Centrifugal separators and milk standardization

Centrifugal separators

Some historical data

A newly invented appliance for separating cream from milk was described in the German trade journal “Milch-Zeitung” dated the 18th of April 1877. This was “a drum which is made to rotate and which, after turning for a time, leaves the cream floating on the surface so that it can be skimmed off in the usual fashion”.

After reading this article, a young Swedish engineer, Gustaf de Laval, said, “I will show that centrifugal force will act in Sweden as well as in Germany.” The daily newspaper “Stockholms Dagblad” of 15th January 1879 reported: “A centrifugal separator for cream skimming has been on show here since yesterday and will be demonstrated every day between 11 a.m. and 12 noon on the first floor of the house of number 41, Regeringsgatan. The machine can be likened to a drum which is driven round by a belt and pulley. The cream, which is lighter than the milk, is driven by centrifugal force to the surface of the milk and flows off into a channel from which it is led into a collection vessel. Under it, the milk is forced out to the periphery of the drum and is collected in another channel, whence it is led to a separate collecting vessel.”

From 1890, the separators built by Gustaf de Laval were equipped with specially designed conical discs, the patent on which had been granted in 1888 to the German Freiherr von Bechtolsheim and had been acquired in 1889 by the Swedish company AB Separator, of which Gustaf de Laval was part-owner. Today, most makes of similar machines are equipped with conical disc stacks.

Sedimentation by gravity

Historically speaking, the centrifugal separator is a recent invention. Up to a hundred years ago, the technique used for separating one substance from another was the natural process of sedimentation by gravity.

Sedimentation takes place all the time. Clay particles moving in puddles will soon settle, leaving the water clear. Clouds of sand stirred up by waves or by the feet of bathers do the same. Oil that escapes into the sea is lighter than water, rises and forms oil slicks on the surface.

Sedimentation by gravity was also the original technique used in dairying to separate fat from milk. Milk fresh from the cow was left in a vessel. After some time, the fat globules aggregated and floated to the surface where they formed a layer of cream on top of the milk. This could then be skimmed off by hand.

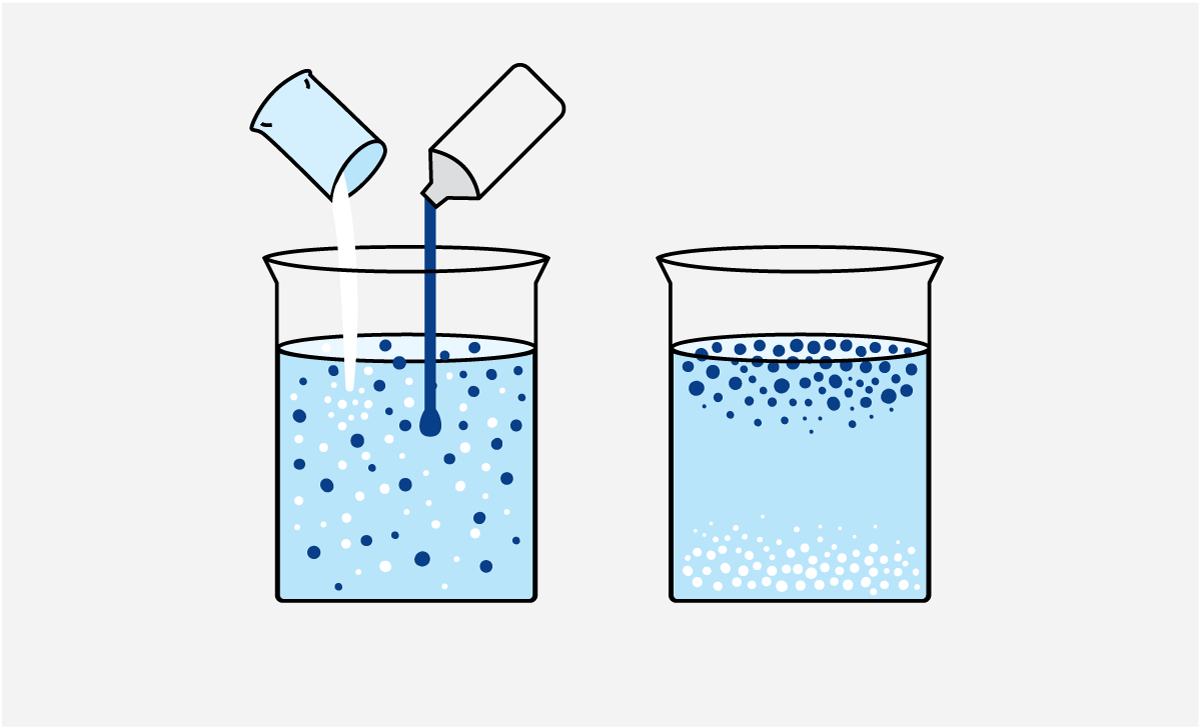

Requirements for sedimentation

The liquid to be treated must be a dispersion; a mixture of two or more phases, one of which is continuous. In milk it is the milk serum, or skim milk, that is the continuous phase. Fat is dispersed in the skim milk in the form of globules with variable diameters up to some 15 μm. Milk also contains a third phase, consisting of dispersed solid particles such as udder cells, straw, hair, etc.

The phases to be separated must not be soluble in each other. Substances in solution cannot be separated by means of sedimentation.

Dissolved lactose cannot be separated by means of centrifugation. It can, however, be crystallised. The lactose crystals can then be separated by sedimentation.

The phases to be separated must also have different densities. The phases in milk satisfy this requirement; the solid impurities have a higher density than skim milk, and the fat globules have a lower density.

How does sedimentation work?

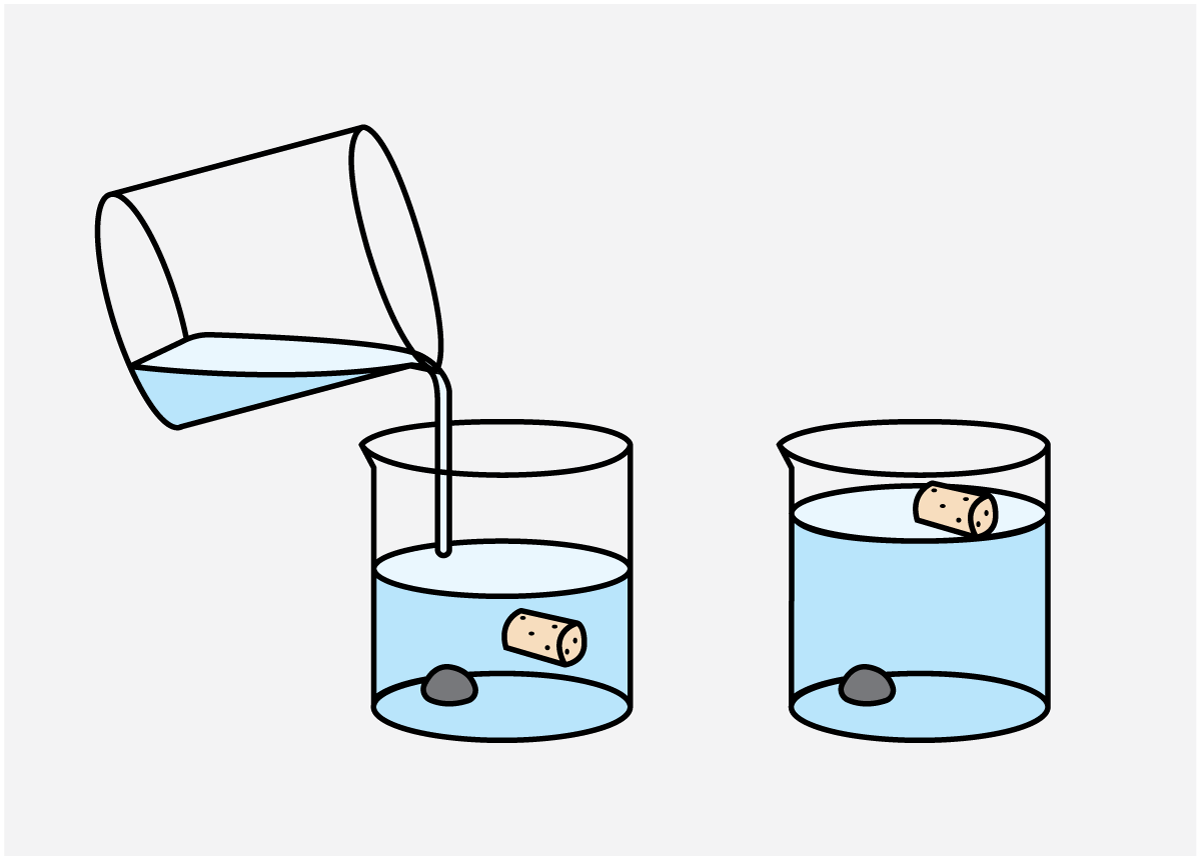

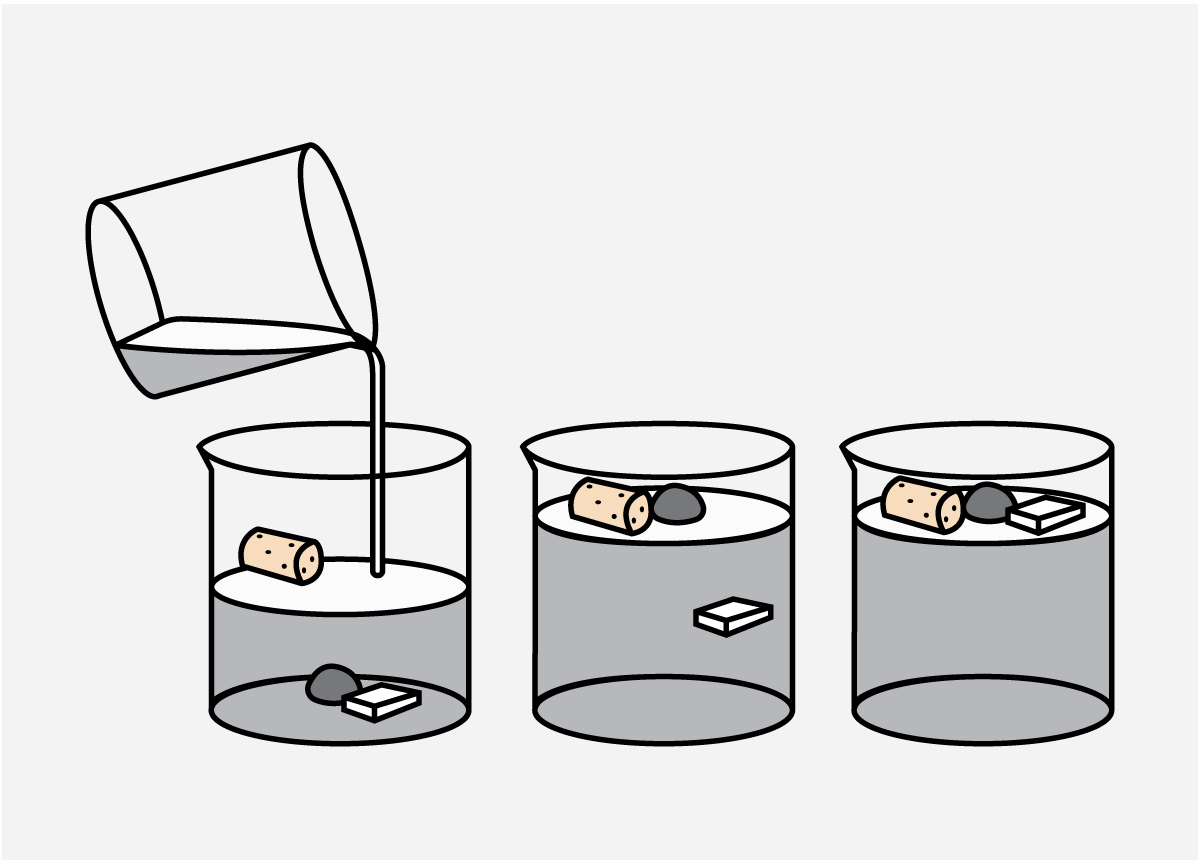

If a stone is dropped into water, we would be surprised if it did not sink. In the same way, we expect a cork to float. We know by experience that a stone is heavier than water and a cork is lighter.

But what happens if we drop a stone in mercury, a liquid metal with a very high density? Or if we drop a piece of iron into mercury? We have no experience to help us predict the result. We might expect the piece of iron to sink. In actual fact, both the stone and the piece of iron will float.

Density

Every substance has a physical property called density. Density is a measure of how heavy a substance is and can be expressed as kg/m3. If we weigh a cubic metre of iron, we will find that the scale shows 7,860 kg. The density of iron is 7,860 kg/m3. The density of water at room temperature is 1,000 kg/m3 and those of stone (granite), cork and mercury at room temperature are 2,700 kg/ m3, 180 kg/m3 and 13,550 kg/m3 respectively.

When an object is dropped into a liquid, it is basically the density of the object, compared with the density of the liquid, that determines whether it will float or sink. If the density of the object is higher than that of the liquid, it will sink, but it will float if the density of the object is lower.

Density is usually denoted by the Greek letter ρ. With the density of a particle ρp and the density of the liquid ρl, it is possible to form the expression (ρp – ρ), i.e. the difference in density between the particle and the liquid. If we drop a stone into water, the difference in density will be (2,700 – 1,000) = 1,700 kg/m3.

The result is a positive number, as the density of the stone is higher than that of water, the stone sinks!

The expression for cork in water is (180 – 1,000) = – 820 kg/m3. This time, the result is negative. Because of the low density of a cork, it will float if it is dropped into water; it will move against the direction of the force of gravity.

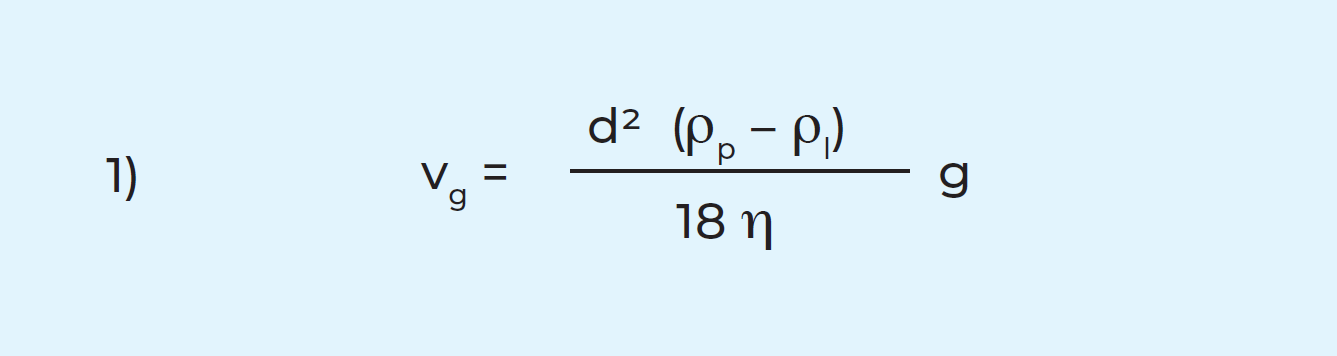

Sedimentation and flotation velocity

A solid particle or liquid droplet moving through a viscous fluid medium under the influence of gravity will eventually attain a constant velocity. This is called the sedimentation velocity. If the density of the particle is lower than the fluid medium the particle will float at a flotation velocity. These velocities are denoted vg (g = the force of gravity). The magnitude of the sedimentation/flotation velocity is determined by the following physical quantities:

- Particle diameter d m

- Particle density ρp kg/m3

- Density of the continuous phase ρl kg/m3

- Viscosity of the continuous phase η kg/m s

- Gravitational attraction of the earth g = 9.81 m/s2

If the values of these quantities are known, the sedimentation/flotation velocity of the particle or droplet can be calculated by means of the following formula, which is derived from Stokes’ law:

The formula below (Equation 1) shows that the sedimentation/flotation velocity of the particle or droplet:

- Increases as the square of the particle diameter; this means that the particle of d = 2 cm will settle/rise four times faster (22 = 4) than a particle of d = 1 cm.

- Increases with increasing differential density between the phases.

- Increases with diminishing viscosity of the continuous phase.

Flotation velocity of a fat globule

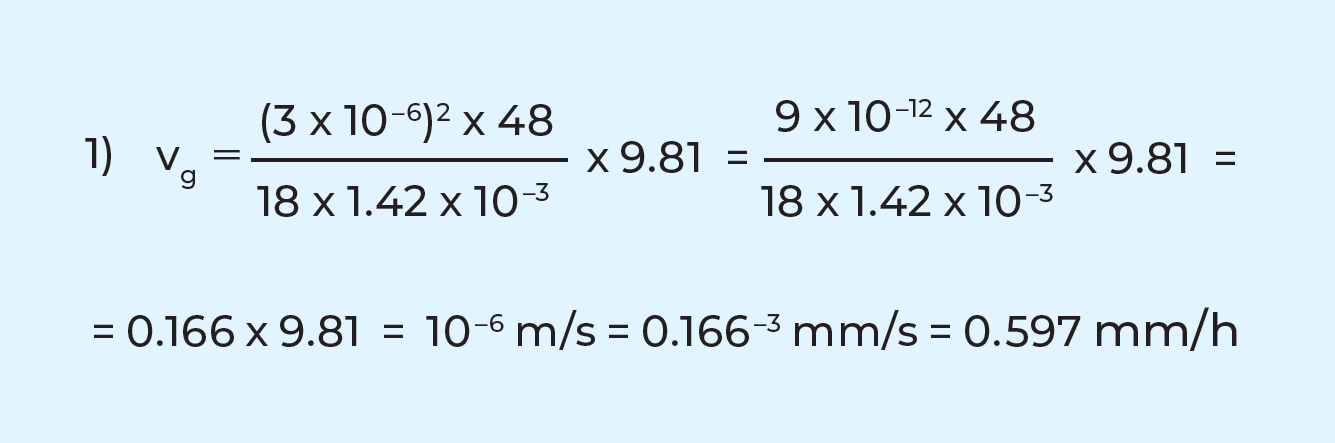

With fresh milk in a vessel, the fat globules will begin to move upwards, towards the surface. The flotation velocity can be calculated with the help of the formula above. The following average values apply at an ambient temperature of about 35 °C:

d = 3 µm = 3 x 10–6 m

(ρp – ρl) = (980 – 1 028) = – 48 kg/m3

h = 1.42 cP (centipoise) = 1.42 x 10–3 kg/m, s

Substituting these values in the formula:

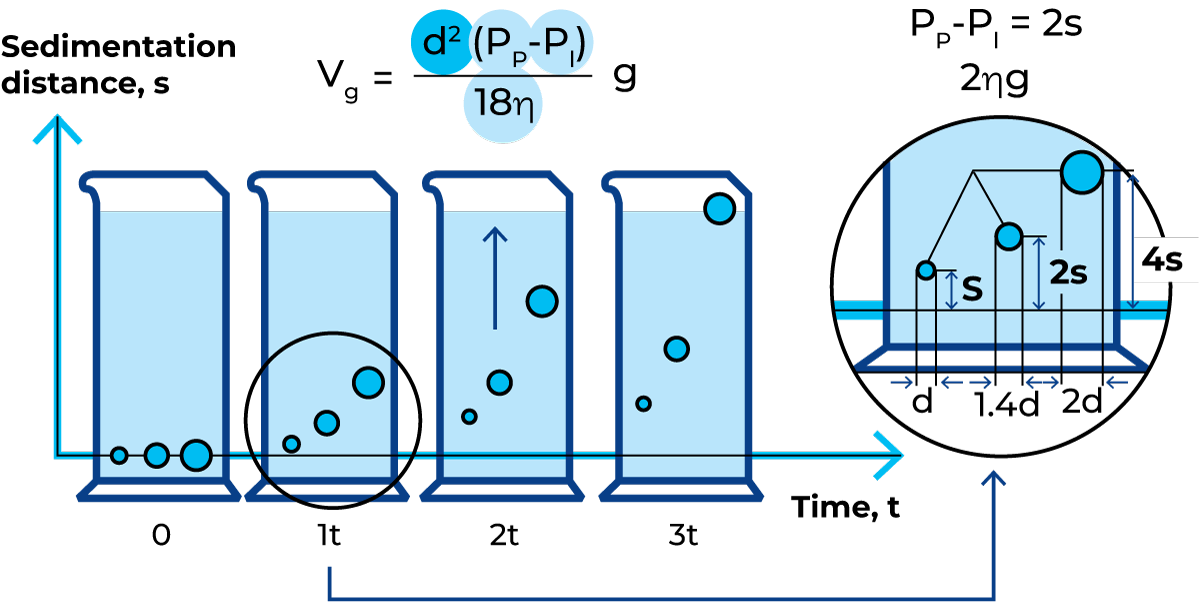

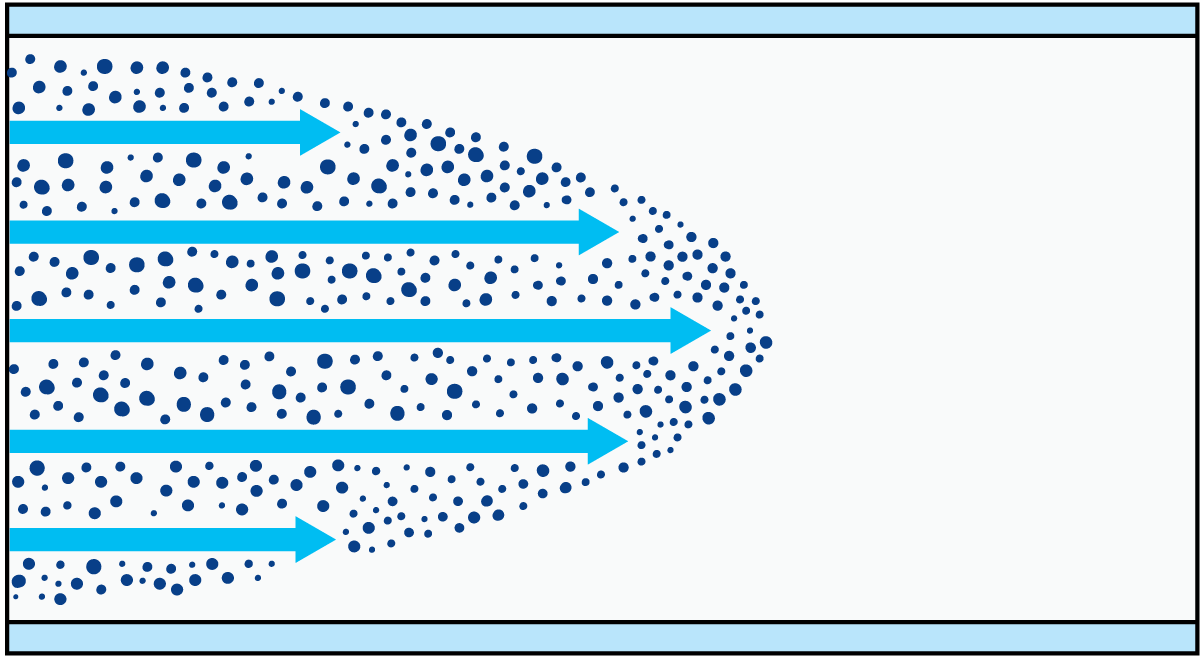

As indicated above, fat globules rise very slowly. A 3 μm diameter fat globule moves upwards at a flotation velocity of 0.6 mm/h. The velocity of a fat globule which is twice the size will be 22 x 0.6 = 2.4 mm/h. In reality, fat globules cluster into larger aggregates, and flotation therefore takes place much more rapidly. Figure 7.2.6 shows schematically how fat globules of different diameters move through the milk serum under the influence of gravity. At zero time, the fat globules are at the bottom of the vessel. After t minutes, a certain amount of sedimentation has taken place, and after 3 t minutes, the largest fat globule has reached the surface. By this time, the medium-sized globule has risen to a point halfway to the surface, but the smallest globule has only covered one-quarter of the distance. The medium-sized globule will reach the surface in 6 t minutes, but the smallest globule will need 12 t minutes to get there.

