LONG-LIFE MILK

For the production of long shelf-life dairy products, the heat treatment used is often referred to as UHT treatment and sometimes also as "sterilisation". This heat treatment means that the product has been heat treated to a degree that ensures microbiological and enzymatic stability over a longer period at ambient storage temperatures. This creates many advantages and allows dairy producers to distribute these products over longer distances without refrigeration and thereby find new markets.

Long shelf-life processing technologies offer numerous advantages for dairy producers, retailers and consumers, as the products can be stored at ambient temperatures for extended periods without spoilage. Therefore, the producer can reach geographically wider and new markets, simplify production planning by reducing product changes and losses, make deliveries easier by using fewer and ambient distribution, and eliminate the return of unsold products. Handling becomes easier for the retailer, as expensive refrigerated display space is not necessary and stock planning is simplified. The reduction of waste and energy consumption from long-life dairy products has a positive impact on their environmental footprint.

Finally, even if long-life dairy products have traditionally been mostly consumed in geographical areas where refrigeration is limited, the development of processing technologies for long-life dairy products today allows the products to be accepted for traditional chilled markets thereby the consumer gains in convenience thanks to less frequent shopping, less congestion in the home refrigerator and emergency reserves on hand for unexpected events.

Raw material quality

The raw milk to be used for the production of long-life dairy products needs to be of good quality as the quality will influence both the processability and shelf-life stability.

Raw milk exposed to high heat treatment must be of very good quality as it is particularly important that the proteins in the raw milk do not cause thermal instability. A fast and indicative test of the heat stability of the proteins is the alcohol test. When a sample of the milk is mixed with an equal volume of an ethyl alcohol solution, the proteins may become unstable and the milk flocculates. The higher the concentration of ethyl alcohol solution that can be added without causing flocculation, the better the heat stability of the milk. Production and shelf-life problems can be avoided to a great extent if the milk remains stable (does not precipitate) even after the addition of alcohol solutions with a 75% alcohol concentration.

The alcohol test is typically used to reject milk that is unsuitable for UHT treatment because it:

- Has a reduced pH – high bacterial count of acid-producing microorganisms

- Has the wrong salt balance – mastitis, inflammation of the udder

- Contains a high level of serum proteins – typical of colostrum or milk from cows suffering from mastitis

Raw milk of bad quality has an adverse effect on both processability and final product quality. Milk with pH below 6.65 at 20 °C has reduced thermal stability and causes not only processing problems as fouling on the heating surfaces resulting in short running times, but also difficulties with cleaning, as well as sedimentation of proteins at the bottom of the packages during storage.

Raw milk stored for a long time at low temperatures may contain high numbers of psychrotrophic bacteria, which can produce heat-resistant enzymes that are difficult to completely inactivate by heat treatment. During storage, the enzymes can cause organoleptic changes such as rancidity, bitterness or even gelation (age-thickening or sweet curdling).

The bacteriological quality of the milk must be high. This applies not only to the total bacterial count but also – more importantly – to the count of spore-forming bacteria that influence the risk of non-sterility.

The milk is unsuitable for UHT treatment if it:

- Has pH < 6.65

- Has alcohol stability < 75%

- Was stored for a long time at low temperatures

Commercial sterility

In the production of long shelf-life dairy products the term “sterilisation” is often used. However, sterilisation is the complete destruction or elimination of all microorganisms.

With the UHT processing procedure, a dairy product is heat treated to achieve “commercial sterility”. A commercially sterile product is defined as one which is free from microorganisms that grow under prevailing conditions. In low-acid products – products with pH above 4.5 – the most heat-resistant microorganisms which can grow are spores. As their heat resistance is much higher than that of vegetative microorganisms, sterilisation processes concentrate attention on the killing effect on spores only, as this ensures the killing of all other microorganisms. The group of low-acid products includes not only milk but most milk-based products.

Sterilising efficiency

When microorganisms and/or bacterial spores are subjected to heat treatment or any other kind of sterilising/disinfectant procedure, not all microorganisms are killed at once. Instead, a certain proportion is destroyed in each period of time for a specific temperature while the remainder survives. If the surviving microorganisms are once more subjected to the same heat treatment for the same length of time, an equal proportion of the remainder will be killed, and so on. In other words, a given exposure to sterilising or disinfectant agents always kills the same proportion of microorganisms present.

where

N0 = number of micro-organisms (spores) originally present,

Nt = number of micro-organisms (spores) present after a given time of treatment (t), and

K = temperature dependent velocity or death rate constant

t = time of treatment

Logarithmic reduction of spores

The lethal effect of heat treatment or sterilisation on microorganisms can thus be expressed mathematically with a logarithmic function.

For a specific constant (k), depending on the heat resistance of a specific microorganism at a specific temperature for a specific time, the number of survivors can be calculated. If plotted as a semi-logarithmic graph with the duration of treatment plotted on the linear axis and the number of survivors on the logarithmic axis, it results in a straight line as it’s a logarithmic function.

A logarithmic function can approach zero, but never reach it! To put it another way, sterility defined as the absence of living bacterial spores in an unlimited volume of product is impossible to achieve. In unlimited volumes, we always have to count on some survivors, otherwise known as the “sterilising effect”, “bactericidal effect” or “sterilising efficiency” concept. These terms state the number of decimal reductions in counts of bacterial spores achieved by a sterilisation process.

Each time a sterilisation process is performed, it can be characterised by a certain sterilising effect. In any heat sterilisation process, the sterilising effect is determined by the time/temperature condition applied. The higher the temperature or the longer the holding time, the more efficient the process, i.e. the greater the sterilising effect.

The sterilising effect is expressed by the number of decimal reductions achieved in the process. For example, a sterilising effect of 9 indicates that out of 109 bacterial spores fed into the process, only 1 (100) will survive. A commonly used terminology is also logarithmic reduction expressed, for example: 9 log reduction.

The efficiency of the sterilisation process is mainly determined by two factors:

- The temperature and the length of time it is applied

- The heat resistance of the microorganisms

Other factors such as product composition, viscosity, uniformity and pH will also affect sterilising efficiency. The design of continuous-flow sterilisation equipment – ultra high temperature (UHT) treatment – usually has a sterilising effect of around 10 – 15 on bacterial spores capable of growing in ambient conditions.

Spores of Bacillus stearothermophilus are generally used as test organisms to determine the sterilising effect of UHT equipment since this strain forms fairly heat-resistant spores. Traditionally, before continuous-flow UHT, spores of Clostridium botulinum have been used for calculation of the effect of in-container sterilisation (see F0 value calculation) as this is the most heat-resistant pathogenic spore. F0 value is still quite frequently used as well as when analysing the heat load during UHT treatment. The UHT or sterilisation process must be designed in such a way that there is only a negligible risk that a product will be spoiled before the consumer uses it, or that it contains surviving and growing pathogenic microorganisms. Clostridium botulinum has always been considered the most significant microorganism in public health terms. Sterilisation processes were designed with the destruction of this microorganism’s spores in mind. However, in heat-treated milk and milk products, the probability of survival and growth of Clostridium botulinum spores is very low indeed.

The lethal effect on bacterial spores starts at a temperature of around 115 °C and increases very rapidly with increased temperature.

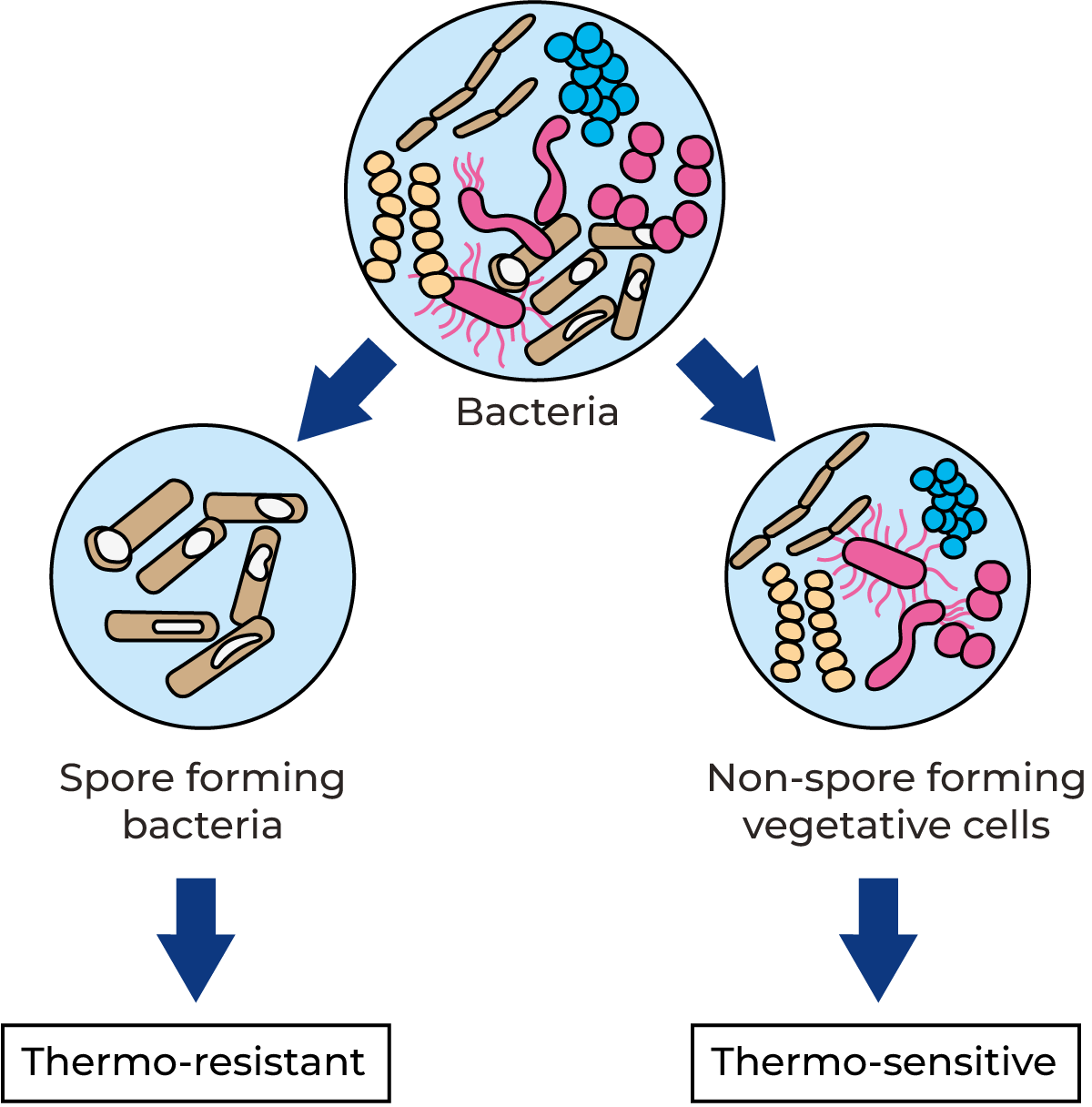

Bacteria can be divided into two groups:

- Vegetative bacteria: Those existing as vegetative cells only. Vegetative bacteria can metabolise, multiply and might cause food poisoning if pathogenic. Vegetative bacteria are easy to kill using heat or other means.

- Spore-forming bacteria: Existing as vegetative bacteria and as bacterial spores as well. While these bacteria are easily killed as long as they are in the vegetative state, their spores are difficult to eliminate. However, the spores cannot metabolise, multiply or cause food poisoning as long as they are still in spore form and if they survive, they need to have a favourable environment (temperature, water activity, etc.) for germination into a vegetative bacterium before being able to proliferate.

Dairy products that are to be heat treated contain a mixed flora of both vegetative bacteria and bacterial spores, as shown in Figure 10.1.

Unfortunately, the correlation between the two is not very good. High spore counts may be found in products with low total counts, and vice versa, so total count determination cannot serve as a reliable basis for the enumeration of spores in food products. Thus, analysing both vegetative and spores is important for analysing raw milk quality.

Q10 value

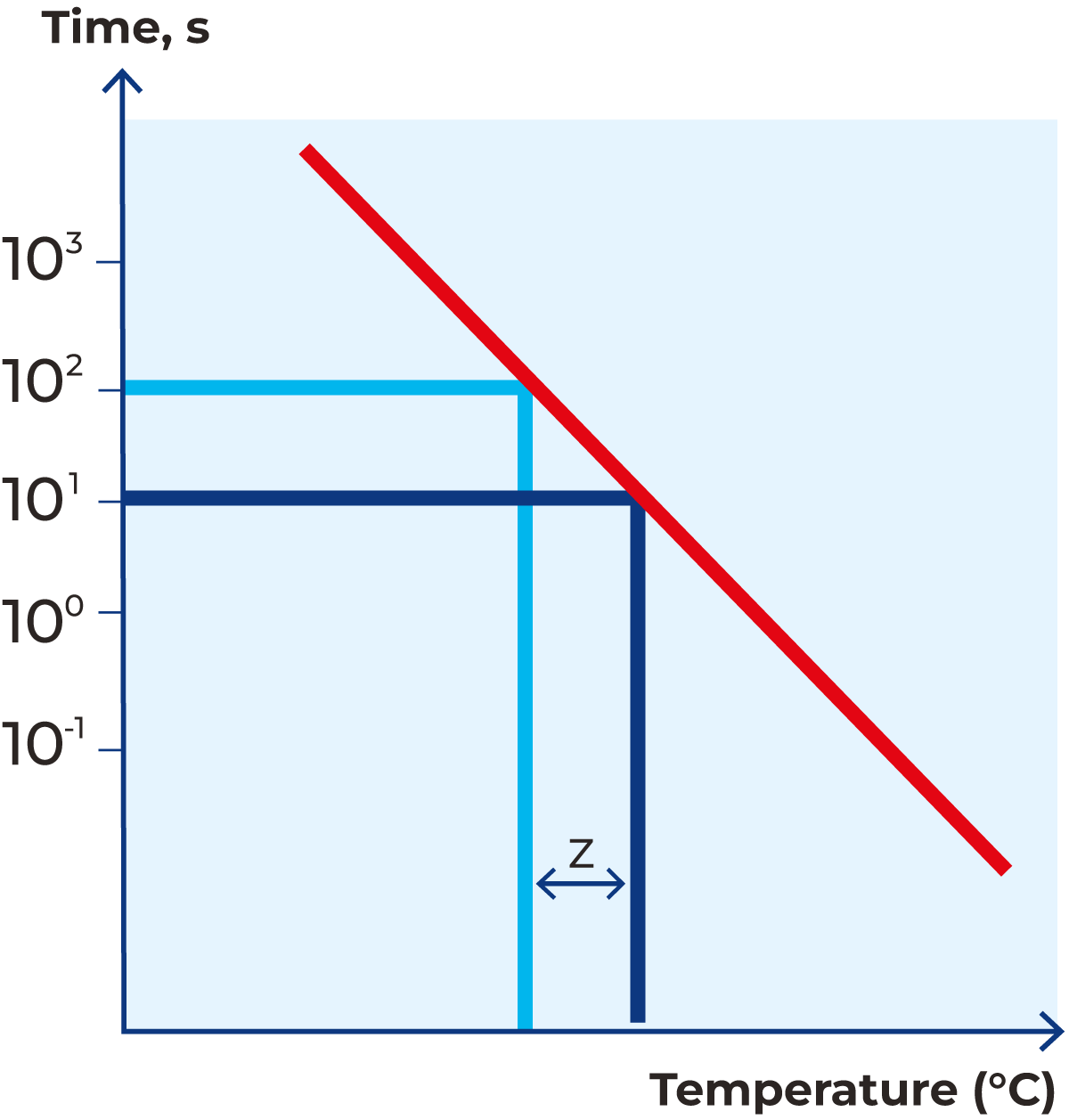

As mentioned above, the sterilising effect of heat treatment increases rapidly with increasing temperature. This, of course, also applies to chemical reactions occurring as a consequence of heat treatment. The Q10 value has been introduced as an expression of this increase in reaction speed. Q10 states how many times the speed of a reaction increases if the temperature of the system is raised by 10 °C.

