COLLECTION AND RECEPTION OF MILK

Milk is brought from the farm (or collection centre) to the dairy for processing. Various types of receptacles have been used, and are still in use, throughout the world, from 2 to 3-litre calabashes and pottery to modern bulk-cooling farm tanks for thousands of litres of milk.

Formerly, when dairies were small, collection was confined to nearby farms. The microorganisms in the milk could be kept under control with a minimum of chilling, as the distances were short, and the milk was collected daily.

Today, the trend is towards progressively larger dairy units. There is a demand for higher production and increased quality of the finished product. Milk must be brought from farther away and this means that daily collection is not always possible. Present-day collection usually takes place every day or every other day.

Keeping the milk cool

The milk should be chilled to +4° C, or below, immediately after milking and be kept at this temperature all the way to the dairy.

If the cold chain is broken somewhere along the way, e.g. during transportation, the microorganisms in the milk will start to multiply. This will result in the development of various metabolic products and enzymes. Subsequent chilling will arrest this development, but the damage will have already been done, meaning the bacteria count is higher, and the milk contains substances that will affect the quality of the end product.

Design of farm dairy premises

The first steps in preserving the quality of milk must be taken at the dairy farm. Milking conditions must be as hygienic as possible and the milking system must be designed and correctly dimensioned to allow gentle milk transport, avoid aeration and ensure efficient cooling.

To meet hygienic requirements, dairy farms have special rooms for milk cooling and storage. Bulk cooling tanks are the most common solution on modern dairy farms. These tanks have a capacity of 300 to 40,000 litres and are fitted with an agitator and cooling equipment to meet certain stipulations. Milk should be cooled as quickly as possible to +4 °C no later than two hours after milking. This is essential for preserving milk quality until it is processed for consumption or used to manufacture other dairy products.

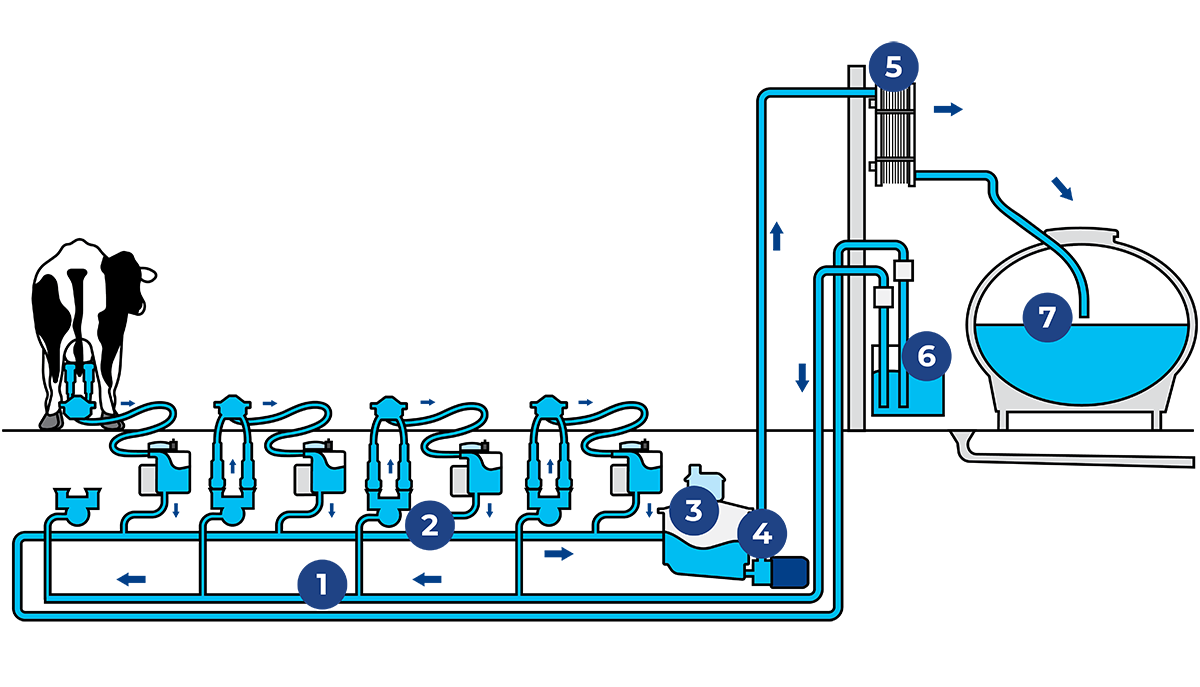

Direct expansion cooling is the most common milk cooling system. The bottom of the tank is designed as an evaporator, while the heat of the milk goes through a stainless steel wall to the refrigerant. The refrigerant evaporates, which removes the heat from the milk. Additional cooling equipment, such as separate plate coolers for chilling the milk before it enters the tank (Figure 6.1), is used on larger farms to avoid mixing warm milk with the already chilled content of the tank.