Batch separation by gravity

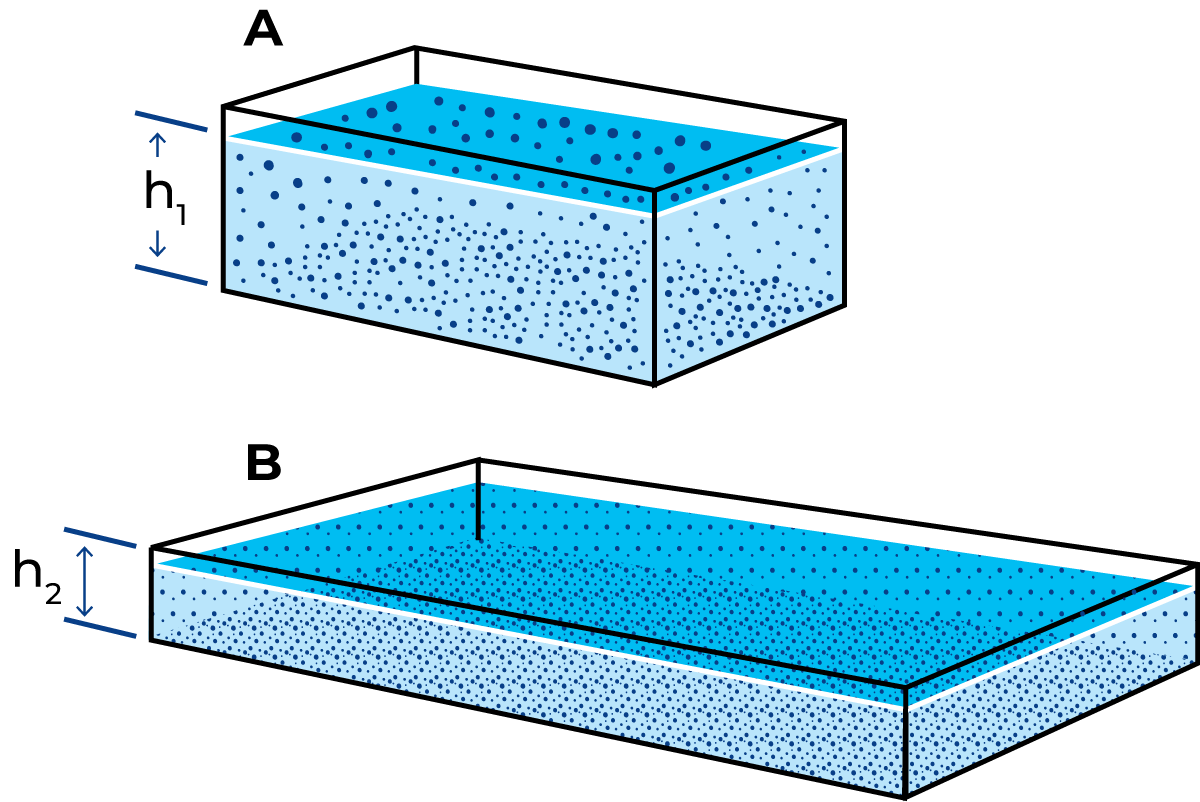

In vessel A in Figure 7.2.7, containing a dispersion in which the dispersed phase consists of solid particles with a uniform diameter d and a density higher than that of the liquid, the suspension must be left long enough for particles starting from the surface to reach the bottom. The sedimentation distance in this case is h1 m.

The time to complete separation can be reduced if the sedimentation distance is reduced. The height of the vessel (B) has been reduced and the area increased so that it still has the same volume. The sedimentation distance (h2) is reduced to 1/5 of h1 and the time required for complete separation is therefore also reduced to 1/5. However, the more the sedimentation distance and time are reduced, the greater the area of the vessel.

Continuous separation by gravity

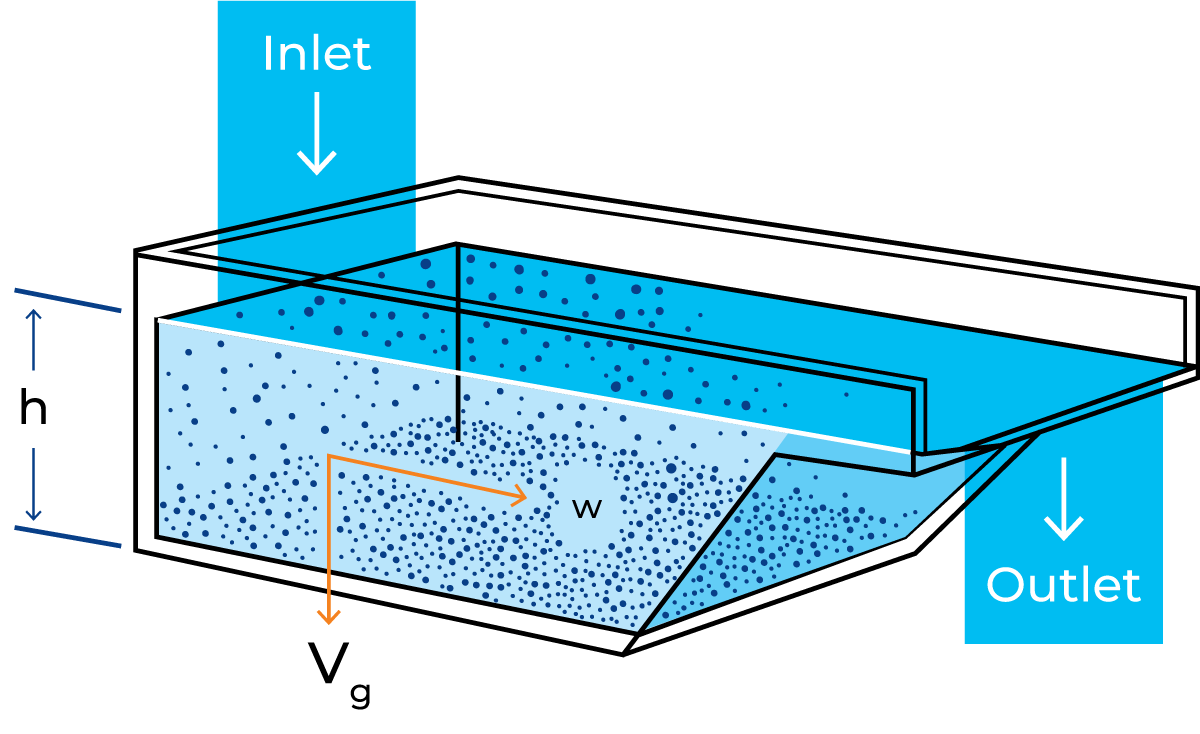

A simple vessel which can be used for continuous separation of particles of non-uniform diameter from a liquid is shown in Figure 7.2.8. The liquid containing the slurried particles is introduced at one end of the vessel and flows towards an overflow outlet at the other end at a certain capacity. On the way, the particles settle at different rates, due to their different diameters.

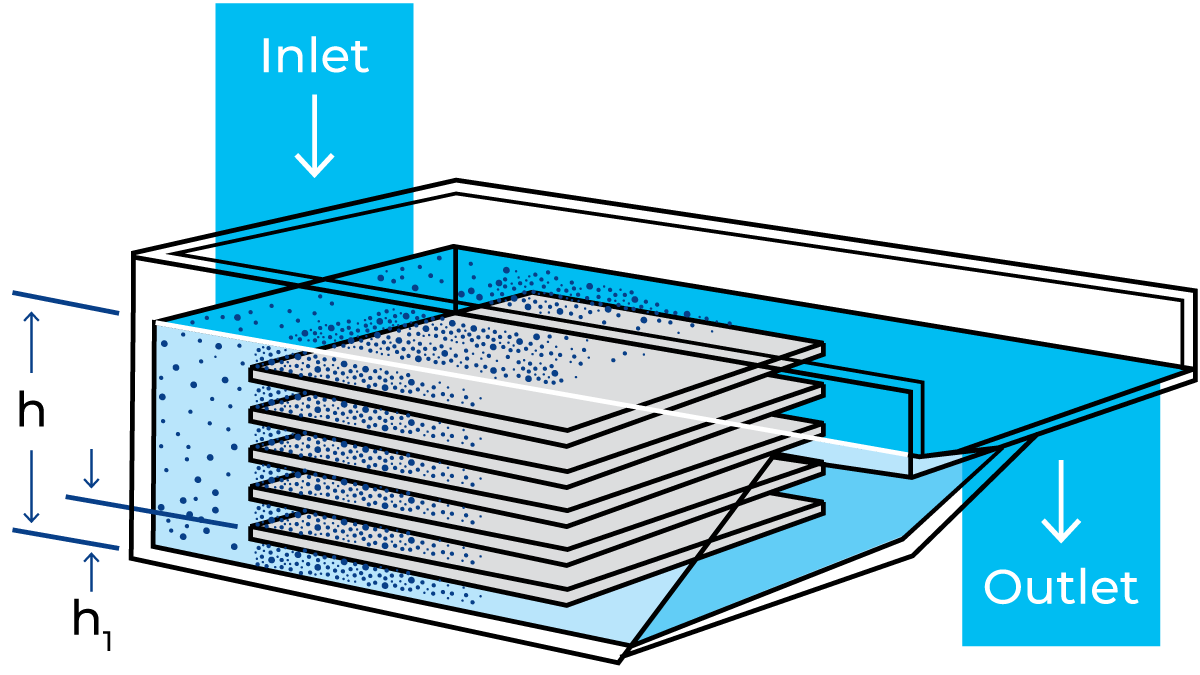

Baffles increase the capacity

The capacity of the sedimentation vessel can be increased if the total area is increased, but this makes it large and unwieldy. It is instead possible to increase the area available for separation by inserting horizontal baffle plates in the vessel, as illustrated in Figure 7.2.9.

There are now a number of “separation channels”, in which sedimentation of particles can proceed at the same rate as in the vessel in Figure 7.2.8. The total capacity of the vessel is multiplied by the number of separation channels. The total area available (i.e. the total number of baffle plate areas) for separation, multiplied by the number of separation channels, determines the maximum capacity that can flow through the vessel without loss of efficiency, i.e. without allowing any particles larger than the designated limit size to escape with the clarified liquid.

When a suspension is continuously separated in a vessel with horizontal baffle plates, the separation channels will eventually be blocked by the accumulation of sedimented particles. Separation will then come to a halt.

If the vessel has inclined baffles instead, as in Figure 7.2.10, the particles that settle on the baffles under the influence of gravity will slide down the baffles and collect at the bottom of the vessel.

Why are particles that have settled on the baffles not swept along by the liquid that flows upwards between the baffles? The explanation is given in Figure 7.2.11, which shows a section through part of a separation channel. As the liquid passes between the baffles, the boundary layer of liquid closest to the baffles is braked by friction so that the velocity drops to zero.

This stationary boundary layer exerts a braking effect on the next layer, and so on, towards the centre of the channel, where the velocity is highest. The velocity profile shown in the figure is obtained – the flow in the channel is laminar. The sedimented particles in the stationary boundary zone are consequently subjected only to the force of gravity.

The projected area is used when the maximum flow through a vessel with inclined baffle plates is calculated.

In order to utilise the capacity of a separation vessel to the fullest, it is necessary to install a maximum amount of surface area for particles to settle on. The sedimentation distance does not affect the capacity directly, but a certain minimum channel width must be maintained, to avoid blockage of the channels by sedimenting particles.

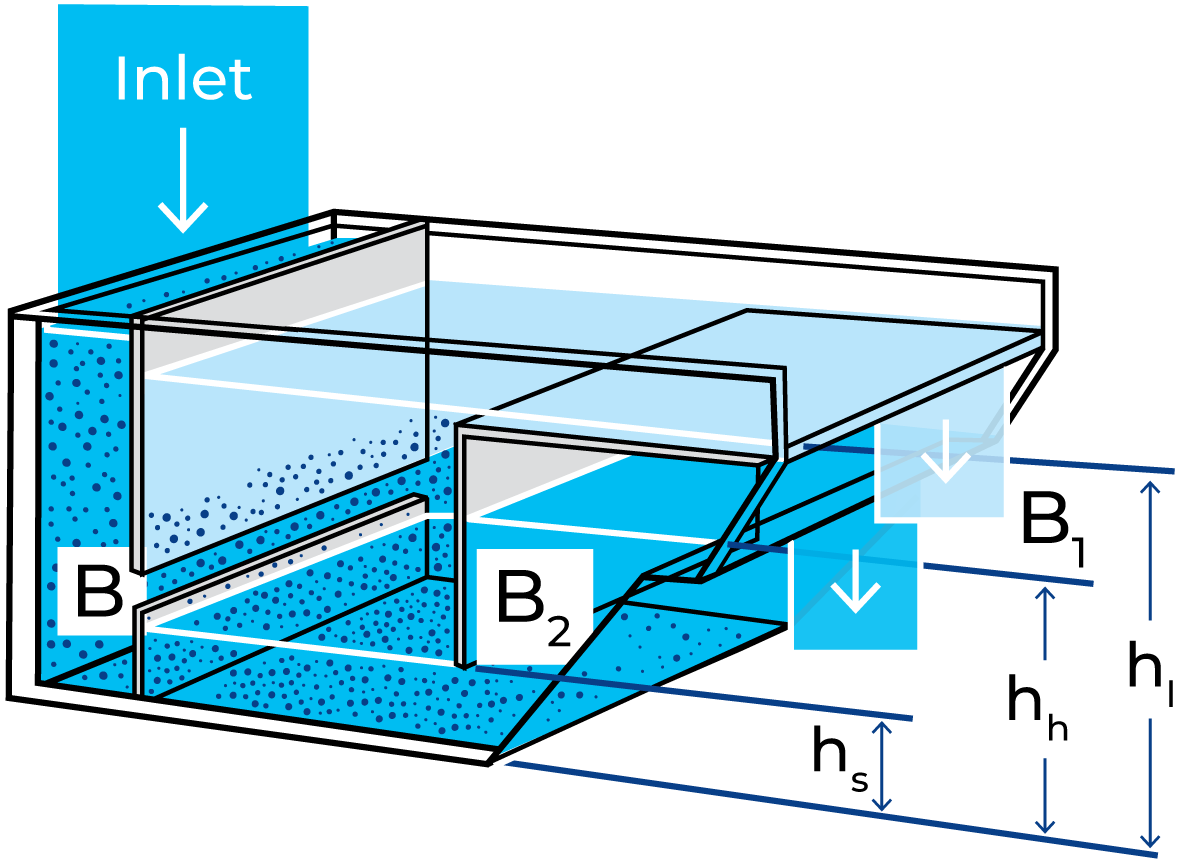

Continuous separation of a solid phase and two liquid phases

A device similar to the one shown in Figure 7.2.12 can be used for separating two mixed liquids from each other via gravity and, at the same time, for separating slurried solid particles from the mixture.

The dispersion passes downwards from the inlet through the opening B. An interface layer then flows horizontally at the level of B. From this level, the solid particles (which have a higher density than both liquids) settle to the bottom of the vessel. The less dense of the two liquid phases rises toward the surface and runs off over overflow outlet B1. The denser liquid phase moves downward and passes below baffle B2, out of the lower outlet. Baffle B2 prevents the lighter liquid from going in the wrong direction.

Separation by centrifugal force

Sedimentation velocity

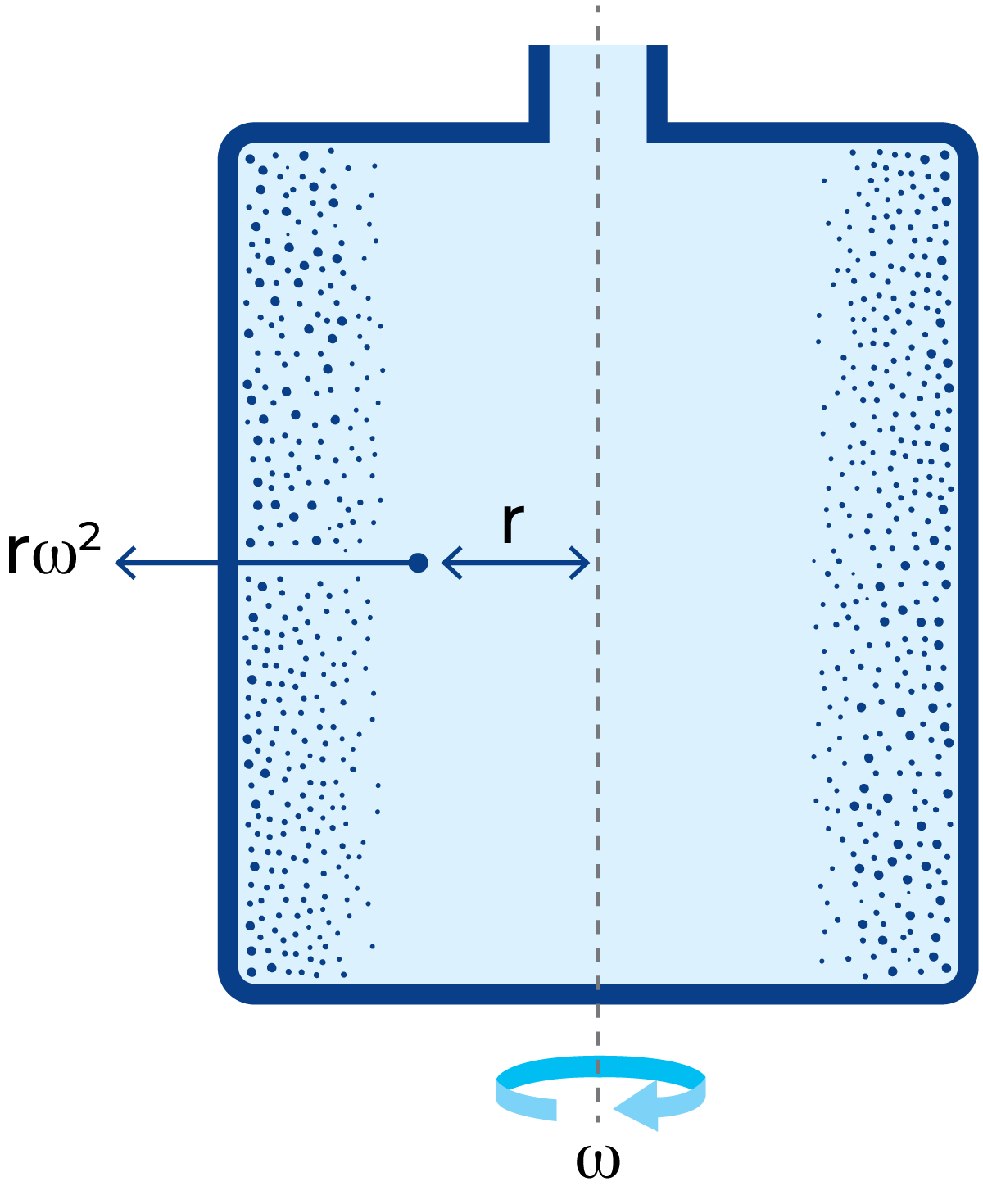

A field of centrifugal force is generated if a vessel is filled with liquid and spun, as shown in Figure 7.2.13. This creates a centrifugal acceleration, a. The centrifugal acceleration is not constant like the gravity g in a stationary vessel. The centrifugal acceleration increases with distance from the axis of rotation (radius, r) and with the speed of rotation, expressed as angular velocity ω, (Figure 7.2.14).

The acceleration can be calculated by the formula 2).

The following formula 3) is obtained if the centrifugal acceleration, a, expressed as rω2, is substituted for the gravitational acceleration, g, in the aforementioned Stokes’ law equation 1.

Equation 3) can be used to calculate the sedimentation velocity, v, of each particle in the centrifuge.

Flotation velocity of a fat globule

Equation 1) was previously used and it was found that the flotation velocity of a single fat globule 3 μm in diameter was 0.166 x 10–6 m/s or 0.6 mm/h under the influence of gravity.

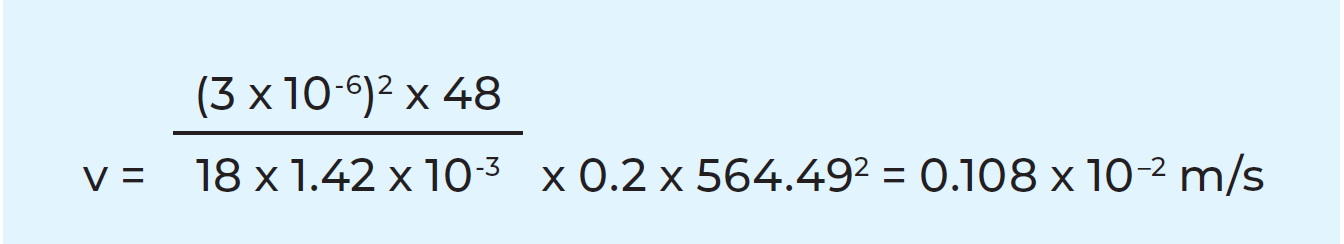

Equation 3) can now be used to calculate the flotation velocity of a fat globule of the same diameter at a radial position of 0.2 m in a centrifuge rotating at a speed of n = 5,400 rpm.

The angular velocity can be calculated as

giving 2π = one revolution and n = revolutions per minute (rpm) with a rotating speed (n) of 5,400 rpm the angular velocity (ω) will be: ω = 564.49 rad/s

The sedimentation velocity (v) will then be:

i.e. 1.08 mm/s or 3,896.0 mm/h.

Dividing the sedimentation velocity in a centrifugal force field by the sedimentation velocity in a gravity field gives the efficiency of centrifugal separation, compared with sedimentation by gravity. The sedimentation velocity in the centrifuge is 3,896.0/0.6 ≈ 6,500 times faster.

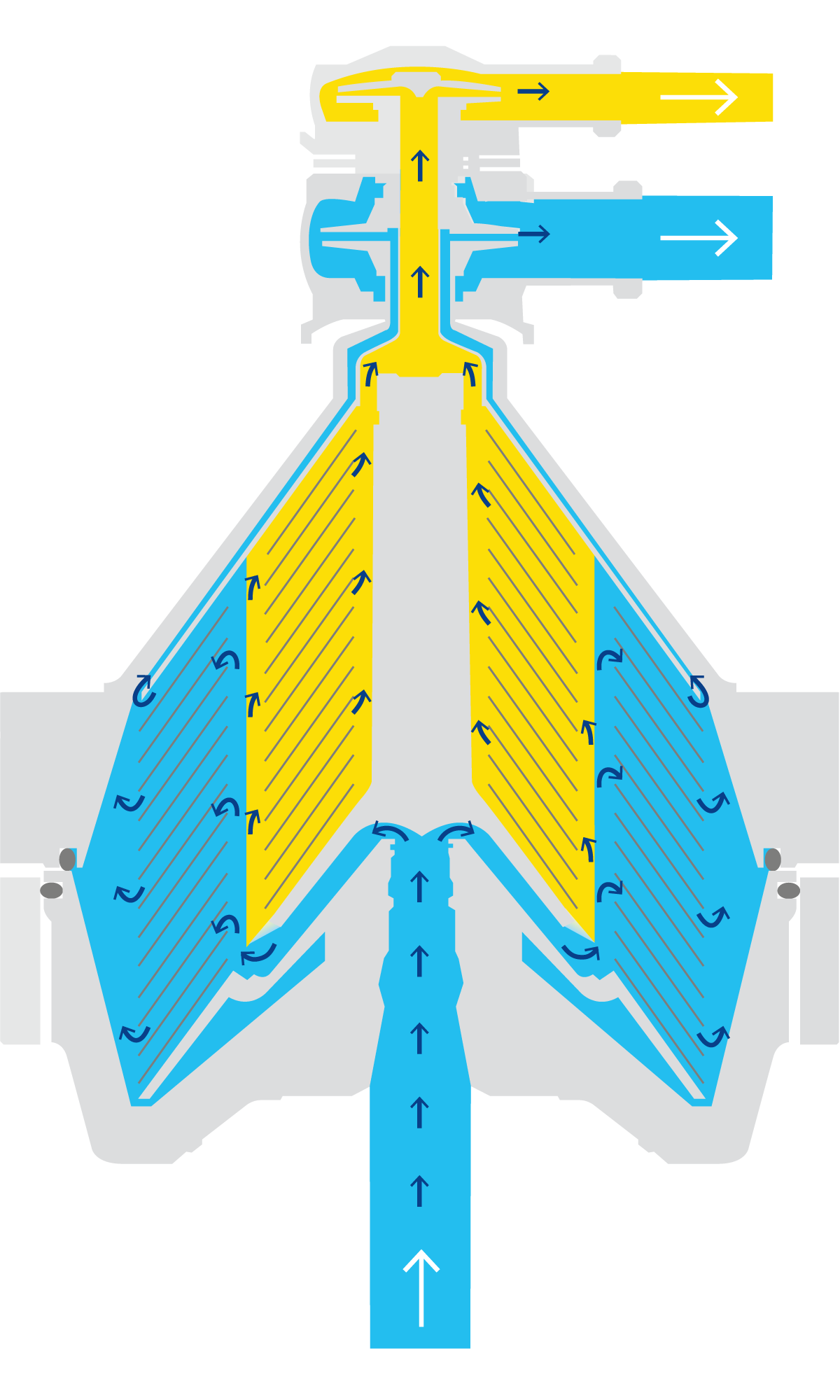

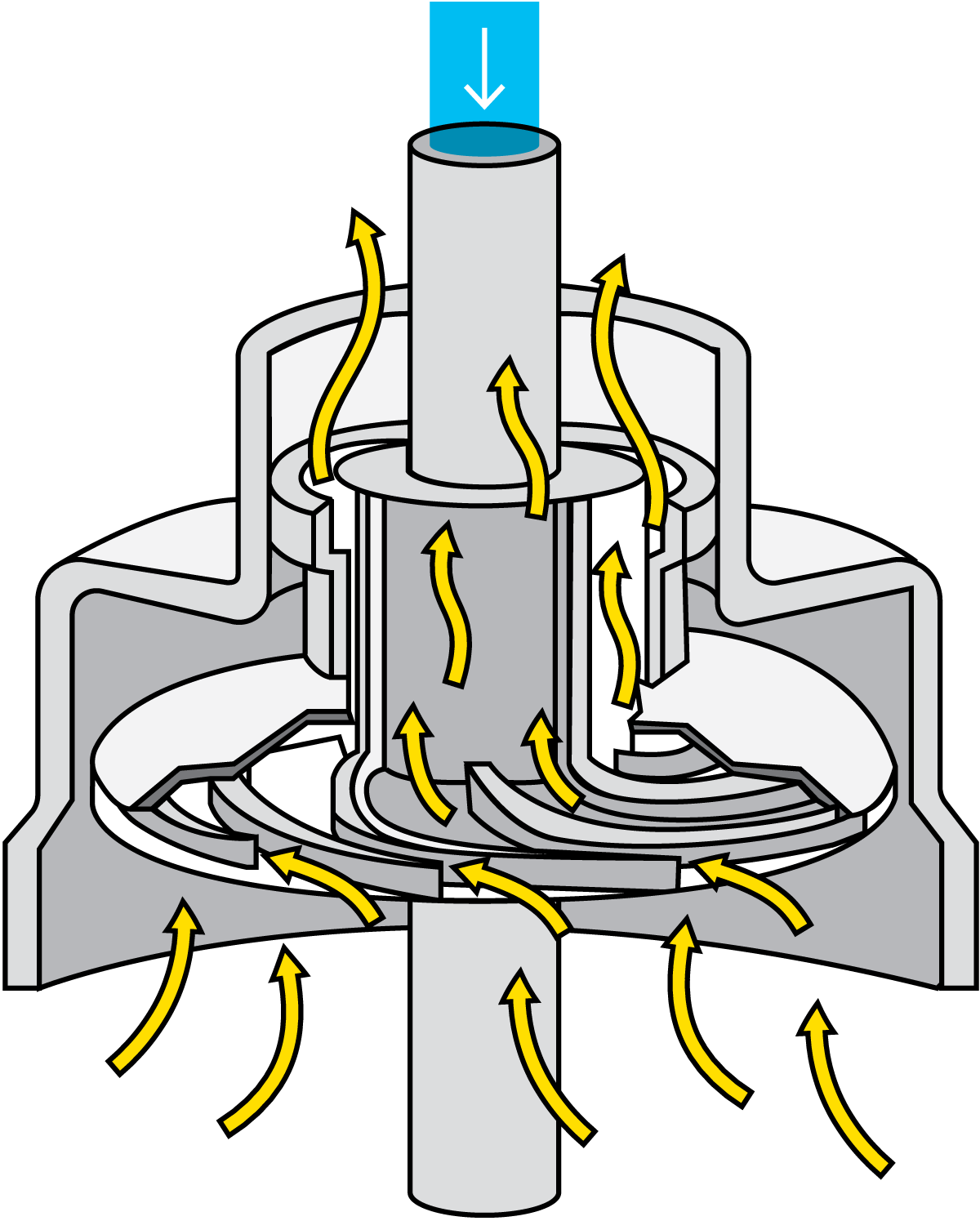

Continuous centrifugal separation of solid particles – Clarification

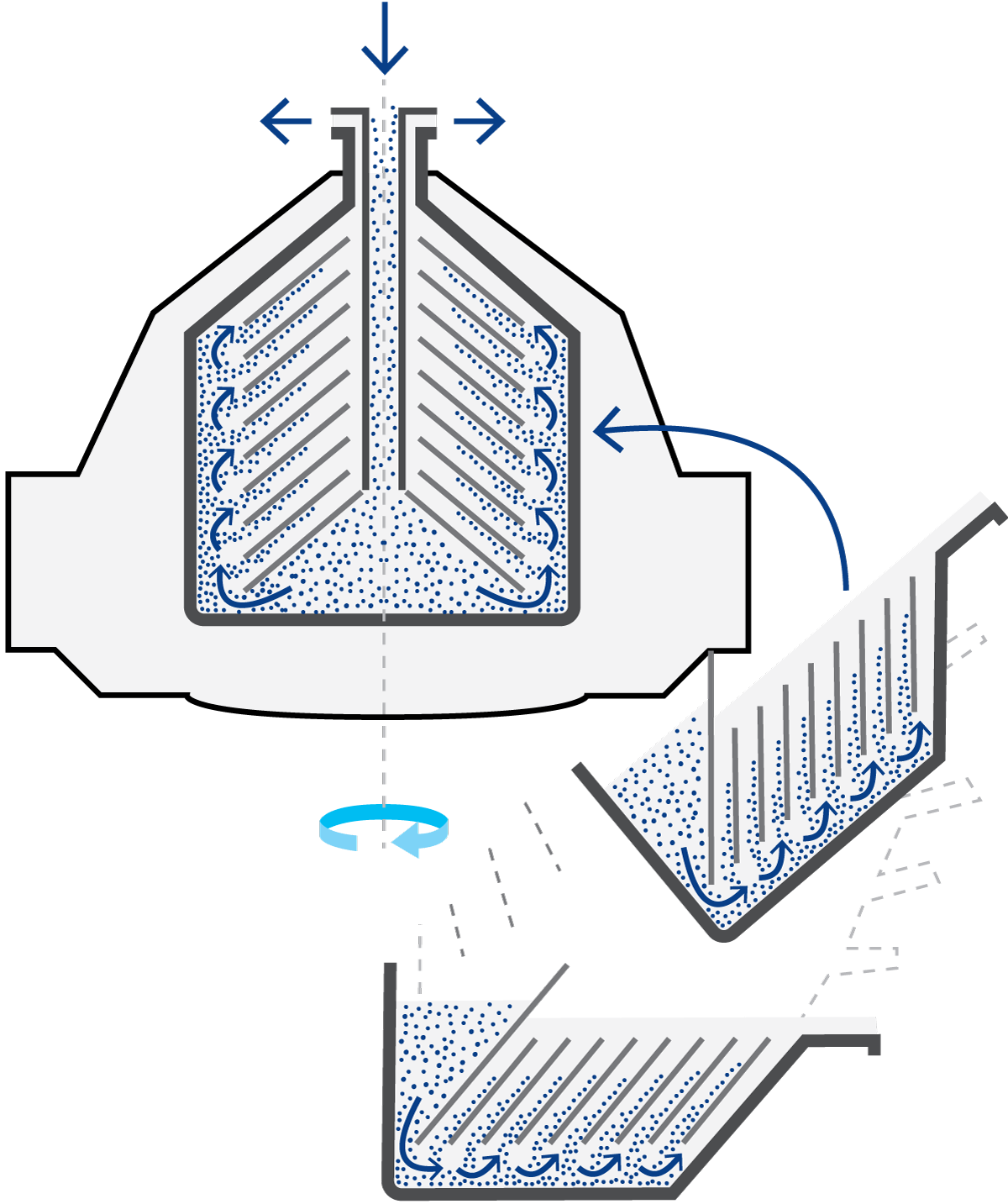

Figure 7.2.15 shows a centrifuge bowl for continuous separation of solid particles from a liquid. This operation is called clarification. Imagine the sedimentation vessel in Figure 7.2.10 turned 90° and spun around the axis of rotation. The result is a sectional view of a centrifugal separator.

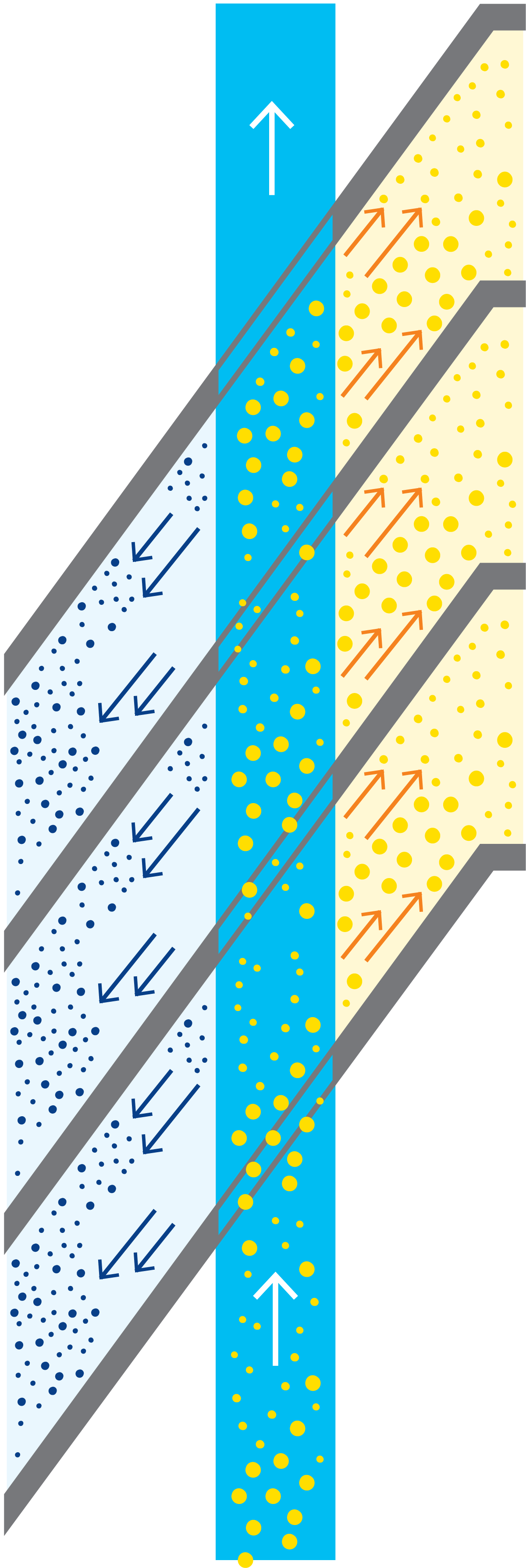

Separation channels

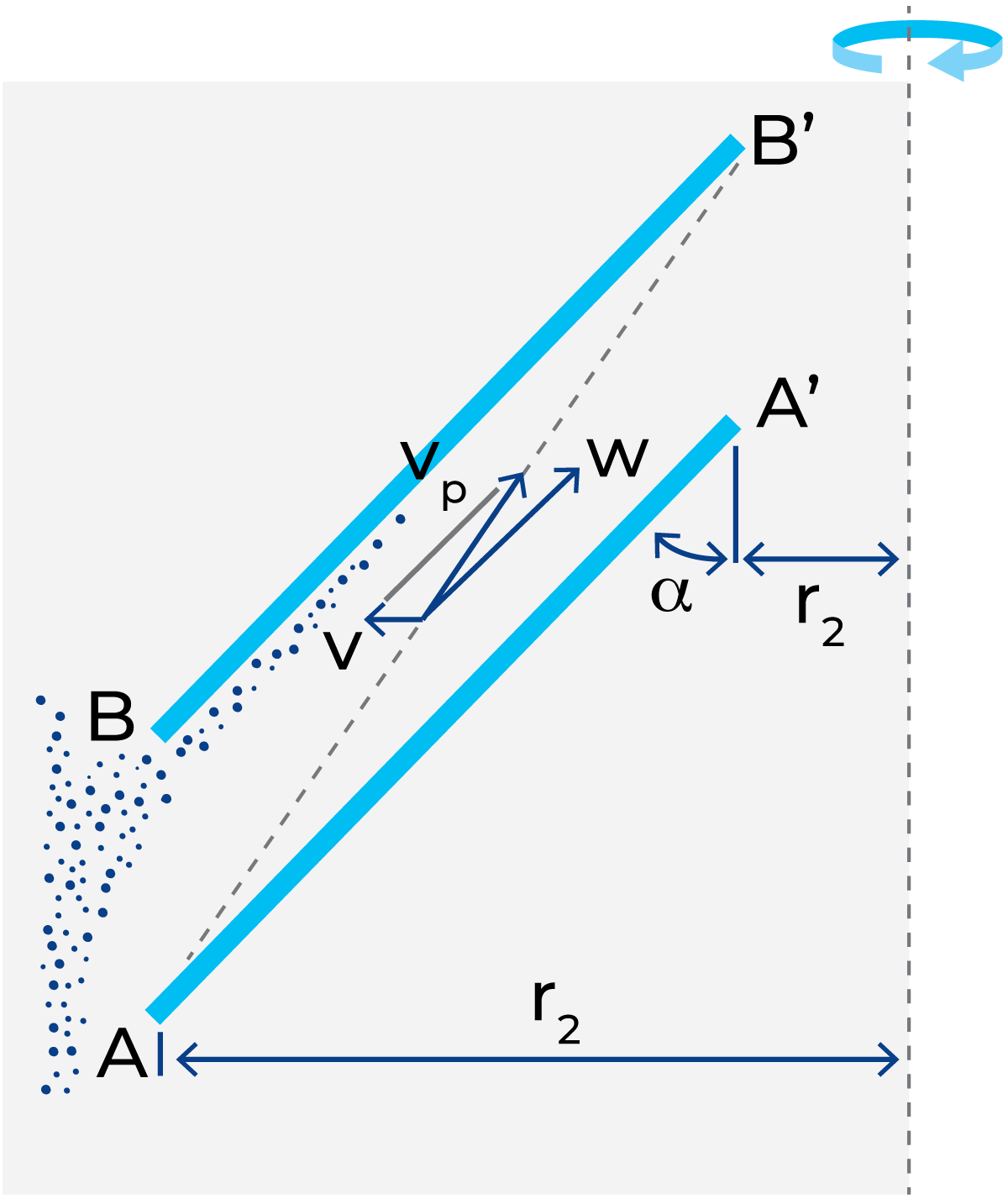

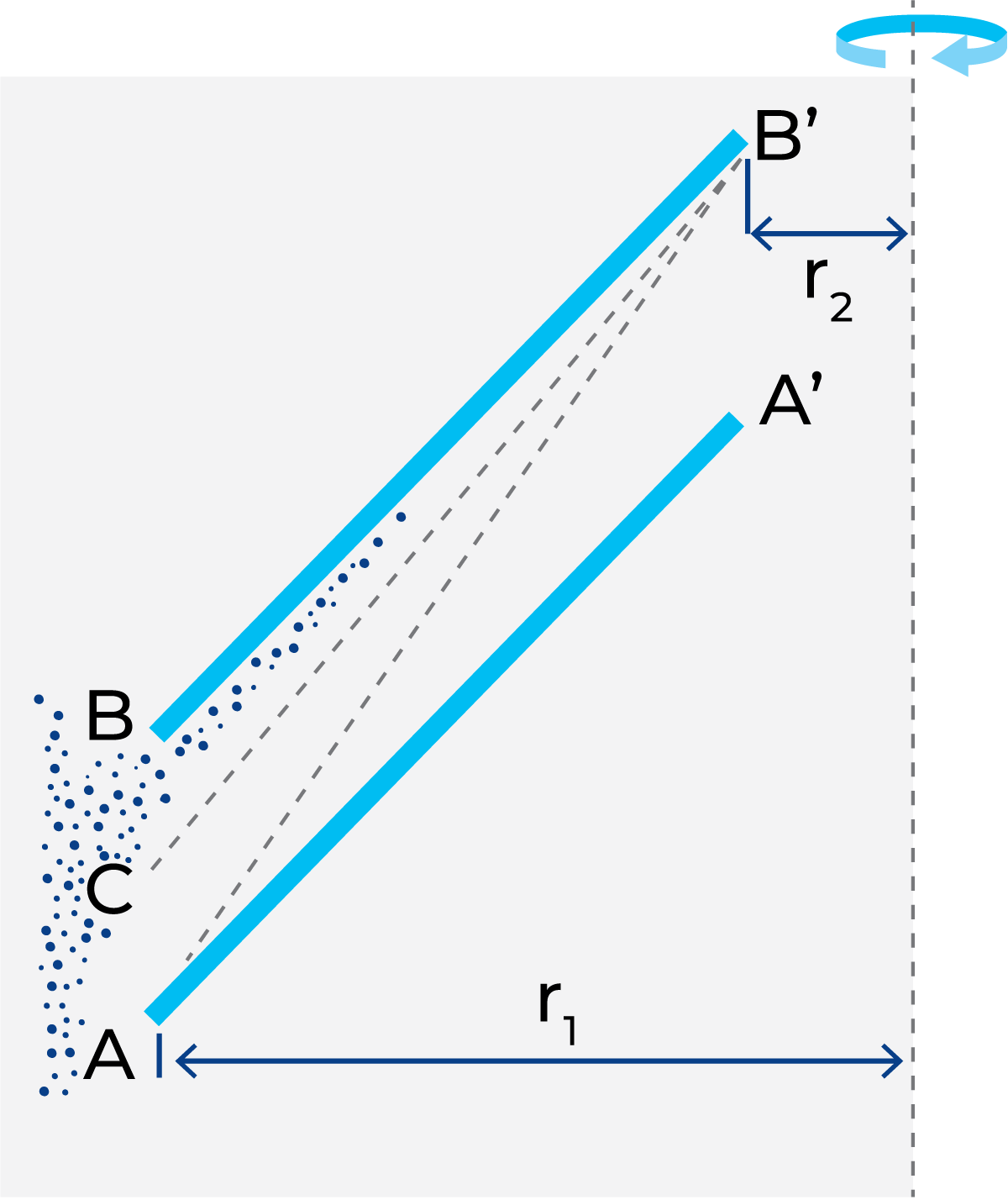

Figure 7.2.15 also shows that the centrifuge bowl has baffle inserts in the form of conical discs. This increases the area available for sedimentation. The discs rest on each other and form a unit known as the disc stack. Radial strips called caulks are welded to the discs and keep them the correct distance apart. This forms the separation channels. The thickness of the caulks determines the width. Figure 7.2.16 shows how the liquid enters the channel at the outer edge (radius r1), leaves at the inner edge (radius r2) and continues to the outlet.

During passage through the channel, the particles settle outward towards the disc, which forms the upper boundary of the channel.

The velocity w of the liquid is not the same in all parts of the channel. It varies from almost zero, closest to the discs, to a maximum value in the centre of the channel. The centrifugal force acts on all particles, forcing them towards the periphery of the separator at a sedimentation velocity, v. A particle consequently moves simultaneously at velocity w with the liquid, and at sedimentation velocity, v radially towards the periphery.

The resulting velocity, vp, is the sum of these two motions. The particle moves in the direction indicated by vector arrow vp. For the sake of simplicity, it is assumed that the particle moves in a straight path as shown by the broken line in the figure.

In order to be separated, the particle must settle on the upper plate before reaching point B', i.e. at a radius equal to or greater than r2. Once the particle has settled, the liquid velocity at the surface of the disc is so small that the particle is no longer carried along with the liquid. It therefore slides outwards along the underside of the disc under the influence of the centrifugal force, is thrown off the outer edge at B and deposited on the peripheral wall of the centrifuge bowl.

The limit particle

The limit particle is a particle of such a size that if it starts from the least favourable position, i.e. point A in Figure 7.2.17, it will only just reach the upper disk at point B'. All particles larger than the limit particle will be separated.

The figure shows that some particles smaller than the limit particle will also be separated if they enter the channel at point C somewhere between A and B. The smaller the particle, the closer C must be to B in order to achieve separation.

Continuous centrifugal separation of milk

Clarification

In a centrifugal clarifier, the milk is introduced into the separation channels at the outer edge of the disc stack, flows radially inwards through the channels towards the axis of rotation and leaves through the outlet at the top as illustrated in Figure 7.2.18. On the way through the disc stack, the solid impurities are separated and thrown back along the undersides of the discs to the periphery of the clarifier bowl. There they are collected in the sediment space. As the milk passes along the full radial width of the discs, the time of passage also allows very small particles to be separated. The most typical difference between a centrifugal clarifier and a separator is the design of the disk stack. A clarifier has no distribution holes. There are slots at the outer periphery of the discs. The number of outlets also differs – a clarifier has one and a separator has two.

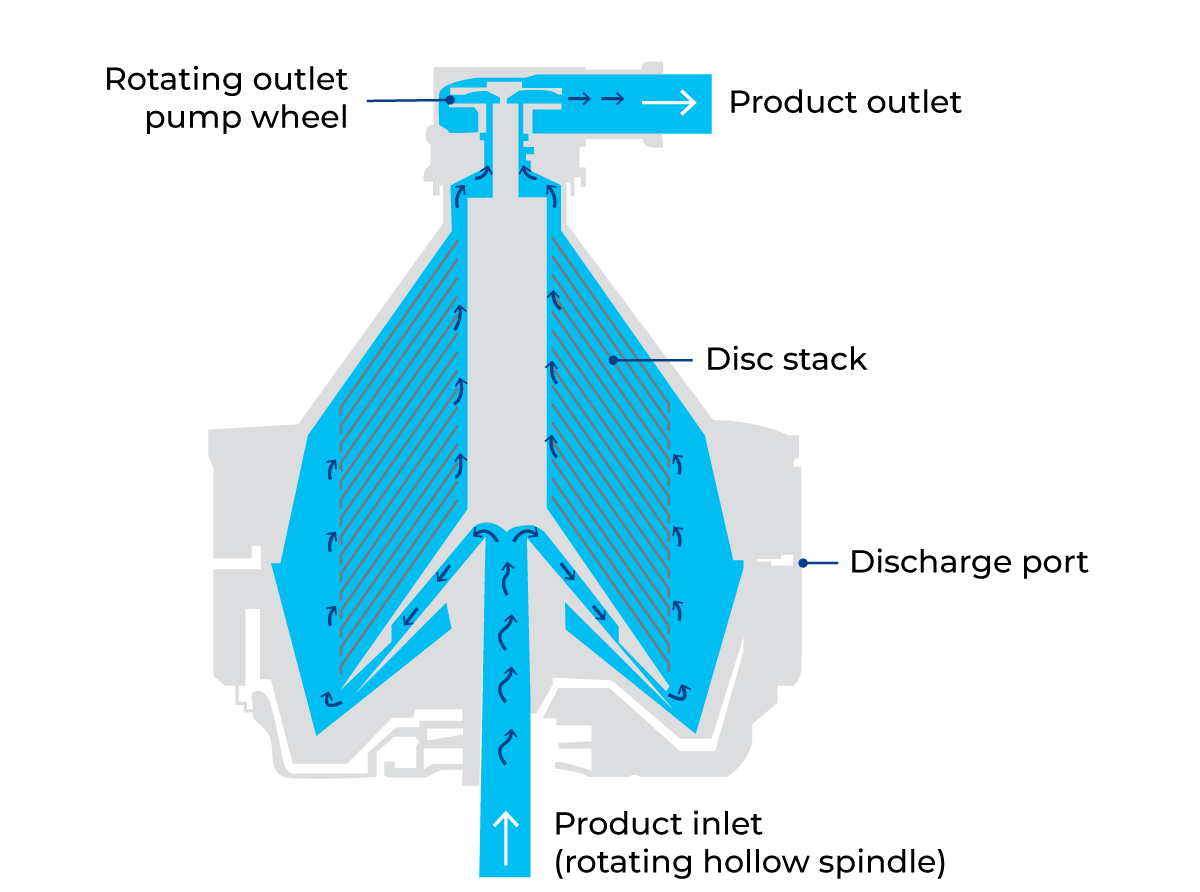

Separation

In a centrifugal separator, the disc stack is equipped with vertically aligned distribution holes. Figure 7.2.19 shows schematically how fat globules are separated from the milk in the disc stack of a centrifugal separator. Figure 7.2.21 shows a disc stack. A more detailed illustration of this phenomenon is shown in Figure 7.2.20.

The milk is introduced through vertically aligned distribution holes in the discs at a certain distance from the edge of the disc stack. Under the influence of centrifugal force, the sediment and fat globules in the milk begin to settle radially outwards or inwards in the separation channels, according to their density relative to that of the continuous medium (skim milk).

As in the clarifier, the high-density solid impurities in the milk will quickly settle outwards towards the periphery of the separator and collect in the sediment space. Sedimentation of solids is assisted by the fact that the skim milk in the channels in this case moves outwards towards the periphery of the disc stack. The cream, i.e. the fat globules, has a lower density than the skim milk and therefore moves inwards in the channels, towards the axis of rotation. The cream continues to an axial outlet.

The skim milk moves outwards to the space outside the disc stack and then through a channel between the top of the disc stack and the conical hood of the separator bowl to a concentric skim milk outlet.

Skimming efficiency

The amount of fat that can be separated from milk depends on the design of the separator, the rate at which the milk flows through it, and the size distribution of the fat globules.

The smallest fat globules, normally < 1 μm, do not have time to rise at the specified flow rate but are carried out of the separator with the skim milk. The remaining fat content in the skim milk normally lies between 0.04 and 0.07%, and the skimming ability of the machine is then said to be 0.04 – 0.07%.

The flow velocity through the separation channels will be reduced if the flow rate through the machine is reduced. This gives the fat globules more time to rise and be discharged through the cream outlet. The skimming efficiency of a separator consequently increases with reduced throughput and vice versa.

Fat content of cream

The whole milk supplied to the separator is discharged as two flows, skim milk and cream, of which the cream normally represents about 10% of the total throughput. The proportion discharged as cream determines the fat content of the cream.

If the whole milk contains 4% fat and the throughput is 20,000 I/h, the total amount of fat passing through the separator will be

Assume that cream with a fat content of 40% is required. This amount of fat must be diluted with a certain amount of skim milk. The total amount of liquid discharged as 40% cream will then be

800 l/h is pure fat, and the remaining 1,200 l/h is skim milk. The installation of regulation valves in the cream and skim milk outlets makes it possible to adjust the relative volumes of the two flows to obtain the required fat content in the cream.

Solids ejection

The solids that collect in the sediment space of the separator bowl consist of straw and hairs, udder cells, white blood corpuscles (leucocytes), red blood corpuscles, bacteria, etc. The total amount of sediment in milk varies but can be about 1 kg/10,000 litres.

The sediment space volume varies depending on the size of the separator, it can be from 3.5 litres up to 30 litres.

In milk separators of the solids-retaining type, it is necessary to dismantle the bowl manually and clean the sediment space at relatively frequent intervals. This involves a great deal of manual labour.

Self-cleaning or solids-ejecting separator bowls are equipped for automatic ejection of accumulated sediment at pre-set intervals (Figure 7.2.22). This eliminates the need for manual cleaning. The system for solids discharge is described at the end of this chapter under “The discharge system”.

Solids ejection is normally carried out at 30-to-60- minute intervals during milk separation.

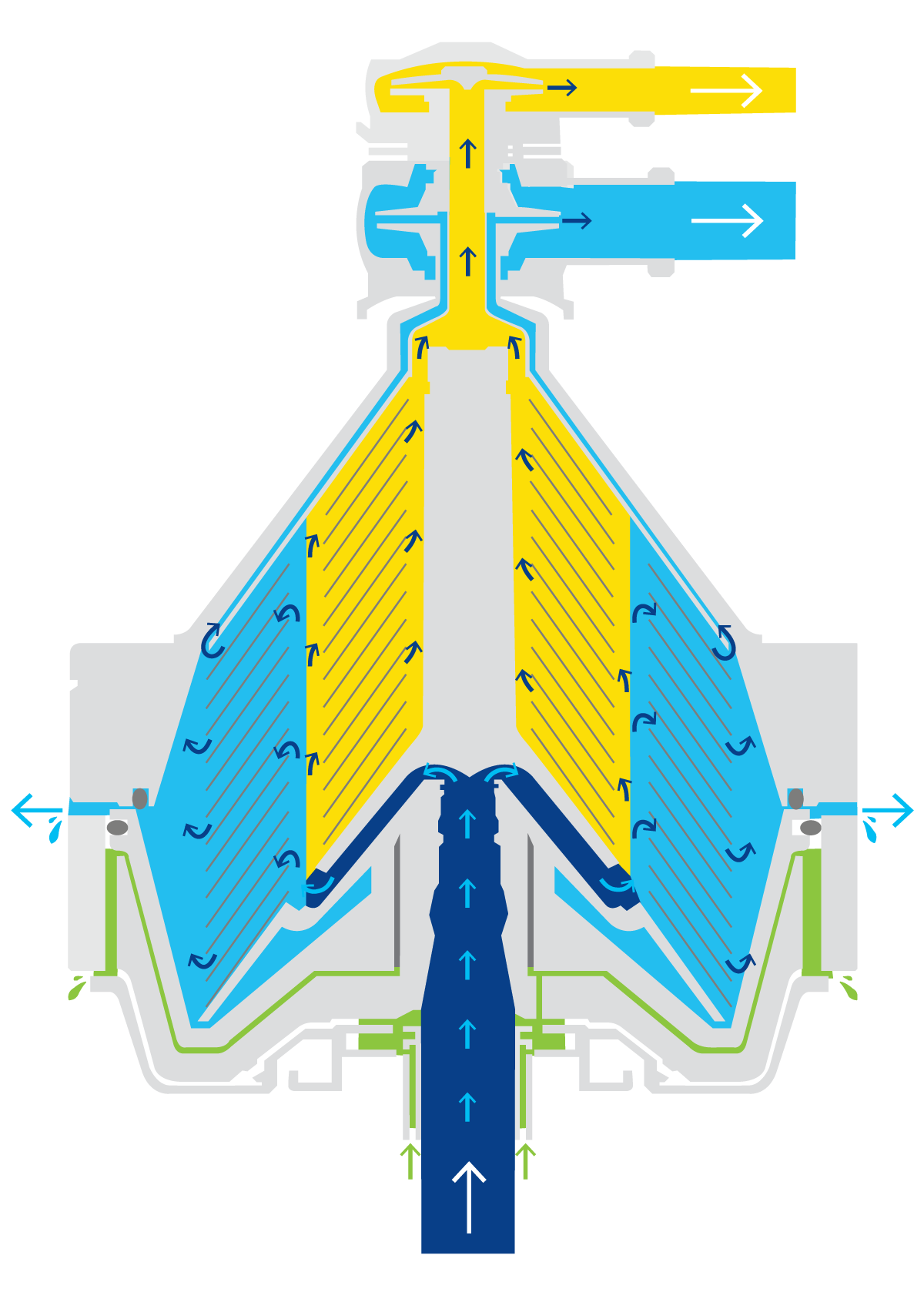

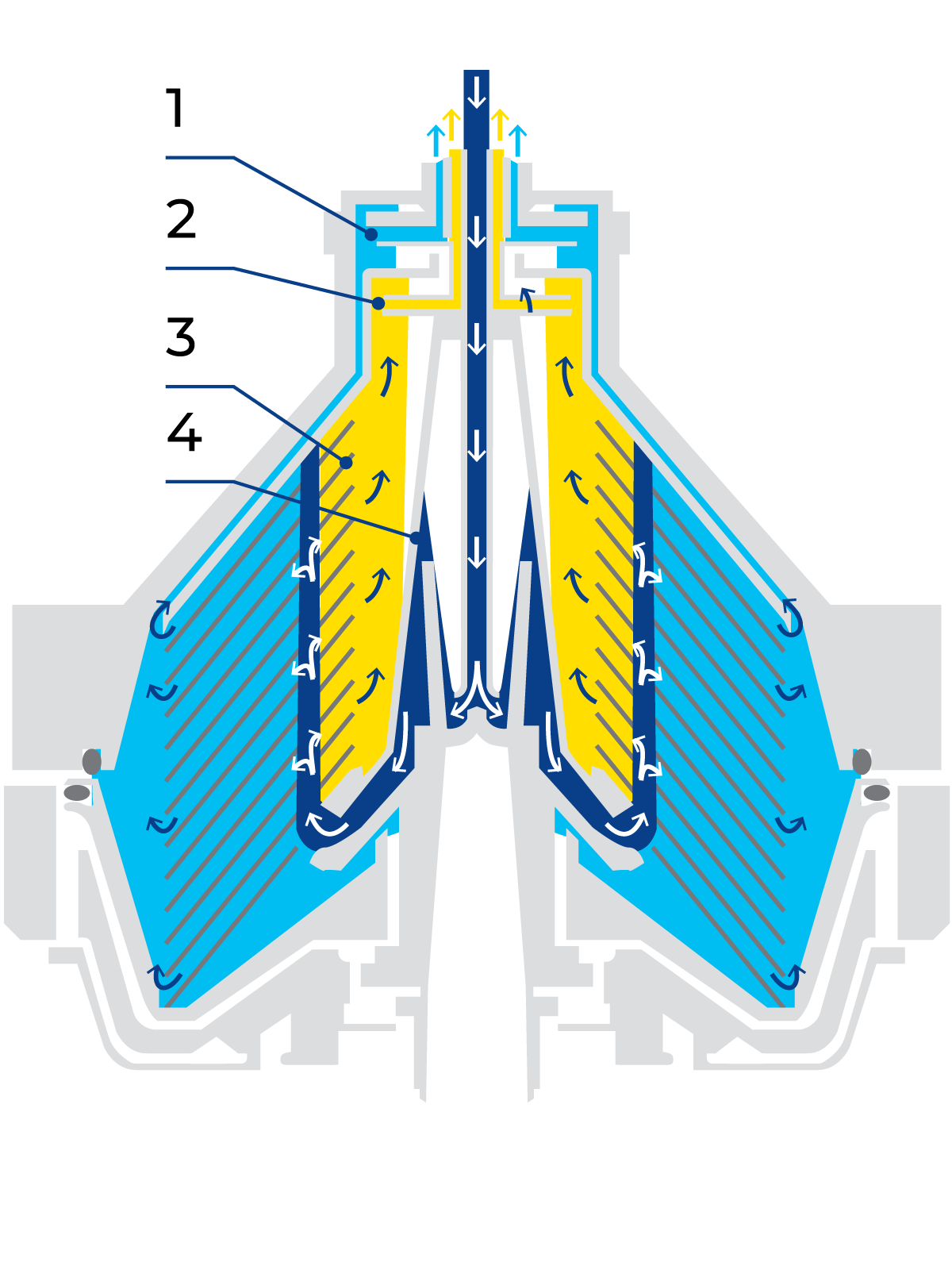

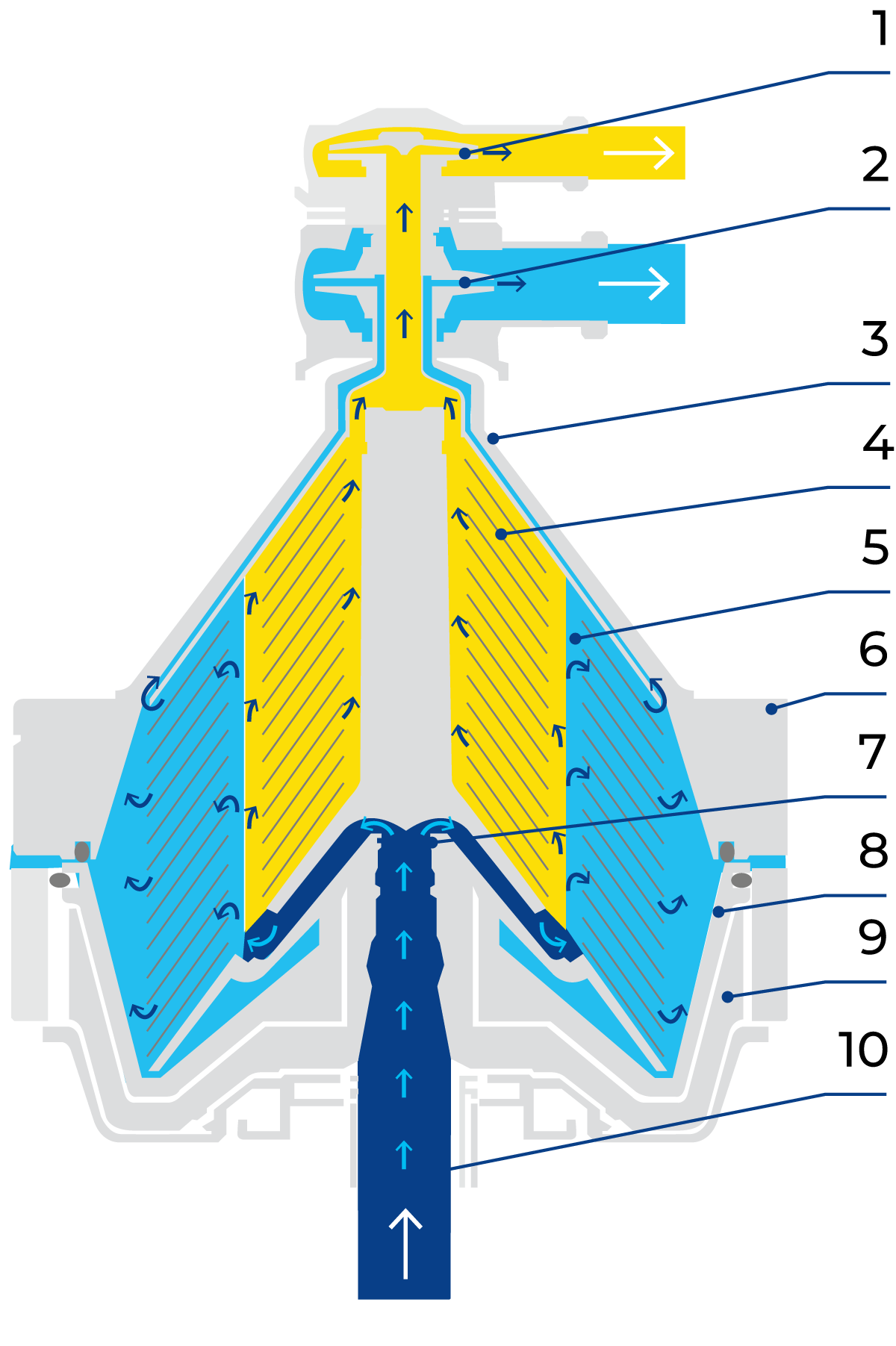

Basic design of the centrifugal separator

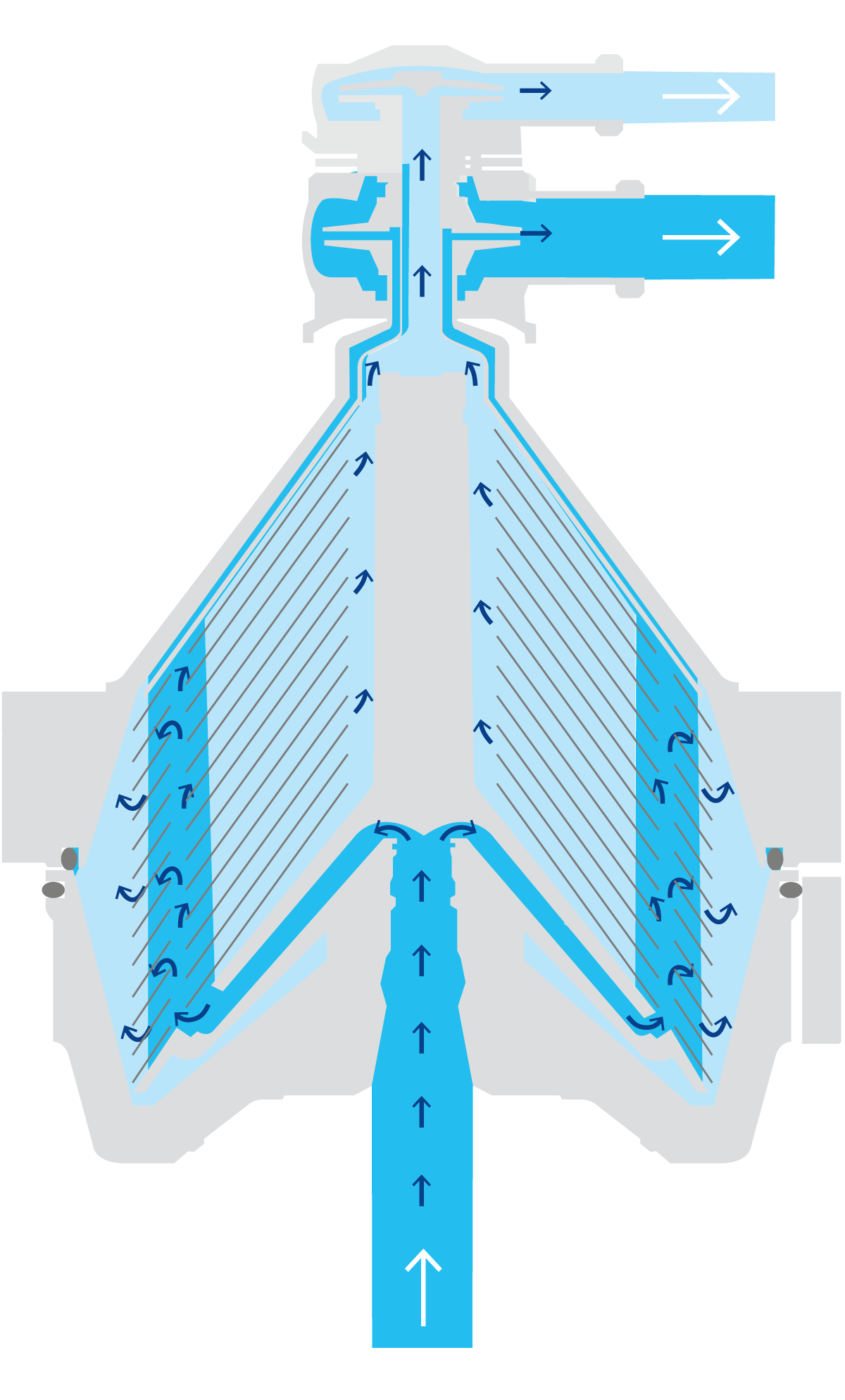

A cross-section through a self-cleaning separator, Figures 7.2.25 and 7.2.26, shows that the bowl consists of two major parts, the body and the hood. They are held together by a threaded lock ring. The disc stack is clamped between the hood and the distributor at the centre of the bowl. There are two types of modern separators: semi-open and hermetic.

Semi-open design

Centrifugal separators with paring discs at the outlet (Figure 7.2.23) are known as semi-open types (as opposed to the older open models with overflow discharge).

In the semi-open separator, the milk is supplied to the separator bowl from an inlet, normally in the top, through a stationary axial inlet tube.

When the milk enters the distributor (4), it is accelerated to the speed of rotation of the bowl, before it continues into the separation channels in the disc stack (3). The centrifugal force throws the milk outwards to form a ring with a cylindrical inner surface.

This is in contact with air at atmospheric pressure, which means that the pressure of the milk at the surface is also atmospheric. The pressure increases progressively, with increasing distance from the axis of rotation to a maximum at the periphery of the bowl.

The heavier solid particles settle outwards and are deposited in the sediment space. Cream moves inwards towards the axis of rotation and passes through channels to the cream-paring chamber (2). The skim milk leaves the disc stack at the outer edge and passes between the top disc and the bowl hood to the skim milk paring chamber (1).

Paring disc

In the semi-open separator, the cream and skim milk outlets have special outlet devices – paring discs, – one of which is shown in Figure 7.2.24. Because of this outlet design, semi-open separators are usually called paring-disc separators.

The rims of the stationary paring discs dip into the rotating columns of liquid, continuously paring out a certain amount. The kinetic energy of the rotating liquid is converted into pressure in the paring disc, and the pressure is always equal to the pressure drop in the downstream line.

An increase in downstream pressure means that the liquid level in the bowl moves inwards. In this way, the effects of throttling at the outlets are automatically counteracted. In order to prevent aeration of the product, it is important that the paring discs are sufficiently covered with liquid.

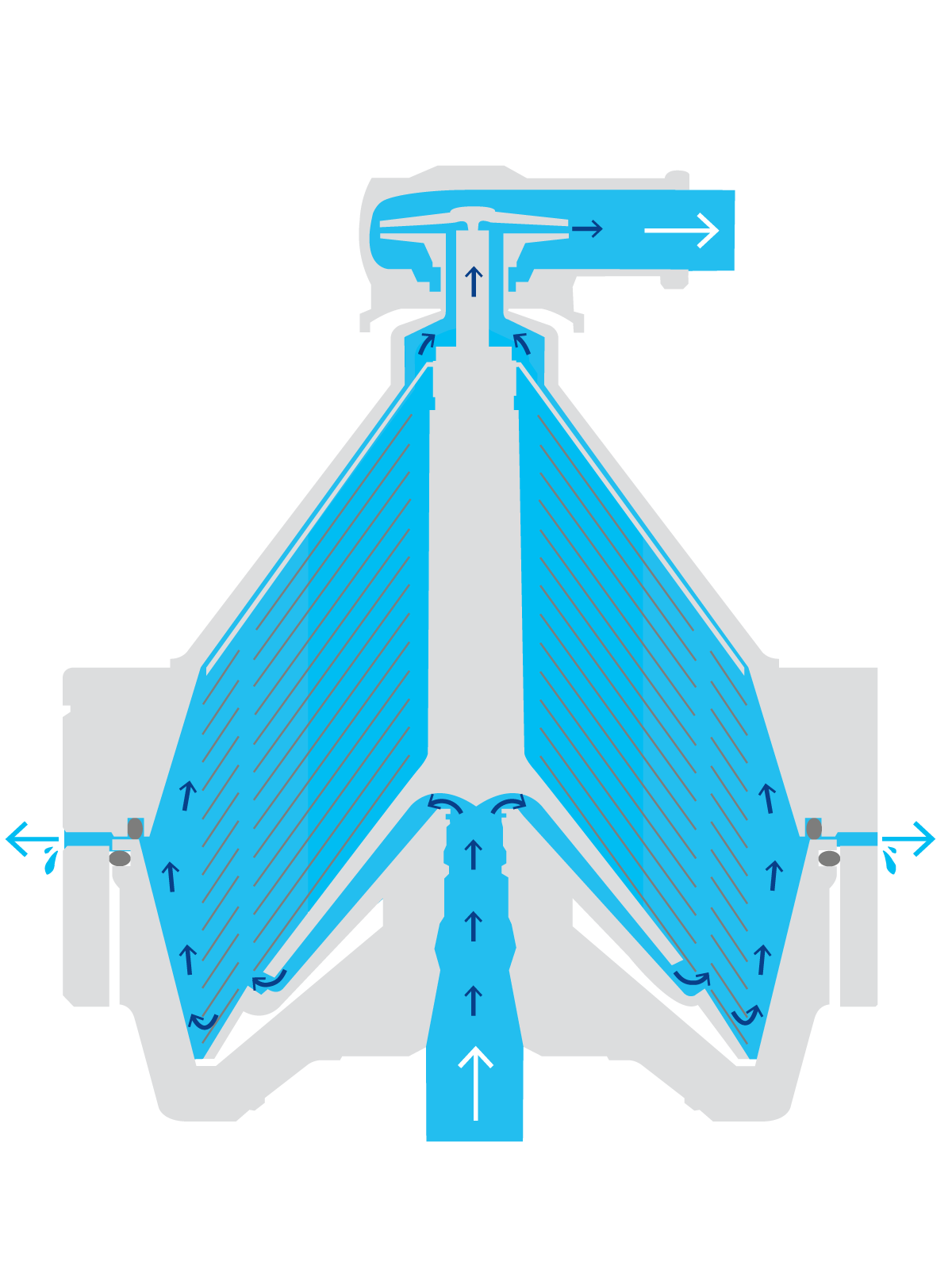

Hermetic design

In the hermetic separator, as seen in Figure. 7.2.25, the milk is supplied to the bowl through the bowl spindle. It is accelerated to the same speed of rotation as the bowl and then continues through the distribution holes in the disc stack.

The bowl of a hermetic separator is completely filled with milk during operation. There is no air in the centre. The hermetic separator can therefore be regarded as part of a closed piping system.

The pressure generated by the external product pump is sufficient to overcome the flow resistance through the separator to the discharge pump at the outlets for cream and skim milk. The diameter of the pump impellers can be engineered to suit the outlet pressure requirements.

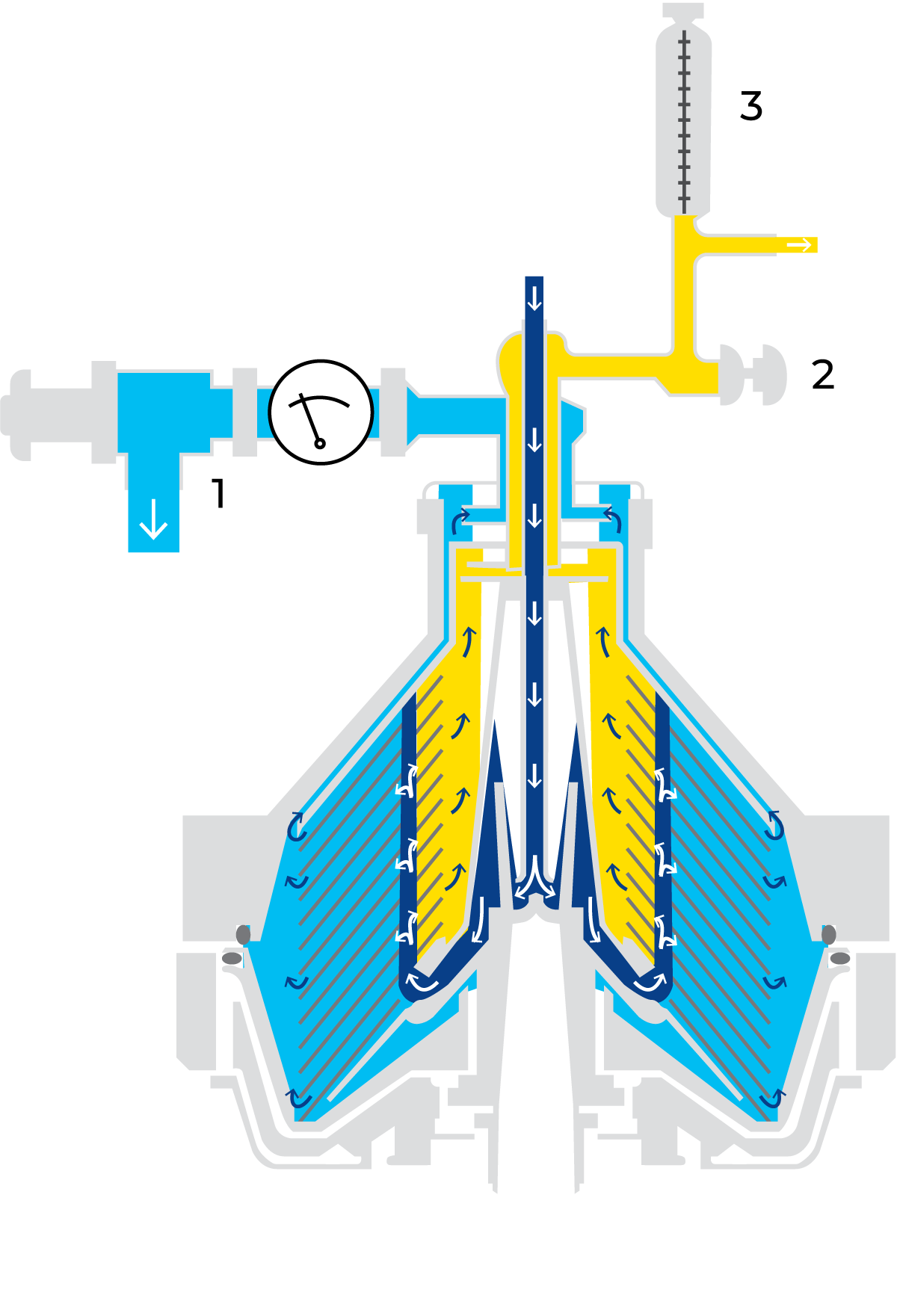

Control of the fat content in cream

Paring disc separator

The volume of cream exiting from the paring-disc separator is controlled by a throttling valve in the cream outlet. Increasingly larger amounts of cream, with a progressively diminishing fat content, will be discharged from the cream outlet if the valve is gradually opened.

A defined flow rate consequently corresponds to a given fat content in the cream. If the fat content of the whole milk is 4% and cream with 40% fat is required, the discharge from the cream outlet must be adjusted to 2,000 I/h (according to the previous calculation). The pressure on the skim milk outlet, (1) in Figure 7.2.27, is set by means of a regulating valve at a certain value, according to the separator and the throughput. The throttling valve (2) in the cream outlet is then adjusted to give the flow volume corresponding to the required fat content.

Any change in the cream flow will be matched by an equal (and opposite) alteration in the skim milk flow. An automatic constant pressure unit is fitted in the skim milk outlet to keep the back pressure at the outlet constant, regardless of changes in the rate of cream flow.

Cream flow meter

In paring-disc separators, the volume of cream discharged is controlled by a cream valve (2) with a built-in flow meter (3). The size of the valve aperture is adjusted with a screw, and the throttled flow passes through a graduated glass tube. A spool-shaped float, within the tube, is lifted by the cream flow to a position on the graduated scale, varying according to the flow rate and viscosity of the cream.

By analysing the fat content of the incoming whole milk and calculating the volume of the cream flow at the required fat content, it is possible to arrive at a coarse setting of the flow rate and adjust the throttling screw accordingly. Fine adjustments can be made when the fat content of the cream has been analysed. The operator then knows the float reading when the fat content of the cream is correct.

The fat content of the cream is affected by variations in the fat content of the incoming whole milk and by flow variations in the line. Other types of instruments are used, e.g. automatic in-line systems, to measure the fat content of cream in combination with control systems which keep the fat content at a constant value.

Hermetic separator

An automatic constant pressure unit for a hermetic separator is shown in Figure 7.2.28. The valve shown is a diaphragm valve and the required product pressure is adjusted by means of compressed air above the diaphragm.

During separation, the diaphragm is affected by the constant air pressure above and the product (skim milk) pressure below. The pre-set air pressure will force the diaphragm down if the pressure in the skim milk drops. The valve plug, fixed to the diaphragm, then moves downwards and reduces the passage. This throttling increases the skim milk outlet pressure to the pre-set value. The opposite reaction takes place when there is an increase in the skim milk pressure, and the pre-set pressure is again restored.

Differences in outlet performance of hermetic and paring-disc separators

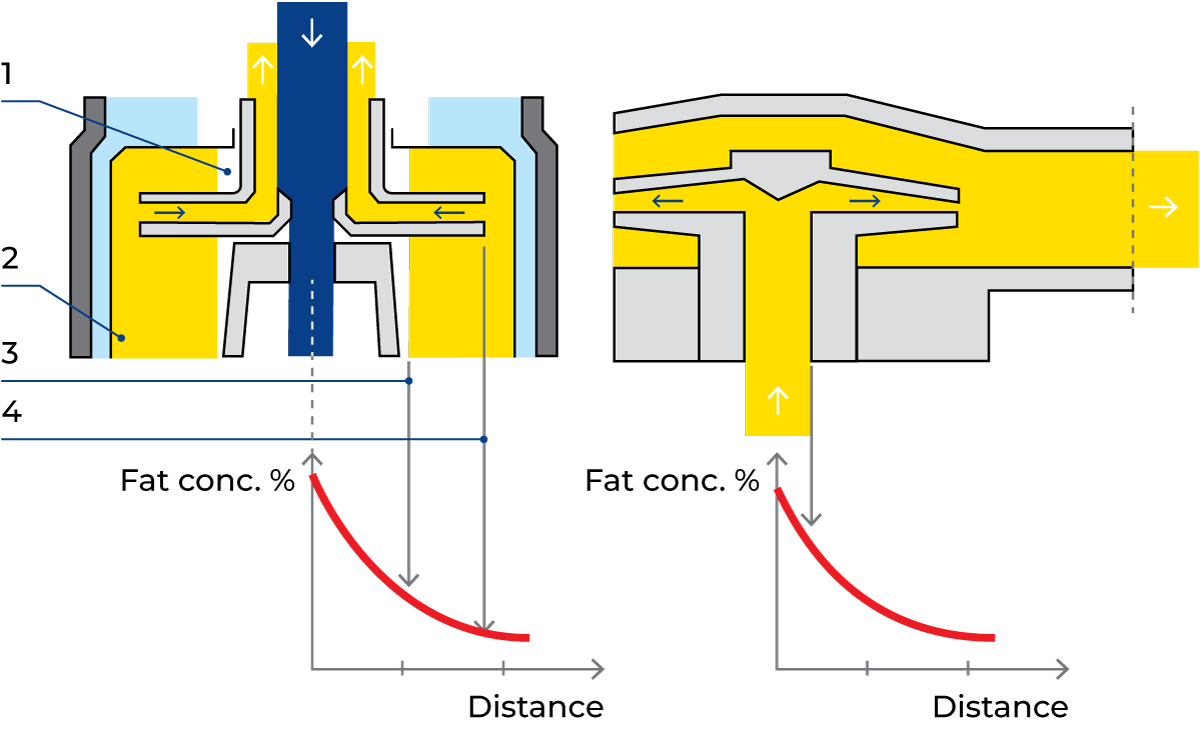

Figure 7.2.29 is a simplified picture of the cream outlets on a paring disc and a hermetic separator. It also shows an important difference between these two machines. In the paring-disc separator, the outer diameter of the paring-disc must penetrate into the rotating liquid column. The distance is determined by the fat content of the cream. The fat content is highest at the inner, free cream level in the separator. From there, the fat content is gradually reduced, as the diameter increases.

An increased fat content in the cream from the separator increases the distance from the inner, free-liquid level of the cream to the outer periphery of the paring disc by the cream level being forced inwards. The fat content at the inner, free-cream level must consequently be considerably higher if, for instance, 40% cream is to be discharged. The cream must be over-concentrated – to a higher fat content – compared with the cream leaving the separator. This could cause the destruction of the fat globules in the innermost zone facing the air column, as a result of increased friction. The outcome will be disruption of fat globules causing sticking problems and increased sensitivity to oxidation and hydrolysis.

Cream from the hermetic separator is removed from the centre, where the fat content is highest. Over-concentration is therefore not necessary.

When removing cream that has a high fat content, the difference in outlet performance is even more important. At 72%, the fat is concentrated to such an extent that the fat globules are actually touching each other. It would be impossible to obtain cream with a higher fat content from a paring-disc separator, as the cream would have to be considerably over-concentrated. The required pressure cannot be created in a paring-disc separator. High pressures can be created in the hermetic separator, which makes it possible to separate cream with a fat content exceeding 72% globular fat.

The discharge system

Production and CIP

During separation, the inner bottom of the bowl – the sliding bowl bottom – is pressed upwards against a seal ring in the bowl hood by the hydraulic pressure from the water beneath it. The position of the sliding bowl bottom is given by the difference in pressure on the top of it, from the product, and on the bottom of it, from the water.

Sediment from the product and the CIP solutions are collected in the sediment space at the periphery of the bowl until a discharge is triggered. To clean the larger surfaces in the bowl of bigger centrifuges efficiently, a larger volume of sediment and liquid is discharged during water rinsing in the cleaning cycle.

Discharge

A sediment discharge sequence may be triggered automatically by a pre-set timer, a sensor of some kind in the process, or manually by a push button.

The details in a sediment discharge sequence vary, depending on centrifuge type, but basically a fixed water volume is added to initiate drainage of the balance water. When the water is drained from the space below the sliding bowl bottom, it drops instantly and the sediment can escape at the periphery of the bowl. New balance water is automatically supplied from the service system (operating water module), to close the bowl. The water moves the sliding bowl bottom upwards, to tighten against the seal ring. A sediment discharge has taken place, in tenths of a second.

The centrifuge frame absorbs the energy of the sediment leaving the rotating bowl. The sediment is discharged from the frame by gravity to a vessel, pump or to sewage.

Drive units

In a dairy separator, the bowl is mounted on a vertical spindle, supported by a set of upper and lower bearings. In most centrifuges, the vertical shaft is connected to the motor axis by a worm gear on a horizontal axis, giving an appropriate speed, and a direct coupling. The speed is controlled by a VFD (Variable Frequency Drive).

Standardization of fat and protein

Principle calculation methods for blending of products

Standardization involves adjustment of the fat content of milk, or a milk product, by addition of cream or skim milk as appropriate to obtain a given fat content.

Various methods exist for calculating the quantities of products with different fat contents that must be blended to obtain a given final fat content. These cover mixtures of whole milk with skim milk, cream with whole milk, cream with skim milk and skim milk with anhydrous milk fat (AMF).

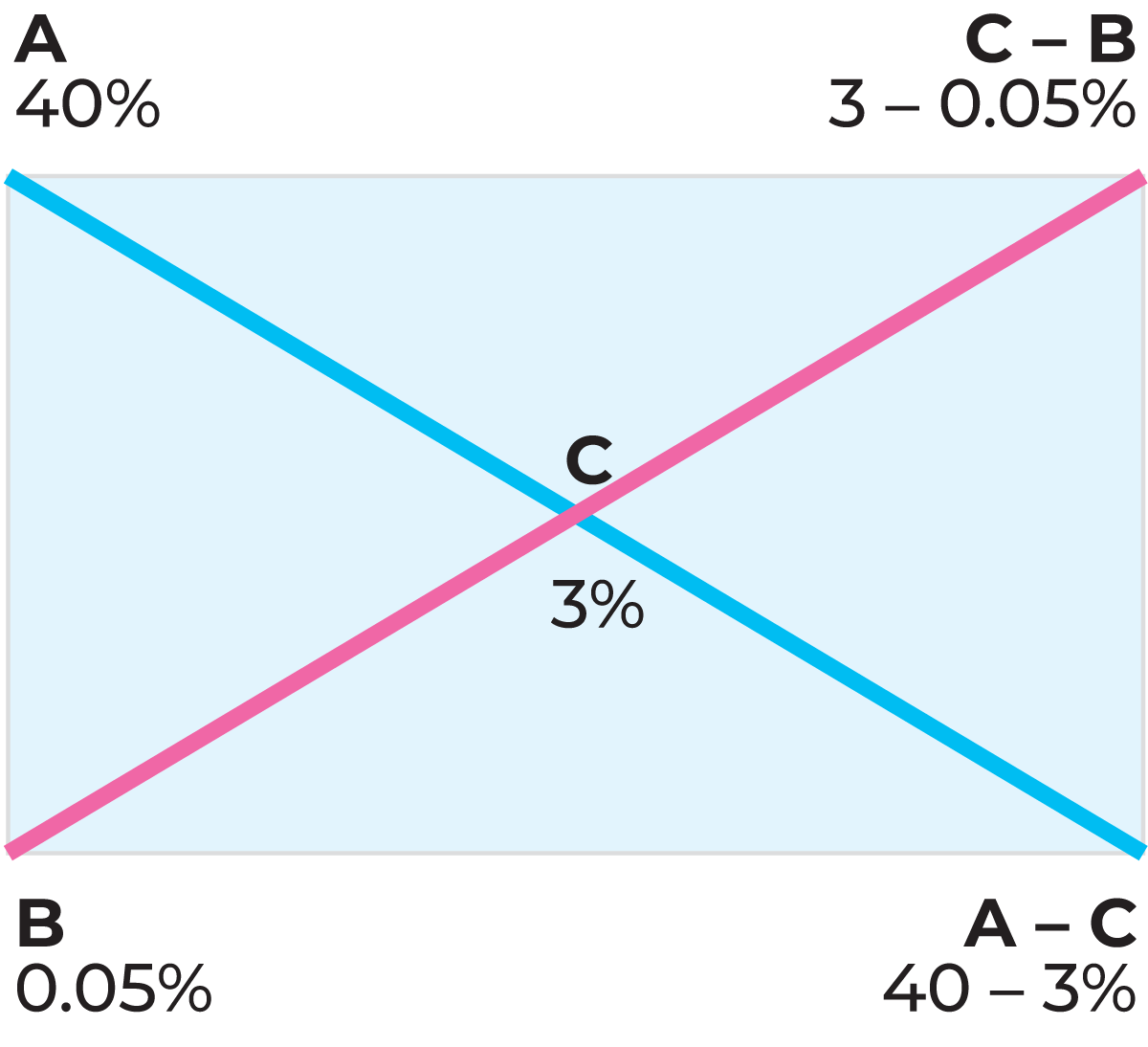

One of these methods, frequently used, is taken from the Dictionary of Dairying by J.G. Davis and is illustrated by the following example:

How many kilograms of cream of A% fat must be blended with skim milk of B% fat to make a mixture containing C% fat? The answer is obtained from a rectangle (Figure 7.2.31) where the given figures for fat contents are placed.

Subtract the fat content values on the diagonals to give C – B = 2.95 and A – C = 37.

The mixture is then 2.95 kg of 40% cream and 37 kg of 0.05% skim milk to obtain 39.95 kg of a standardized product containing 3% fat.

A Cream fat content, % 40

B Skim milk fat content, % 0.05

C Fat content of the end product, % 3

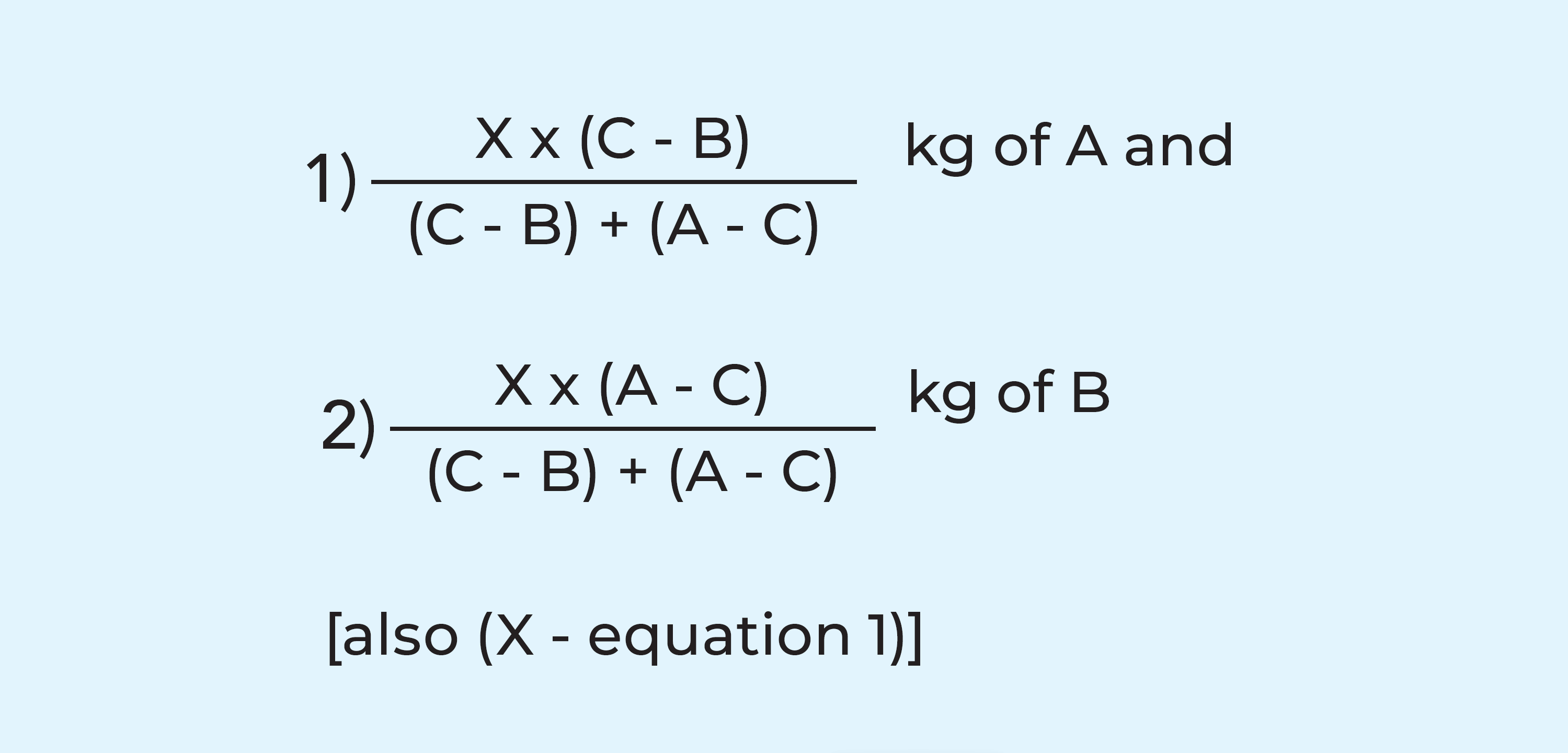

From the equations below, it is then possible to calculate the amounts of A and B needed to obtain the desired quantity (X) of C.

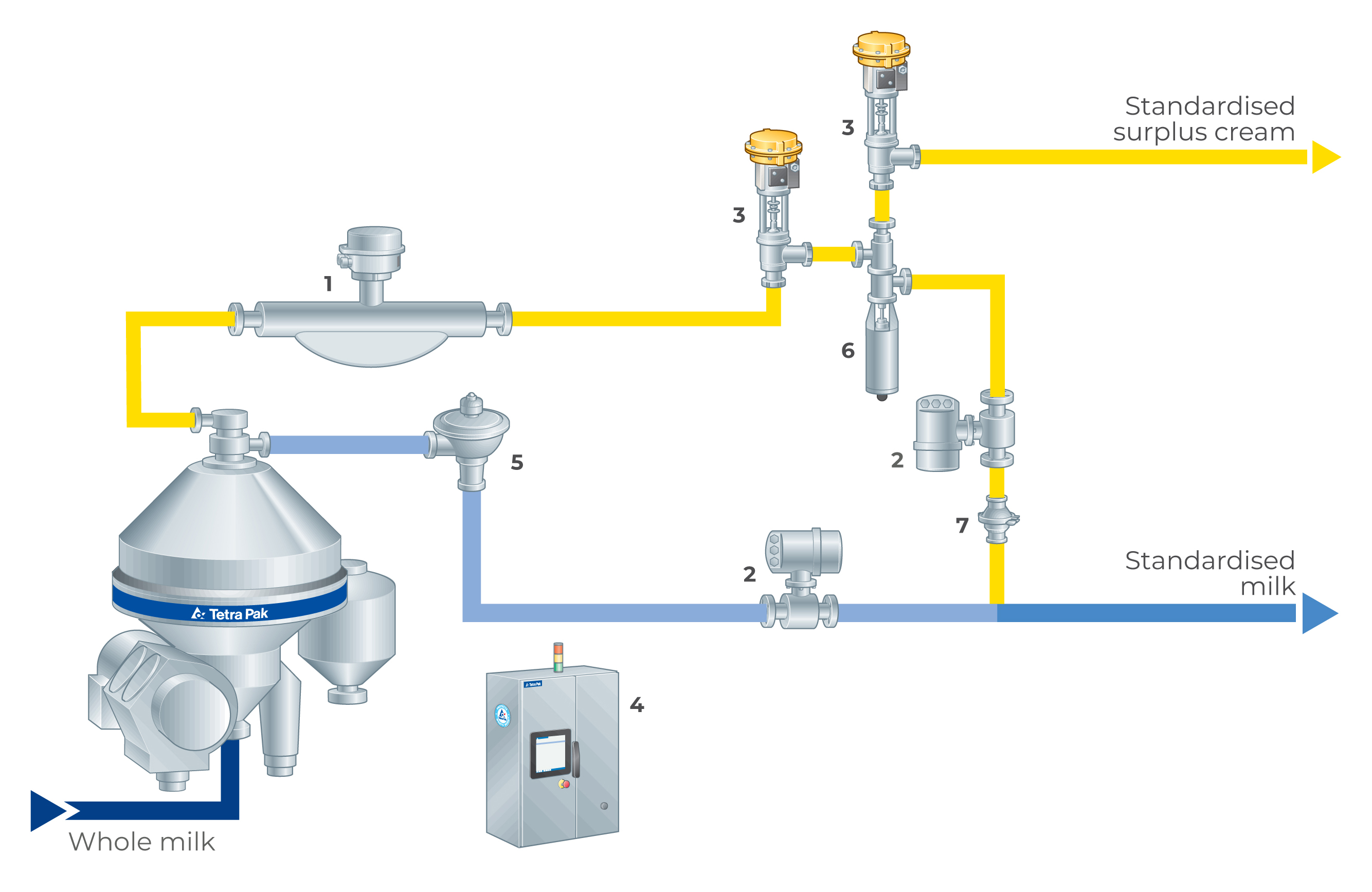

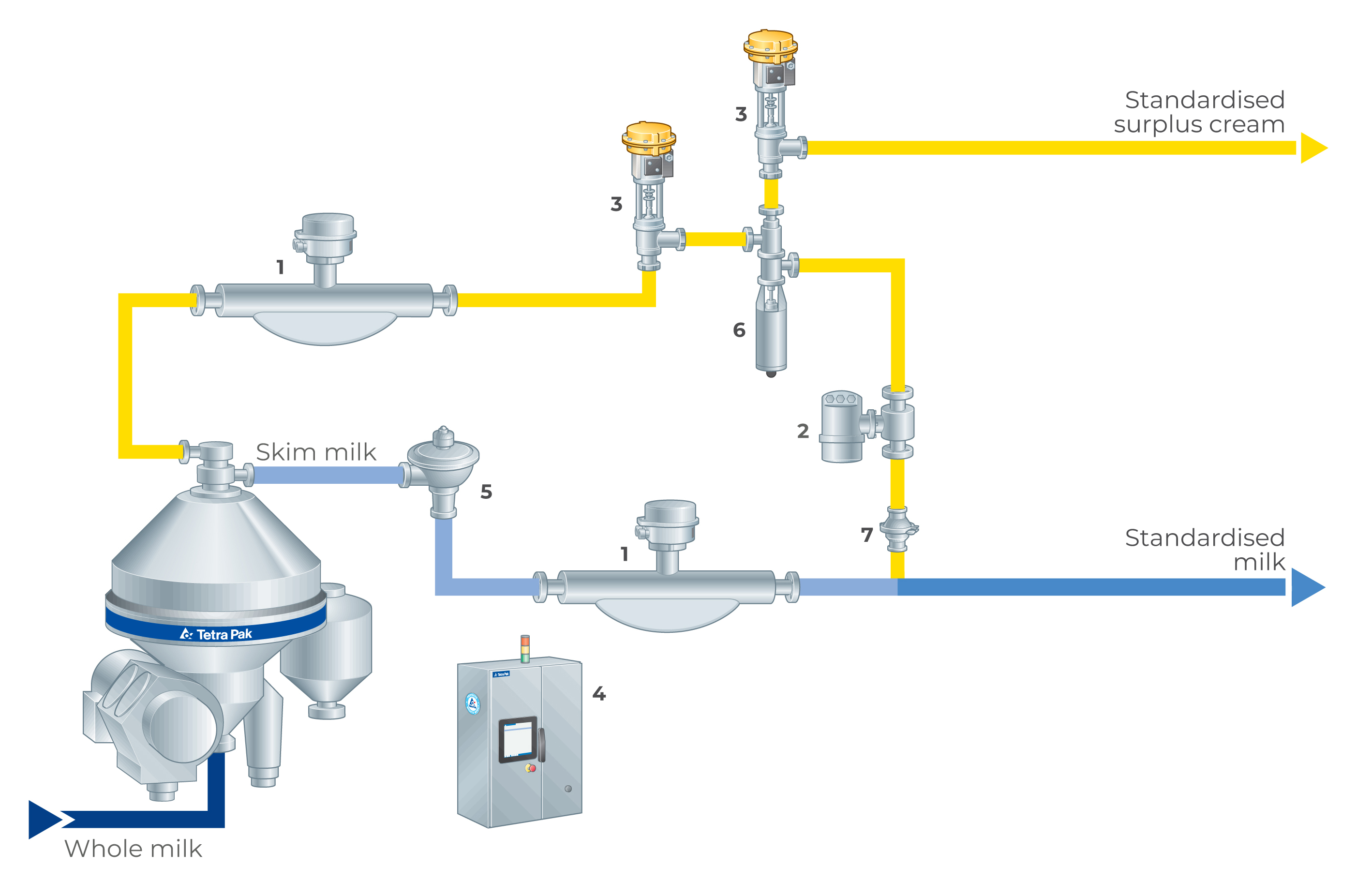

Principle of standardization

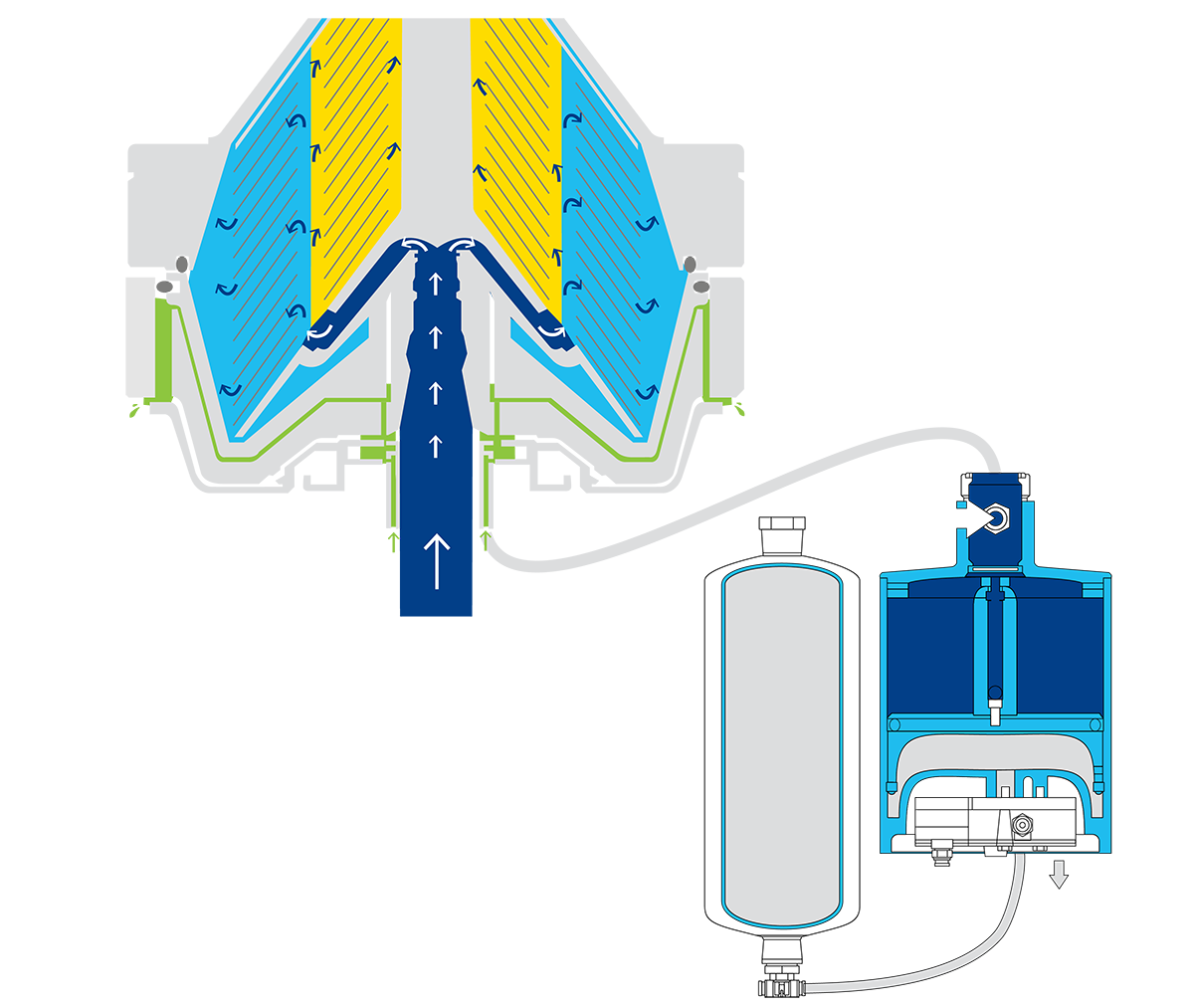

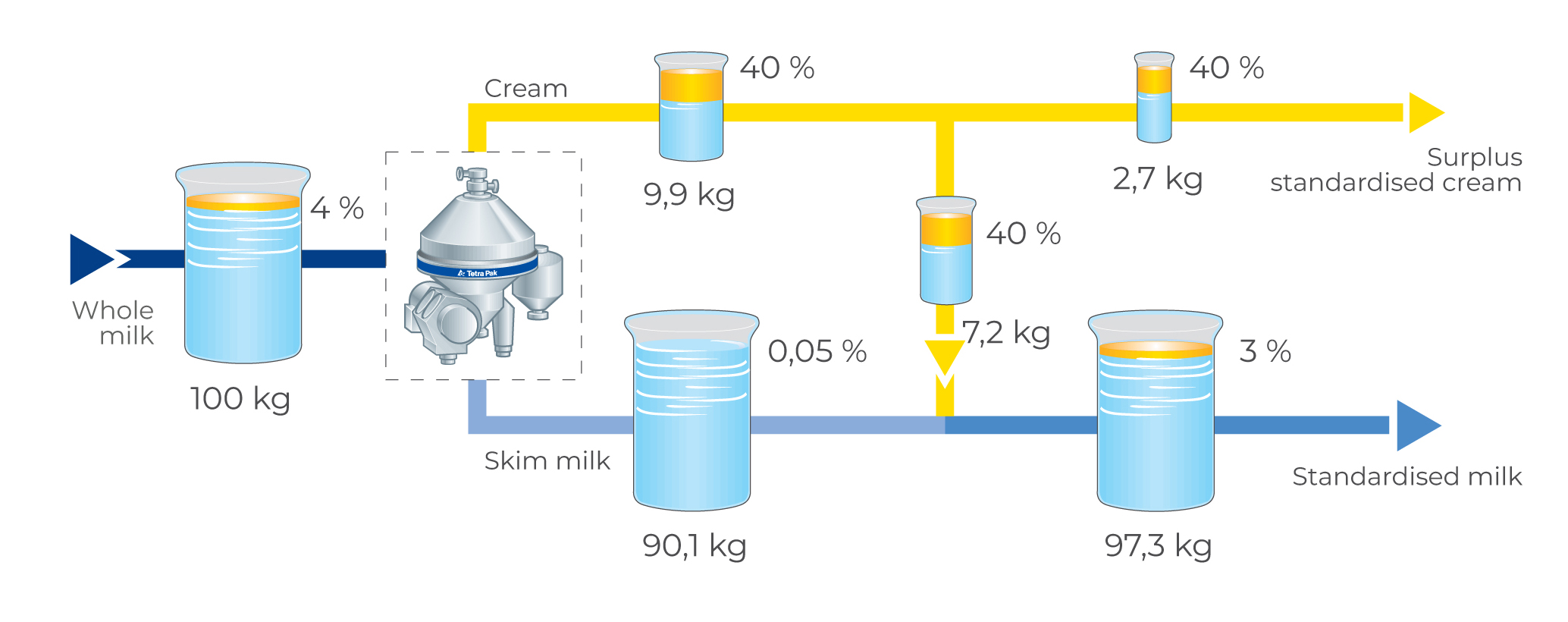

The cream and skim milk leaving a separator have constant fat contents if all other relevant parameters remain constant. The principle of standardization – regardless of whether the control is manual or automated – is illustrated in Figure 7.2.32.

The figures in the illustration are based on the treatment of 100 kg of whole milk with 4% fat. The requirement is to produce an optimal amount of 3% standardized milk and surplus cream containing 40% fat.

Separation of 100 kg of whole milk yields 90.35 kg of skim milk with 0.05% fat and 9.65 kg of cream with 40% fat.

The amount of 40% cream that must be added to the skim milk is 7.2 kg. This gives a total of 97.55 kg of 3% market milk, leaving 9.65 – 7.2 = 2.45 kg surplus 40% cream.

Direct in-line standardization

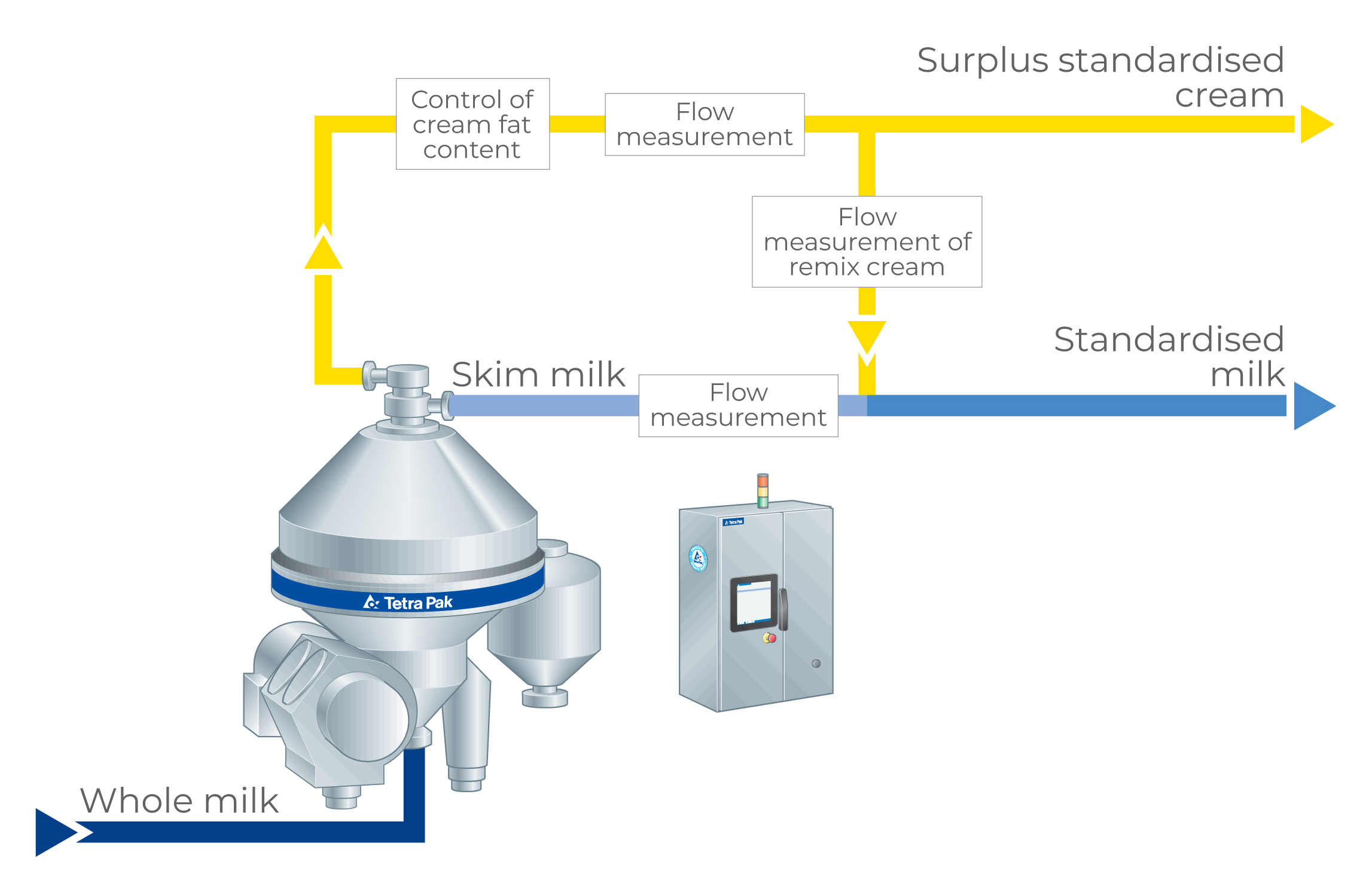

In modern milk processing plants with a diversified product range, direct in-line standardization is usually combined with separation. Previously, standardization was done manually, but, along with increased volumes to process, the need for fast, accurate standardization methods, independent of seasonal fluctuations of the raw milk fat content, has increased. Control valves, flow, mass flow and temperature transmitters, and a computerised control loop are used to adjust the fat content of milk and cream to desired values. This equipment is usually assembled in units (Figure 7.2.34).

The pressure in the skim milk outlet must be kept constant in order to enable accurate standardization. This pressure must be maintained, regardless of variations in flow or pressure drop caused by the equipment after separation, and this is done with a constant pressure valve located close to the skim milk outlet.

For precision in the process, it is necessary to measure variable parameters such as:

- Fluctuations in the fat content of the incoming milk

- Fluctuations in throughput

- Fluctuations in pre-heating temperature

Most of the variables are interdependent; any deviation in one stage of the process often results in deviations in all stages. The cream fat content can be regulated to any value within the performance range of the separator, with a standard deviation based on repeatability of 0.15% fat. For standardized milk, the standard deviation based on repeatability should be less than 0.015%.

Usually, whole milk is heated to 55 – 65 °C in the pasteurizer before being separated. Following separation, the cream is standardized to a pre-set fat content. To achieve this, the calculated amount of cream intended for standardization is routed and remixed with an adequate amount of skim milk. The surplus cream is directed to the cream pasteurizer. The course of events is illustrated in Figure 7.2.33.

Under certain circumstances, it is also possible to apply an in-line standardization system to a cold milk centrifugal separator. However, it is then very important that all fat fractions of the milk fat are given enough time at the low temperature (10 – 12 hours) for complete crystallisation. The reason is that the density will vary with the degree of crystallisation and will thus affect the measuring accuracy of the mass flow transmitter, which is always calibrated after installation.

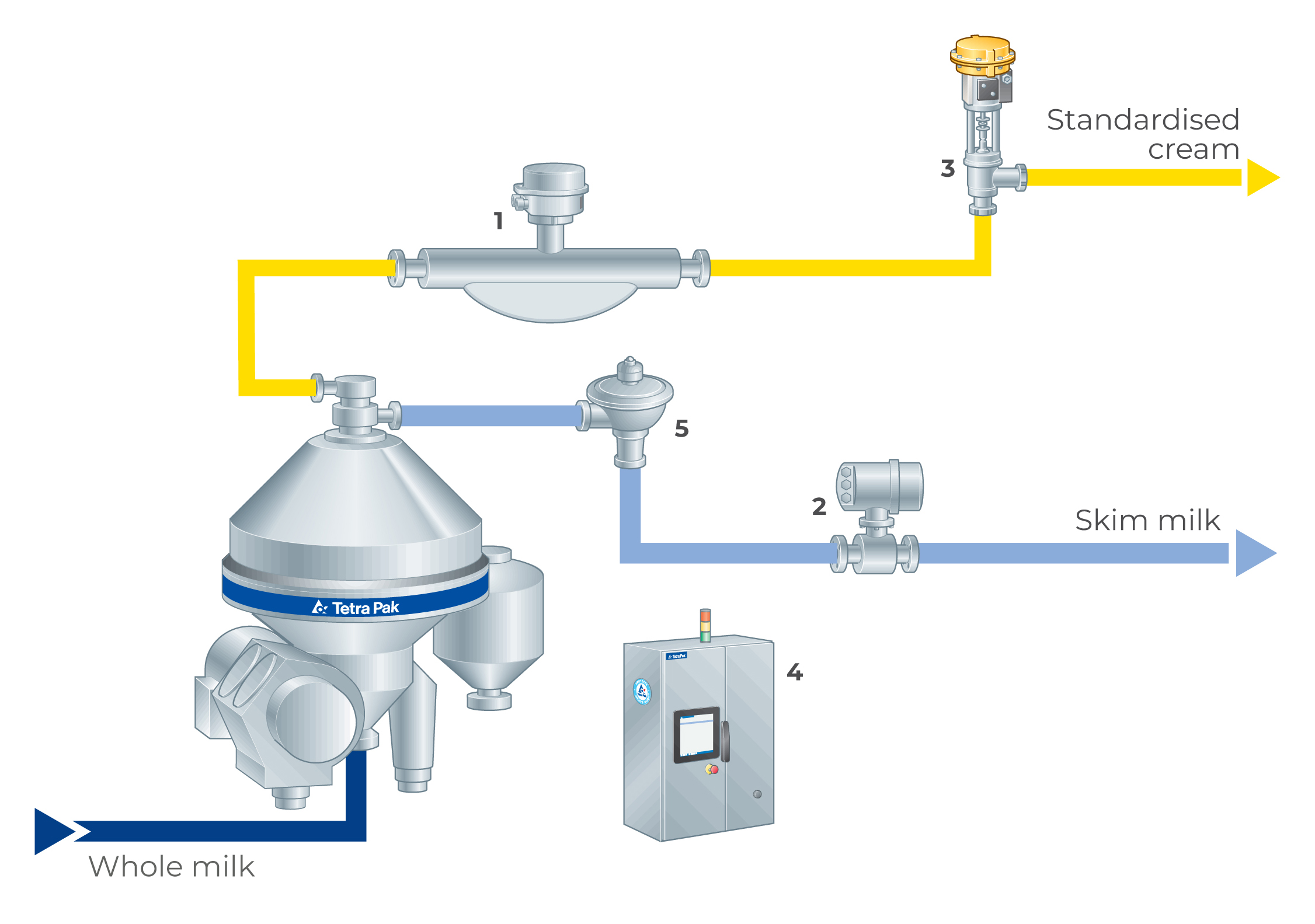

Cream fat control system

The fat content of the cream in the outlet from the separator is determined by the cream flow rate. The cream fat content is inversely proportional to the flow rate. Some standardization systems therefore use flow meters to control the fat content. This is the quickest method and – as long as the temperature and fat content in the whole milk are constant before separation – also an accurate method. The fat content will be wrong if these parameters change.

Various types of instruments can be used for continuous measurement of the fat content in cream. The signal from the instrument adjusts the cream flow so that the correct fat content is obtained. This method is accurate and sensitive to variations in the temperature and fat content of the milk. However, the control is slow, and it takes a long time for the system to return to the correct fat content when a disturbance has occurred.

There are two transmitters in Figure 7.2.35 measuring the flow of standardized cream and skim milk respectively. With the data from these two flows, the control system (4) calculates the flow of whole milk to the separator. A mass flow transmitter (1) measures the cream density and converts this value into fat content. Combining fat content and flow rate data, the control system activates the modulating valve (3) to obtain the required cream fat content.

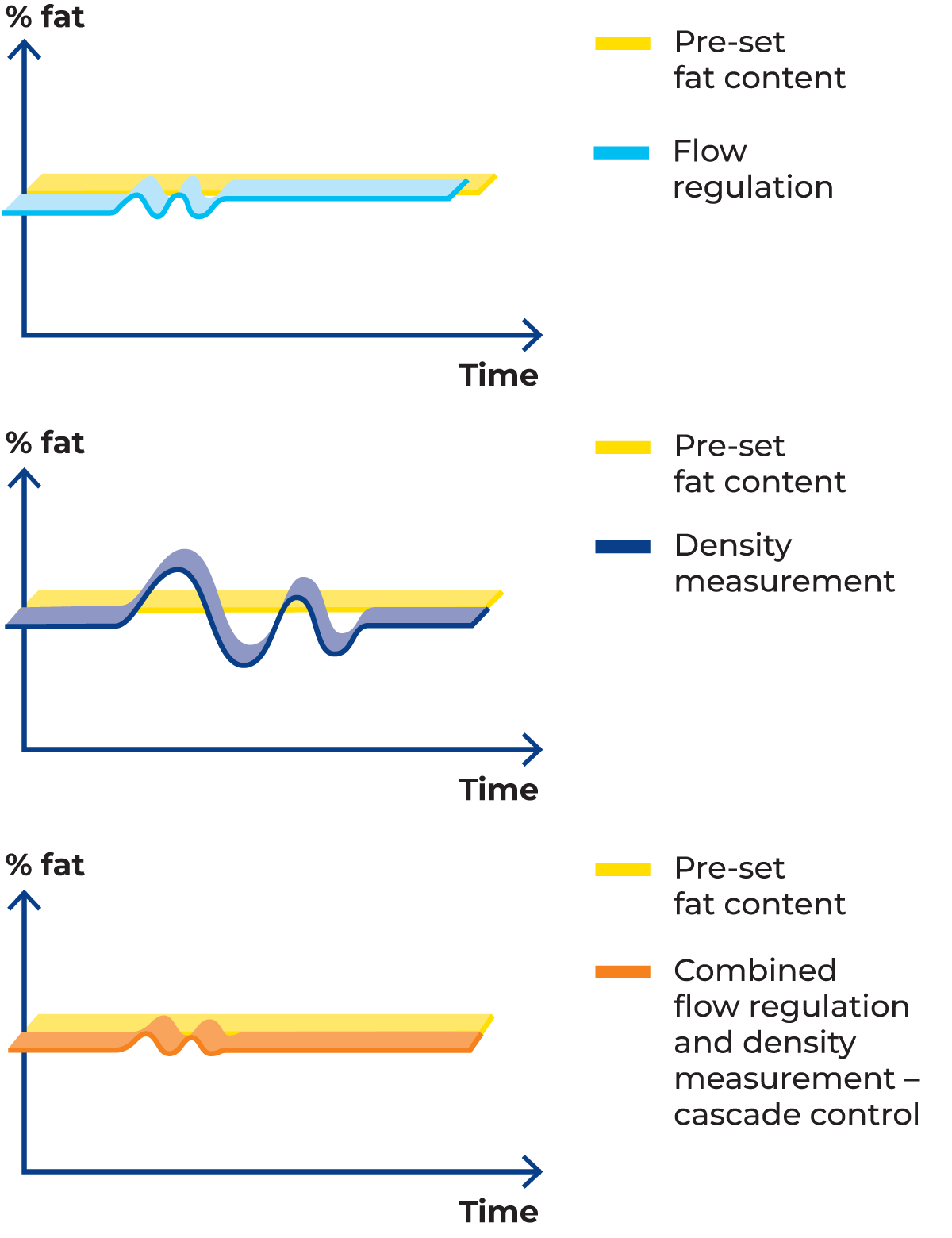

Cascade control

A combination of accurate measurement of the fat content and rapid flow metering, known as cascade control, offers great advantages, as illustrated in Figure 7.2.36. When disturbances occur, caused for example by the recurrent partial discharges of the self-cleaning centrifuges or changes in the temperature of the cream or the fat content of the incoming milk, the diagram shows that:

- The flow control system alone reacts fairly quickly, but the fat content of the cream deviates from the pre-set value after stability is restored.

- The density measurement system alone reacts slowly, but the fat content of the cream returns to the pre-set value.

- When the two systems are combined in cascade control, a rapid return to the pre-set value is achieved.

The cascade control system thus results in fewer product losses and a more accurate result. The computer monitors the fat content of the cream, the flow rate of the cream and the setting of the cream regulating valve.

The mass flow transmitter (See 1 in Figure 7.2.35) in the circuit measures the density of the cream continuously (mass per unit of volume, e.g. kg/m3), which is inversely proportional to the fat content as the fat in cream has a lower density than the milk serum.

The mass flow transmitter transmits continuous density readings to the computer in the form of an electric signal. The strength of the signal is proportional to the density of the cream. Increasing density means that there is less fat in the cream and the signal will increase.

Any change in density modifies the signal from the mass flow transmitter to the computer; the measured value will then deviate from the setpoint value, which is programmed into the computer. The computer responds by changing the output signal to the regulating valve by an amount corresponding to the deviation between measured and set-point values. The position of the regulating valve changes and restores the density (fat content) to the correct value.

In Figure 7.2.35 the mass flow transmitter (1) in the control circuit continuously measures the flow and density in the cream line and transmits a signal to the computer.

Cascade control is used to make necessary corrections due to variations in the fat content in the incoming whole milk. Cascade control works by comparing:

- The flow through the mass flow transmitter, which is proportional to the cream fat content.

- The density measured by the mass flow transmitter, which is revised according to the cream fat content.

The computer in the control panel (4) then calculates the actual whole milk fat content and alters the control valves to make the necessary adjustments. The standardized milk fat content is recorded continuously.

Fat control by density measurement

Measurement of the cream fat content is based on the fixed relationship, which exists between fat content and density. The fat content varies inversely with density because the fat in cream is lighter than the milk serum.

In this context, it is important to remember that the density of cream is also affected by temperature and gas content. Much of the gas, which is the lightest phase in the milk, will follow the cream phase, reducing the density of the cream. It is therefore important that the amount of gas in the milk is kept at a constant level. Milk can contain varying levels of air and gases, but 6% can be taken as an average figure. More air than that can cause problems such as inaccuracy in the volumetric measurement of milk, increased fouling of equipment during heating, etc. More about air in milk is mentioned in Chapter 7.7, Deaerators.

The simplest and most common way of doing this is to let the raw milk stand for at least one hour in a tank (silo) before it is processed. Otherwise, a deaerator should be integrated into the plant, ahead of the separator.

The density of the cream is reduced if the separation temperature is increased, and vice versa. To achieve variation in the separation temperature, a temperature transmitter is installed in the cream pipe. The temperature transmitter continuously measures the temperature of the liquid, and the temperature values are transmitted to a control module.

The mass flow transmitter continuously measures the density of the liquid and the density values are transmitted to a control module.

Flow transmitter

The flow transmitter continuously measures the flow of the liquid, and the flow values are transmitted to a control module.

Flow control valves for cream and skim milk

The computer compares the measured value signal from the mass flow transmitter with a pre-set reference signal. As shown in Figure 7.2.35, if the measured value deviates from the pre-set value, the computer modifies the output signal to the control valve in the line after the mass flow transmitter. This resets the valve to a position which alters the cream flow from the separator to correct the fat content.

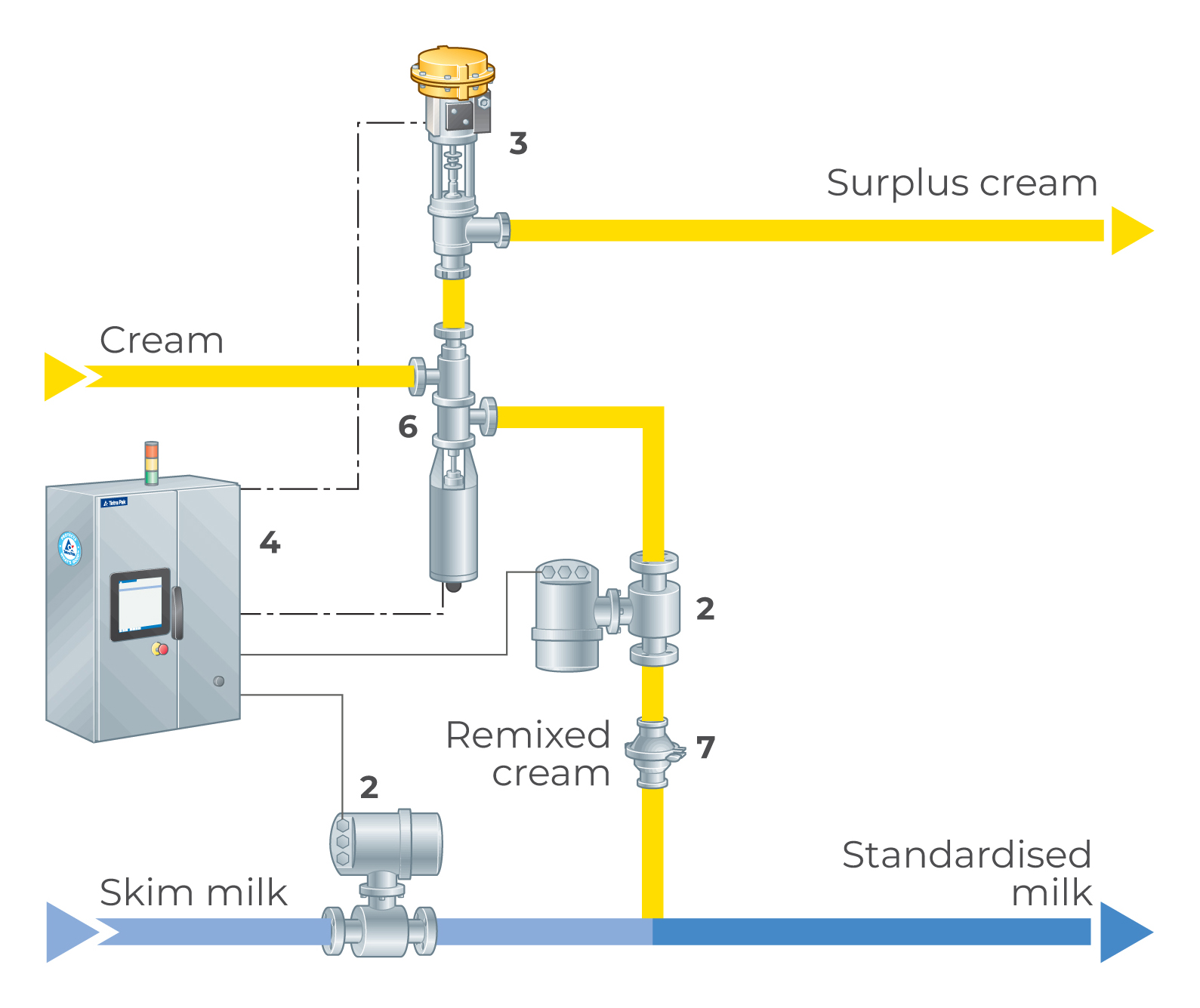

Control circuit for remixing of cream

The control circuit in Figure 7.2.37 controls the amount of cream to be continuously remixed into the skim milk to obtain the required fat content in the standardized milk. It contains two flow transmitters (2). One is located in the line for the cream to be remixed, and the other is in the skim milk line.

The signals from the flow transmitters are conveyed to the computer, which generates a ratio between the two signals. The computer compares the measured value of the ratio with a pre-set reference value and transmits a signal to a regulating valve in the cream line.

An insufficient fat content in the standardized milk means that not enough cream is being remixed. The ratio between the signals from the flow transmitters will therefore be lower than the reference ratio, and the output signal from the computer to the control valve changes. The valve closes, creating a higher pressure drop and a higher pressure which forces more cream through the remixing line. This affects the signal to the computer; the adjustment proceeds continuously and ensures that the correct quantity of cream is remixed.

Remixing is based on known constant values of the fat content in the cream and skim milk. The fat content is normally regulated to a constant value between 35 and 40% and the fat content of the skim milk is determined by the skimming efficiency of the separator.

Accurate density control, combined with constant pressure control at the skim milk outlet, ensures that the necessary conditions for remixing control are satisfied. Cream and skim milk will be mixed in the exact proportions to give the pre-set fat content in the standardized milk even if the flow rate through the separator changes, or if the fat content of the incoming whole milk varies.

The flow transmitter and the regulating valve in the cream remixing circuit are of the same type as those in the circuit for control of the fat content.

The complete direct standardization line

The complete direct standardization line is illustrated in Figure 7.2.38. The pressure control system at the skim milk outlet (5) maintains a constant pressure, regardless of fluctuations in the pressure drop over downstream equipment. The cream-regulating system maintains a constant fat content in the cream discharged from the separator by adjusting the flow of cream discharged. This adjustment is independent of variations in the throughput or in the fat content of the incoming whole milk. Finally, the ratio controller mixes cream of consistent fat content with skim milk in the necessary proportions to give standardized milk of a specified fat content. The standard deviation, based on repeatability, should be less than 0.015% for milk and 0.15% for cream.

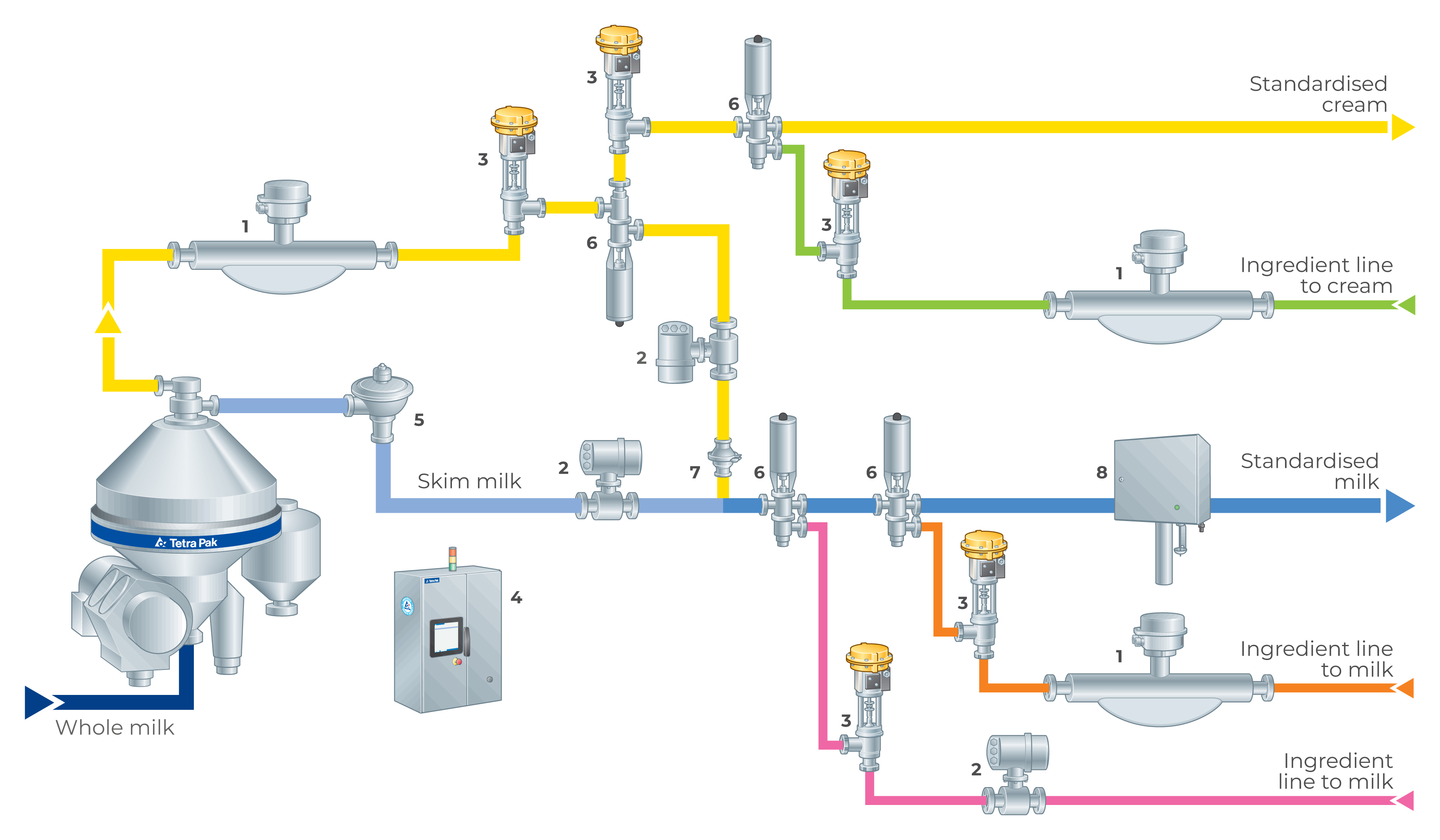

Some options for fat standardization

In cheese production, for example, there is sometimes a requirement to standardize fat to SNF. Introducing a second mass flow transmitter, located in the skim milk pipe connected with the separator, satisfies this requirement. This arrangement is illustrated in Figure 7.2.39, where the mass flow transmitters serve two functions:

1. To increase the accuracy of fat standardization

2. The density value is the base for the calculation of the SNF content

The control system converts the density of the skim milk into SNF content, a value which is then used to control the ratio of fat to SNF.

If, on the other hand, the fat content of the incoming milk is lower than the content specified for the standardized milk, a calculated volume of skim milk is leaked from the stream leaving the separator, and the remaining volume is mixed with the cream.

Protein standardization

It is also possible to connect a product-analysis instrument to analyse the actual protein content in the standardized milk. With this option, it is possible to standardize with a fat-to-protein ratio. By combining the product-analysis instrument with an extra ingredient line with a protein ingredient, it is possible to standardize both the fat and the protein content at the same time.

For the production of cheese milk, this installation is a fully automatic process to achieve the correct fat-to-protein ratio. To have the flexibility to produce high- and low-fat cheeses with different protein content, it is possible to connect three independent ingredient lines to the standardized milk line. This arrangement is illustrated in Figure 7.2.40.

Ingredients

Other options are also possible, such as the addition of cream and whey cream, which is sometimes needed in the standardisation of milk intended for cheese making. The fat content of the cream ingredient can be measured automatically with a mass flow meter. In order to utilise the cream obtained from the separation of whey, a corresponding volume of ordinary cream is “bled” off. This arrangement allows the cream of better quality to be utilised for the production of quality butter and various types of cream, such as whipping cream. This arrangement is illustrated in Figure 7.2.40.

Spore and bacteria removing separators

A specially designed centrifugal separator is used for the process of removing spores and bacteria from milk.

Originally, this type of separator was developed to improve the shelf life of market milk. However, nowadays it is often used as a complement to pasteurization or thermisation on cheese milk as well as to improve milk and whey powder quality.

Bacteria, especially heat-resistant spores, have a significantly higher density than milk. This type of separator is therefore a particularly efficient means of ridding milk of bacteria spores. Since these spores are also resistant to heat treatment, it makes a useful complement to thermisation, pasteurization and sterilisation.

The original spore removing separator was a solid bowl centrifuge, with nozzles in the periphery of the bowl. It was long considered necessary to have a continuous flow of the heavy phase, either through a peripheral nozzle or over the heavy phase outlet, to achieve efficient separation. This was possibly true of the old solid-bowl centrifuges with vertical cylindrical walls, but in self-cleaning separators with a sludge space outside the disc stack, bacteria and spores can be collected over a period of time and intermittently discharged at pre-set intervals.

There are two types of spore removing separators:

- The two-phase type has two outlets at the top: one for continuous discharge of spore and bacteria concentrate via a special top disc and one for the bacteria-reduced phase. Figure 7.2.41.

- The one-phase type has only one outlet at the top of the bowl for cleaned milk. The spore and bacteria concentrate is collected in the sludge space of the bowl and discharged at pre-set intervals. Figure 7.2.42.

The amount of spore and bacteria concentrate flow from a two-phase separator can be 3 – 10% of the feed depending on the process solution, while the corresponding amount from the one-phase depends on the machine size and discharge interval.

The spore-and-bacteria concentrate always has a higher dry matter content than the milk from which it originates. This is because some of the larger casein micelles are separated out together with the bacteria and spores. Higher temperature increases the amount of protein in the spore and bacteria concentrate. The optimal temperature range is 50 to 55 °C.

The reduction effect on spores and bacteria is expressed as a percentage.

Spore removing separators are being used, for example, by cheese producers, consumption-milk producers and powder producers. Bacteria belonging to the genus Clostridium – anaerobic spore-forming bacteria – are among the most feared by cheesemakers, as they can cause late blowing of cheese, even if present in small numbers. This is why the spore removing separator is used for cheese milk. Consumption-milk producers use the same type of separator to reduce amounts of aerobic spore-forming bacteria, like Bacillus cereus, to prolong the shelf life of milk. Whey and milk-powder producers use bacteria-and-spore removing separators to reduce both aerobic and anaerobic spore-forming bacteria in their high-quality powders.

The arrangements for the integration of the spore removing separator into a cheese milk pasteurization plant are discussed in Chapter 14, Cheese.

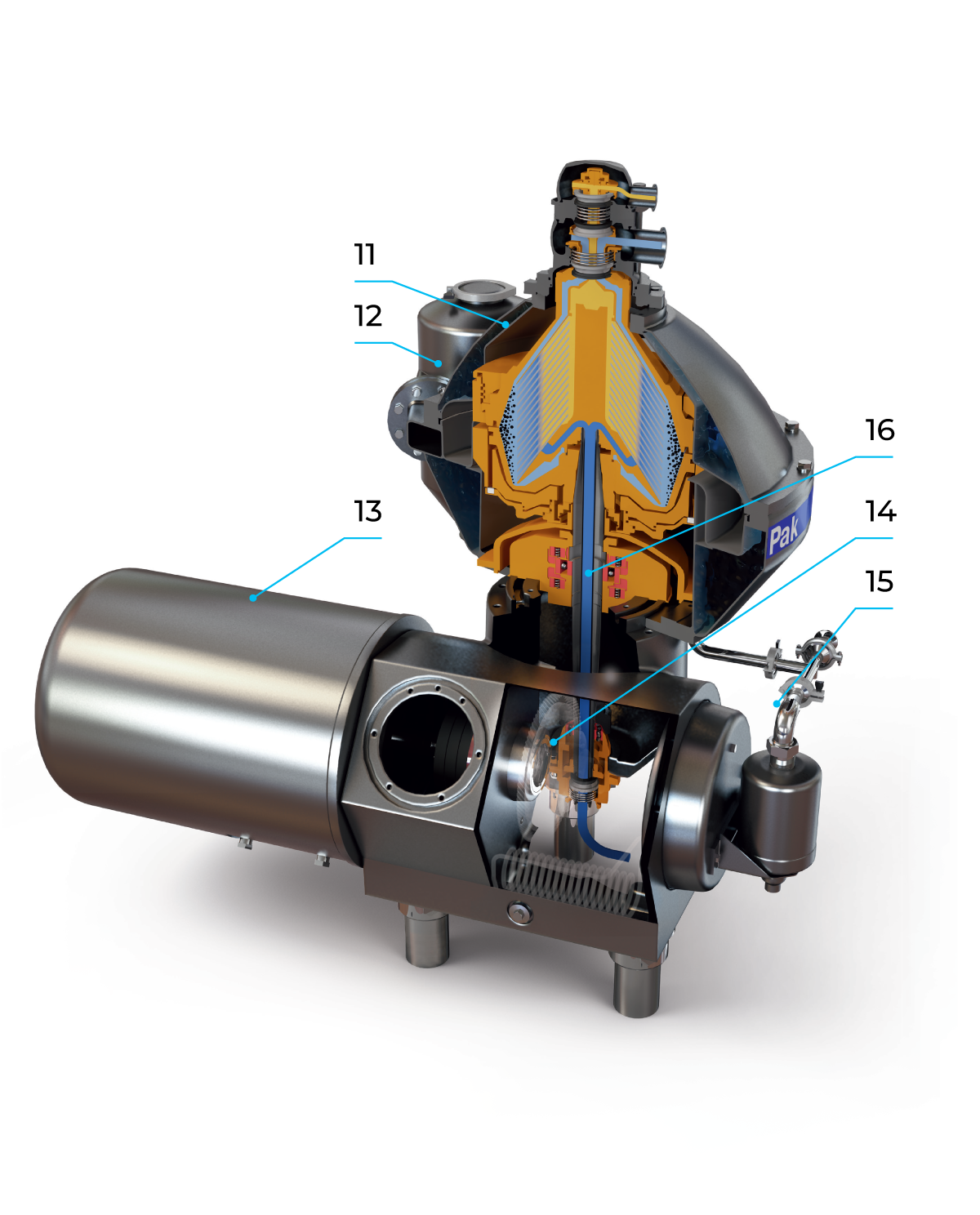

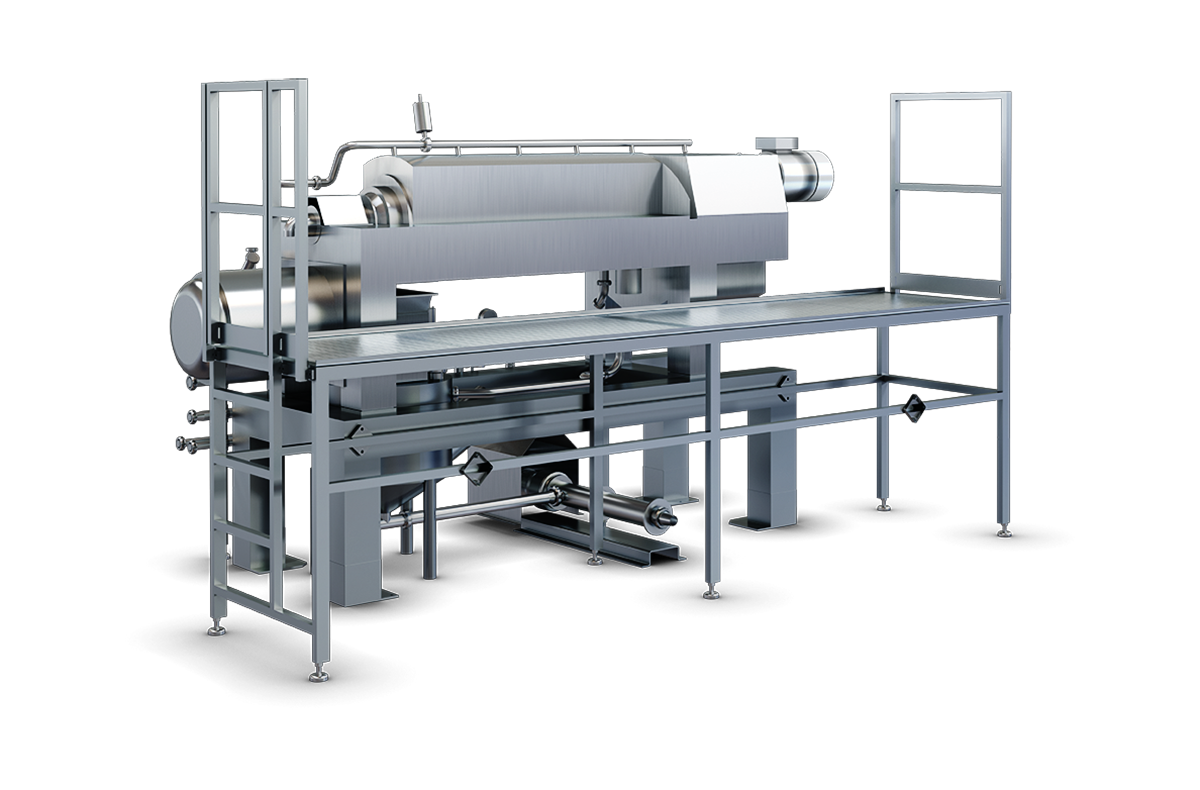

Decanter centrifuges

Centrifuges are used in the dairy industry to harvest special products like precipitated casein and crystallised lactose. The previously described disc-bowl centrifugal clarifiers, however, are not suitable for these duties due to the high solids content of the feed.

The types most often used are sanitary basket centrifuges and decanter centrifuges (Figure 7.2.43). Decanters, which operate continuously, have many applications. They are also used, for example, in plants producing soya milk from soybeans, and specially adapted models are widely used to de-water sludge in wastewater treatment plants.

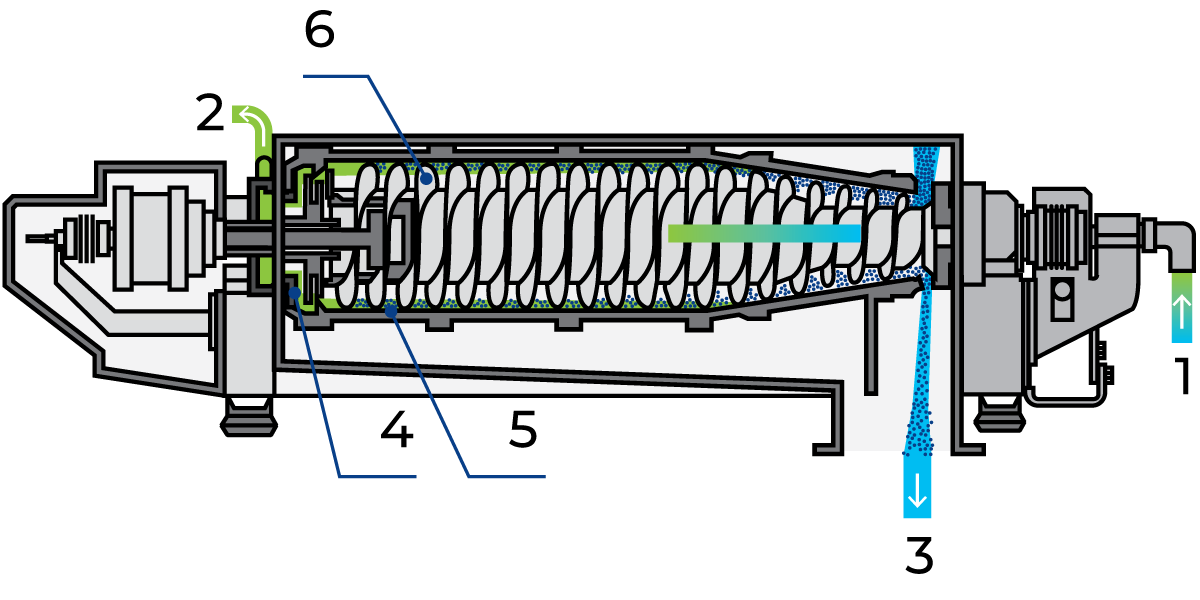

A decanter centrifuge is a machine for continuous sedimentation of suspended solids from a liquid by the action of centrifugal force in an elongated rotating bowl. The characteristic which distinguishes the decanter from other types of centrifuges is that it is equipped with an axial screw conveyor for continuous unloading of separated solids from the rotor. The conveyor rotates in the same direction as the bowl, but at a slightly different speed to give a “scrolling” effect. Other characteristic features of the decanter include:

- A slender cono-cylindrical bowl rotating about a horizontal axis.

- Countercurrent flow with solids discharge from the narrow end and dischagre of liquid phase from the wide end.

The function of the decanter centrifuge

The feed suspension is introduced through an inlet tube to the feed zone of the conveyor, where it is accelerated and directed into the interior of the spinning rotor (Figure 7.2.44).

The solids, which must have a higher specific gravity than the liquid, settle out at the inner wall of the bowl almost instantaneously, due to the intense centrifugal acceleration – normally in the range of 2,000 – 4,000 g – leaving a clear inner ring of liquid.

Solids discharge

The compact solids phase is transported axially towards the narrow end of the rotor by means of the screw conveyor, which is geared to turn at a slightly different speed than the bowl. On the way to the discharge ports, the solids are lifted out of the liquid pool by the flights of the screw conveyor up along the dry beach. On the beach, more liquid drains off and flows back into the pool. The dry solids are then finally discharged from the bowl through the discharge ports into the collecting chamber of the vessel that surrounds the rotor. From there, they are removed by gravity from the machine through an outlet funnel.

Liquid discharge (open)

The liquid phase, forming a hollow cylinder due to the centrifugal force, flows in a helical channel between the flights of the conveyor towards the large end of the rotor. There the liquid overflows radially-adjustable weirs into the centre chamber of the collecting vessel and is discharged by gravity.

Liquid discharge (pressurised)

Some decanter centrifuges are equipped for pressurised discharge of the liquid phase by a paring disc (4) in Figure 7.2.44. The liquid overflowing the weirs enters a paring chamber where it once more forms a hollow rotating cylinder. The channels in the stationary paring disc are immersed in the rotating liquid, which causes a pressure differential. The liquid travels down the channels, converting the energy of rotation into a pressure head, sufficient to pump the liquid out of the machine and to succeeding processing steps.

Continuous process

In a decanter centrifuge, the three stages of the process – inflow, sedimentation into concentric layers and separate removal of the liquid and solid phases – proceed in a fully continuous flow.

Principal components

The principal components of a decanter centrifuge are the bowl, conveyor and gearbox (together comprising the rotor) and the frame, with hood, collecting vessels, drive motor and belt transmission.

The bowl

The bowl normally consists of a conical section and one or more cylindrical sections flanged together. The cylindrical part provides the liquid pool and the conical part the dry beach.

The shell sections are usually ribbed or grooved on the inside to prevent the solids from sideslipping as the conveyor rotates.

The conical section terminates in a cylindrical stub with one or two rows of solid discharge ports depending on the machine type. These ports are, in most cases, lined with replaceable bushings of stellite or ceramic material to prevent abrasion. The wide end is closed by an end-piece with four or more liquid-overflow openings determining the radial level of liquid in the rotor. The liquid level can easily be varied by adjustment of the weir rings. In cases when the clarified liquid phase discharge is by means of a paring disc (4), the adjustable weirs lead into the paring chamber. The rotor is driven by an electric motor via V-belts and pulleys.

The conveyor

The conveyor is suspended in the bowl on bearings and rotates slowly or fast relative to the bowl, pushing the sediment towards the sludge ports at the narrow end. The configuration of the conveyor screw flights varies according to application: the pitch (spacing between flights) may be coarse or fine, and the flights may be perpendicular to the axis of rotation or perpendicular to the conical part of the bowl mantle. Most models are equipped with single-flight conveyors, but some have double flights.

The gearbox

The function of the gearbox is to generate the scrolling effect, i.e. the difference in speed between bowl and conveyor. It is fitted to the hollow shaft of the bowl and drives the conveyor through a coaxial spline shaft.

An extension of the sunwheel shaft, i.e. the central shaft of the gearbox, projects from the end opposite the bowl. This shaft can be driven by an auxiliary motor, enabling the conveyor speed to be varied, relative to the speed of the bowl.

The gearbox may be of planetary or cyclo type; the former produces a negative scrolling speed (the conveyor rotates slower than the bowl), while the latter, equipped with an eccentric shaft, gives a positive scrolling speed.

Frame and vessel

There are various designs of frame and vessel, but in principle, the frame is a rigid mild steel structure carrying the rotor parts and resting on vibration insulators. The vessel is a welded stainless steel structure with a hinged hood which encloses the bowl. It is divided into compartments for collection and discharge of the separated liquid and solid phases.

Liquid may be discharged by gravity or under pressure by a paring disc (4) in Figure 7.2.43. Solids are discharged by gravity, assisted by a vibrator, if necessary, into a collecting vessel or onto a conveyor belt for onward transport.