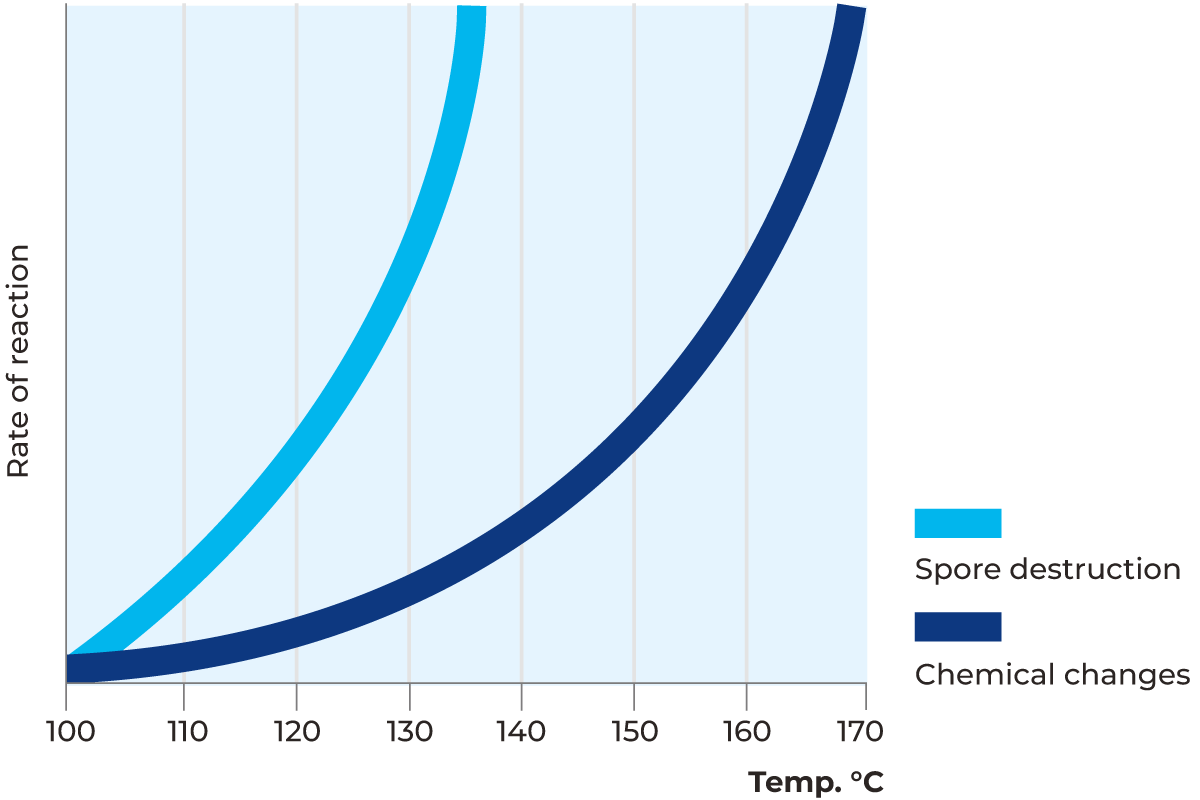

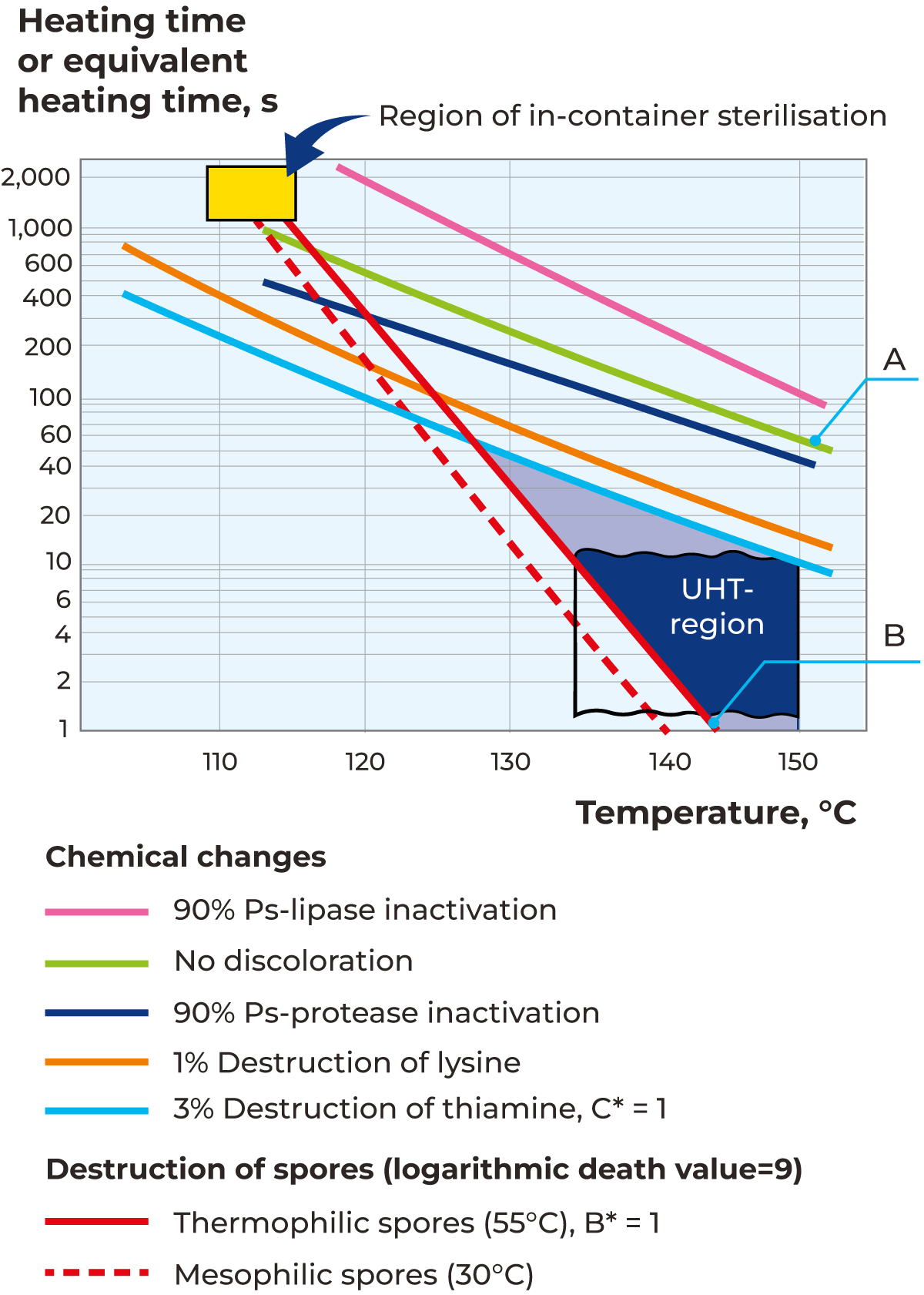

The Q10 value for flavour changes – and most chemical reactions – is around 2 to 3, i.e. if the temperature of a process is raised by 10 °C, the speed of chemical reactions doubles or triples. Q10 values can also be determined for the killing of bacterial spores. The values found range between 8 and 30. The variation is so wide because different kinds of bacterial spores react differently to temperature increases. The changes in chemical properties and spore destruction by the influence of increased temperature are shown in Figure 10.2. From this graph, we see that in the range of UHT temperatures (> 135 °C), the bacteriological killing effect increases considerably with temperature, whereas the rate of chemical changes remains modest. This shows that UHT treatment has an advantage over in-container sterilisation operating at low temperatures for a long time. Utilising ultra-high temperatures with short holding times on a dairy product provides a high sterilisation effect while causing only minimal chemical changes in the treated product. In-container sterilisation operating at low temperatures for a long time leads to more extensive changes in product quality. See Figures 10.5 and 10.6.

F0 value

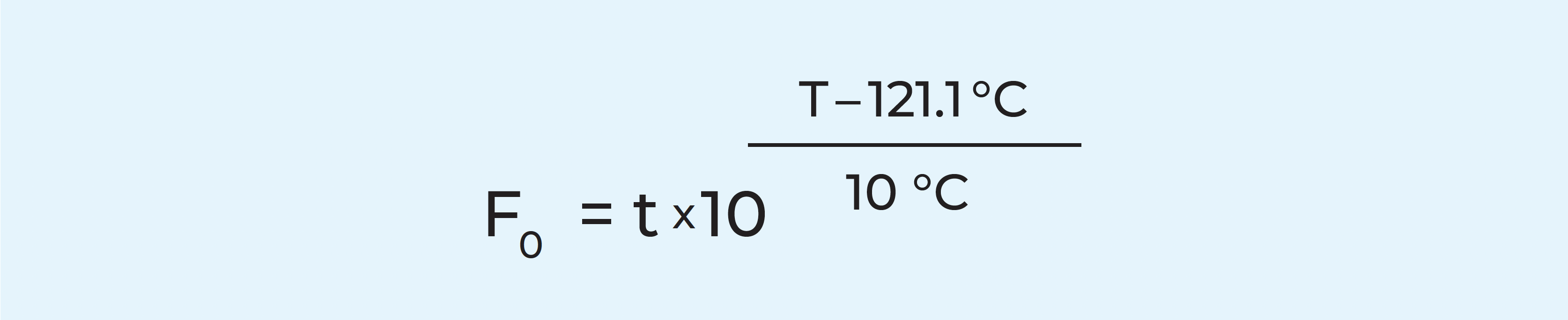

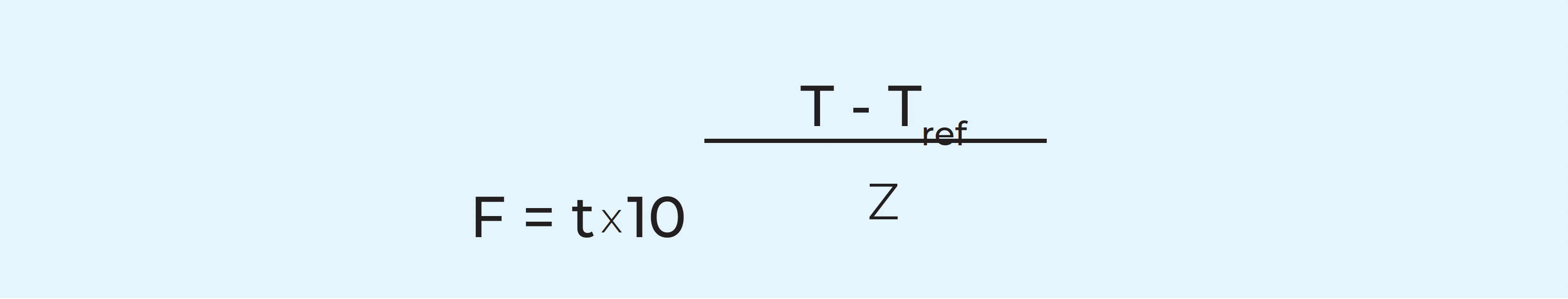

The combined effect of time and temperature on the killing rate of Clostridium botulinum spores is expressed in terms of the F0 value. It is calculated according to the following mathematical formula:

where:

t = sterilisation time most often expressed in minutes, e.g. the holding time in seconds divided by 60

T = sterilisation temperature in °C

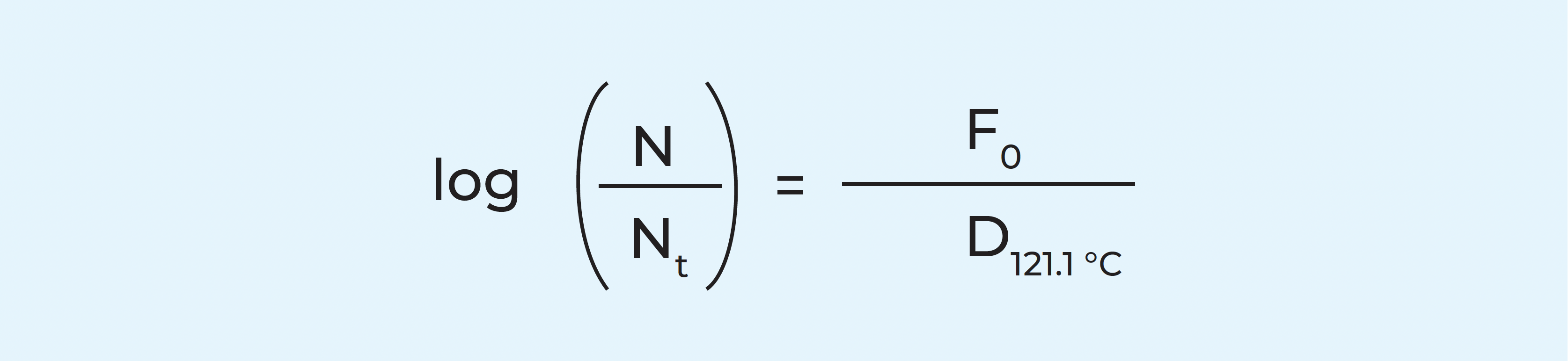

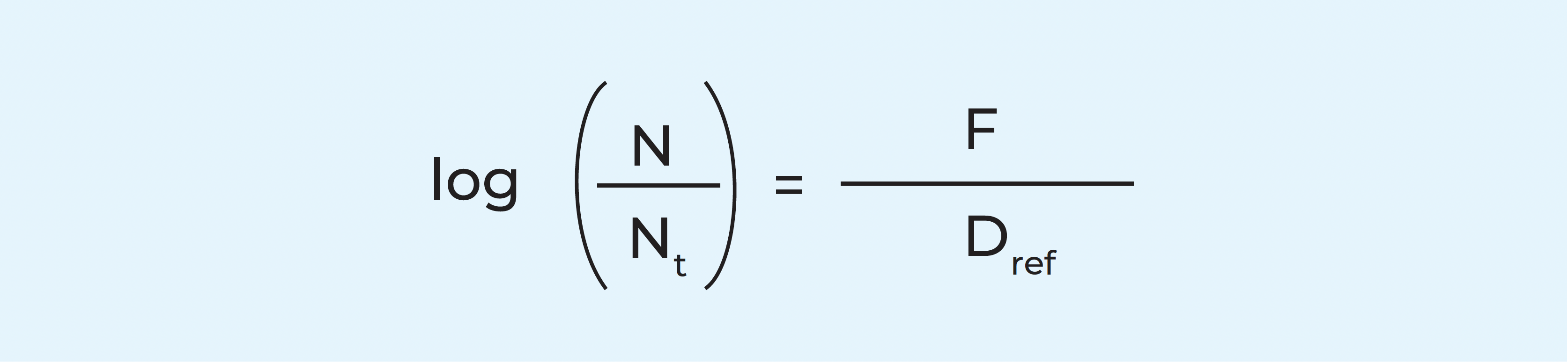

There is a direct correlation between the F0 value (expressed in minutes) and the logarithmic reduction of Cl. botulinum spores:

where:

N0 = the number of spores of Clostridium botulinum at time 0

Nt = the number of spores in the final product at time t

D121.1 °C = the time necessary at 121.1 °C for decimal reduction (1 logarithm = 1 log) of spores of Clostridium botulinum (about 0.25 minutes)

Based on that F0 value, 1 minute gives 4 log reduction of Clostridium botulinum spores.

A general guide commonly used to obtain commercially sterile milk from good quality raw milk in practice is to apply a heat treatment corresponding to an F0 value of 5 – 6 minutes. According to legislation in some countries, a minimal F0 value of 3 minutes is required for a food safety perspective (correspondent to 12 log reduction of spores of Clostridium botulinum). The actual F0 needed to obtain commercial sterility and food safety is dependent on the microbiological flora in the product before heat treatment.

As mentioned above, the F0 value is valid just for spores of Clostridium botulinum with a specific z-value of 10 °C. Similar values can be calculated for other microorganisms but then the value will be called the F value and other z-values will be used:

Note that the index 0, reserved for Clostridium botulinum spores, is omitted and

where:

Tref = the reference temperature, in °C, at which Dref is valid

z = the temperature increase, in °C, which is required to obtain the same lethal effect at a 10th of the time (for example, 10.5 °C for Bacillus stearothermophilus spores)

Dref = the decimal reduction time for the microorganism at the temperature Tref

It should be noted that the z-value used in the F and F0 equation above is the z-value at the reference temperature Tref (i.e. zref) however, the actual z-value changes with temperature (ztemp). Normally, the difference between sterilisation and reference temperature is comparably small (temperature change of about 20 °C maximum), the z-value (i.e. zref) might be an acceptable approximation, but further extrapolation is not recommended. However, as the killing of bacterial spores starts around 115 °C, the spore reduction is taking place the entire time the product is above this temperature – not only at the final temperature, which is most often neglected.

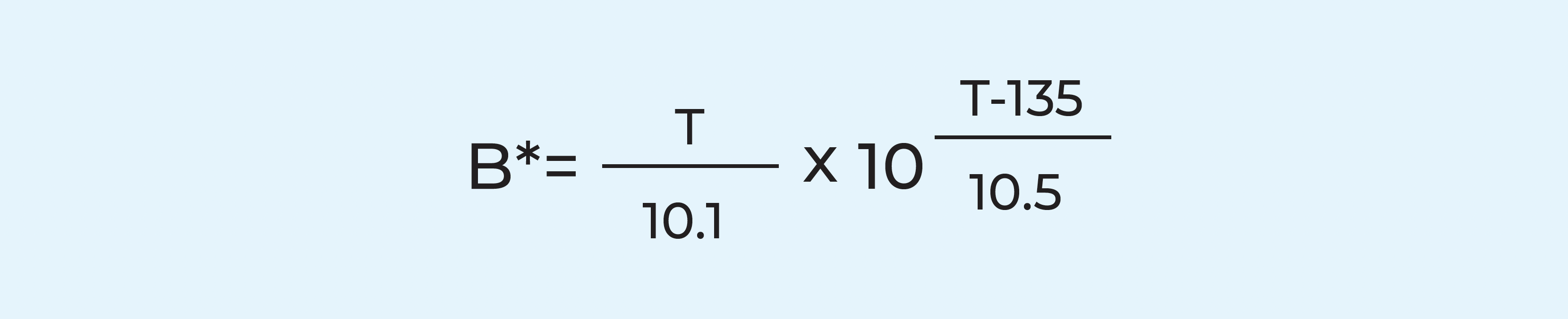

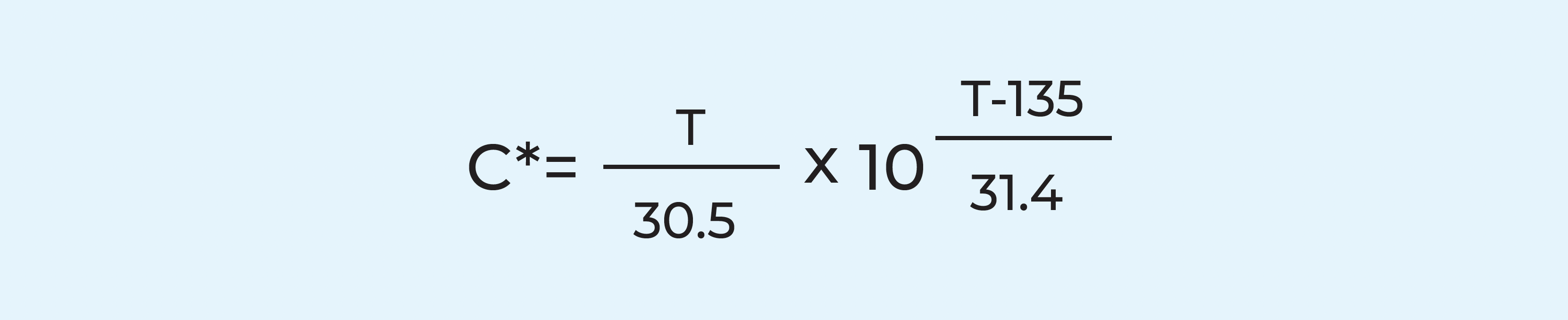

B* and C* values

The relationship between temperature and time for UHT treatments is also defined by reference to two other parameters:

Bacteriological effect: B* (known as B star)

Chemical effect: C* (known as C star)

These values are based on experiments performed by Horak (1980) on milk where the destruction of thermophilic spores was studied (incubated at 55 °C to enumerate thermophilic microorganisms). The results were presented in the form of a straight line relating log of time against temperature at a constant sterilising effect. These data were extrapolated to give the line that would correspond to 9 decimal reductions of this natural thermophilic spore population – B* value 1.

B* is based on the assumption that commercial sterility is achieved at 135 °C for 10.1 seconds. with a corresponding z-value of 10.5 °C. This reference process is given a B* value of 1.0.

Similarly, the C* value of 1 is based on the conditions for 3% destruction of thiamine. This is equivalent to 135 °C for 30.5 seconds with a z-value of 31.4 °C.

Generally, a UHT process operates satisfactorily with regard to the keeping quality of the product when the following conditions are fulfilled:

C* < 1

Commercial sterility regulations

Commercial sterility means the absence of microorganisms capable of growing in the food at normal non-refrigerated conditions at which the food is likely to be held during manufacture, distribution, and storage. The temperature and time combination to achieve commercial sterility is often referred to as a combination within 135 – 150 °C for 1 – 10 seconds. However, as the necessary applied heat load to achieve commercial sterility is dependent on the microbiological status of the raw material, the actual necessary temperature and time might be higher and longer.

Legislations related to UHT processing

The condition achieved by application of heat, sufficient, alone or in combination with other appropriate treatments, to render the food free from microorganisms capable of growing in the food at normal non-refrigerated conditions at which the food is likely to be held during distribution and storage.

UHT (ultra-high temperature) treatment of milk and liquid milk products is the application of heat to a continuously flowing product using such high temperatures for such time that renders the product commercially sterile at the time of processing. When UHT treatment is combined with aseptic packaging, it results in a commercially sterile product.

The condition achieved by the application of heat which renders the food free of microorganisms capable of reproducing in the food under normal non-refrigerated conditions of storage and distribution; and viable microorganisms (including spores) of public health significance; or by the control of water activity and the application of heat, which renders the food free of microorganisms capable of reproducing in the food under normal non-refrigerated conditions of storage and distribution. According to CFR Title 21§113.3 / Pasteurized milk ordinance, the term “Ultra-Pasteurized” is used when a milk and/or milk product has been heat treated at or above 138 °C for at least 2 seconds before or after packaging.

According to EU Regulation 1662/2006 amending EU Regulation 853/2004, specific hygiene rules for food of animal origin:

Ultra-high temperature (UHT) treatment is achieved by a treatment involving a continuous flow of heat at a high temperature for a short time (not less than 135 °C in combination with a suitable holding time) such that there are no viable microorganisms or spores capable of growing in the treated product when kept in an aseptic closed container at ambient temperature.

Sufficient to ensure that the products remain microbiologically stable after incubating for 15 days at 30 °C in closed containers or for seven days at 55 °C in closed containers or after any other method demonstrating that the appropriate heat treatment has been applied.

In practice, the temperature range of UHT is 137 – 142 °C for 4 – 6 seconds but is product dependent.

Verification of commercial sterility

The products subjected to commercial sterilisation must be microbiologically stable at room temperature, either measured after storage until the end of shelf life or incubated at 55 °C for 7 days (or at 30 °C for 15 days) in accordance with appropriate standards.

“The fastest moving particle”

To achieve commercial sterility, the product is heated to the sterilisation temperature and is held at that temperature for the time necessary to achieve commercial sterility. In a continuous product flow, like UHT treatment, the time needed to achieve commercial sterility takes place in the holding section or tube, (Codex Alimentarius Commission (WHO/FAO)). It is therefore essential that the flow rate for the fastest particle/volume element or shortest retention time is adequately determined for each product flow, design of holding cell, product type and characteristics. Particular attention to the fastest particle is paid in some countries (especially the United States) with special reference to the holding time for the “fastest moving particle”.

Depending on the flow pattern of the liquid (turbulent or laminar flow), the efficiency coefficient for milk is in the interval of 0.5 – 1.00. This involves applying a correction factor in calculations of holding times. In special cases, for example in the US, it is calculated that the fastest moving particle passes a holding cell twice as fast as the average particle, i.e. the efficiency coefficient (η) is 0.5. In most relevant cases in industrial installations, the equipment is designed for maintaining turbulent flow, and an efficiency factor of 0.85 – 1.00 is utilised.

Chemical and bacteriological changes at high heat treatment

When milk is held at a high temperature for a long time, certain products are formed by chemical reactions, which can cause discolouration as a result of the Maillard reaction (browning). It also acquires a cooked and caramelised flavour, and there is occasionally a great deal of sediment formation. By heat treating the milk at higher temperatures for a shorter time, many of these defects are largely avoided. However, the optimum time/temperature combination must be chosen to enable satisfactory spore destruction to achieve commercial sterility while keeping heat load or damage to the product to a minimum.

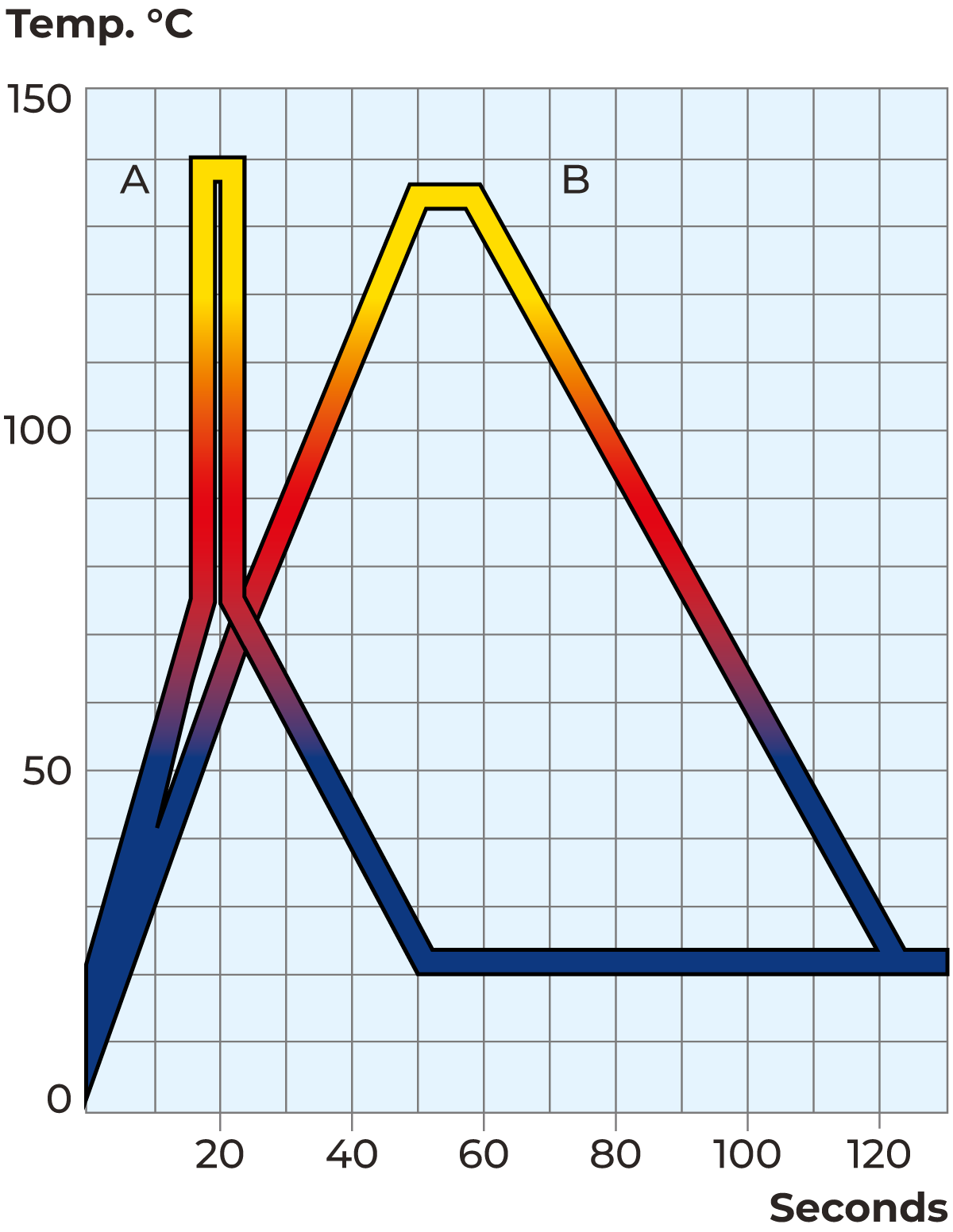

Figure 10.4 shows the relationship between the sterilising effect and the browning reaction in milk. Line A represents the lower limit of time/temperature combinations that cause the milk to turn brown. Line B is the lower limit of combinations for commercial sterility (B* > 1, destruction of thermophilic spores). The regions for in-container sterilisation and UHT treatment are also marked in the figure.

The figure shows that while the two methods have the same sterilising effect, there is a great difference in the chemical effects: the browning reaction and destruction of vitamins and amino acids. As described with the Q10 value, at higher temperatures the change in speed of killing of microorganisms is larger than from chemical reactions. Therefore, at higher temperatures for shorter times, the changes are much smaller. This is the reason UHT milk tastes better and has a higher nutritive value than in-container sterilised milk.

Taste is a very subjective factor and UHT-treated milk has improved over the years. As a result of applying an optimum UHT treatment to a milk of good quality, many people find it very difficult to tell the difference between UHT and pasteurized milk.

As was mentioned in Chapter 2, when milk is heat treated, lactulose is formed from lactose and this chemical reaction is used as an indicator for heat load applied to the milk. By analysing their lactulose contents, it is possible to differentiate pasteurized, UHT and in-container sterilised milk but it is also possible to differentiate between the different UHT heating technologies (see paragraph about UHT treatment). The lower the heat load has been, the lower the lactulose content and less impact on sensory and other chemical reactions.

Since the introduction of UHT-treated milk to the market, the quality and primarily the sensory attributes have been discussed. In the early days, even if the colour of UHT milk was almost the same as for a pasteurized milk, the UHT milk had a cooked flavour and sulfuric smell. The cooked off notes that were not well accepted by some consumers in some countries originated from structural changes in the proteins, denaturation, and interactions between proteins (Chapter 2). However, since then, due to many efforts to improve the product quality, the flavour of UHT milk has come closer to that of ordinary pasteurized milk.

In this context, it is important to mention that the temperature at which the milk is organoleptically tested has a big influence on the result. At refrigeration temperature, around 5 – 7 °C, the UHT flavour is suppressed. Therefore, when, for instance, a comparison is made between the influence of various methods of UHT treatment, the organoleptic evaluation should be carried out at 20 °C after the samples have been stored at 20 °C for various periods, for example, 2, 4 and 6 weeks.

Tests carried out in this way show that significant differences exist between direct and indirect methods, the latter exposing the milk to a higher heat load.

Shelf life

Another term used in connection with UHT treatment to characterise the quality of the treatment is the shelf life of the product. This is defined as the period during which a product can be stored without the quality falling below a certain acceptable minimum level. Shelf life for commercially sterile products is not governed by microbiological growth, as all microorganisms capable of growing have been killed. Thus, it is somewhat subjective and depends to a large extent on consumer and producer acceptance levels, which may differ from producer to producer or country to country.

The physical and chemical limiting factors of shelf life are cream layer formation, incipient gelling, increase in viscosity and heavy sedimentation. The organoleptic limiting factors are deterioration of taste, smell or colour. How fast these changes take place depends on both the raw milk quality and the processing and storage conditions.

Cream layer formation

In most countries, packed milk is expected to be homogeneous, i.e. when a consumer opens a package of milk, they do not wish to see a cream layer floating on the top surface. On the other hand, creaming is a natural phenomenon, with milk fat globules having a lower density than milk serum and thus with time will rise to the top of the package. As outlined in section 7.3 on homogenizers, high-pressure homogenization is used to decrease the size of the fat globules and thus decrease the rate of cream layer formation. For UHT milk, it is important to adjust the degree of homogenization and the resulting NIZO value after the intended shelf life. A milk sold on a local market with, e.g. 3 months of shelf life can be homogenized to a lower degree than milk sent for export with a shelf life of, e.g. 9 months. It should be noted that homogenization alone is not the only factor responsible for creaming. Storage of the milk during its shelf life will also have a large impact on how fast the creaming takes place. In addition, as will be outlined below, raw milk quality and enzymatic activity are also factors.

Enzymatic activity

In addition to being governed by the natural creaming phenomena described above, shelf life can also be limited by enzymatic activity. Enzymes are active proteins that have the ability to cut other proteins into smaller pieces. This action will then lead to loss of the colloidal stability, causing sedimentation and gelation to occur. In addition, bitter off-flavours may develop. In milk, there are two main groups of enzymes: plasmin, which are indigenous enzymes originating from the cow's immune system, and bacterial enzymes produced by mainly Gram-negative (G-) psychrotrophic bacteria. It’s important to note here that the enzymes are produced in the raw milk, when the bacteria are still alive. After the UHT treatment, the bacteria are killed, but due to the high heat stability, the enzymes remain active.

How much enzymatic activity remains in the milk after heat treatment depends largely on the severity of the heat treatment. In general, an indirect heat treatment inactivates more enzymes than a direct heat treatment. For example, in indirectly produced UHT milk, almost all plasmin is inactivated, and shelf life is mainly regulated by the bacterial proteases. While in UHT milk produced in a direct system, both plasmin and bacterial proteases remain active.

The higher the raw milk quality, the less enzymes in the milk. This implies clean milking equipment, cooling of the milk directly after milking and as little time from milk collection to processing as possible. This is all to keep the levels of bacteria low and give them as little time as possible to produce heat-stable enzymes. Healthy cows are the most important factor in keeping plasmin levels in milk low.

Nutritional aspects

When studying any type of food process, it is important to consider the nutritional aspects. Extensive research has been carried out on the effect of heat treatment on milk, and the effect of UHT treatment on the constituents of milk can be summarised as shown in the text box:

Fat: No changes

Lactose: Marginal changes

Proteins: Partial denaturation of whey proteins

Mineral salts: Partial precipitation

Vitamins: Marginal losses

There are no changes in the nutritional value of fat, lactose and mineral salts, but there are marginal changes in the nutritional value of proteins and vitamins.

The major protein in milk, casein, is not affected by heat treatment. Denaturation of whey proteins does not mean that the nutritional value (in terms of biological value/bioavailability, i.e. digestibility and availability of lysine for our body to absorb) is lower in UHT milk than in raw milk. UHT treated milk compared to raw milk has no significant difference in nutritional value, but in-container sterilisation results in reduced nutritional value.

The small loss of the essential amino acid lysine causes marginal changes. However, it has been shown that about 0.4 – 0.8% of the lysine is lost, and this figure is the same for pasteurized milk. The corresponding value for in-container sterilised milk is 6 – 10%.

Some of the vitamins in milk are considered to be more or less thermostable regarding pasteurization or UHT treatment. Among these are the fat-soluble vitamins A, D and E and some of the water-soluble group B vitamins. However, the degradation of vitamin A can be much higher if the product is fortified. Other vitamins are less stable in response to heat, e.g. B9 (folic acid) and B12 (cobalamin). The time/temperature curve in Figure 10.4 shows that thiamine losses are less than 3% in UHT-treated milk, but considerably higher in in-container sterilised milk (approximately 20 – 50%). The same relationship regarding the destruction of vitamins can be found in all other heat-sensitive vitamins in UHT and in-container sterilised milk, for example, B6, B12, folic acid and vitamin C. Losses of vitamin B2 and vitamin C in in-container sterilised milk may be as high as 100%. Some of the vitamins, e.g. folic acid and vitamin C, are oxidation-sensitive, and their losses occur mainly during storage due to a high oxygen content in the milk or the package. However, milk is not a good source of vitamin C and folic acid, as the content is far below the recommended daily intake.

The general conclusion should therefore be that UHT milk and pasteurized milk are of about the same quality, while in-container sterilised milk is of inferior quality in terms of nutritional value.

Production of long-life dairy products

Two methods are used for the production of long shelf-life milk for ambient storage:

- In-container sterilisation

- Ultra-high temperature (UHT) treatment followed by aseptic filling into packages, protecting the product against light and atmospheric oxygen.

In-container sterilisation

Two processes are used for sterilisation in bottles or cans:

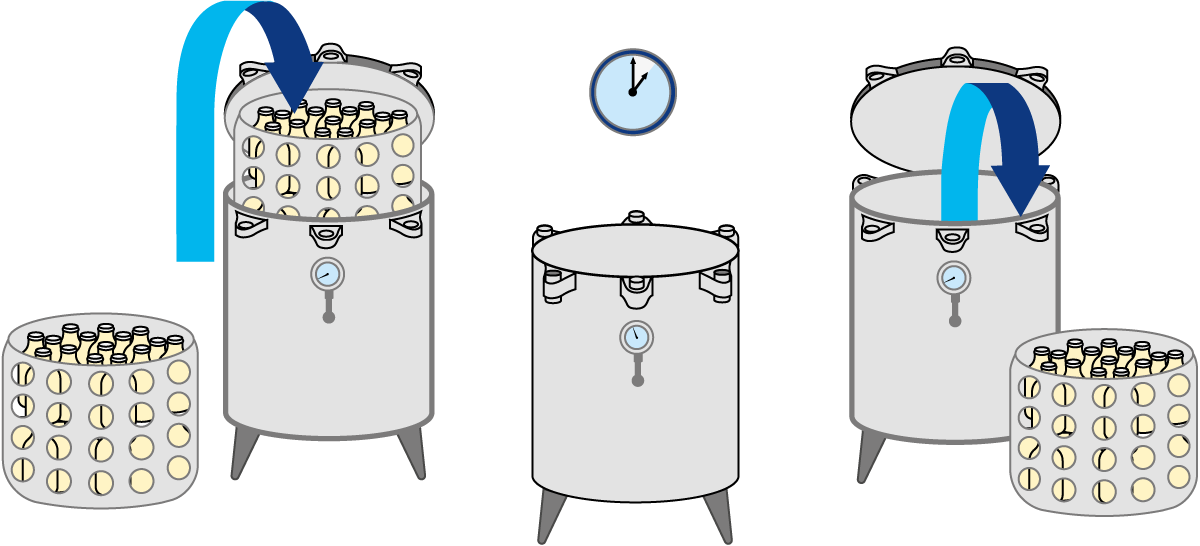

- Batch processing in autoclaves, Figure 10.7

- Continuous processing systems such as:

- Vertical hydrostatic towers, Figure 10.8

- Horizontal sterilisers, Figure 10.9

Batch processing

The batch system can be operated by three methods:

- In stacks of crates in a static pressure vessel (autoclave), Figure 10.7

- In a cage that can be rotated in a static autoclave

- In a rotary autoclave

The rotary methods have an advantage over the static method due to the quicker uptake of heat from the heating medium, the greater uniformity of treatment concerning bacterial kill and the colour of the finished product.

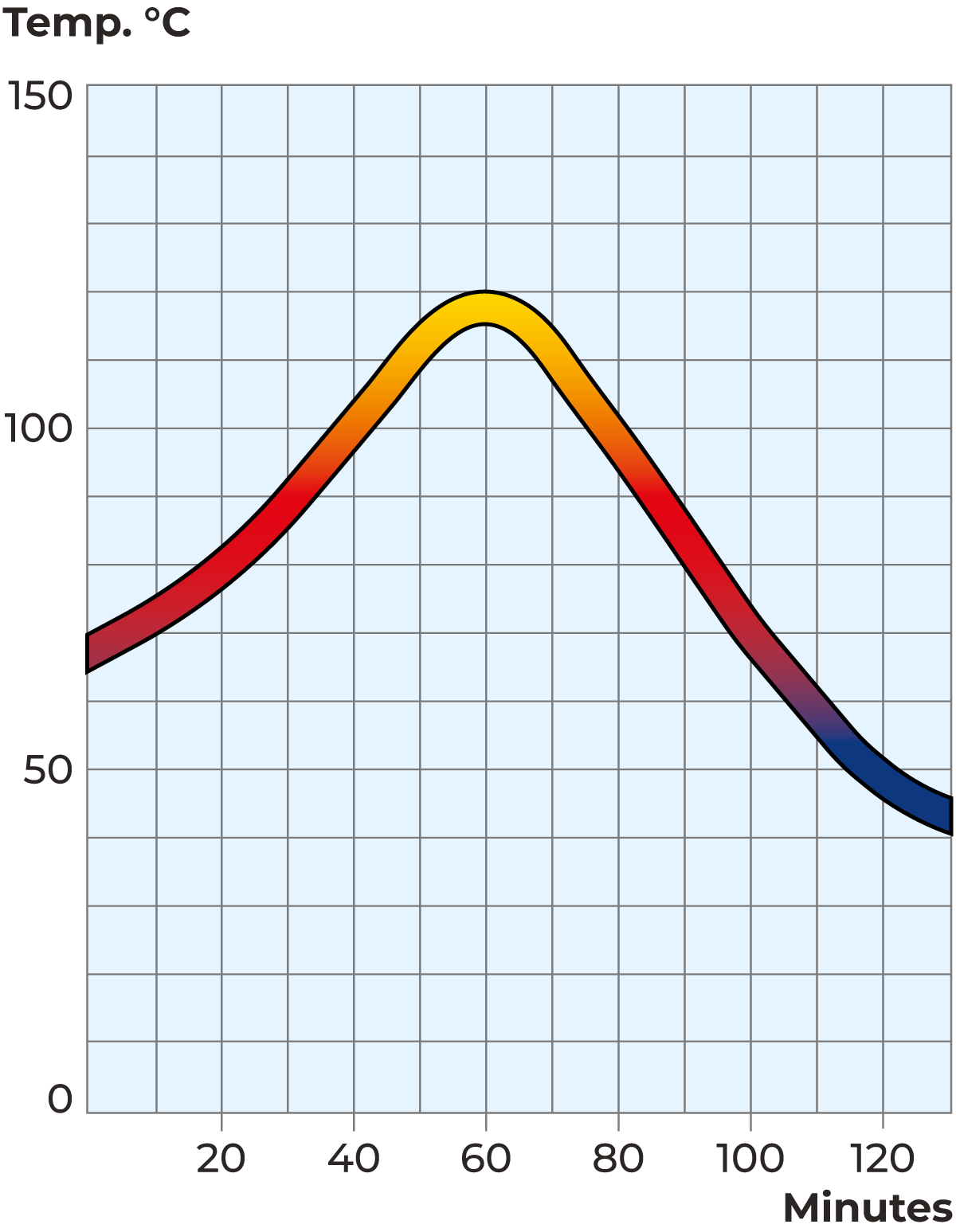

In autoclave sterilisation, the milk is usually pre-heated to about 80 °C and then transferred to clean, heated bottles. The bottles are capped, placed in a steam chamber and sterilised, normally at 110 – 125 °C for 3 – 40 minutes. The batch is then cooled, and the autoclave is filled with a new batch. The principle is the same for cans.

Batch sterilisation in autoclaves is a technique that is used more often for canned solid foods than for liquid products. The fact that sterilisation takes place after bottling or canning eliminates the need for aseptic handling, but on the other hand, heat-resistant packaging materials must be used.

Continuous processing

Continuous systems are normally preferred, and these operate at higher capacities. For continuity of operation, the design of machines for continuous production depends on the use of a pressure lock system through which the filled containers pass from low-pressure/low-temperature conditions into a relatively high-pressure/high-temperature zone. After this, they are subjected to steadily decreasing temperature/pressure conditions and are eventually cooled with chilled or cold water.

There are two main types of machines on the market for continuous sterilisation, differing in the type of pressure lock system used.

- The hydrostatic vertical bottle steriliser

- The horizontal rotary valve-sealed steriliser

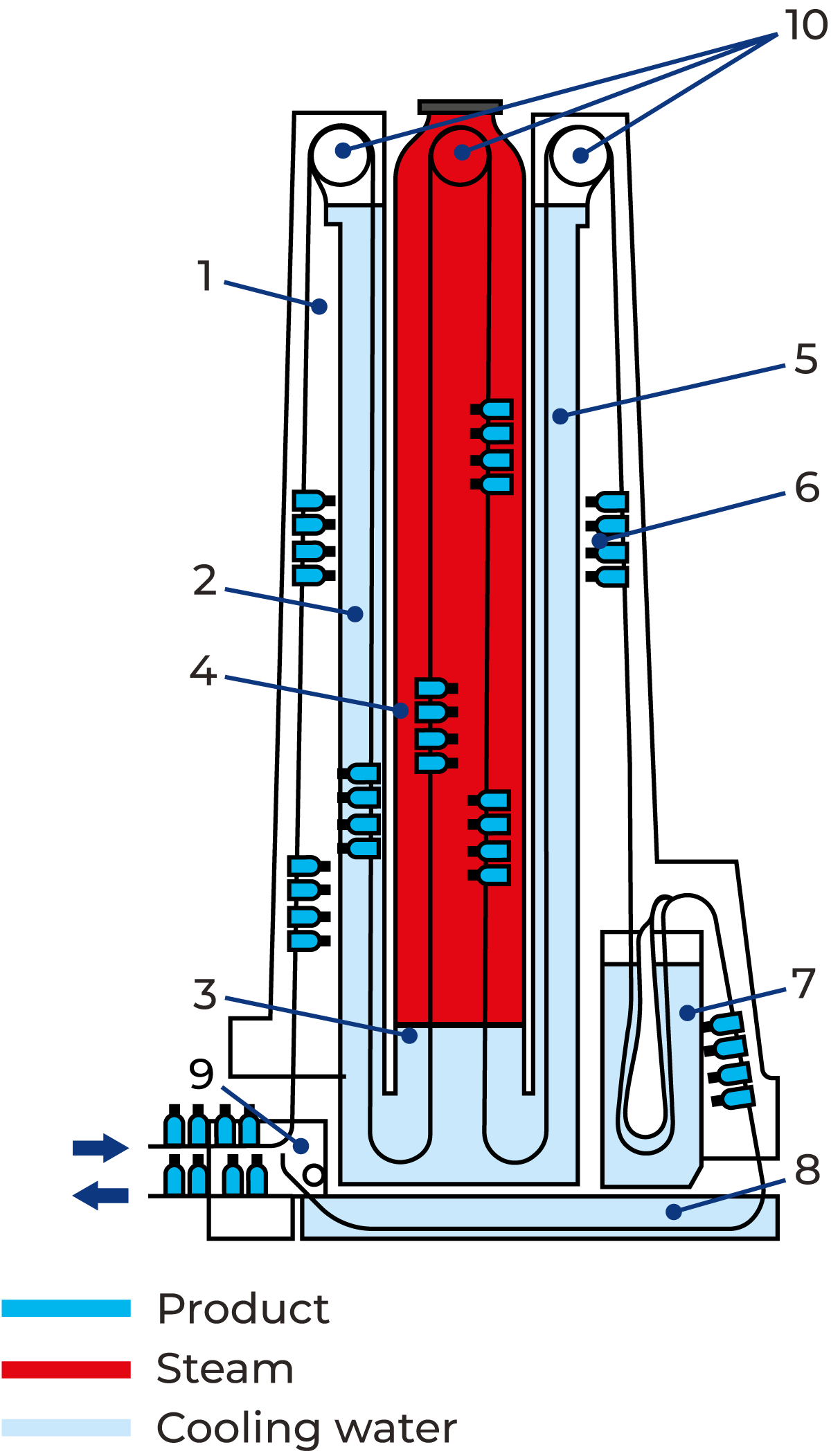

Hydrostatic vertical steriliser

This type of steriliser, often referred to as the tower steriliser (Figure 10.8), basically consists of a central chamber maintained at sterilising temperature by steam under pressure, counterbalanced on the inlet and discharge sides by columns of water providing equal pressure. The water on the inlet side is heated and the water on the outlet side is cooled, each at a temperature adjusted to give maximum heat uptake/ abstraction compatible with avoidance of breakage of the glass due to thermal shock.

In the hydrostatic tower, the milk containers are slowly conveyed through successive heating and cooling zones. These zones are dimensioned to correspond to the required temperatures and holding times in the various treatment stages.

In many cases, the milk is pre-treated in a pre-sterilising plant similar to a UHT plant. The milk is heated to 135 °C or higher for a few seconds and then cooled to 30 – 70 °C (depending on the material of the bottle – as a rule, plastic bottles require the lower temperature), and transferred to clean, heated bottles before it is treated in the hydrostatic tower. Pre-sterilisation can take place in an indirect or direct plant. The main reason for pre-sterilisation is either to decrease the number of spores that will be finally removed by the second sterilisation in the container or to achieve the same sterility level in the pre-sterilisation step as in the UHT plant. Thus, the second sterilisation will remove only the microorganisms that entered the product due to the non-aseptic filling process (F0 = 1 – 2 minutes). Both pre-sterilisations are applied in order to lower the heat load in the heating tower, reducing unwanted the unwanted chemical and organoleptic changes and approaching the quality obtained by the UHT process followed by aseptic filling.

The time cycle of a hydrostatic steriliser is approximately one hour, including 3 – 30 minutes for passage through the sterilising section at 115 – 125 °C.

The hydrostatic steriliser is suitable for sterilisation of bottles made of glass or plastic.

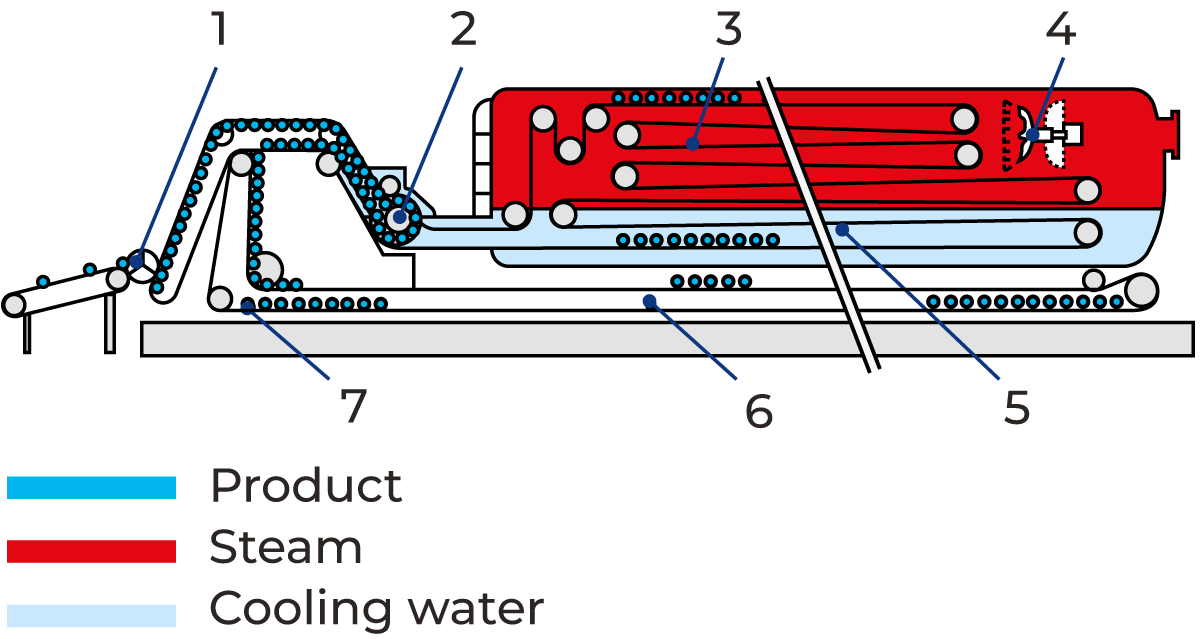

Horizontal sterilizer

The rotary valve-sealed steriliser (Figure 10.9) is a comparatively low-built machine with a mechanically driven valve rotor, through which the filled containers are passed into a relatively high-pressure/high-temperature zone, where they are subjected to sterilising temperatures of 132 – 140 °C for 10 – 12 minutes.

With an overall cycle time of 30 – 35 minutes, a capacity of 12,000 units per hour can be achieved.

The rotary valve-sealed steriliser can be used for sterilisation of plastic bottles and glass bottles, as well as flexible containers made of plastic film and plastic laminates.

Another system that ought to be mentioned in this context is the horizontal continuous rotating autoclave for evaporated milk in cans. This design comprises design comprises three cylindrical vessels, each containing a helical strip attached to a roller inside the vessel. Several channels are formed so that the cans are forwarded along the roller during processing and simultaneously rotated. This type of steriliser is also equipped with a double detector system – one at the exit of the pre-heater and the other at the end of the pressure cooler – making it possible to detect non-sterile cans.

UHT treatment

In a modern UHT plant, the milk is pumped through a closed system. On the way it is pre-heated, high-heat treated, homogenized, cooled and filled into a package aseptically without any reinfection. Low-acid liquid products (pH above 4.5 – milk is more than pH 6.5) are usually treated at 135 – 150 °C for a few seconds, by either indirect heating, direct steam injection or steam infusion. All parts of the system downstream of the actual high-temperature heating section are of aseptic design to eliminate the risk of reinfection.