As with all other parts of a milking plant, the milk cooling tank has to be cleaned. This should be performed immediately after it has been emptied.

Tanks are cleaned by automatic cleaning units where a cleaning solution is pumped through spreaders, which direct the cleaning solution by spraying all the surfaces to be cleaned. At some dairy farms around the world, open balance tanks are still used that are manually cleaned.

Delivery to the dairy

The raw milk arrives at the dairy in insulated road tankers. The milk must be kept properly chilled during transport. Transport should be as gentle as possible to minimise air intrusion. Air intrusion from milk sloshing around in the tanker is bad for milk quality and will make processing at the dairy more difficult.

Bulk collection

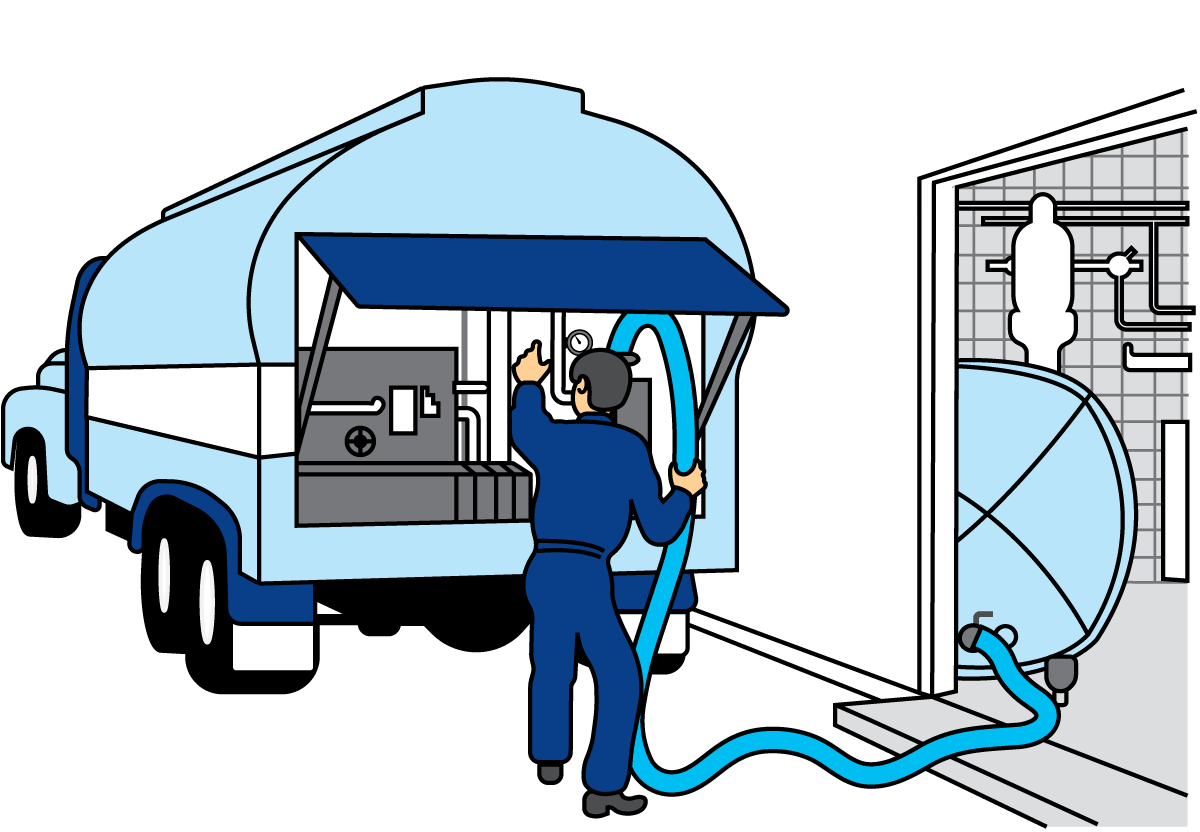

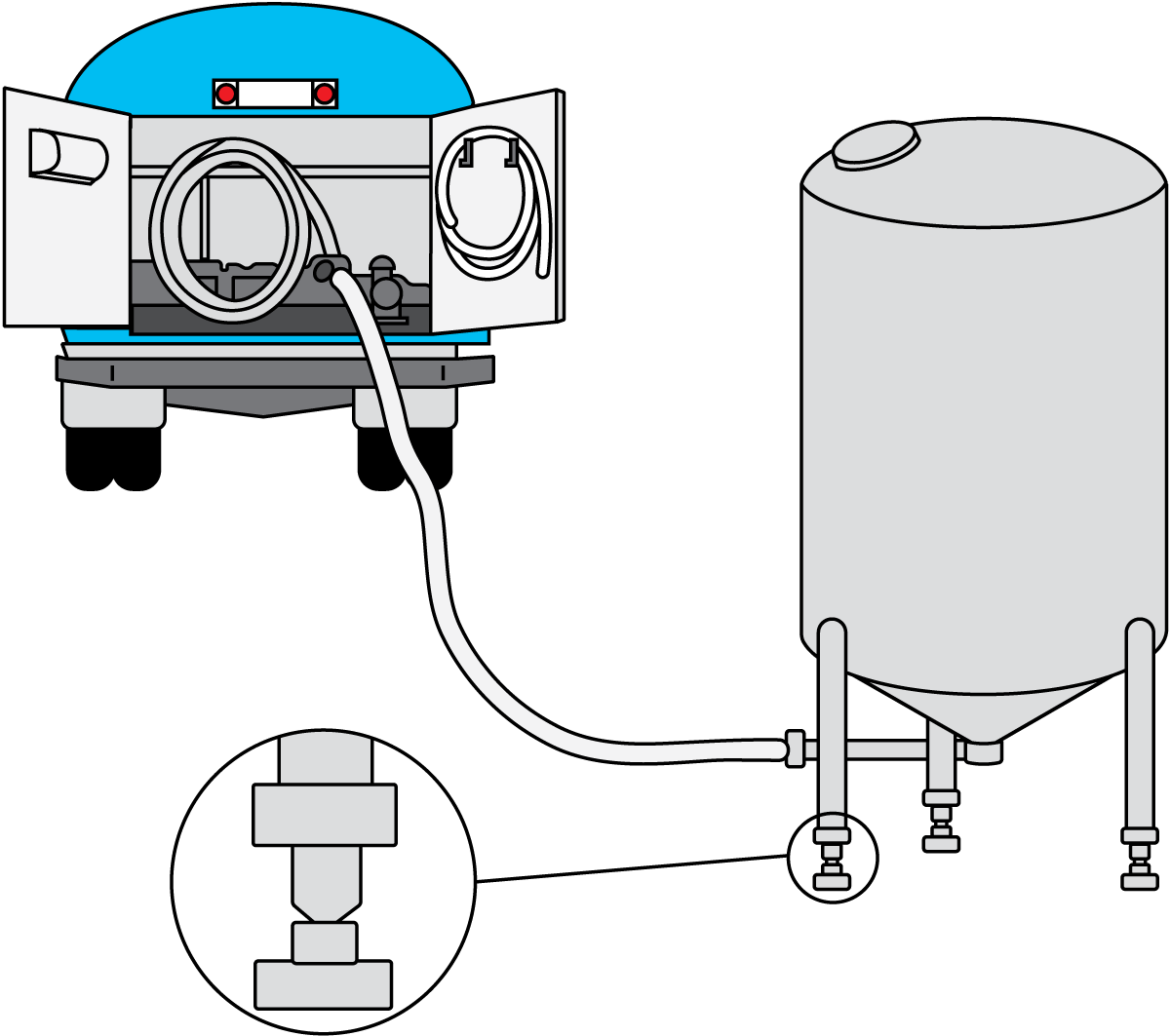

When milk is collected by tanker, it must be possible to drive all the way to the farm milk room. The loading hose from the tanker is connected to the outlet valve on the farm cooling tank (Fig. 6.2). The tanker is usually fitted with a flow meter and pump so that the volume is automatically recorded. Otherwise, the volume is measured by recording the level difference which, for the size of the tank in question, represents a certain volume. In many cases, the tanker is equipped with an air-eliminator.

Pumping is stopped as soon as the cooling tank has been emptied. This prevents air from being mixed into the milk. The tank of the bulk-collection vehicle is divided into several compartments to prevent the milk from sloshing around during transportation. Each compartment is filled in turn, and when the tanker has completed its scheduled round, it delivers the milk to the dairy.

Milk reception at the dairy

Dairies have special reception departments to handle the milk brought in from the farms. The milk reception department handles the testing of milk quality, measuring the amount of milk and the transfer of milk to the processing departments of the dairy.

Testing milk for quality

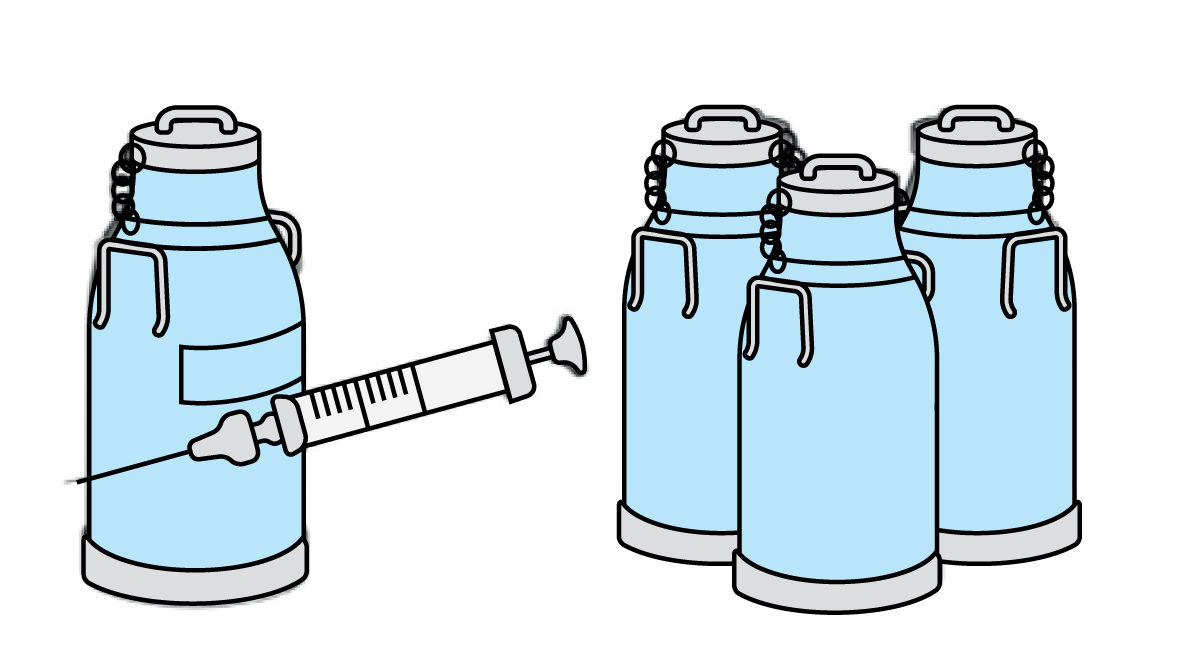

Milk from sick animals and milk which contains antibiotics or sediment must not be accepted by the dairy (Fig. 6.3). Even traces of antibiotics in milk can render it unsuitable for the manufacture of products which are acidified by the addition of bacteria cultures, e.g. yoghurt and cheese.

Normally, only a general assessment of the milk quality is made at the farm. The composition and hygienic quality are usually determined by several tests upon arrival at the dairy. The outcome of some of these tests has a direct bearing on the compensation to the farmer.

The most common tests carried out on milk supplies are detailed below. Further information about raw milk quality and its impact on processing can be found in Chapter 5: Raw milk quality.

Taste and smell

In the case of bulk collection, the driver takes a sample of the milk at the farm for testing at the dairy. Milk that deviates in taste and smell from normal milk receives a lower quality rating. This affects the payment to the farmer. Milk with significant deviations in taste and smell should be rejected by the dairy.

Cleaning checks

The inside surfaces of farm tanks are carefully inspected. Any milk residue is evidence of inefficient cleaning and will result in a deduction in accordance with a quality payment scheme.

The common tests carried out on milk supplies are:

- Taste and smell

- Cleaning

- Hygiene

- Somatic cell count

- Bacteria count

- Protein content

- Fat content

- Freezing point

- pH value

- Milk acidity

- Alcohol stability

Hygiene or Resazurin Tests

The bacteria content of the milk is a measure of its hygienic quality. Resazurin tests are used frequently. Resazurin is a blue dye which becomes colourless when it is chemically reduced by the removal of oxygen. When it is added to the milk sample, the metabolic activity of the bacteria present has the effect of changing the colour of the dye at a rate which bears a direct relationship to the number of bacteria in the sample.

Two hygiene tests use this principle. One is a quick screening test, which may form the basis for the rejection of a bad churn supply. If the sample starts to change shade immediately, the consignment is considered unfit for human consumption.

The other test is a routine test and involves storage of the sample in a refrigerator overnight before a Resazurin solution is added. The sample is then incubated in a water bath and held at 37.5 °C for two hours.

Somatic cell count

A large number (more than 400,000 per ml of milk) of somatic cells in the milk indicates that the cows are suffering from udder diseases. The cell content is determined with specially designed particle counters (e.g. a Coulter counter).

Bacteria count

A simplified form of bacteria count can also be used to assess the bacteria content. In this, the Leesment method, the bacteria are cultivated at 30 °C for 72 hours in a 0.001 ml milk sample with a nutritive substrate. The bacteria count is determined using a special screen.

Protein content

Many dairies pay farmers according to the protein content of the milk. This is analysed with instruments using infrared rays. Up to 300 analyses per hour can be performed.

Fat content

Various methods can be used to determine the butterfat content. The Gerber test is the most widely used method for whole milk.

Freezing point

Many dairies check the freezing point of the milk to determine whether or not it has been diluted with water. Milk of normal composition has a freezing point of –0.54 to –0.59 °C. The freezing point will rise if water is added to the milk. Special instruments are used for this check.

pH value

Measuring the pH value of milk is a preliminary quality control step to identify microbiological spoilage as well as chemical contamination. Milk normally has a pH of about 6.7 (6.6 – 6.8) at 20 °C.

Milk acidity (by titration)

Some dairies evaluate the acidity of milk samples using a titration method. Acidity in milk is caused by intense microbiological activity in the milk before arrival at the milk reception and can therefore be measured to give a rough estimate of the milk quality. Potential acidity can be expressed in several units.

For more details about titratable acidity, please see Chapter 2: The chemistry of milk.

Alcohol test (alcohol stability)

Dairies can assess the stability of milk proteins by their precipitation with alcohol at different concentrations. The alcohol test can use different concentrations of ethanol solutions (pure ethanol, free from additives) depending on the intended use of the milk. These concentrations can be between 68% – 76% (v/v).

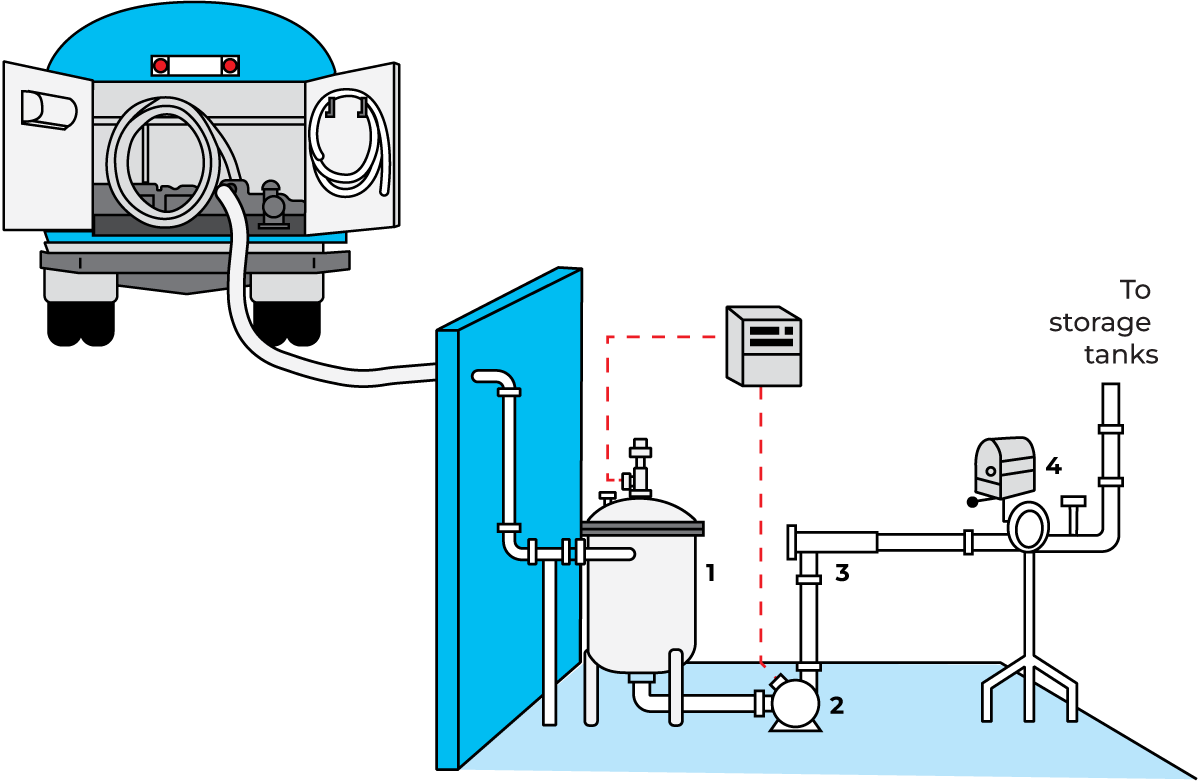

Tanker reception

At the entrance of the dairy, the driver will identify the tanker with a code or a tag. The tanker is then driven to the tanker reception area, either directly or via a weight bridge. The design of the tanker reception area is either open or in the form of a reception hall. The number of lanes with unloading places is determined in order to minimise waiting times for the tankers. When reaching the unloading bay, the tanker connects to the milk reception line. Many dairies use an air eliminator in the reception line. This makes it easier to get an accurate reading from the flow transmitter in the line. After the air eliminator, the milk is pumped via a strainer and a flow transmitter to the raw milk silos.

