CULTURES AND STARTER MANUFACTURE

Bacteria cultures, known as ‘starters’, are used in the manufacture of yoghurt, kefir and other cultured milk products as well as in buttermaking and cheesemaking. The starter is added to the product and allowed to grow there under controlled conditions. In the course of the resulting fermentation, the bacteria produce substances that give the fermented product its characteristic properties such as acidity (pH), flavour, aroma and texture. The drop in pH, which takes place when the bacteria ferment lactose to lactic acid, has a preservative effect on the product, while at the same time, the nutritional value and digestibility are improved.

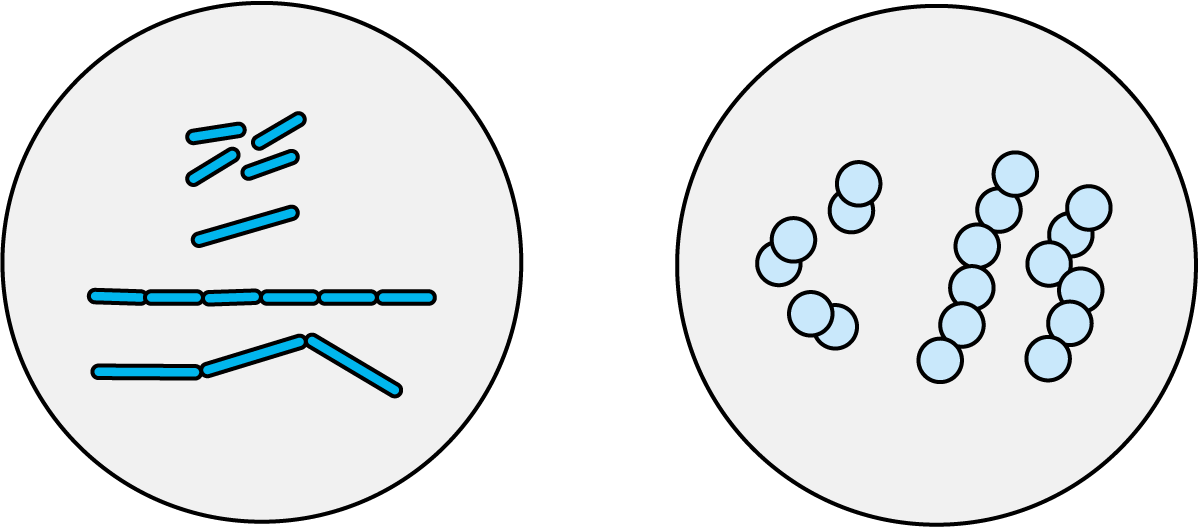

Lactic acid bacteria

Lactic acid bacteria are found on plants in nature, but some species occur in particularly large numbers in places where there is milk. Others are found in the intestines of animals. The group includes both bacilli and cocci, which can form chains of varying length, but which never form spores.

Lactic acid bacteria are facultatively anaerobic. Most of them are killed by heating to 70 ºC, though the lethal temperature for some is as high as 80 ºC. Lactic acid bacteria prefer lactose as a source of carbon. They ferment lactose to lactic acid. The fermentation may be pure or impure, i.e. the end product may be almost exclusively lactic acid (homofermentative fermentation), or other substances may also be produced, such as acetic acid, carbon dioxide and ethanol (heterofermentative fermentation).

Fermentation capacity varies according to species. Most lactic acid bacteria form between 0.5 and 1.5% lactic acid, but some species form up to 3%.

Lactic acid bacteria need organic nitrogen compounds for growth. They get them from casein in milk by breaking it down with the help of protein-splitting enzymes. However, the ability to split casein varies greatly from one species to another

Fermented dairy products and cheeses have different characteristics, and different starter cultures are therefore used in their manufacture. Starter cultures can be classified according to their preferred growth temperatures:

- Mesophilic bacteria – optimal growth temperatures of 20 to 30 °C

- Thermophilic bacteria – optimal growth temperatures of 40 to 45 °C The cultures may be of:

- Single-strain type; containing only one strain of bacteria

- Multiple-strain type; a mixture of several strains, each with its own specific effect

The purpose of the different strains in a multiple-strain starter is to produce the desired result in symbiosis, not to compete with each other. Their characteristics must therefore be complementary in this respect. Bacterial characteristics such as optimum growth temperature and salt tolerance are very important in the composition of a culture. Table 12.1 lists essential data for some important culture bacteria.

Dairies normally buy ready-mixed starters – commercial cultures – from starter culture-producing companies. These companies put a lot of effort into research and development to compose special cultures for a given product, e.g. butter, cheese and a large number of fermented milk products. Thus, the dairies can obtain cultures with selected properties for specific product characteristics such as texture, flavour and viscosity. The dairies can buy the commercial cultures in two different formats

- Deep-frozen, highly concentrated cultures in readily soluble form

- Freeze-dried (lyophilised), highly concentrated cultures in powder form

The highly concentrated cultures are also known as DVS (Direct Vat Set) or DVI (Direct Vat Inoculation) cultures, and can be used for direct inoculation of the product as well as for the production of bulk starter.

Source: Novonesis *

In the case of yoghurt, the main reason for adding cultures other than Streptococcus thermophilus and Lactobacillus bulgaricus is to supply the product with probiotic properties

Starter cultures in the dairy

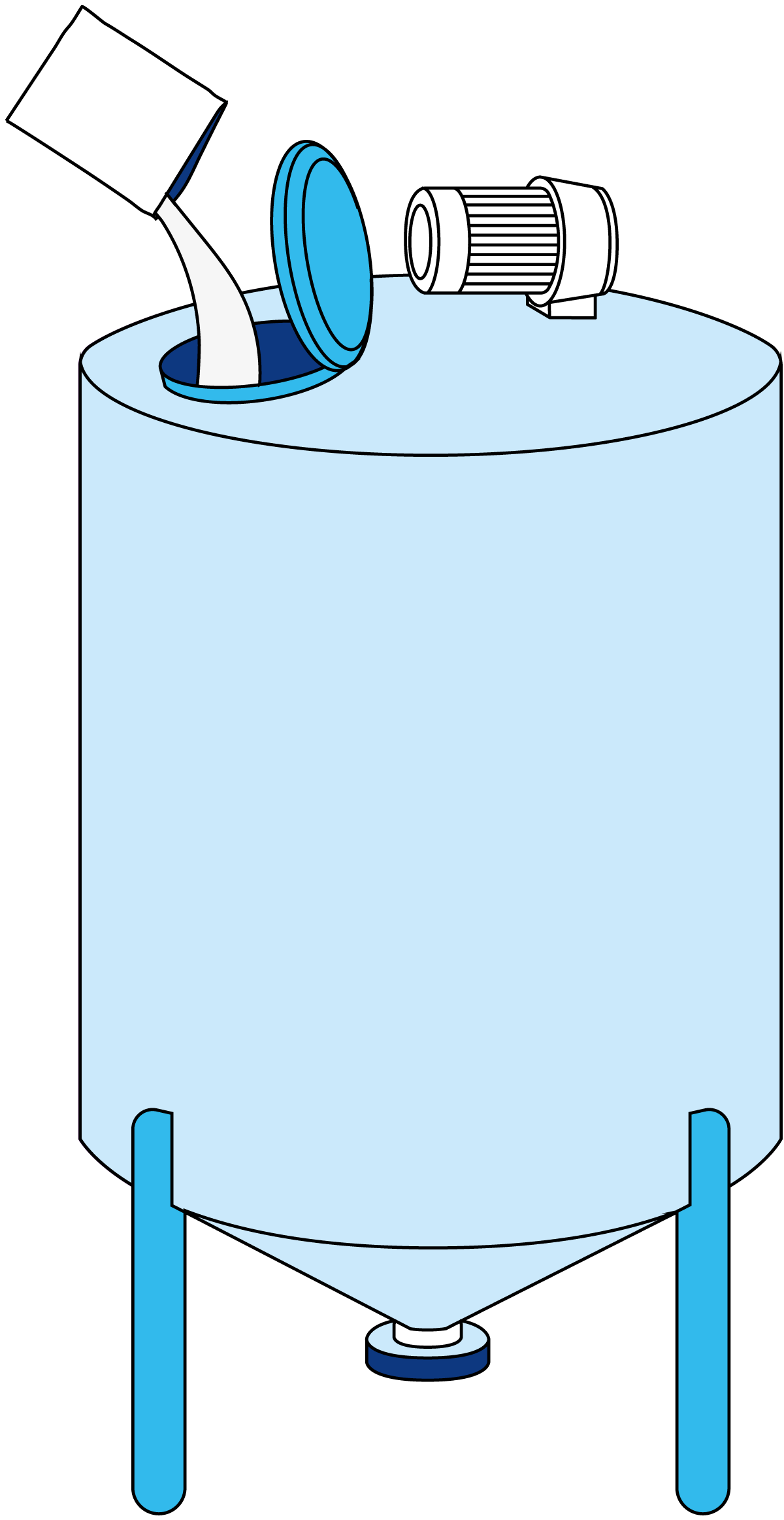

Historically it was common that dairies bought a mother culture from a culture supplier. The dairy then propagated the culture itself in water baths and bulk starter tanks to get a sufficient amount for their production. Today, most dairies buy highly concentrated starter cultures (DSV/DVI) and use them directly in production, without further propagation in the dairy. However, some, especially cheese-producing dairies, still propagate their own bulk starter as shown in Figure 12.2.

Bulk starter production

Starter manufacture is one of the most important and also one of the most difficult processes in the dairy. Production failures can result in heavy financial loss, as modern dairies process large quantities of milk.

Very careful attention must therefore be paid to the manufacturing technology and choice of process equipment. Starter production demands the very highest standard of hygiene. The risk of airborne infection by yeasts, mould fungi and bacteriophages must be reduced to an absolute minimum. Dairies that still propagate their own bulk starters should preferably prepare it in a separate room supplied with filtered air at a pressure slightly above normal atmospheric pressure. The cleaning system for the equipment must also be carefully designed to prevent detergent and other CIP residues from coming into contact with the cultures and spoiling them.

