenized, rather only the cream together with a small proportion of skim milk. This form of homogenization is mainly applied to the pasteurized milk market. The basic reason is to reduce operating costs and energy consumption. Additionally, investment costs will be lower since a smaller homogenizer can be used. Total power consumption is cut by some 70% because of the smaller volume passing through the homogenizer.

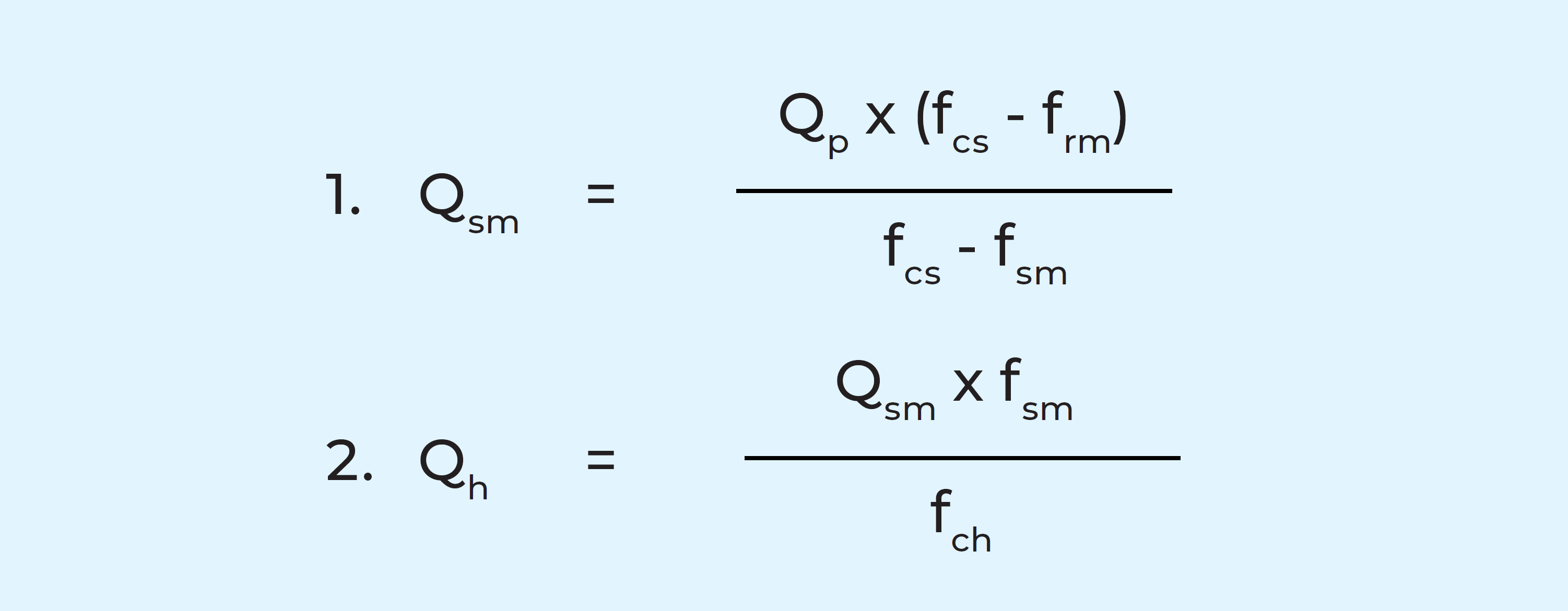

As sufficiently good homogenization can be reached when the product contains at least 0.2 g casein per g fat, a maximum cream fat content of 18% is recommended. The hourly capacity of a homogenizer used for partial homogenization can be dimensioned according to the following example.

The formulae for the calculations are:

The hourly output of pasteurized standardized milk, Qsm, will be approximately 9,840 l. Inserted into Formula 2, this gives an hourly homogenizer capacity of approximately 1,915 l, i.e. about one-fifth of the output capacity. The flow pattern in a plant for partially homogenized milk is illustrated in Figure 7.3.8.

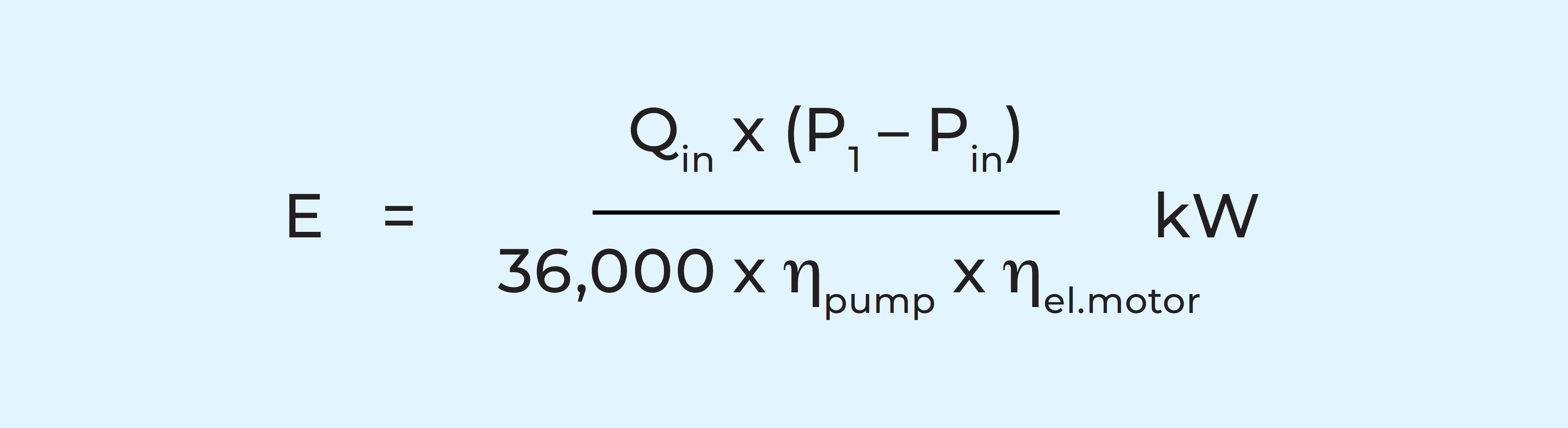

Energy consumption and influence on temperature

The electrical power input needed for homogenization is expressed by the formula:

The efficiency coefficients are typical values. From the figures for feed capacity and pressures given above, the electric power demand will be 68 kW. Of this, 55 kW is used for pumping and converted to heat in the homogenization device, and 13 kW is released as heat to the cooling water and the air. As mentioned above, part of the pressure energy supplied is released as heat. Given the temperature of the feed, Tin, the homogenization pressure, P1, the pressure after homogenization, Pout, and that every 4 MPa (40 bar) in pressure drop raises the temperature by 1 °C, the following formula is applicable: