ANHYDROUS MILK FAT (AMF) AND BUTTEROIL

Anhydrous milk fat and butter oil are products consisting of more or less pure milk fat. Although they are modern industrial products, they have ancient traditional roots in some cultures. Ghee, a milk fat product with more protein and a more pronounced flavour than AMF, has been known in India and Arab countries for centuries.

Defined by Codex Alimentarius standard CODEX STAN 280-1973, Anhydrous milk fat, milk fat, anhydrous butter oil and butter oil are fatty products derived exclusively from milk and/or products obtained from milk by means of processes which result in almost total removal of water and non-fat solids. Ghee is a product exclusively obtained from milk, cream or butter by means of processes which result in almost total removal of water and non-fat solids, with an especially developed flavour and physical structure.

The compositions of those products are given in the Codex standard below:

In this chapter, the expression “AMF” will be used for all products described in the Codex standard.

AMF characteristics

Butter has been the traditional form of storage for milk fat, but in some cases, AMF is preferable because it requires less storage space.

Butter is regarded as a fresh product, although it can usually be stored at +4 °C for up to six weeks. If it is stored for a longer period, for example, up to 10 – 12 months, a storage temperature of at least –25 °C is mandatory.

AMF is typically packed in 200-litre drums of nitrogen (N2) headspace and can be stored for several months at +4 °C. AMF is liquid at temperatures above 36 °C and solid below 16 – 17 °C.

AMF is convenient to use in liquid form because it is easy to mix with, and meter into other products. Thus, AMF is used for the recombination of various dairy products, but it is also used in the chocolate and ice cream manufacturing industries.

Demand for butter is decreasing, partly due to the increased use of AMF. One field of application where the use of AMF will increase is in blends of different fat contents and with mixtures of butter and vegetable oils to make products with different functional properties.

Customised fat products for various applications can be obtained by fractionation of AMF.

Production of AMF

Principles of production

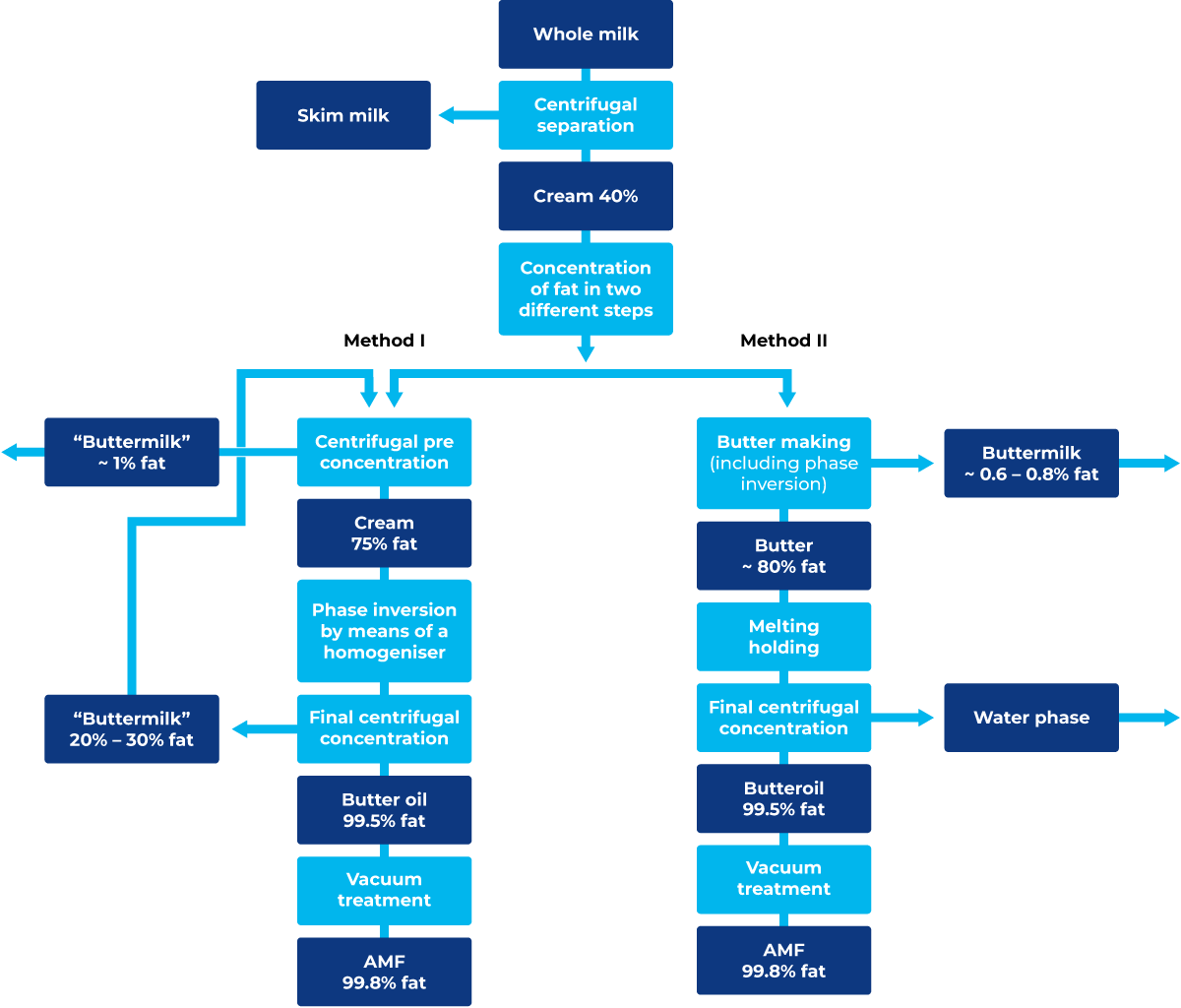

Production of AMF principally takes place according to two methods: continuous flow direct from cream (milk) and from reworked butter. The block chart in Figure 15.1 visualises the two methods.

The quality of the AMF depends on the quality of the raw material, so there should be no difference, regardless of the chosen method. If, for any reason, the respective qualities of cream and butter should be considered not good enough, there are some means of improving quality by polishing (washing) the oil or even neutralising it before the final evaporation step. These operations are discussed below under AMF Refining.