Stages in the process

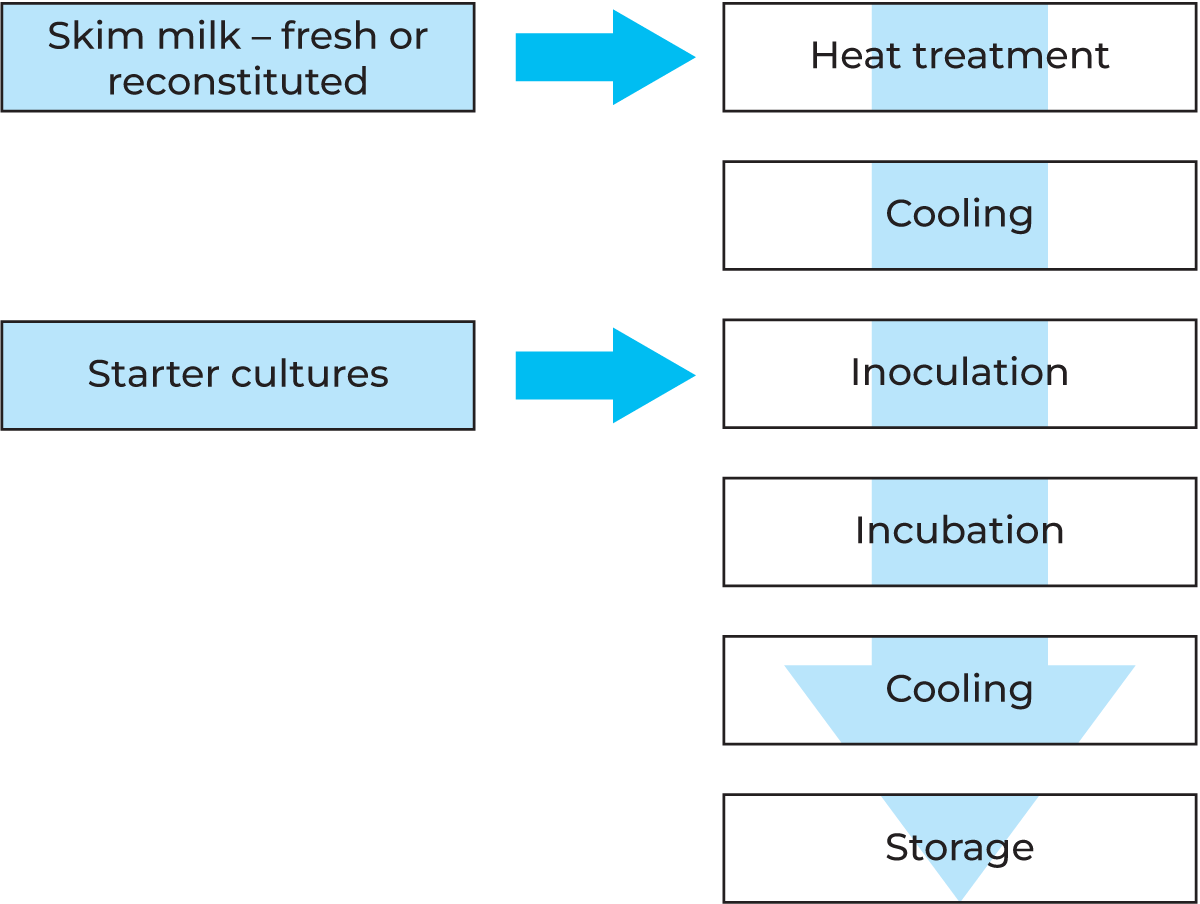

The process, presented in Figure 12.3, shows the preparation of a bulk starter.

It comprises the following stages:

- Heat treatment of the medium

- Cooling to inoculation temperature

- Inoculation

- Incubation

- Cooling of the finished culture

- Storage of the culture

Skim milk is the medium most frequently used for starter production, but reconstituted skim milk with 9 – 12% dry matter (DM), made from top-grade skim milk powder, is another alternative.

The basic reason for using fresh or reconstituted skim milk is that anomalies in the flavour of the culture are much more readily apparent. Fresh milk from selected farmers is also used in some dairies.

A medium with constant composition, such as reconstituted antibiotic-free skim milk, is more reliable than fresh skim milk.

The medium can also be modified by the addition of growth factors such as Mn2+ (Manganese), e.g. 0.2 mg MnSO4 per litre of culture, which is supposed to promote the growth of Leuc. mesenteroides subsp. cremoris. Phage-inhibiting media (PIM) offer an alternative for the production of single-strain or multi-strain starters. These media contain phosphates, citrates or other chelating agents which make Ca2+ (calcium) insoluble. The reason for doing this is that most phages require Ca2+ for proliferation. Removing Ca2+ from the medium protects the lactic acid bacteria from being infected and thus avoids failure of starter activity. Skim milk powders with PIM are available in certain markets. Phage robust cultures are also available today.

Heat treatment of the medium

The first step in starter manufacture is heat treatment of the medium. It is heated to 90 – 95 °C and held at that temperature for 30 to 45 minutes. This heat treatment improves the properties of the medium through

- Destruction of bacteriophages

- Elimination of inhibitory substances

- Some decomposition of protein

- Expulsion of dissolved oxygen

- Destruction of original living microorganisms

Cooling to inoculation temperature

After heat treatment, the medium is cooled to inoculation temperature, which differs according to the type of bacteria culture used. It is important that the temperatures recommended by the producer of the commercial culture, or empirically determined optimum temperatures, are maintained.

In the propagation of multi-strain cultures, even small deviations from the proper incubation temperature may favour the growth of one strain at the expense of the other(s), resulting in a failure to obtain the desired typical characteristics of the end product.

Typical inoculation temperature ranges are 20 – 30 °C for mesophilic types of bacteria and 42 – 45 °C for thermophilic types.