Measuring milk amount by weight

Bulk-collected milk can be measured by weight in two ways:

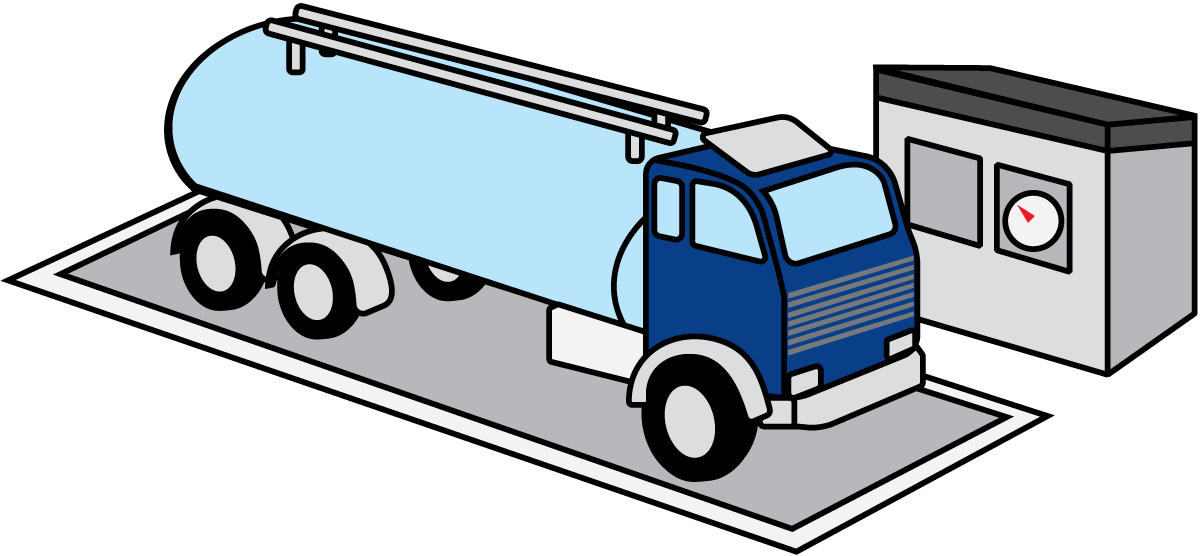

- Weighing the tanker on a weight bridge before and after unloading and then subtracting one value from the other (Figure 6.5).

- Using special weighing tanks with load cells in the feet (Figure 6.6).

When the weight bridge method is used, the tanker is driven from the entrance to the weight bridge and the total weight is recorded. After unloading, the empty tanker is again weighed and the amount of milk is calculated. Before being weighed, the tanker normally passes a vehicle-washing station. This is of special importance when the weather is bad.

When the weighing-tank method is used, the milk is pumped from the tanker into a special tank with load cells built into the feet. After recording the weight, the milk is pumped to a silo tank.

Measuring milk amount by volume

This method uses a flowmeter. It is important to prevent air from entering along with the milk. Measuring can be improved by fitting an air-eliminator before the flowmeter (Figure 6.7).

The tanker outlet is connected to an air-eliminator and from this, the milk – free from air – is pumped through the flowmeter, which continuously indicates the total flow. When all the milk has been delivered, the total amount is recorded.

The pump is started by the control system, which senses when the milk in the air-eliminator has reached the preset level for preventing air from being sucked into the line. The pump is stopped as soon as the milk level drops below a certain level. From the tanker reception area, the milk is pumped to a storage (silo) tank.

Tanker cleaning

As a rule, tankers are cleaned every day at the end of a collection round. If the tanker makes several rounds a day, cleaning should take place after each round. Cleaning can be carried out by connecting the tanker to a cleaning system while in the reception area, or by driving it to a special cleaning station. Many dairies also clean the outside of their tankers every day so that they always look clean when they are on the road. In more and more countries, new rules are being introduced regarding the disinfection of tankers to avoid spreading animal diseases.

Chilling the incoming milk

Normally, a temperature increase to slightly above +4 °C is unavoidable during transportation. Therefore, the milk is usually cooled to below +4 °C in a plate heat exchanger in the transfer line to the raw milk silos.

Raw milk storage

The untreated raw milk is stored in large vertical tanks – silo tanks – which have capacities from about 50,000 litres up to 500,000 litres.

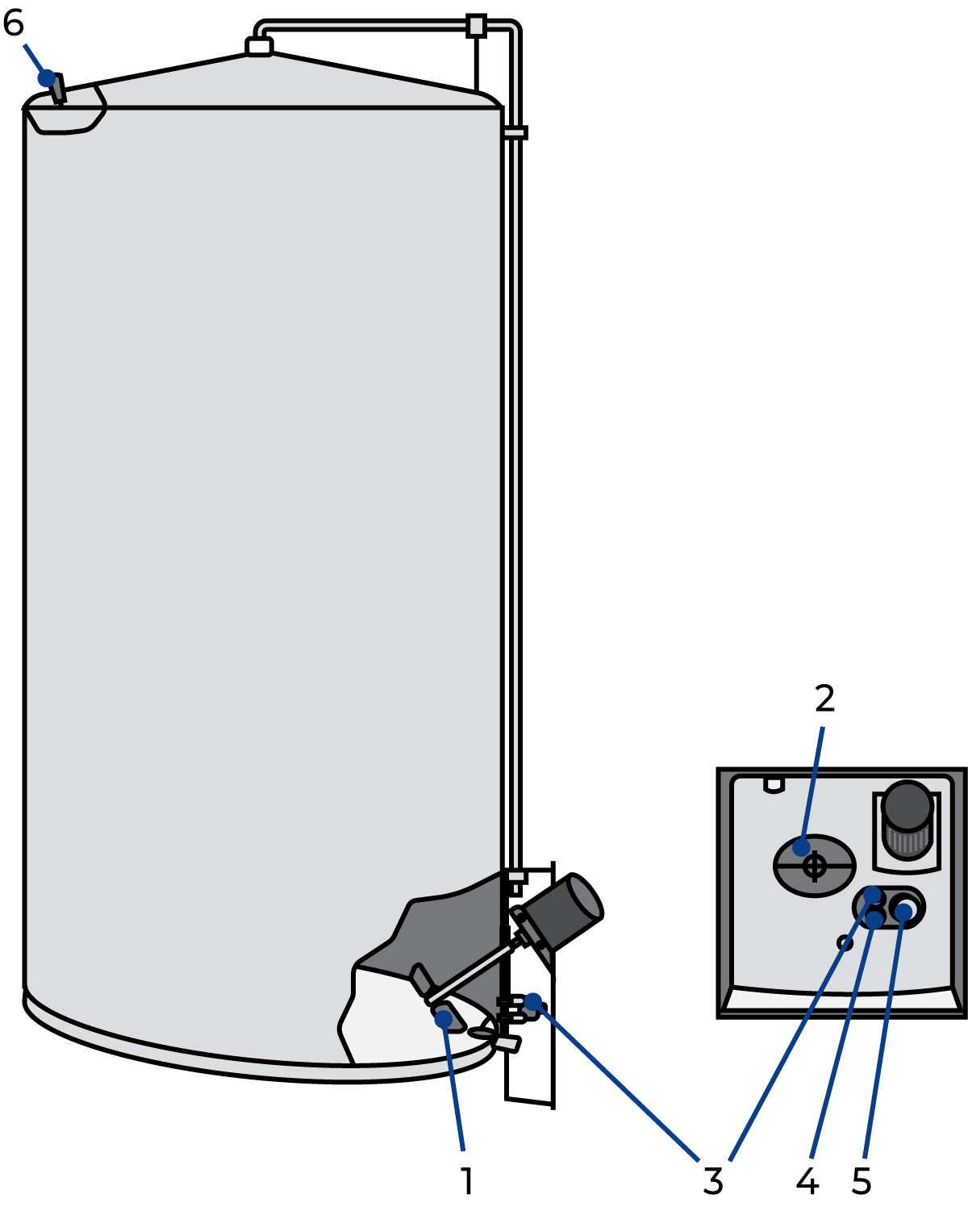

Silo tanks are located outdoors. Tanks are insulated. Sometimes they are also equipped with a cooling jacket, where chilled water is circulated to keep the milk cold.

The outdoor silo tanks have alcoves for ancillary equipment (Fig. 6.8). The alcoves face inwards towards a covered processing area.