Manufacture of AMF from cream

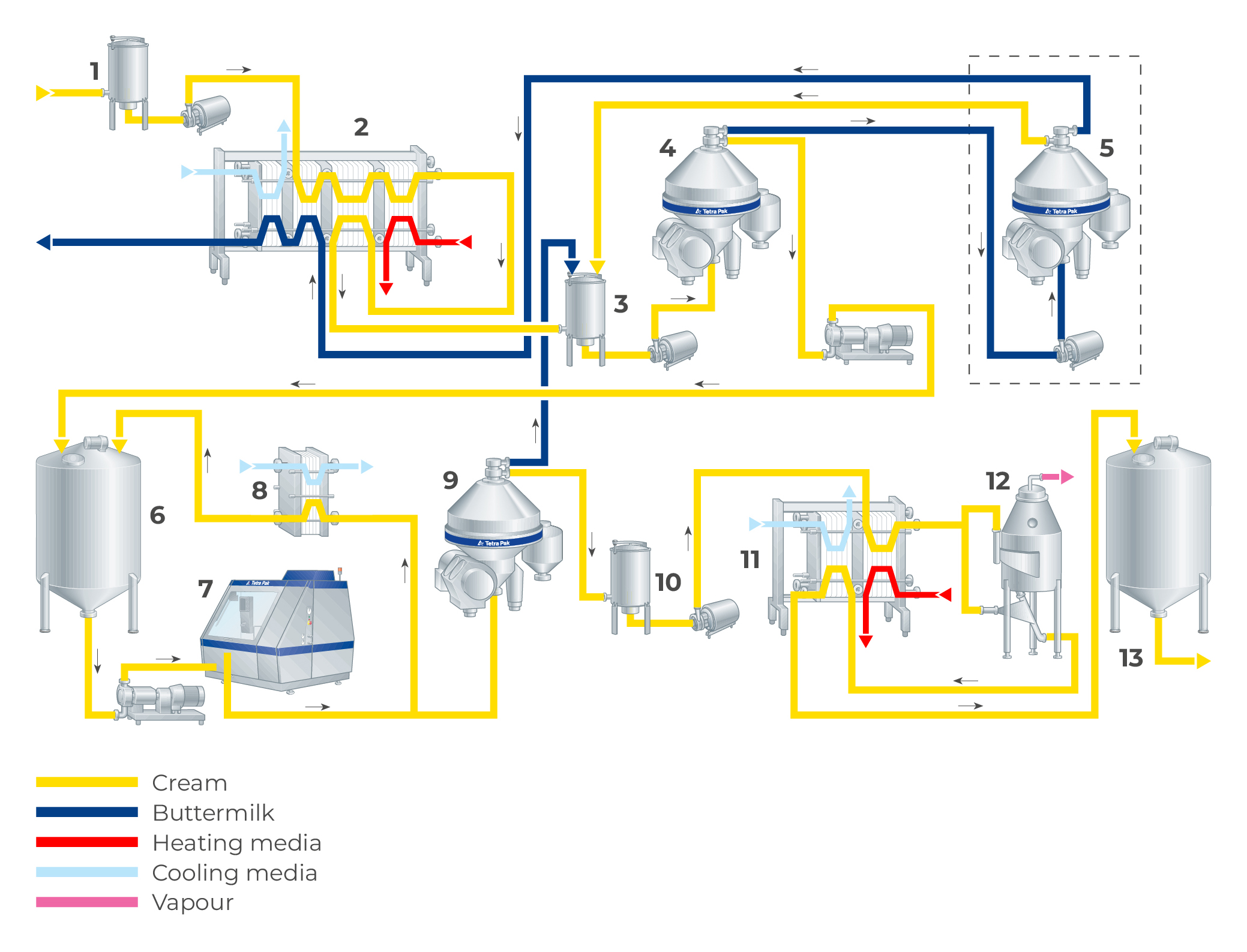

A production line for the manufacture of AMF from cream is outlined in Figure 15.2. Pasteurised or non-pasteurised cream of 35 – 40% fat content enters the AMF plant via the balance tank (1) and is routed via the plate heat exchanger (2) for temperature adjustment or pasteurisation to the centrifuge (4) for pre-concentration of the fat to about 75%. The temperature at pre-concentration and downstream to the plate heat exchanger (11) is maintained at approx. 60 °C. The “light” phase is collected in a buffer tank (6) to await further processing, while the “heavy“ phase, typically called buttermilk, can be passed through a separator (5) for recovery of fat which will then be mixed with incoming cream (3). The skimmed buttermilk goes back to the plate heat exchanger (2) for heat recovery and then to a storage tank.

After intermediate storage in the tank (6), the cream concentrate is fed to a homogeniser (7) for phase inversion (disruption of the fat globules to release the fat), after which it is passed through the final concentrator (9). In this concentrator, the product is separated into a light phase with 99.5% fat and a heavy phase with a substantial amount of fat, which is returned to the process via a balance tank (3).

As the homogeniser operates at a slightly higher capacity than the final concentrator, the surplus product not caught by the concentrator is recirculated to the buffer tank (6). Part of the mechanical energy used in the homogenisation process is converted into heat; to avoid disturbing the temperature cycle of the plant, this surplus heat is removed in the cooler (8).

Finally, the oil consisting of some 99.5% fat is pre-heated to 95 – 98 °C in a plate heat exchanger (11) and routed into a vacuum chamber (12) to obtain a moisture content not exceeding 0.1%, after which the oil is cooled (11) to approximately 40 °C, the typical packing temperature.

The key components of an AMF plant using cream are thus separators for the concentration of fat and homogenisers for phase inversion.

Manufacture of AMF from butter

AMF is often produced from butter, especially from butter that is not expected to be used within a reasonable period of time. There may be some difficulty in achieving a completely bright oil after the final concentration step when freshly produced butter is the starting material; the oil tends to be impaired by slight cloudiness. This phenomenon does not occur with butter that has been stored for two weeks or more.

The reason for this phenomenon is not fully understood, but it is known that it takes some time (weeks) after churning before the “body” of the butter is fully developed. It has also been noted that when samples of butter are heated, the emulsion of fresh butter seems to be more difficult to split than that of aged butter and that it does not have a very bright colour.

Sweet cream, non-salted butter is normally used as the raw material, but cultured cream, salted butter may also be used.

Figure 15.3 shows a standard plant for the production of AMF from butter. The plant is fed with butter from boxes (25 kg) which have been stored for some period of time. The raw material may also be frozen butter stored at –25 °C.