Inoculation

For inoculation, a determined quantity of bacteria culture is transferred to the heat-treated medium after the temperature has been adjusted to the correct level. To prevent any deviations in the culture, it is most important that the starter dosage, the propagation temperature and the time are kept constant. The amount of starter used can also affect the relative proportions of different bacteria which produce lactic acid and aroma substances. Variations in the amount of starter can consequently cause variations in the product. Each manufacturer must therefore determine which practical conditions suit their particular production process best.

Incubation

As soon as inoculation has taken place and the starter has been mixed into the medium, the bacteria begin to multiply – incubation begins. The incubation time is determined by the types of bacteria in the culture, the inoculation dosage, etc., and can vary from 3 to 20 hours. It is most important that the temperature is carefully controlled and that no contaminants are allowed to come into contact with the culture.

During the incubation period, it is essential that the person responsible for production regularly checks acidity development and otherwise follows the routines found to give optimal results.

Careful handling of all starter cultures is a very important aspect of the processing of cultured milk products; this task should therefore always be given to skilled personnel.

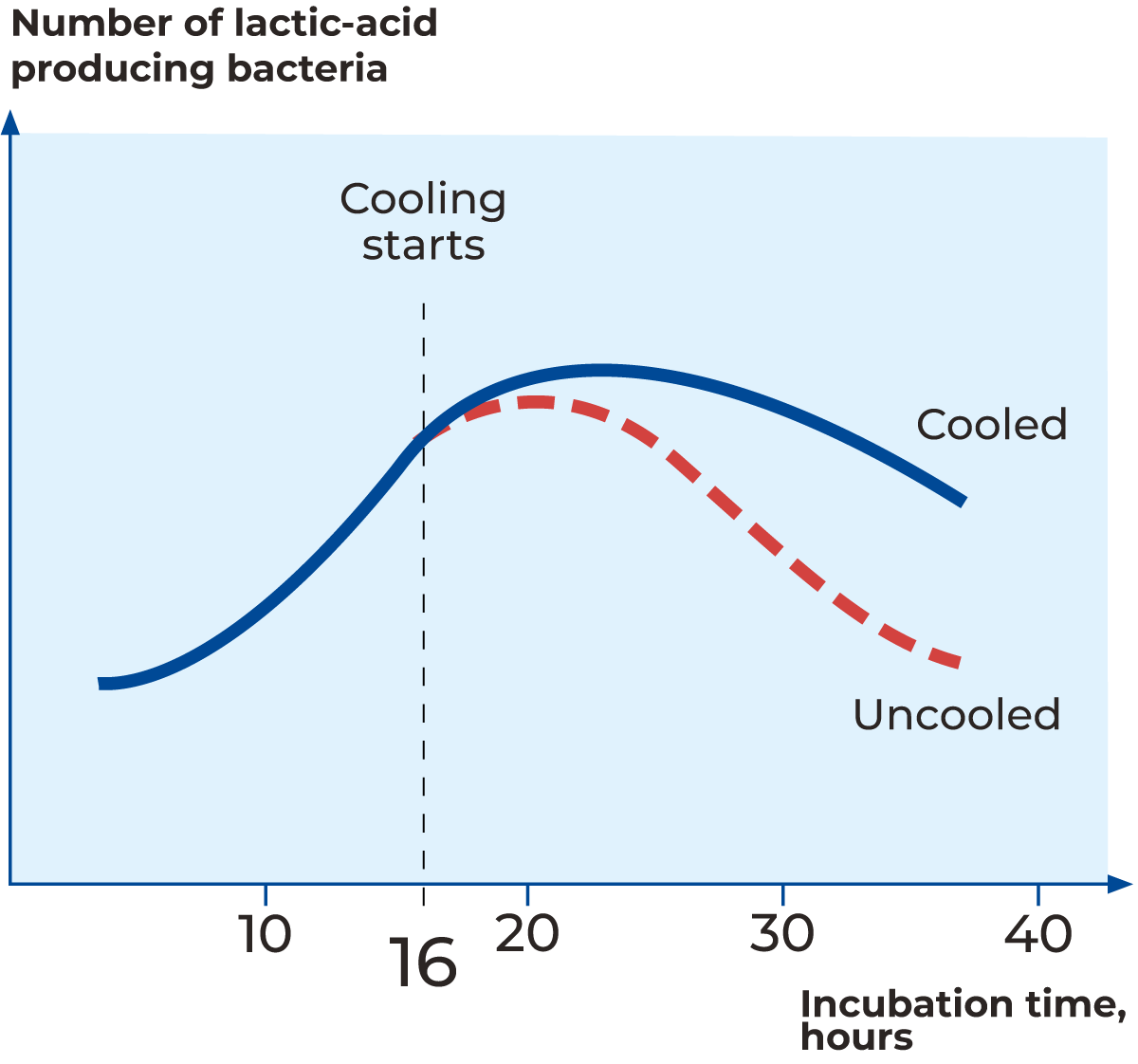

Cooling the culture

Cooling is started at an empirically determined acidity to stop bacterial growth and thus preserve the activity of the culture at a high level. Figure 12.4 demonstrates the course of events for an ordinary lactic-acid-forming culture inoculated with 1% mother culture at 20 °C.

Cooling to 10 – 12 °C is often practised when the culture is going to be used within the next six hours. If the culture needs to be stored for an extended period, (more than six hours), it is advisable to cool it to about 5 °C.