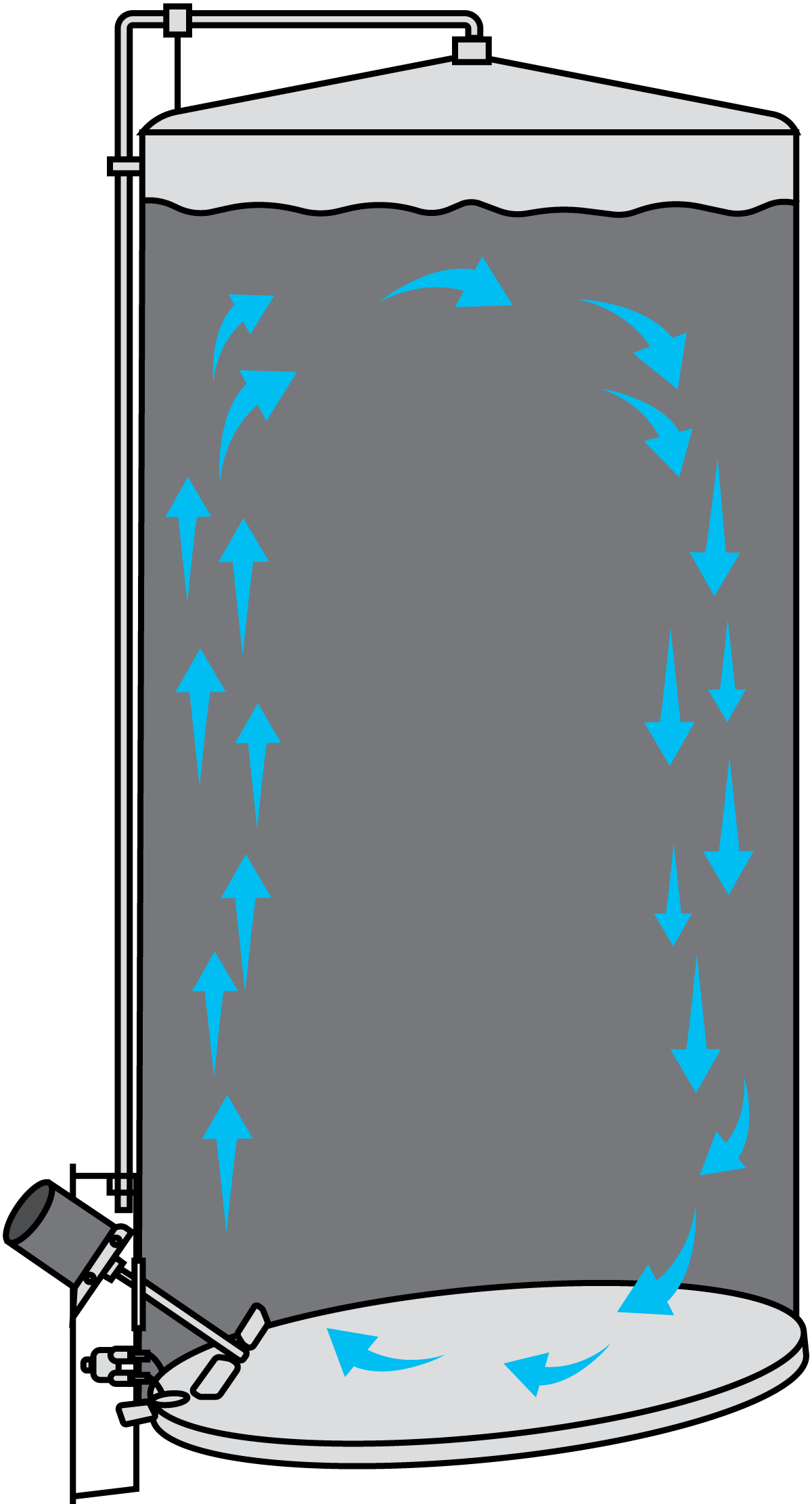

Agitation in silo tanks

Raw milk silos must have an arrangement for agitation to prevent cream separation due to gravity. The agitation must be gentle. Too harsh agitation can cause air intrusion. It can also damage the fat globules, exposing the fat to attacks from the lipase enzymes present in raw milk. The tank in Figure 6.9 has a side-mounted propeller agitator, often used with good results in silo tanks. In very high tanks it may be necessary to fit two agitators at different levels to obtain the required effect. Agitators in raw milk silos are operated intermittently, i.e. running for a few minutes and then turned off for a few minutes.

Tank temperature indication

Keeping raw milk cold during storage is very important to minimise degradation of the milk quality. A temperature sensor in the alcove is used to monitor the milk temperature.

Level indication

A level sensor in the alcove is used to monitor the level in the silo. This information is used to plan the unloading of the milk at reception and its transfer to the process. It is also used to stop the agitator(s) when the level drops too low. Running the agitator at a low level will cause air intrusion.

Low-level sensor

A low-level sensor at the outlet pipe is used to indicate that the silo is empty. This is used when switching between silos when transferring milk to the process.

Overflow protection

A high-level sensor is fitted at the top of the tank to prevent overfilling. This sensor closes the inlet valve when the tank is full, and the milk supply is switched to the next tank.