CONDENSED MILK

The method of preserving milk by sterilising evaporated milk in sealed containers was developed at the beginning of the 1880s. Earlier, in about 1850, the method of preserving evaporated milk by the addition of sugar had been perfected by an American inventor. The manufacture of condensed milk, using these two methods, has since then been developed into a large-scale industry. Production methods have evolved to include the use of continuous heating systems, followed by aseptic packaging technology.

A distinction is made between two different types; unsweetened and sweetened condensed milk. Both products can be made from fresh milk or recombined milk (milk powder, fat and water).

Unsweetened condensed milk (also called double concentrated milk, evaporated milk or recombined concentrated milk when recombined) is a sterilised product, light in colour and with the appearance of cream. The product has a large market, for example in tropical countries, at sea and for the armed forces. It is also used where fresh milk is not available as a fresh milk substitute and consumed as it is or after the addition of water. In many countries where normal milk is available, it is used as a coffee whitener.

The condensed milk is made from fresh milk or recombined with skim milk powder, buttermilk powder, fat (AMF or vegetable fat) and water (see also Chapter 20, Recombined milk products). When using vegetable fat, the product is called “filled”. The increased dry matter is reached through either evaporation, RO concentration of fresh milk or by recombination from milk powder.

Outline of condensed milk

The evaporated product, unsweetened condensed milk, was traditionally packed in cans, which were then sterilised in autoclaves or horizontal sterilisers. At present, many of these products are continuously heat treated with UHT systems and filled aseptically.

Sweetened condensed milk is basically concentrated milk, to which sugar has been added. The product is yellowish in colour and highly viscous. The high sugar concentration in sweetened condensed milk increases the osmotic pressure to such a level that most of the microorganisms are inhibited or destroyed. This product is not heat treated after packaging as its high sugar content preserves it for a long shelf life. The sugar concentration in the water phase must not be less than 62.5% or more than 64.5%. At the latter level, the sugar solution reaches its saturation point, and some sugar may then crystallise, causing sandiness or forming a sediment.

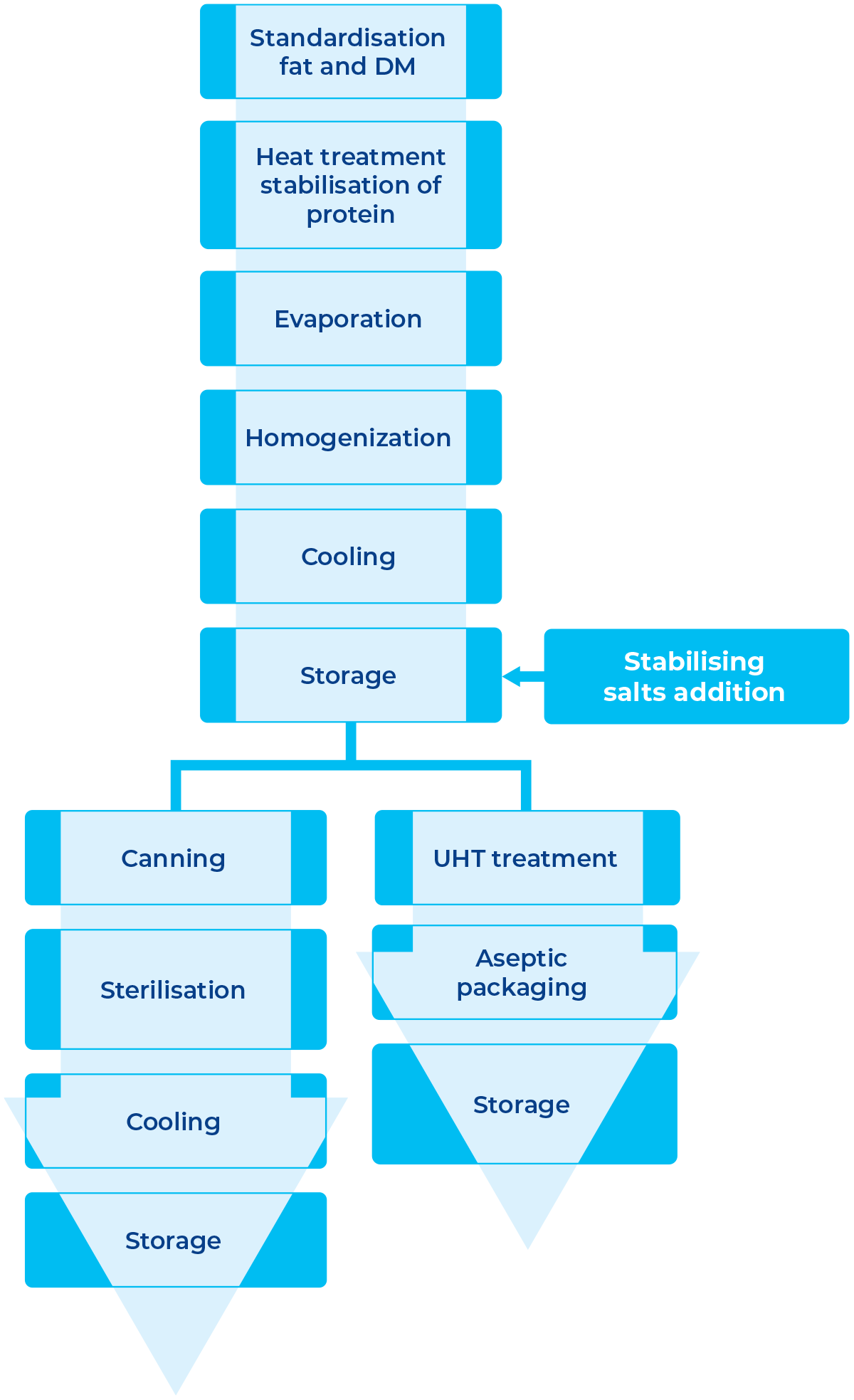

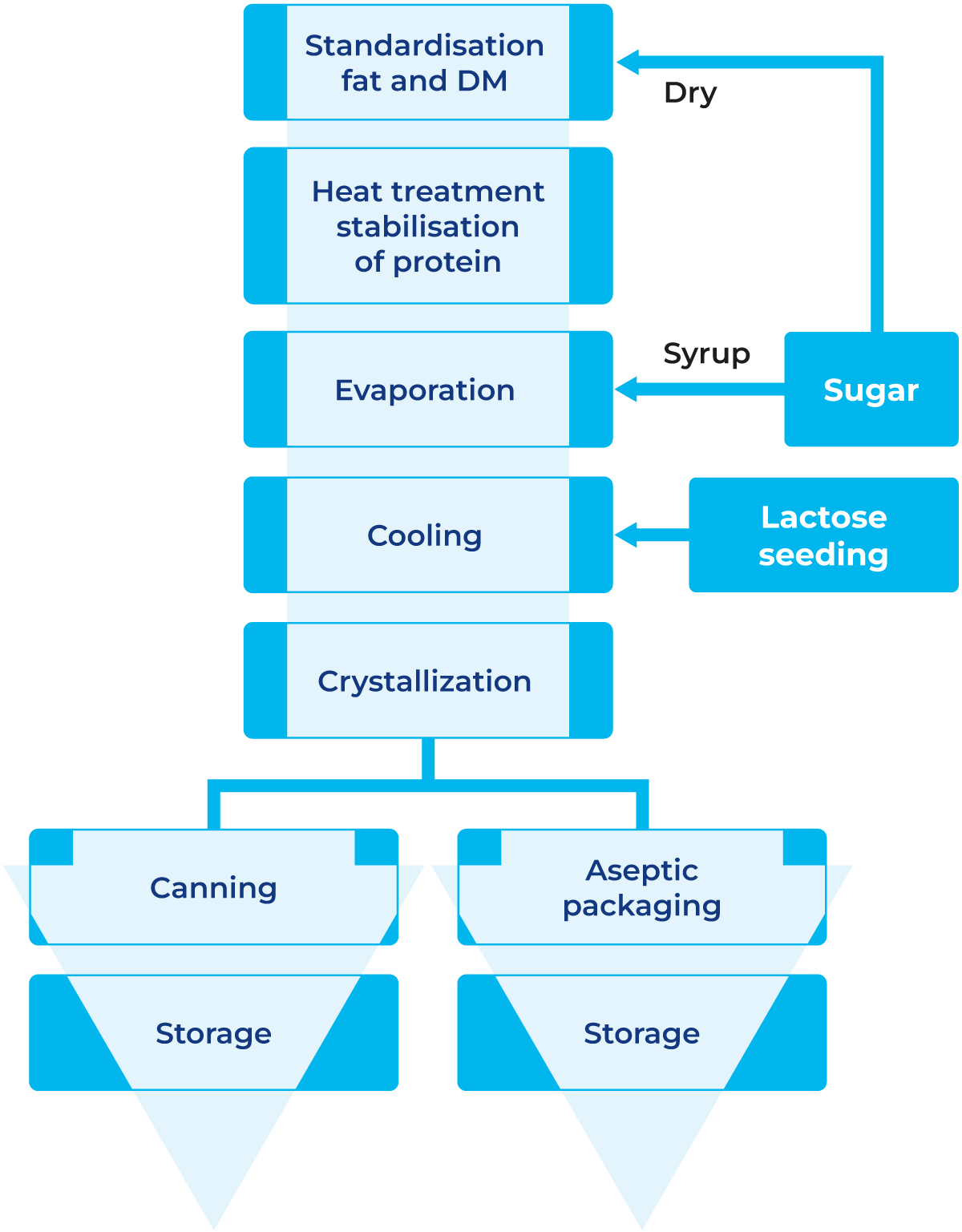

The manufacturing processes for these two products are shown as block diagrams in Figures 17.1 and 17.2.

The first stage, in both cases, comprises precision standardization of the milk fat content and the dry matter content (DM). This is followed by heat treatment, which serves partly to destroy the microorganisms in the milk, and partly to stabilise the milk so that it will not coagulate in the subsequent sterilisation process. Raw material requirements and the initial treatment are similar for both products. After that, the processes differ.

Unsweetened condensed milk

In the manufacture of unsweetened condensed milk from fresh milk (also called evaporated milk), the standardized and heat-treated milk is pumped to an evaporator, where it is concentrated. The concentrate is then homogenized and cooled. Checks are carried out on the heat stability, and stabilising salts (usually disodium hydrophosphate and sodium di-hydrophosphate) are added to adjust the heat stability of the concentrate. In the case of canned products, the concentrate is packed and sterilised in an autoclave. The cans are cooled before being placed in storage.

In the case of UHT-treated products, the stabilised concentrate is first sterilised and then packed aseptically.

Figure 17.3 shows the process stages in the manufacture of unsweetened condensed milk from fresh milk as raw material. Similar technology is also utilised when the production of concentrated milk is based on recombination. In this case, standardization is taking place during recombination or reconstitution.

Raw material

There are two chief considerations regarding raw material quality for the manufacture of condensed milk:

- The number of spores and heat-resistant bacteria

- The ability to tolerate intensive heat treatment without coagulating (thermal stability)

Bacteriological quality of the raw material

Evaporation takes place under a vacuum in falling film evaporators at a temperature which should not exceed 65 – 70 °C. At temperatures below 65 °C, spores and heat-resistant bacteria have ideal growth conditions, which will influence the number of spores in the raw material. This applies to both concentrate to produce condensed milk from fresh milk as well as the production of milk powder, for use as a raw material for recombined products. Precise control of the bacteria in the process is thus an essential requirement in the manufacture of condensed milk or concentrate for drying.

Thermal stability of the raw material

The ability of milk to withstand intensive heat treatment depends largely on its acidity and on the salt balance. The latter is affected by seasonal variations, the nature of the fodder and the stage of lactation. It is possible to improve the ability of the milk to withstand the required level of heat treatment by additives like stabilising salts or by pre-treatment.

Pre-treatment

Pre-treatment is essential for the final quality and includes standardization of fat content, solids-non-fat, as well as heat treatment.

Standardization

Condensed milk is marketed with a stipulated content of fat and dry solids. The figures vary in terms of the applicable standard but are normally 7.5% fat and 17.5% solids-non-fat. This product is often called “double-concentrated milk” and has 25% total solids. Another common standard is “triple concentrated milk” with 33% total solids (often 4 – 10% fat content).

Modern automatic standardization systems permit continuous and extremely accurate standardization of both fat content and the relation between fat content and solids-non-fat of the basic milk. More information on standardization will be found in Chapter 7.2, Centrifugal separators and milk standardization. In the production of condensed milk from fresh milk, the milk is standardized before evaporation to the composition which will result in the desired fat and dry matter after evaporation. In the case of recombined product, the final composition is reached already at the recombination stage.

Pre-heating

Before being sterilised, the standardized milk undergoes intensive heat treatment to destroy microorganisms and improve its thermal stability. In the case of production starting with fresh milk, the heat treatment (often integrated into the evaporation plant) takes place in a tubular or plate heat exchanger at a temperature of 100 – 120 °C for 1 – 3 minutes, followed by cooling to about 70 °C before the milk enters the evaporator.

In the case of recombined product, this step is included in the preprocessing stage of powder production. Milk powder recommended to produce condensed milk should be so-called HHHS quality (see also Chapter 18, Recombined milk products).

During heat treatment, a large proportion of the whey proteins is denatured, while calcium salts are precipitated. In this way, the protein complex of the milk is stabilised, so that with the help of stabilising salts, it can withstand subsequent sterilisation without coagulation during the process or subsequent storage.

The nature of the heat treatment will largely determine the colour and viscosity of the end product and is thus extremely important for product quality.

Evaporation

Evaporation is only applied during the production of condensed milk from fresh milk and the evaporator is usually of the multistage falling-film type. The milk passes through steam-heated tubes under vacuum. Boiling takes place at between 65 and 70 °C. The dry matter content of the milk increases as the water is boiled off. The density is checked continuously.

Homogenization

The concentrated milk is pumped from the evaporator to a homogenizer, which operates at a pressure of 5 – 25 MPa (50 – 250 bar). Homogenization disperses the fat and prevents the fat globules from coalescing during subsequent sterilisation.

Homogenization should not be too intensive, because that might impair the stability of the protein, with the consequent risk of the milk coagulating during sterilisation.

It is therefore necessary to find the exact homogenization pressure that is high enough to produce the required fat distribution, yet low enough to eliminate the risk of coagulation.

For in-can sterilisation, the pressure is generally between 12.5 and 25 MPa (125 to 250 bar) in a two-stage process. In UHT processing, homogenization during pre-treatment is normally low or bypassed if the incoming milk to the evaporator was homogenized, just to avoid separation during storage of the concentrate prior to the final heat treatment. The main homogenization then takes place during the UHT treatment, normally in the downstream (aseptic) position.

Final standardization and intermediate storage

After homogenization, the milk concentrate is cooled to 5 – 8 °C if it is to be stored and await the sterilisation. A final check of the fat content and the solids-non-fat is usually made at this stage. Long-term storage (> 16 hours) should be avoided, not only to prevent bacterial growth, but long cold storage may increase the tendency of sediment formation and age gelation of the final product.

As mentioned previously, the heat stability of the condensed milk can be improved by the addition of stabilising salts, usually sodium phosphates. In canning technology, the quantity of phosphate to be added is determined by sample sterilisation, sterilisation, during which varying amounts of stabilising salts are added and the cans with different salt additions are sent through autoclave sterilisation. The adjustment of the salt content in the UHT application is much more difficult because testing of much larger volumes of concentrate with different salt additions is necessary. On most occasions, the salt addition is based on experience from previous productions.

Any addition of vitamins is also done at this stage.

Canning

Canning machines for condensed milk automatically fill and seal the cans before sterilisation. The canning temperature is selected to give the lowest possible froth formation.

Sterilisation in can

The filled and sealed cans pass from the filling machine to the autoclave, which operates either continuously or on the batch principle. In a batch autoclave, the cans are first stacked in special crates, which are then stacked inside the autoclave. In a continuous autoclave, the cans pass through on a conveyor belt at a precisely controlled speed (see also Figures in Chapter 10, Long-life dairy products). In both types of autoclaves, the cans are kept in motion during sterilisation to distribute the heat more quickly and more evenly in the cans. Any proteins aggregated during heat treatment are uniformly distributed throughout the milk. After a certain period of heating, the milk reaches the sterilisation temperature of 110 – 120 °C. This temperature is maintained for 15 – 20 minutes, after which the product is cooled (in can) to storage temperature.

The heat treatment is intense. This results in a light brown colouration, due to chemical reactions between the protein and the lactose (Maillard reaction or browning reaction).

UHT treatment

UHT treatment is mainly done using tubular heat exchanger plants (described in Chapter 10, Long-life dairy products). The product is pumped to the UHT plant, where it is heated to 120 – 128 °C for a period ranging from 2 to 8 minutes. Low-temperature long-time treatment is mainly to simulate the in-container sterilisation process and get the same sensory appearance as the canned product – light beige colour, slightly caramelised taste and increased viscosity.

The time/temperature combination of the UHT treatment as well as the homogenizing conditions (mainly conducted aseptically) are the main factors determining the final product colour, viscosity and storage stability. After cooling, the milk is packed aseptically in paperboard packages and stored.

Storage and inspection

The canned condensed milk can be stored for practically any length of time at a temperature of 0 – 15 °C. The milk goes brownish if the storage temperature is too high, and protein may precipitate if the storage temperature is too low.

UHT-treated condensed milk normally has a shelf life of 6 – 9 months.

Sweetened condensed milk (SCM)

Sweetened condensed milk can be made from fresh milk or as a recombined product based on skim milk powder, anhydrous milk fat (AMF) and water. For cheaper production, the AMF can be replaced by vegetable fat, preferably palm oil, but occasionally coconut oil. There is also the option of a combined process where increased dry matter content in the product based on fresh milk is reached by the addition of milk powder and increased fat by the addition of cream – a product which is partly fresh milk and partly milk-powder-based.

Source: P. Waltra et al. Dairy Technology (1999)

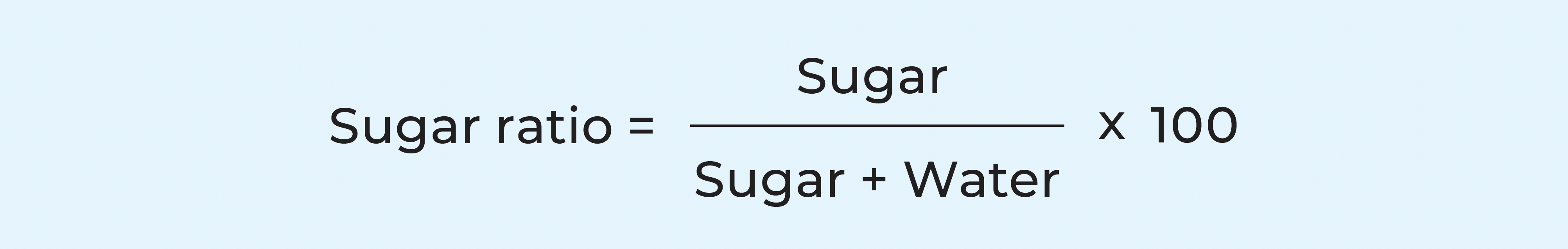

There are two main standards for sweetened condensed milk – British standard and American standard (shown in Table 17.1). The high sugar content, low water activity (aw ≈ 0.78) and high osmotic pressure make the product in principle “self-preserved”. A good sugar ratio is 62.5 – 64.5%. If the sugar ratio is < 62.5% there is a potential risk for microbiological growth. If it is > 64.5% there is a risk for sugar crystallisation causing sandiness of the final product.

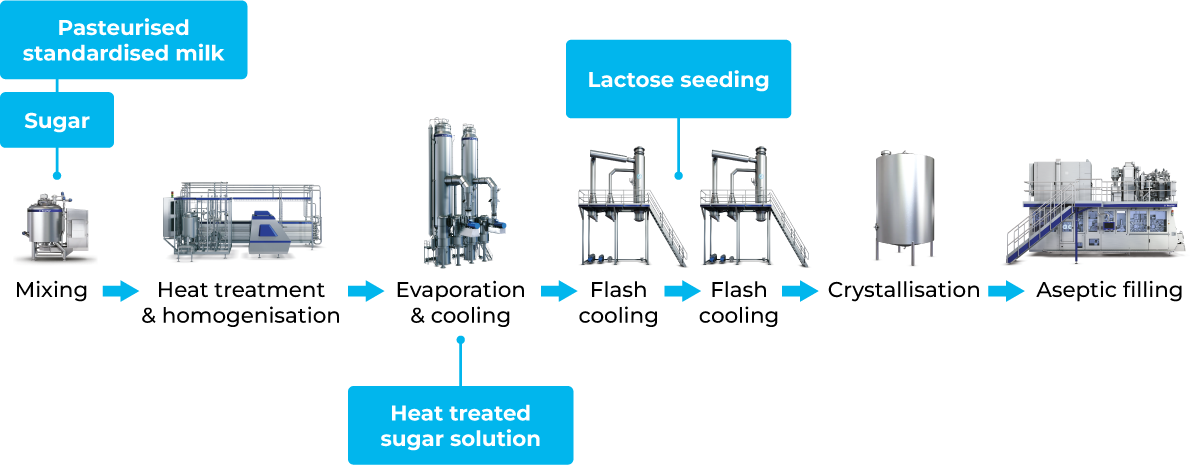

Figure 17.4 shows a process line for sweetened condensed milk manufactured from fresh milk. Before evaporation, the fat and solids-non-fat values of the milk have been standardized to predetermined levels in the same way as for unsweetened condensed milk. The milk has also been heat-treated to kill mainly osmophilic yeast, yeasts, micrococci and spores of moulds as well as inactivate enzymes which could cause problems. The heat treatment is very important to stabilise the protein complex, avoid age gelation and create the desired viscosity and colour of the final product. A gel can form if the heat treatment is too severe or too low. The most common heat treatment is heating to 110 – 120 °C for 1 – 2 minutes. The milk is usually heat-treated at 82 °C for 10 minutes if a product with a relatively high viscosity is required. If a low-viscosity product is required, the temperature/time combination should be at a higher temperature for a shorter time, for example, 116 °C for 30 seconds.

When production is based on recombination, medium heat (MH) or high heat (HH) powder is used instead of applying strong heat during the heating step in sweetened condensed milk production, and pasteurization is carried out at a lower temperature of 88 – 95 °C for 30 – 60 seconds.

The addition of sugar is a key step in the manufacture of sweetened condensed milk. It is important that the correct proportion is added. As described earlier, the shelf life of the milk depends on its osmotic pressure being sufficiently high.

In the production of sweetened condensed milk based on fresh milk, the two methods of addition of sugar are:

- Addition of dry sugar before heat treatment

- Addition of sugar syrup in the evaporator

The stage at which the sugar is added affects the viscosity of the end product. One theory maintains that the early addition of sugar can cause the product to become too viscous during storage.

When production is based on recombination, the sugar addition is almost always carried out in the form of dry sugar at the mixing step.

Evaporation

Evaporation of sweetened condensed milk is carried out in essentially the same way as for unsweetened. When sugar is added to the evaporator, the syrup is drawn into the evaporator and mixed with the milk at the halfway stage of the process. Evaporation then continues until the required dry matter content has been reached. The dry matter content is checked indirectly by determining the density of the concentrate.

Some manufacturers homogenize the concentrate at 5 – 7.5 MPa (50 – 75 bar) immediately after evaporation, as a measure to regulate the viscosity of the product.