In large-scale production, or production during more than one shift, it is more convenient to prepare starters at regular intervals of, say, four hours. This means that active cultures are available at all times, making it easier to follow the prescribed processing schedule and to assure consistently high quality in the end products.

Preservation of starters

A great deal of research work has been done to find the best way to treat starters in order to preserve their activity during storage. One method is freezing. The lower the temperature, the better the cultures keep. Freezing with liquid nitrogen to –160 °C and storage below –45 °C preserves cultures very well

Modern forms of starter cultures – deep-frozen or freeze-dried (lyophilised) – can be stored for a considerable time provided that the manufacturers’ recommendations are followed.

Table 12.3 shows the recommendations issued by Novonesis.

It should be noted that deep-frozen cultures require lower storage temperatures than freeze-dried cultures. Moreover, deep-frozen cultures are supplied in insulated polystyrene boxes packed with dry ice or distributed in special freezing containers. Freeze-dried cultures, on the other hand, can be transported at temperatures up to some 20 °C for up to 10 days without shortening the stated shelf life, provided that they are stored at the recommended temperature after arrival at the buyer’s premises.

Direct inoculation with highly concentrated cultures

Deep-frozen or freeze-dried highly concentrated culture should be added to the fermentation tank or cheese vat hygienically. Often the starter culture is added directly to the tank, through the manhole. Opening the tank for the addition does however also mean risking re-infection of the product. This risk can be reduced by for instance applying sterile air over-pressure in the tanks, but there are also some alternative ways of inoculation.