Compared to traditional sterilisation in hydrostatic towers, UHT treatment of milk saves time and labour, and utilises less energy and space. As UHT is a high-speed process and the milk passes the final temperature much faster, it has much less heat intensity compared to in-container sterilisation and as a result much less effect on the colour and flavour of the milk.

Aseptic processing

UHT technology preserves liquid food products by exposing them to brief, intensive heating. This treatment destroys the microorganisms in the product and makes it commercially sterile.

As discussed, commercial sterility applies only as long as the product remains under aseptic conditions. It is therefore necessary to prevent re-infection during transportation and filling. After heat treatment, the product must be transported and filled in previously sterilised packaging materials under aseptic conditions. Any intermediate storage between treatment and packaging must also take place under aseptic (sterile) conditions. This is why UHT processing is also called aseptic processing.

Development UHT

UHT technology preserves liquid food products by exposing them to brief, intensive heating. This treatment destroys the microorganisms in the product and makes it commercially sterile.

As discussed, commercial sterility applies only as long as the product remains under aseptic conditions. It is therefore necessary to prevent re-infection during transportation and filling. After heat treatment, the product must be transported and filled in previously sterilised packaging materials under aseptic conditions. Any intermediate storage between treatment and packaging must also take place under aseptic (sterile) conditions. This is why UHT processing is also called aseptic processing.

General UHT operating phases

These operating phases are common to all UHT systems and are therefore not described under each system.

Pre-sterilisation

Before the start of production, the plant must be pre-sterilised to avoid reinfection of the treated product.

The pre-sterilisation involves:

- Hot water sterilisation so that the minimum temperature necessary (normally 125 °C) will be reached at all points in the line in contact with the product. The minimum time for hot water sterilisation is 30 minutes from the moment the relevant temperature has been reached in the whole aseptic part of the plant.

- Adjustment of the plant to conditions required for production.

Production

The production phases vary according to the different processes and are described below.

Aseptic intermediate cleaning

Aseptic intermediate cleaning (AIC) is a useful tool in cases where a plant is used for very long production runs. A 30-minute AIC can be carried out whenever it is necessary to remove fouling in the production line without losing aseptic conditions. The plant does not have to be resterilised after AIC, which decreases downtime and permits longer production runs, as well as reducing energy and cleaning chemicals consumption.

Common aseptic products

- Fresh and recombined liquid milk

- Concentrated milk

- Dairy creams

- Flavoured milk drinks

- Fermented milk products (yoghurt, buttermilk, etc.)

- Whey-based drinks

- Ice cream mix

- Desserts (custards and puddings)

- Protein drinks

- Soy drinks

- Baby foods

- Fruit and vegetable juices

- Beverages such as tea and coffee

- Toppings and creams based on vegetable fat

- Soups

- Sauces

- Purées

- Dressings

- Nutritional solutions

CIP

The full CIP cycle takes 70 to 90 minutes and is normally carried out immediately after production.

The CIP cycle for direct or indirect UHT plants may comprise sequences for pre-rinsing, caustic cleaning, hot-water rinsing, acid cleaning and final rinsing, all automatically controlled according to a pre-set time/ temperature program. The CIP program must always be optimised for different operating conditions in different plants.

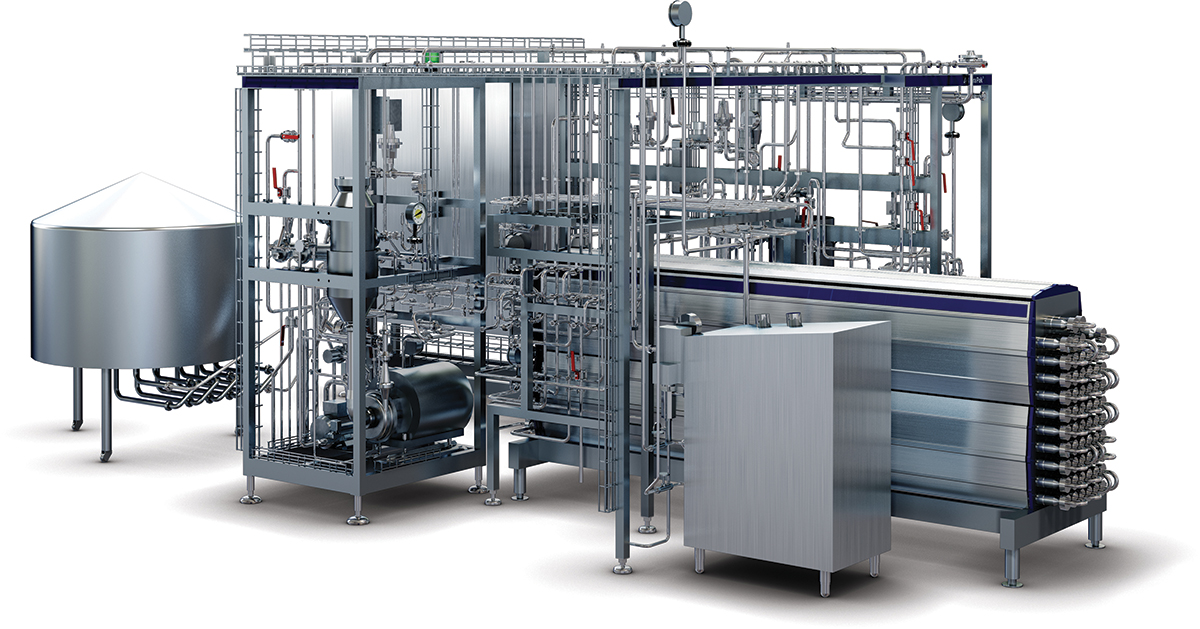

UHT systems

UHT treatment is a continuous process, and its application is therefore limited to products that can be pumped. UHT treatment can be applied to a wide range of dairy and food products. The list shown is not exhaustive. Many other liquid food products are likely to be of great interest to dairies in the future UHT plants are often flexibly designed to enable the processing of a wide range of products in the same plant. Both low-acid products (pH > 4.5) and high-acid products (pH < 4.5) can be treated in a UHT plant. However, only low-acid products require UHT treatment to make them commercially sterile. Spores cannot develop in high-acid products such as juice or fermented dairy products with pH < 4.5, and heat treatment is therefore intended only to kill yeast and moulds. Normal high temperature pasteurization (85 – 95 °C for 15 – 30 seconds) is sufficient to make high-acid products commercially sterile.

UHT plants are fully automatic and have four operating modes: plant pre-sterilisation (SIP), production, AIC (aseptic intermediate cleaning) and CIP (full cleaning in place). Safety aspects must be a prime consideration in the design of a UHT plant. The risk of supplying an unsterile product to the aseptic filling machine must be eliminated. Interlocks in the control programming provide security against operator errors and tampering with the process. It is, for example, impossible to start production if the plant is not properly pre-sterilised or if the system loses sterility during production. In such a case, this system automatically stops the production and has to be cleaned and sterilised.

All sequences involved in starting, running and cleaning the plant are initiated from a control panel, which contains all the necessary equipment for control, monitoring and recording of the process.

Various UHT systems

There are two main types of UHT systems on the market: direct and indirect. More on these systems can be found in Chapter 7.1.

Indirect heat treatment involves the transfer of heat through a stainless-steel wall between the medium and the product. In the direct systems, the product comes in direct contact with the heating medium, followed by flash cooling in a vacuum vessel.

The direct systems are divided into:

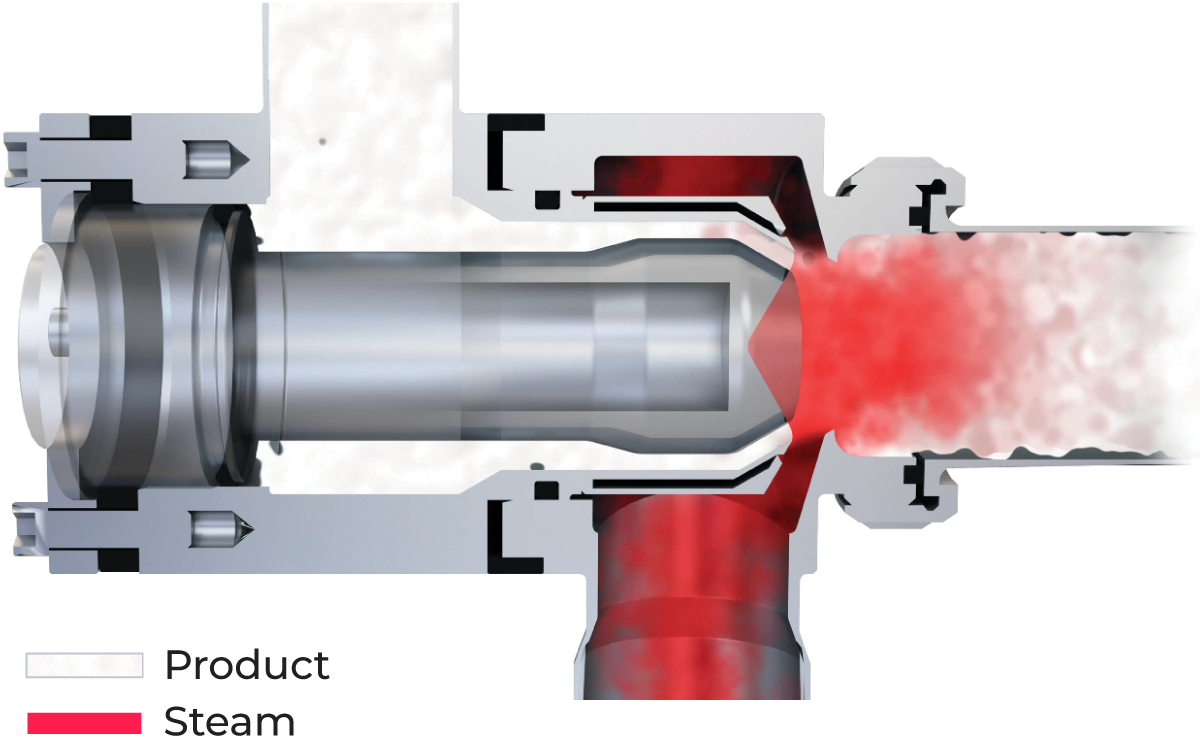

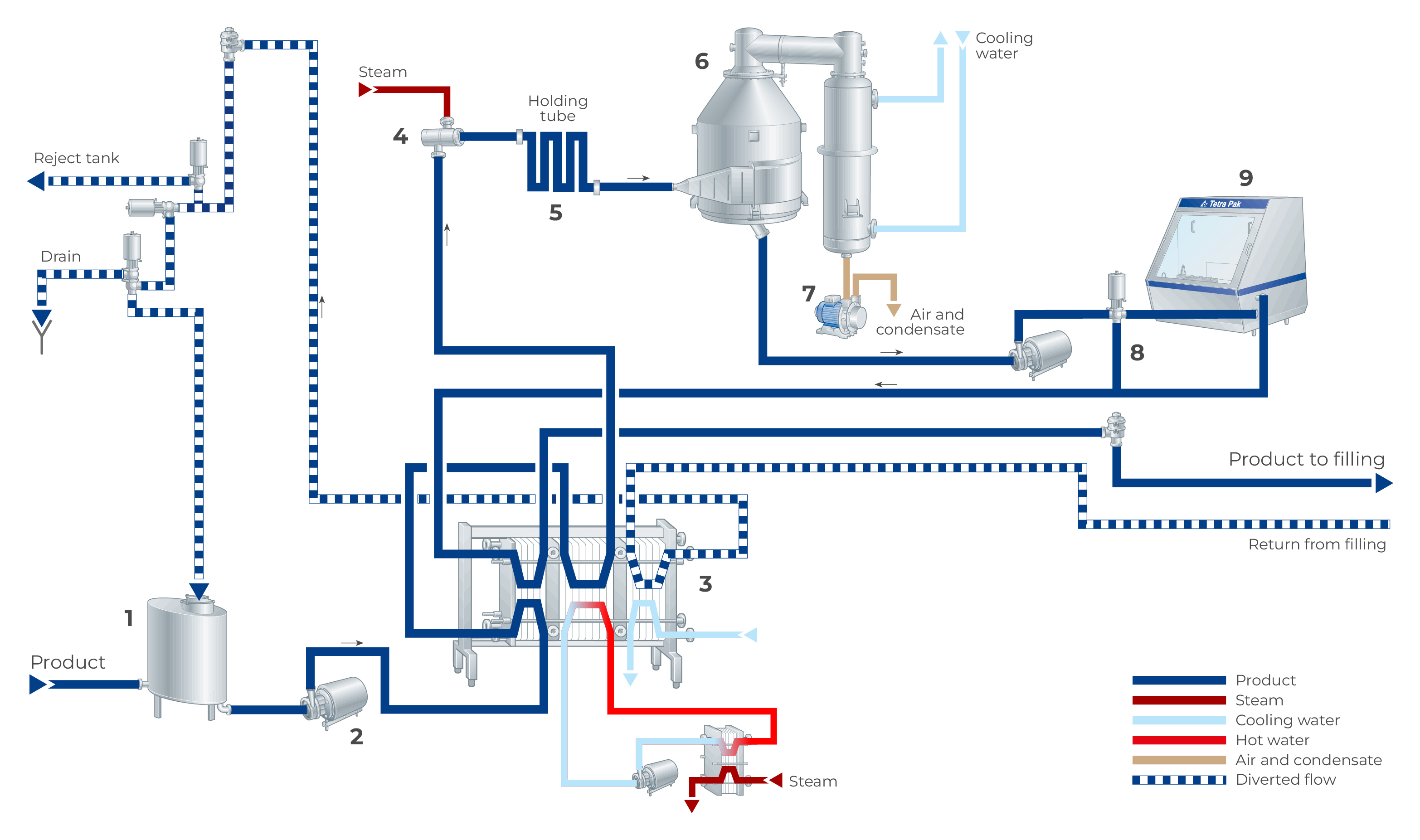

- Steam injection systems (steam injected into product), Figure 10.10

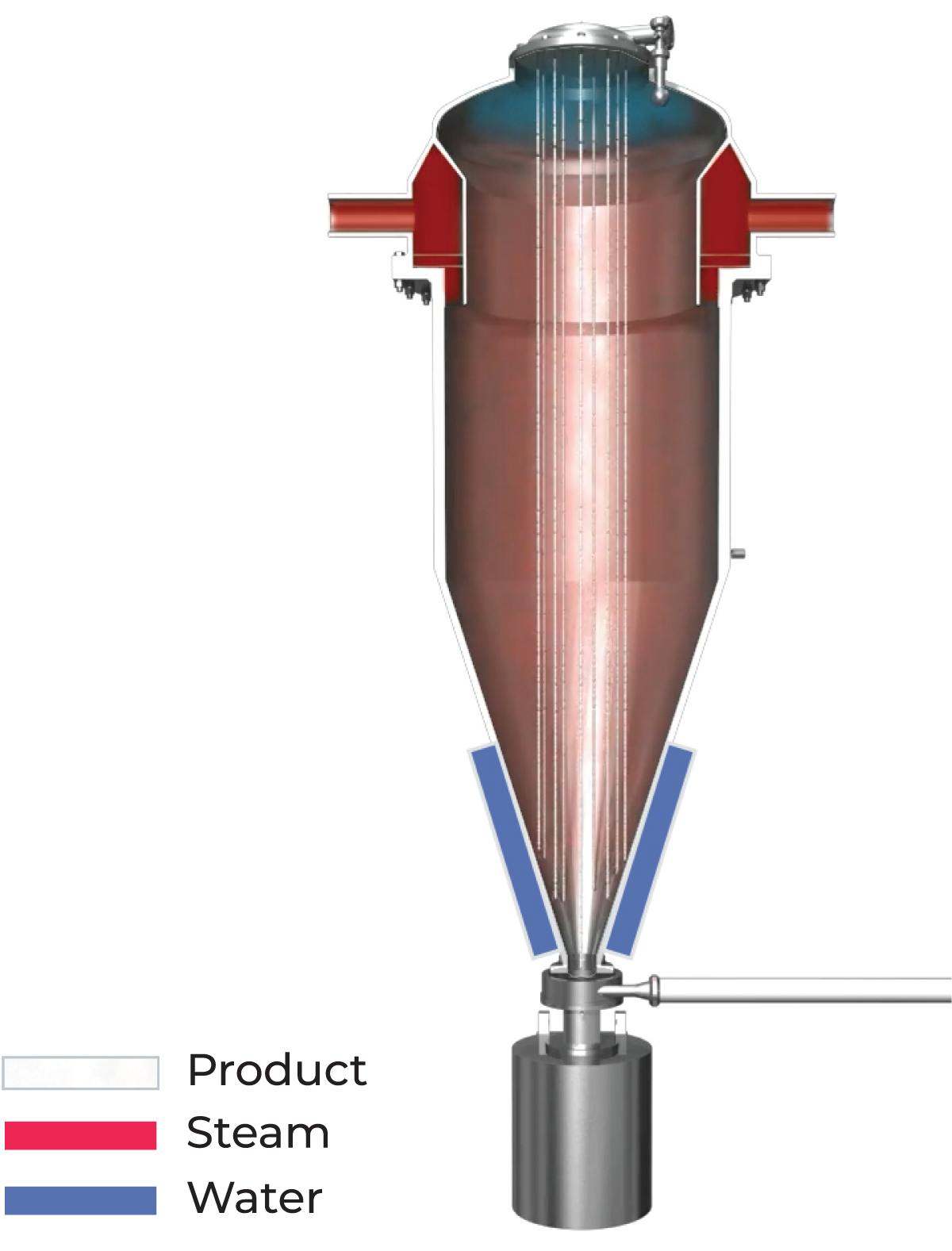

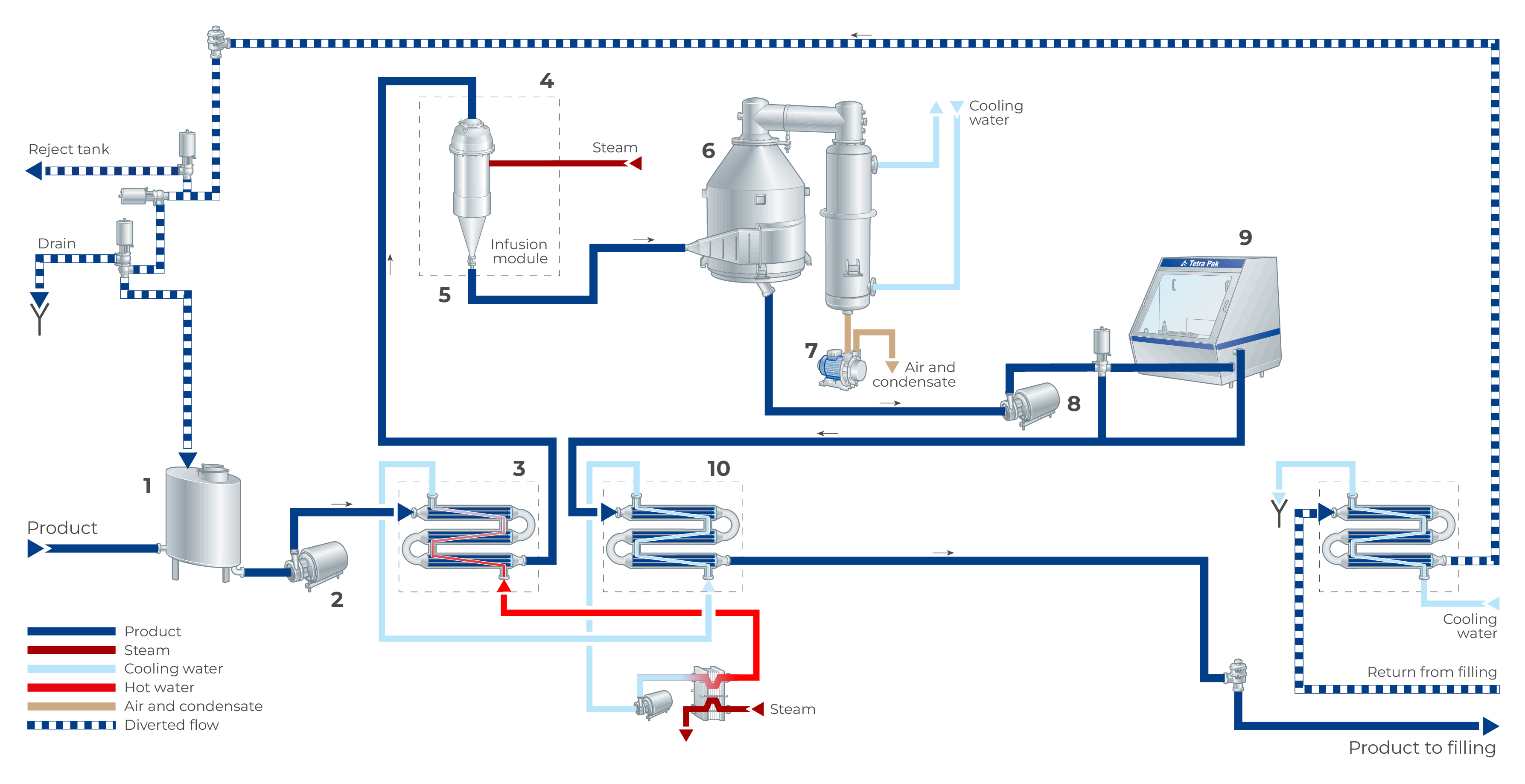

- Steam infusion systems (product introduced into a steam-filled vessel), Figure 10.11

It is also possible to combine direct heating and indirect cooling without subsequent flash cooling. In this case, the condensate created by the steam while heating will dilute the product.

In the indirect systems, the heat is transferred from the heating media to the product through a partition (plate or tubular wall).

The indirect systems can be based on:

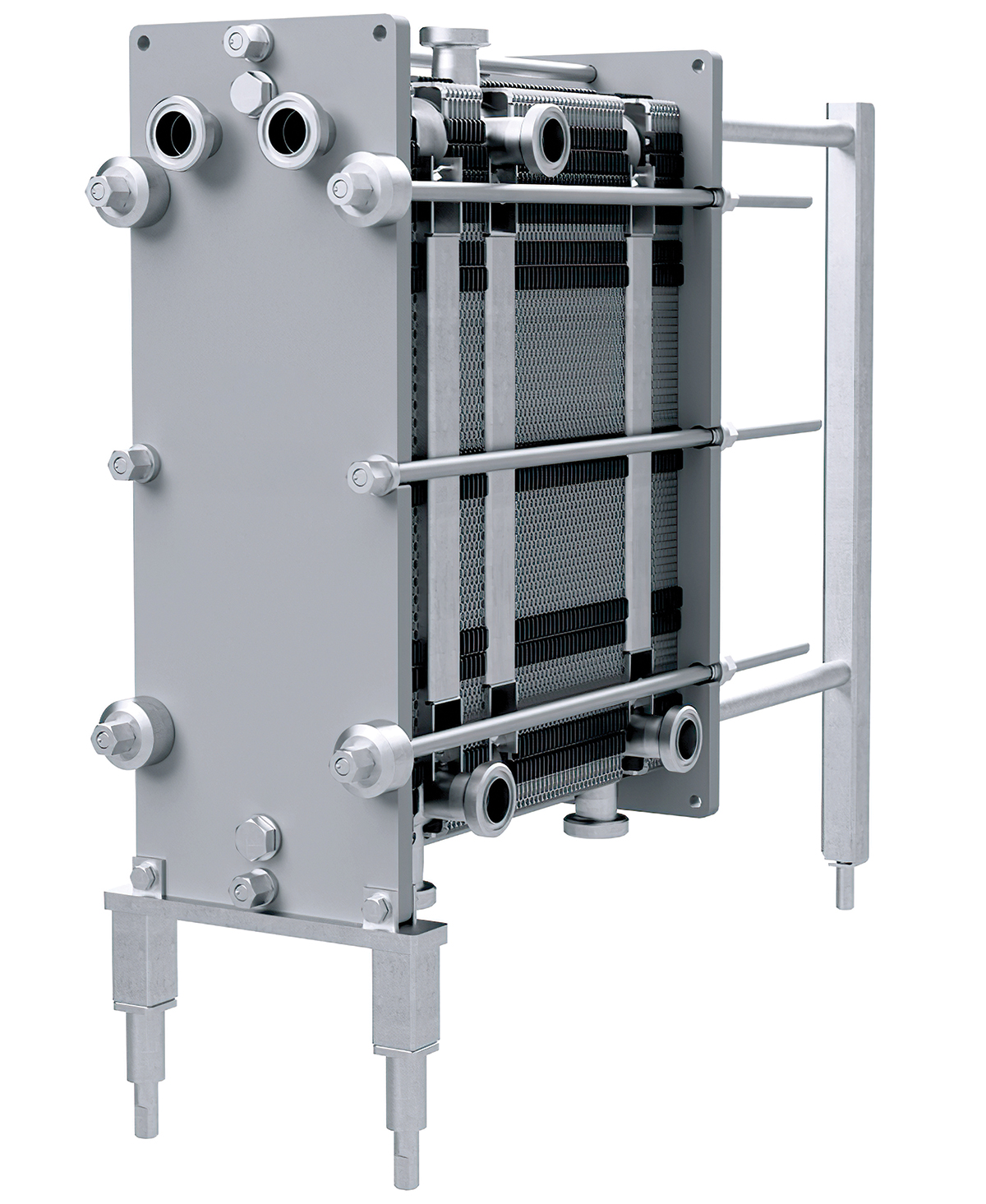

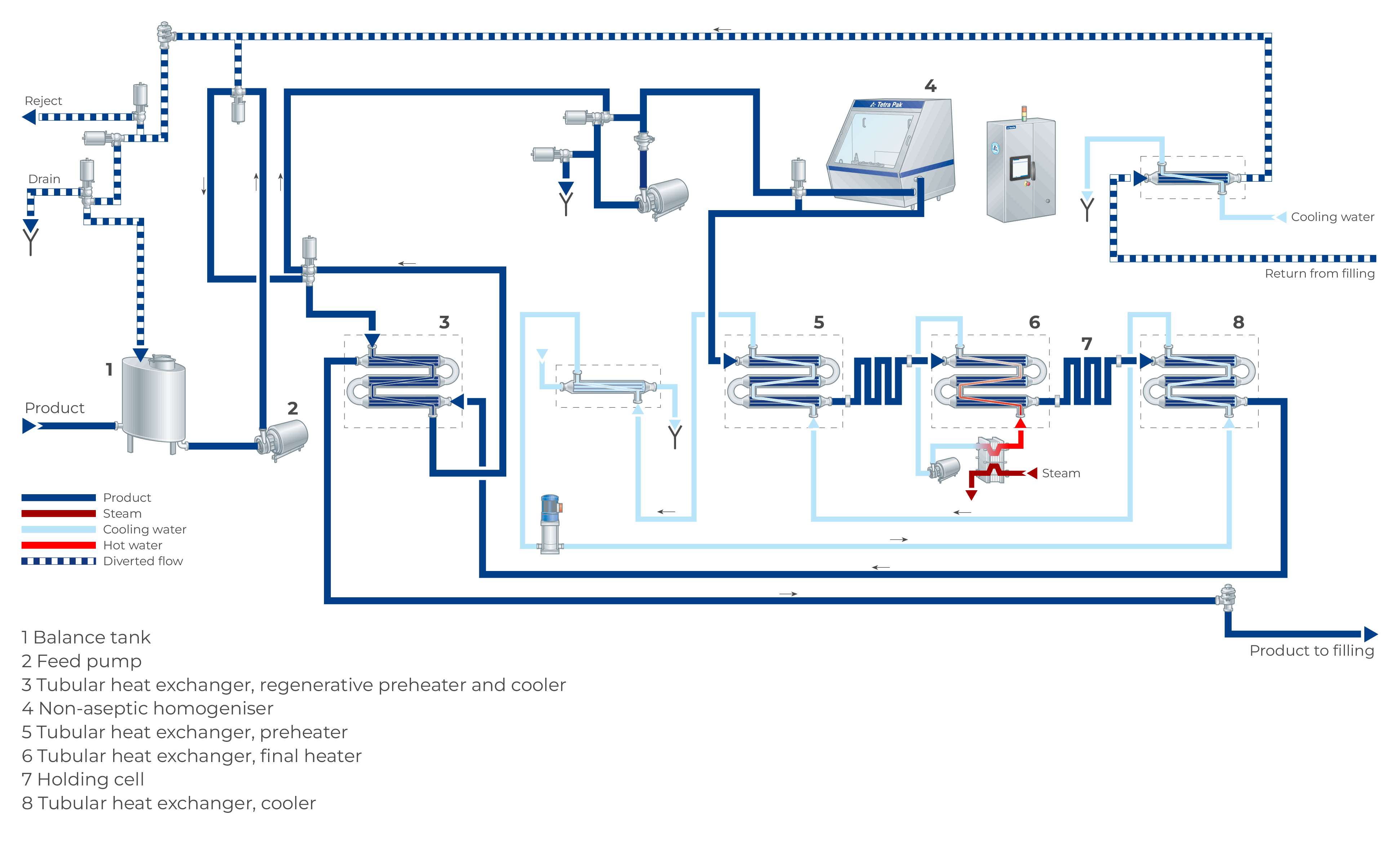

- Plate heat exchangers, Figure 10.12

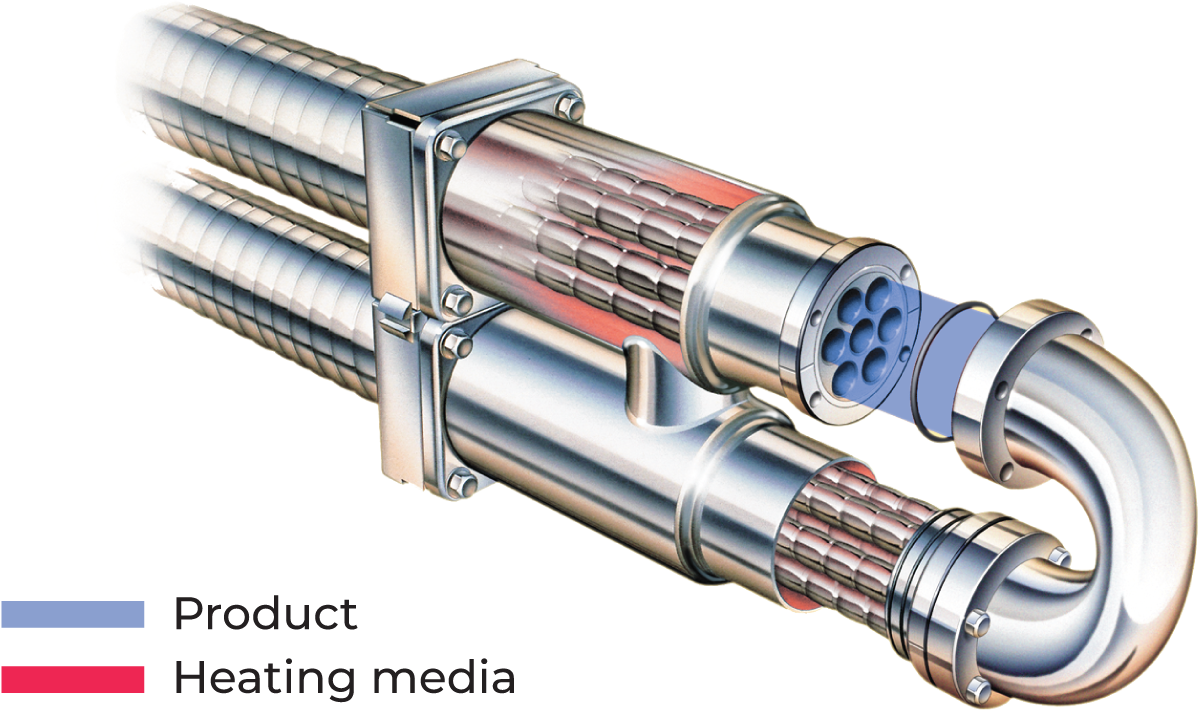

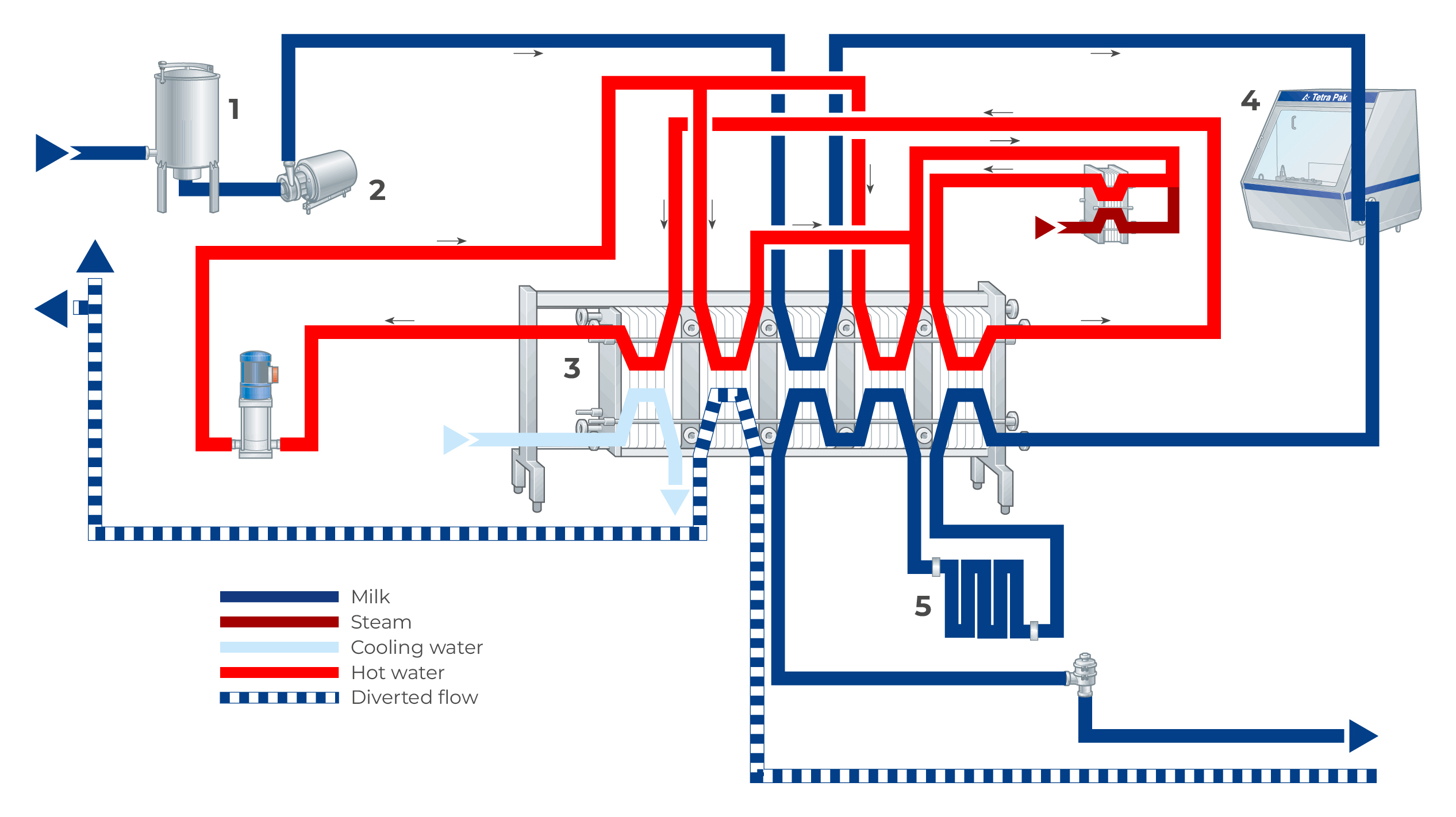

- Tubular heat exchangers, Figure 10.13

- Scraped surface heat exchangers

- Coiled tubular heat exchanger

Furthermore, it is possible to combine the heat exchangers in the indirect systems according to product and process requirements. Scraped surface and coiled tubular heat exchangers are used for very high-viscous products or products with large particles like soups and sauces, desserts, puddings, custards, pea purées, dressings, etc., and are very seldom used for dairy applications.