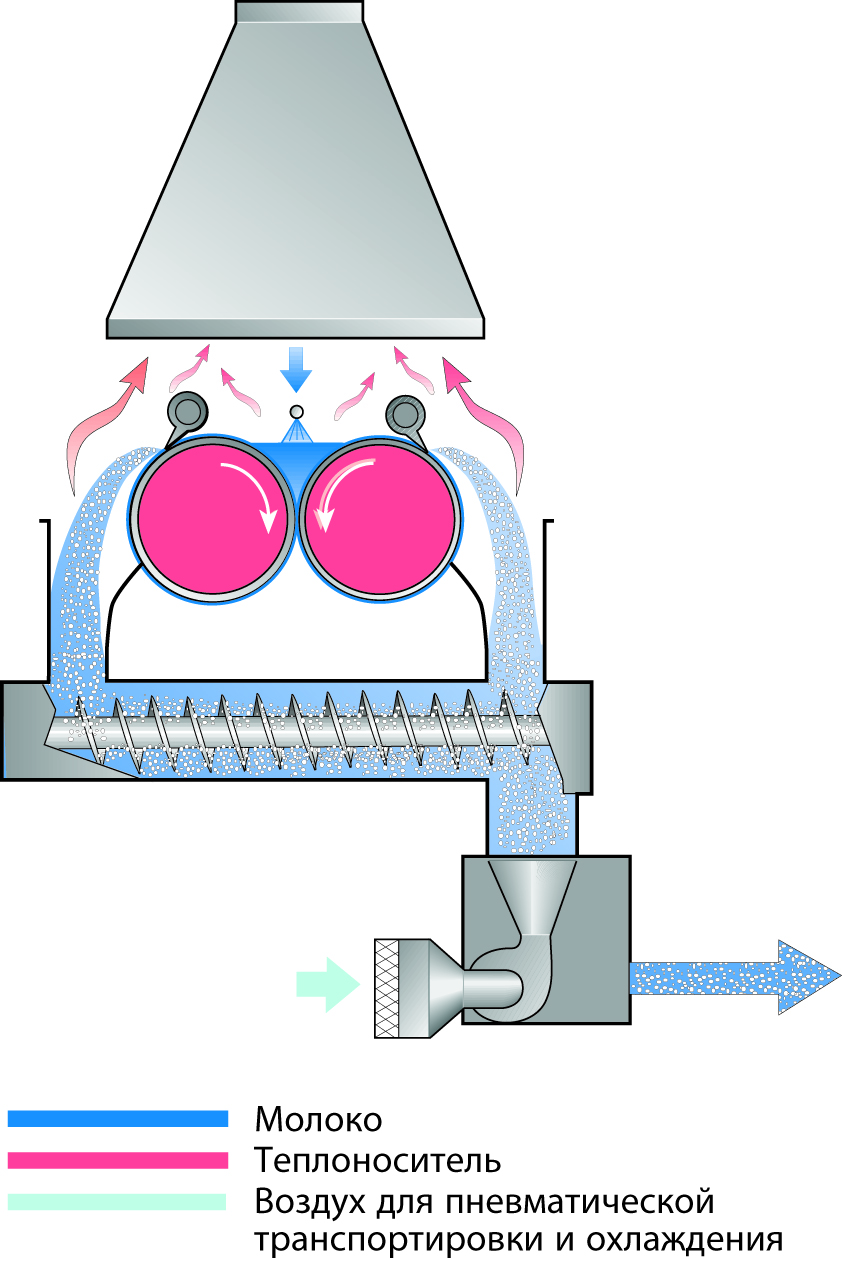

Cooling and crystallisation

Sweetened condensed milk must be cooled after evaporation. This is the most critical and important stage in the whole process in terms of achieving a smooth and creamy mouthfeel. The water in the condensed milk can only hold half the quantity of lactose present in the recipe in solution. The remaining half will therefore be precipitated in the form of crystals. If the surplus lactose is allowed to precipitate freely during slow crystallisation, the sugar crystals will become fewer and larger, and the product will be gritty and unsuitable for many applications. It is consequently preferable to control the crystallisation of lactose so that very many (but small) crystals are formed. The largest crystal size permitted in first grade sweetened condensed milk is 10 μm. These crystals will remain dispersed in the milk under normal storage temperatures (15 – 25 °C) and are not felt on the tongue.

Sweetened condensed milk contains 38 – 45 g lactose per 100 g of water but lactose solubility is only 20 g. Furthermore, since there is also a large amount of sugar (sucrose) present, the final solubility will be just 10 g of lactose in 100 g of water. This means that 75% of the lactose will crystallise. Crystallisation is accomplished by cooling the mixture rapidly under vigorous agitation, without air being trapped, and very often by flash cooling. The lactose crystallisation is achieved by cooling and the addition of very small lactose “seeds” (crystals). These seeds work as nuclei during lactose crystallisation. Fast cooling and crystal addition create an environment for the building of many very small crystals. This process is sometimes called “mass crystallisation”. Seed crystals, in the form of finely ground lactose crystals, are added at a rate of about 0.05% of the total mix, either as a powder or as a slurry, when the condensed milk has a temperature of about 30 – 35 °C. At this temperature, the sugar solution is supersaturated, so that the seeds of lactose do not dissolve. However, the temperature must not be so low that spontaneous nucleation can occur before the seed crystals are mixed in.

These conditions are created by using two flash cooling steps. In the first, the condensed milk is cooled from about 60 to 35 °C and in the second from 35 to 18 °C. In between these two flash coolers, the lactose seeding takes place.

As complete crystallisation takes time, the final crystallisation is done largely in crystallisation tanks and finishes in the package.

The viscosity of sweetened condensed milk is high, which means that a very robust agitator is needed in the storage tanks.

Packing

Sweetened condensed milk should be yellowish in colour and have a high viscosity. Traditionally, it is packed in cans, which in this case must be cleaned and sterilised before filling, as no sterilisation takes place after canning.

Nowadays, it is also possible to pack sweetened condensed milk in aseptic paperboard-based packages.