In-line inoculation

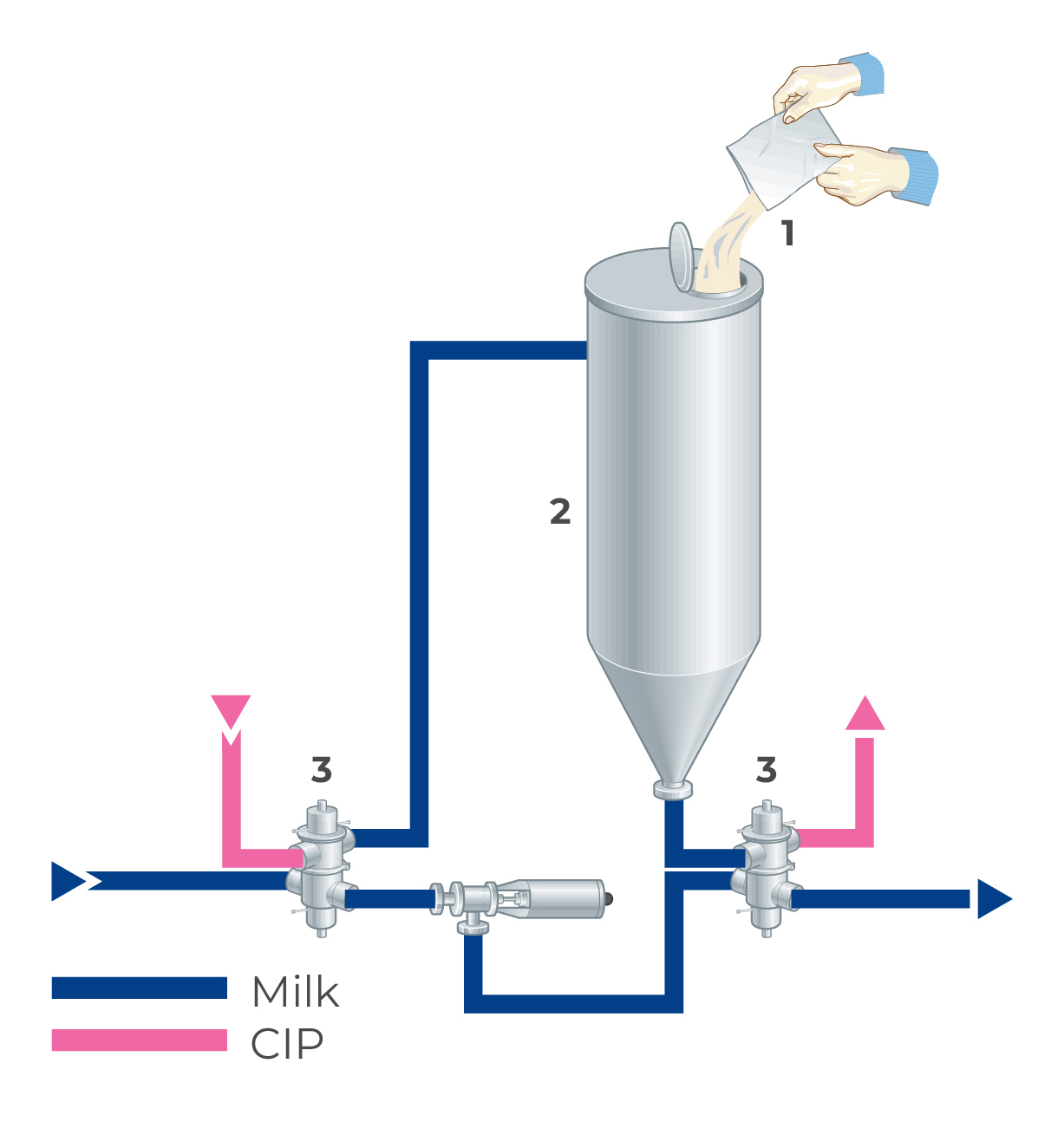

The highly concentrated culture can be inoculated directly in the milk stream prior to the incubation tank. A bypass line including a small container is connected to the milk pipe illustrated in Figure 12.5. The container is loaded with freeze-dried or deep-frozen culture enough for inoculation of one incubation tank. When the operator decides to inoculate the tank during milk filling, he opens the valves for the bypass line and the milk will bring in the culture to the tank.

After inoculation of the tank, the bypass line and container are cleaned and sterilised. The container can then be loaded with culture again for inoculation of the second incubation tank. The small container can be built into a sterile air cabinet in order to minimise the reinfection risk.

Automatic inoculation system (AISY)

For dairies or cheese factories with a lot of tanks to be inoculated, a special inoculation system, AISY, has been developed by the culture company Novonesis and Tetra Pak. The AISY system combines the advantages of highly concentrated cultures and an automatic inoculation system. The system is shown in Figure 12.6. Highly concentrated cultures are transferred into a buffer tank and diluted with cold water. After a few minutes of stirring, the diluted culture can be added in-line to the milk stream or automatically pumped to fermentation tanks or cheese vats for inoculation of the milk.