Direct UHT systems

The more rapidly the product can be heated and then subsequently cooled down again, the less impact the process has on the chemical changes in the product, such as changes in taste, colour and even to some extent, nutritional value.

The most effective way of achieving rapid heating is to mix high-temperature steam directly with the product, followed by flash cooling in a vacuum vessel. This is called a direct system.

Flash cooling is an operation, which as well as cooling, also involves deaeration and deodorisation of the treated product. In addition, deaeration secures higher homogenization efficiency and will also positively influence the storage stability of the processed product in terms of preventing oxidation during storage.

The rapid heating and cooling explain why direct systems deliver superior product quality and are often chosen to manufacture heat-sensitive products, such as premium quality market milk, enriched milk, cream, formulated dairy products, soy milk and soft ice mix, as well as dairy desserts and baby food.

Processing of starch-based products in a direct system might have a positive effect on texture and smoothness, thus enhancing the mouthfeel.

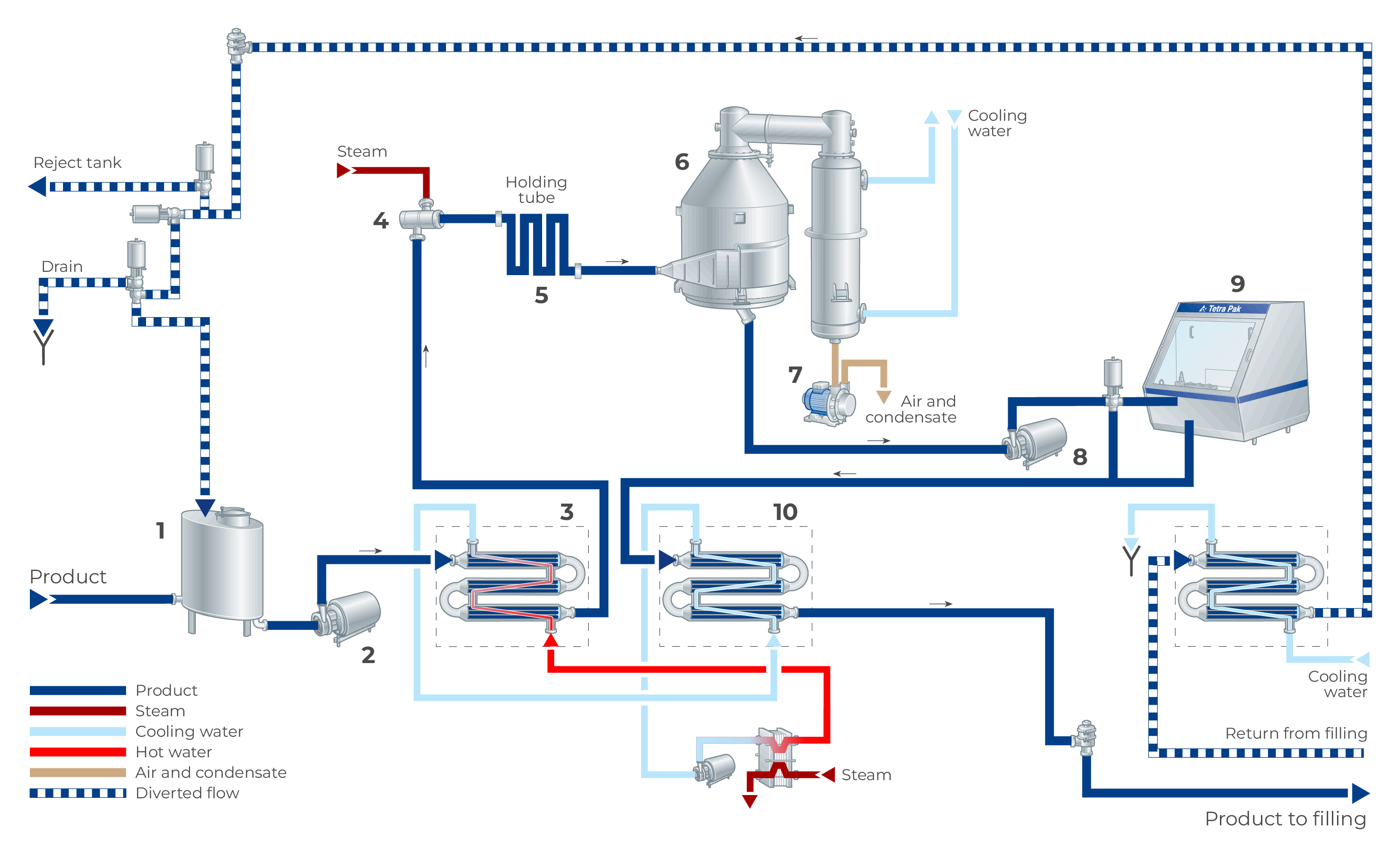

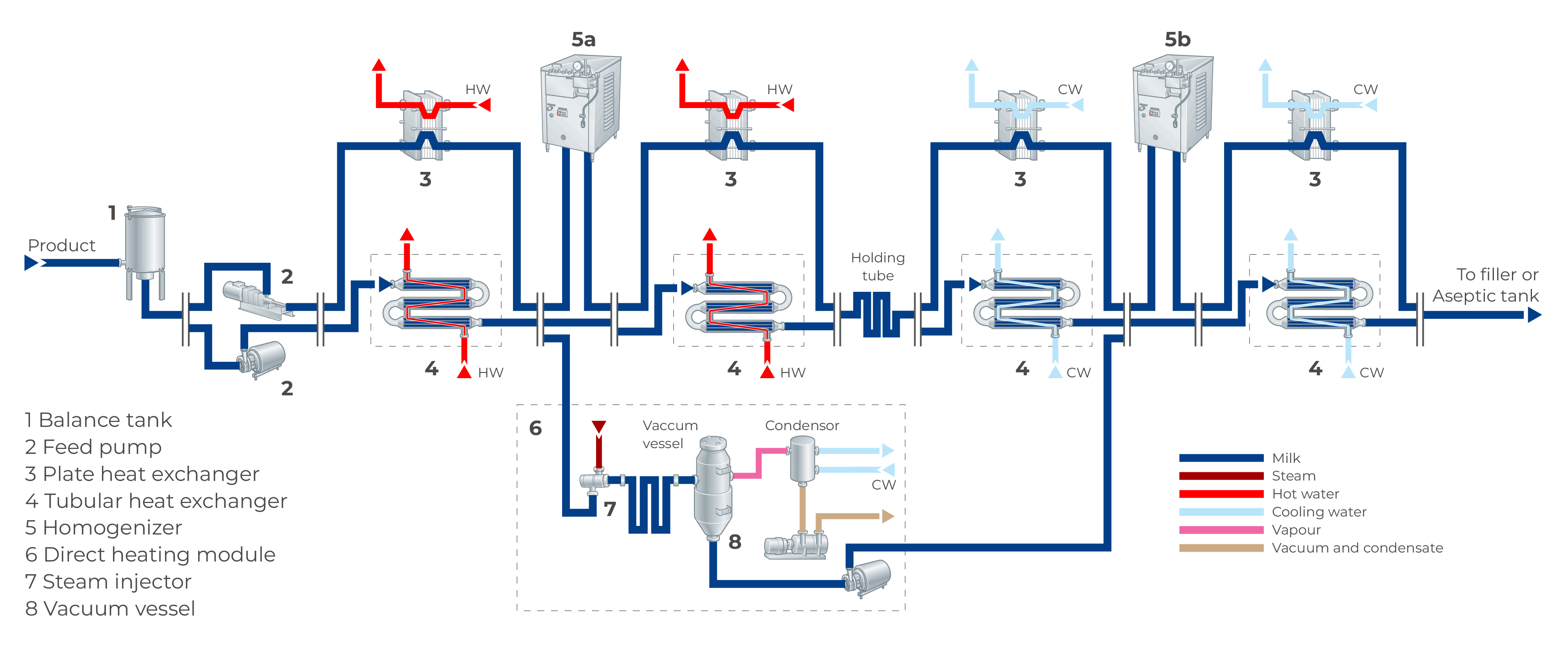

Direct UHT plant based on steam injection and tubular heat exchanger

In the flowchart in Figure 10.14, the product at about 4 °C is supplied from the balance tank (1) and forwarded by the feed pump (2) to the pre-heating section of the tubular heat exchanger (3). After pre-heating to approximately 80 °C, the product then continues to the ring nozzle steam injector (4). The steam injected into the product instantly condensates to water and raises the product temperature to about 140 – 150 °C (the pressure prevents the product from boiling). The product is held at UHT temperature in the holding tube (5) for a few seconds before it is flash-cooled. Flash cooling takes place in the vacuum vessel (6) where the temperature instantly drops to pre-heating temperature due to the partial vacuum which is maintained by a pump (7). The vacuum is controlled so the amount of water vapour flashed off from the product equals the amount of steam previously injected. A centrifugal pump (8) feeds the UHT-treated product to the aseptic two-stage homogenizer (9).

After homogenization, the product is cooled to approximately 20 °C in the tube heat exchanger (10) and then continues directly to an aseptic filling machine or to an aseptic tank for intermediate storage before being packed. If the sterilisation temperature drops during production, the product is diverted into a reject tank and the plant is flushed by water. The plant must be cleaned and sterilised before restart.

Plants with capacities of 2,000 – 45,000 l/h are available. The tubular heat exchanger can be designed without (Fig 10.14) or with (Fig 10.17, item 3) product to product regenerative section As an alternative to the below design, the tube heat exchanger in Figure 10.14 (3 and 10) can be exchanged for plate heat exchangers, as shown in Figure 10.15. For treating products of low or medium viscosity, tubular is the preferred solution.

Direct UHT plant based on steam infusion

The main difference between steam infusion and steam injection systems is the way the milk and steam are brought together.

The basic principle of steam infusion is to heat a product by passing it through an atmosphere of steam, as shown in Figure 10.11. The product enters the infusion vessel at the top into a product-spreading system. In the product-spreading system, the product is distributed into small streams as it enters the infusion vessel and forms into droplets. As the droplets are falling down in the atmosphere of steam, the milk is heated up by condensations of steam at the surface of the droplets. The spreading system may vary between different infusion designs, but the resulting milk droplet size must be uniform so that the rate of heat transfer does not vary. If the droplet size varies, the infuser will depart from the theoretical model upon which the design is based.

As the milk hits the conical bottom of the infusion vessel, the milk must have reached its final temperature. The conical bottom is jacked and cooled to a slightly lower temperature than sterilisation, creating a flow of condensate. As the product lands, it thereby reduces fouling formation on the hot surface. After landing in the cone, gravity causes the product to flow further to the bottom of the vessel, where it is pumped to the holding cell. Otherwise, the process in Figure 10.16 is similar to the steam injection system as shown in Figures 10.14 and 10.15.

Indirect UHT plants

The most cost-effective method of UHT processing is indirect heating – a heating method in which the processed product never comes into direct contact with the heating medium, as there is always a wall in between. This technique applies to all types of heat exchangers. However, in dairy applications, tubular-based systems are most common for UHT treatment. Furthermore, homogenization can be applied either before or after the final heating of the product. By applying homogenization before UHT treatment, a non-aseptic homogenizer can be used. However, an aseptic downstream homogenizer might improve the texture and physical stability of certain products that have a high content of protein or fat.

Double (using one homogenizer upstream and one downstream) can be used to obtain premium quality and long shelf-life stability for some products. This process solution is appropriate for products such as coffee cream and evaporated concentrated milk.

Indirect UHT plants are a suitable choice for processing milk, flavoured milk products, cream, dairy desserts, yoghurt drinks, concentrated milks and other non-dairy applications, such as juices, nectars and tea.

Indirect UHT plant based on tubular heat exchangers

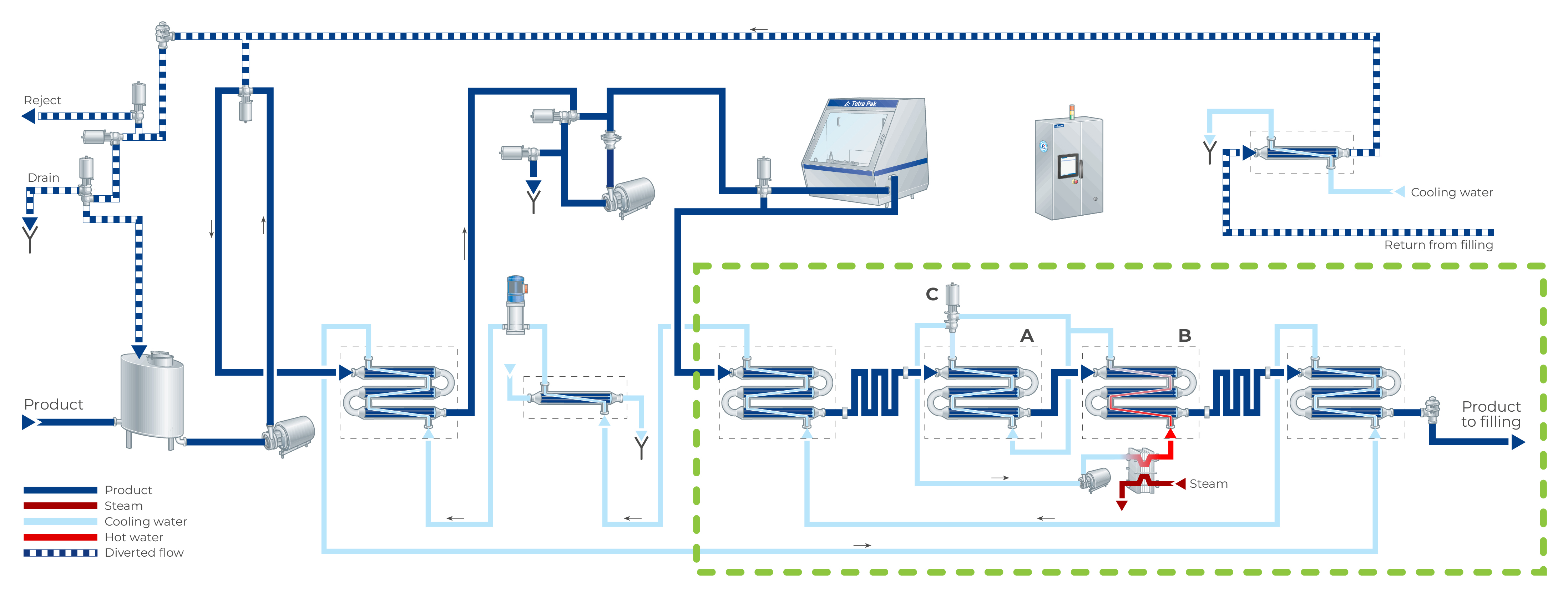

A tubular system is chosen for UHT treatment of products with low or medium viscosity that may or may not contain particles or fibres. The term medium viscosity is a diffuse concept, as the viscosity of a product can vary depending on raw material, additives and mechanical treatment. Soups, tomato products, fruit and vegetable products, certain puddings and desserts are examples of medium-viscosity products well suited to treatment in a tubular concept. Currently, tubular systems are the most utilised type of UHT plants. UHT plants of indirect heating technology are built for capacities up to 40,000 l/h. A typical flowchart is shown in Figure 10.17.

The product (at about 4 °C) is pumped from the storage tank to the balance tank (1) of the UHT plant and from there by the feed pump (2) to the regenerative section of the tubular heat exchanger (3). In this section, the product is heated to about 75 °C by using product-to-product heat recovery. The cold untreated product is heated by the hot UHT-treated product, which is cooled at the same time. The pre-heated product is then homogenized (4) at a pressure of 180 – 250 bar (18 – 25 MPa). As discussed, homogenization before UHT treatment is possible in indirect UHT plants, which means that non-aseptic homogenizers can be used, thereby lowering cost. However, an aseptic downstream homogenizer might improve the texture and physical stability of certain products.