After having been stripped of the boxes, the butter is melted by indirect heating in equipment of various kinds. Before the final concentration starts, the temperature of the melted butter must reach 60 °C.

As a rule, melting by direct heating (steam injection) leads to the formation of a new type of emulsion with small air bubbles forming a dispersed phase, which is very difficult to separate. In the subsequent concentration, this phase is concentrated together with the oil and causes cloudiness.

After melting and heating, the hot product is pumped to a holding tank (2) where it may be held for up to 30 min, primarily to ensure complete melting, but also to allow the protein to aggregate.

From the holding tank, the product is pumped to the final concentrator (3), after which the light phase, containing 99.5% fat, proceeds to a plate heat exchanger (5) for heating to 90 – 95 °C. From there, it proceeds to a vacuum vessel (6) and finally back to the plate heat exchanger (5) for cooling to the packing temperature of approximately 40 °C.

The heavy phase can be pumped into a tank for buttermilk or into a waste-collecting tank, depending on whether it is “pure” or contaminated with a neutraliser.

If the butter comes direct from a continuous buttermaker, the same risk of obtaining a cloudy oil arises as in the aforementioned case of fresh butter. However, with a final concentrator of hermetic design, it is possible to regulate the level inside the machine to obtain a bright oil phase of 99.5% fat at a slightly lower volume, and a heavy phase of relatively high fat content (about 7%) at a slightly higher volume. The heavy phase should then be reseparated, and the cream obtained should be recycled by mixing it with the cream fed to the continuous buttermaker.

AMF refining

AMF can be refined for various purposes. Examples of refining processes are:

- Polishing

- Neutralisation

- Fractionation

- Decholesterolisation

Polishing

Polishing involves washing the oil with water to obtain a clear, shiny (bright) product. In this step, 20 – 30% water is added to the oil coming from the final concentrator. The water temperature should be the same as the oil temperature. After a short hold, the water is separated out again, taking water-soluble substances (mainly protein) with it.

Neutralisation

Neutralisation is performed to reduce the level of free fatty acids (FFA) present in the oil. High levels of FFA give rise to off-flavours in the oil and the products in which it is used.

Alkali (NaOH) at a concentration of 8 – 10% is added to oil in an amount corresponding to the level of FFA. After a hold of around 10 seconds, water is added in the same proportion as for polishing, and the saponified FFA is separated out together with the water phase. It is important that the oil and alkali are well mixed, but this must be done gently to avoid re-emulsification of the fat.

The arrangement of a neutralisation step is shown in Figure 15.4. The alkali solution in the tank (1), at 8 – 10% concentration and a temperature equal to that of the oil leaving the final concentrator, is dosed (2) into the oil stream. After thorough mixing (3), the flow passes a holding section (4) for 10 seconds, after which hot water is dosed into the stream (5) in an amount of some 30% of the flow en route to a second concentrator (6), via a mixing unit (7).

Fractionation

Fractionation is a process where the oil is separated into high-melting and low-melting fats. These fractions have different properties and can be used in various products.

There are several methods of fractionating fat, but the most commonly used is one in which no additives are used. The process can be briefly described as follows:

The AMF, often polished to obtain the highest possible degree of purity in the “raw oil”, is melted and then cooled slowly to a calculated temperature at which the specified fraction crystallises out while fractions with lower melting points remain liquid. The crystals are harvested with special filters. The filtrate is then cooled to a lower temperature at which other fractions crystallise and are harvested, and so on.

Decholesterolisation

Decholesterolisation is a process in which cholesterol is removed from the AMF. A frequently used method is to mix the oil with a modified starch, beta-cyclodextrin (BCD). The BCD molecule surrounds the cholesterol and forms a precipitate, which can be separated out by centrifugation.

Packaging

AMF is filled in containers of various sizes. For households and restaurants, containers of 1 kg to 19.5 kg are available and for industrial use, drums of at least 185 kg are used.

Normally an inert gas, nitrogen (N2), is first injected in the container. As the N2 gas is heavier than air, it sinks to the bottom. When filling the AMF – which is heavier than N2 – the AMF will sit underneath and the N2 gas will create an “air-tight lid”, preventing the AMF from air-induced oxidation.