The pre-heated, homogenized product continues to the second preheating section (5) and to final heating section (6) of the tubular heat exchanger, where it is heated to about 138 °C. Heating is performed by hot water in a closed water circuit. After heating, the product passes through the holding tube (7), dimensioned for about 4 seconds.

Finally, cooling is performed regeneratively in two sequences: first against the cold end of the hot water circuit (8), and then against the cold incoming product (3). The product that leaves the regenerative cooler continues directly to aseptic packaging or an aseptic tank for intermediate storage.

In Figure 10.17, the milk is heated and cooled by product-to-product regenerative heating at temperatures below 75 °C. A UHT system can be designed with or without product-to-product regenerative heating. Additionally, to what temperatures the regenerative section is designed also changes.

The running time of indirect systems can be prolonged even further by the installation of a stabilising holding tube, which stabilises milk proteins and thus minimises fouling in the heat exchangers.

The tubular heat exchanger comprises a number of tubes assembled into modules that can be connected in series and/or in parallel to offer a complete optimised system for any heating or cooling duty. This system can also be provided with a split heating arrangement.

If the temperature drops during production, the product is diverted into a reject tank and the plant is flushed with water. The plant must be cleaned and sterilised before restart.

As for the direct UHT treatment, an alternative to the indirect tubular UHT systems is a UHT system based on plate heat exchangers.

The processing principle, shown in Figure 10.18, does not differ very much from the UHT plant with a tubular heat exchanger.

Split heating

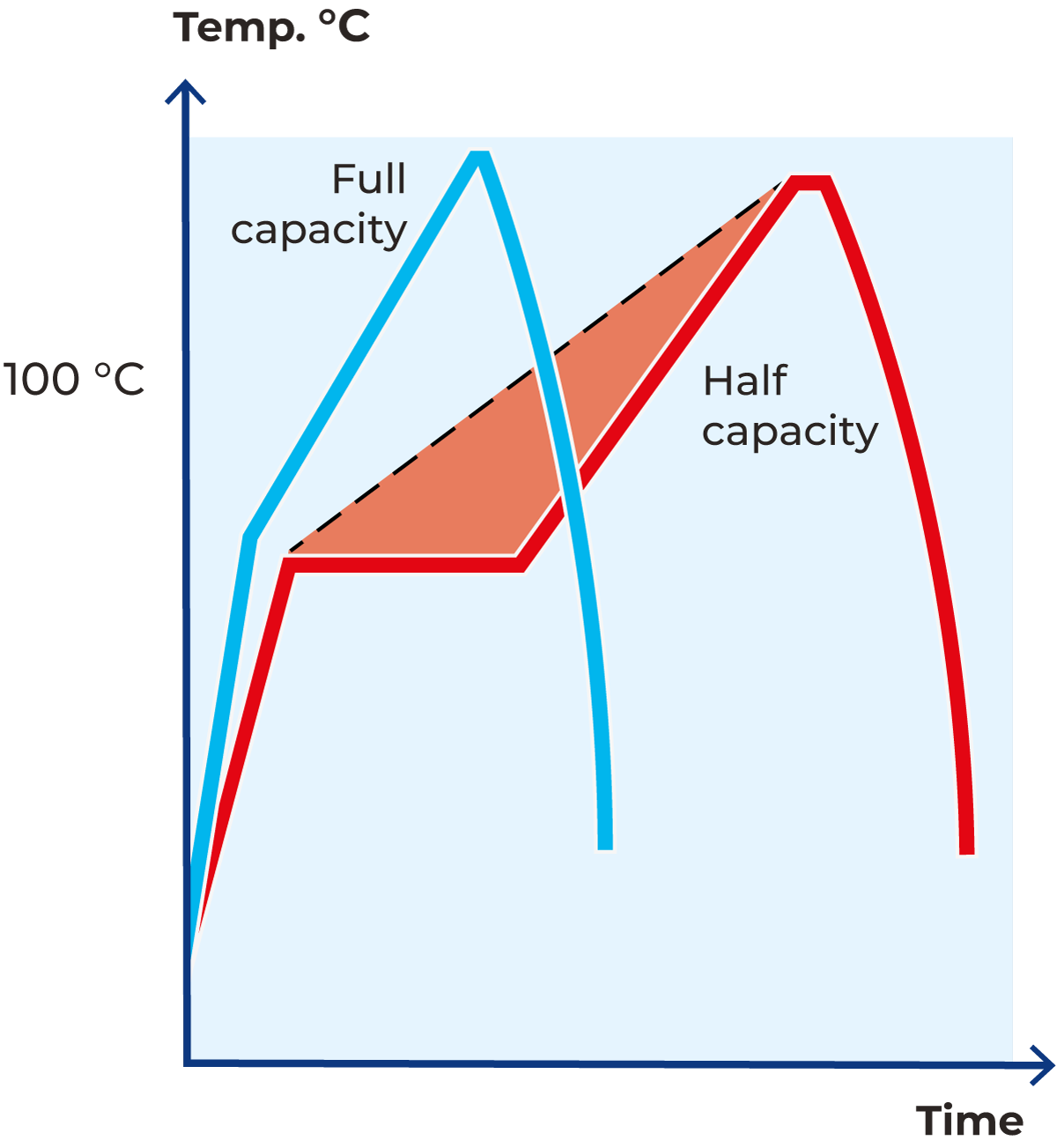

In many cases, indirect UHT plants are designed for a variable capacity between 50 and 100% of the nominal, and are directly connected to a line of aseptic packaging machines. To reduce the over-processing of the product, if one of the packaging machines stops, the heating section can be divided and split into subsections (a split heater).

The split heating system is illustrated in Figure 10.19. In the event of a 50% reduction of the flow compared with nominal, a valve (C) is activated so that the heating medium bypasses outside the first heating section (A). The temperature of the product will thus be kept at the pre-heating temperature (75 °C) until the product reaches the second (final) heating section (B) where heating to the relevant UHT temperature takes place.

The time/temperature curves in Figure 10.20 show the difference in the heat load on the product at nominal and half capacity. The dotted line on the graph represents the temperature development in a system without split heating facilities running at 50% of nominal capacity.

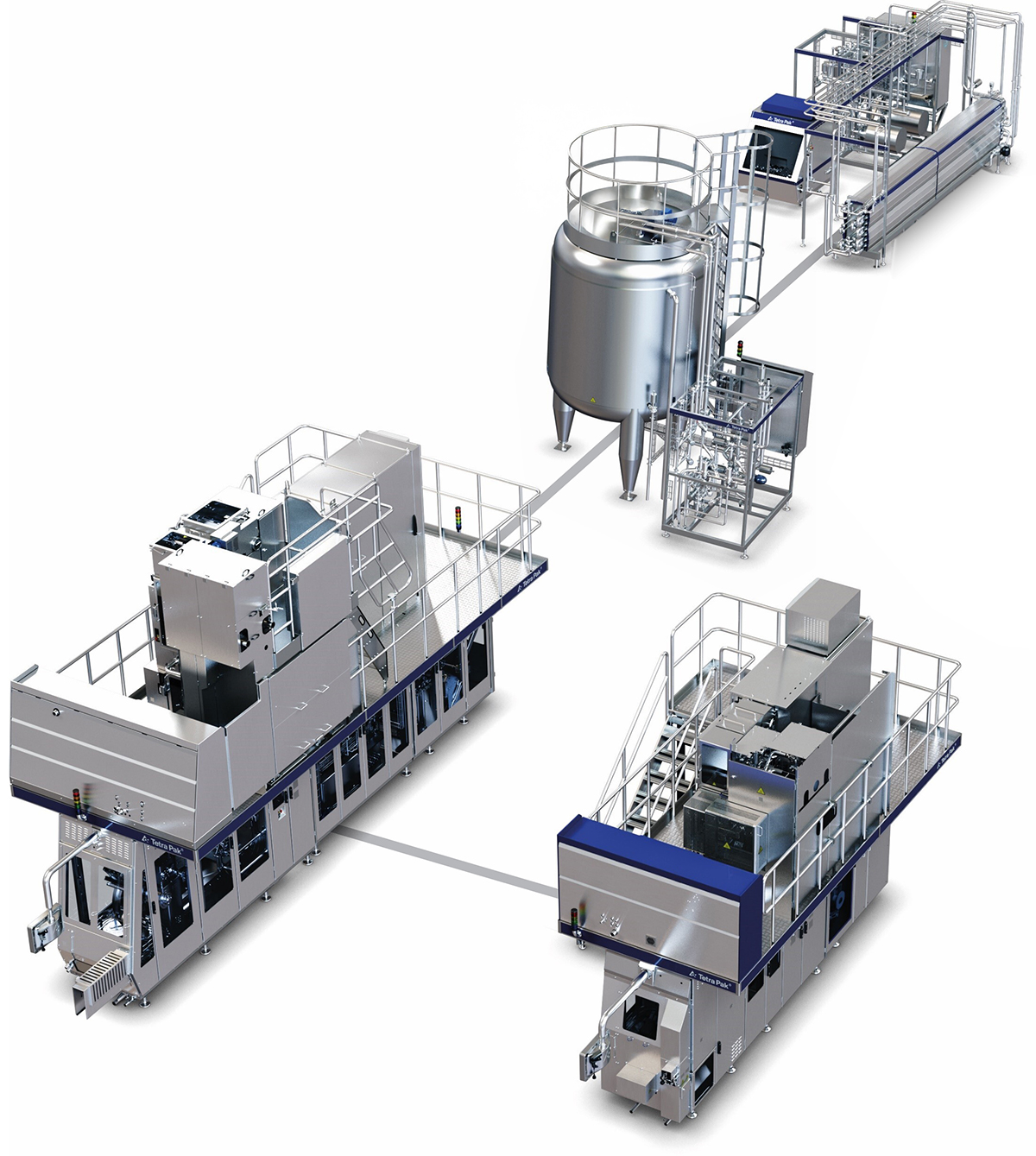

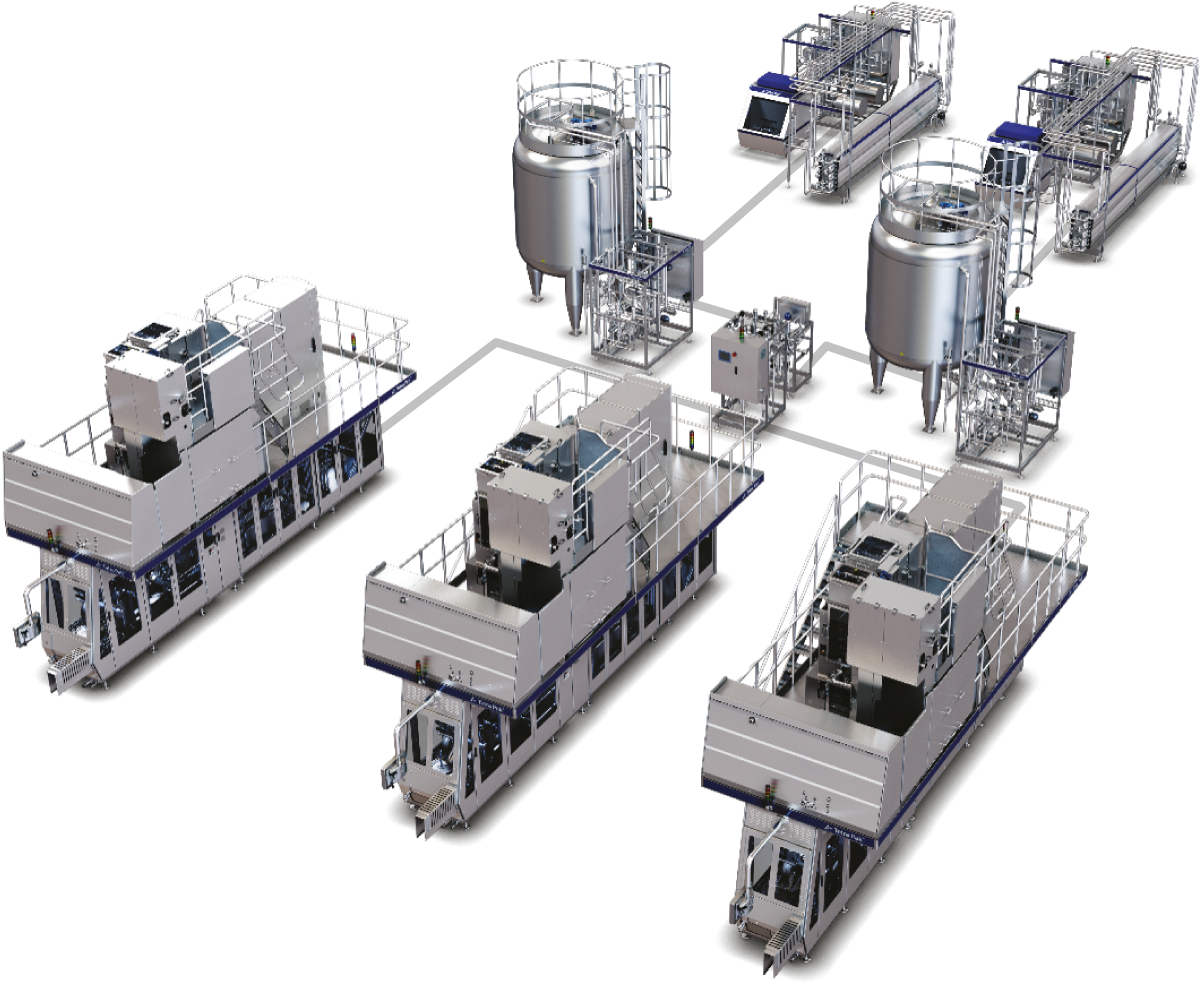

Aseptic storage

The aseptic tank shown in figure 10.21 is used as an intermediate storage of UHT-treated dairy products. It enables increased productivity in a continuous production line by balancing product supply to the filling machine(s) and allowing the UHT unit and filling machines to operate independently without disturbance from unplanned stops or cleaning.

Product flow and service media connections are placed in a separate valve and control module.

The aseptic tank can be configured in different ways in UHT lines, depending on factors such as:

- Plant design and layout.

- Capacities of the various units in the process and packaging lines.

- Required flexibility.

Two common configurations are shown in Figures 10.22 and 10.23.

- 10.22. The aseptic tank acts as a buffer storing surplus product, which is the most common installation. Often the steriliser is designed with a slight overcapacity compared to the filling machine. This builds some level in the aseptic tank over time to allow for intermediate cleaning of the steriliser while continuing production of the filing machine.

- 10.23. Two tanks with the flexibility to send product to any filling machine in the production line offering great flexibility in production planning.

Direct feed from the UHT unit to the filling machine requires recirculation of some product to maintain a constant pressure towards the filling machines. In this way, the product is partly reprocessed and the total heat load will be higher. In addition, recirculation will increase the consumption of media. Direct feed is not recommended for products that are sensitive to reprocessing and where low heat load is important.

The optimum arrangement of UHT plants, aseptic tanks and aseptic packaging machines must thus be decided for each individual process.

Aseptic packaging

Aseptic packaging means the packaging of a commercially sterile product into sterilised containers followed by hermetically sealing with a sterilised closure in a manner which prevents microbiological recontamination of the sterile product.

Based on the definition of Aseptic Processing and Packaging from Codex Alimentarius CXC 40-1993, the term "aseptic" implies the absence of any organisms capable of growth in the product, from the package and from the filling machine’s “aseptic zone” (where filling takes place). “Hermetic” indicates suitable mechanical properties to exclude the entry of bacteria into the package or, more strictly, to prevent the passage of microorganisms, gas or vapours into or from the container.

For products with a long non-refrigerated shelf life, the package must also provide high protection against light and atmospheric oxygen to protect the nutritional value and sensorial properties of the packaged product. Milk cartons for long-life products consist of high-quality carton board, sandwiched between layers of polyethylene plastic.

UHT pilot plants

Special pilot plants are available for testing small quantities of new, interesting products. In these plants, it is possible to study the effects of varying technological parameters related to the UHT process, such as temperature programs, holding times, heating method (direct or indirect) and deaeration vs. no deaeration, in addition to homogenizing pressures and temperatures. Many technological parameters are related to the product, such as recipes, ingredients, pre-treatment, etc.

These product parameters are just as important as the process parameters, and the successful development of a new UHT product requires that all of them be studied together. At the same time, the pilot plant can be used to study heat-related properties of the product such as stability, sensitivity, and heat resistance of spores.

Many development and innovation centres in the food and dairy industry have installed UHT pilot plants for product development. Such plants are also found in schools, universities and other scientific institutions that are interested in food and dairy technology. Some manufacturers of UHT plants also have pilot plants for research and trials of customers’ products.

The complete UHT plant can consist of one module for indirect heating in tubular heat exchangers or plate heat exchangers and additional modules for direct heating with injection or infusion and homogenization.

The flow chart in Figure 10.25 illustrates a pilot plant for indirect heating in tubular heat exchanger or plate heat exchanger, or alternatively in a tubular heat exchanger and additional modules for direct heating and homogenization of the product, either upstream (non-aseptic, 5a) or downstream (aseptic, 5b).